Performance Trends in Insulating Glass - Architectural Testing

Performance Trends in Insulating Glass - Architectural Testing

Performance Trends in Insulating Glass - Architectural Testing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Performance</strong> <strong>Trends</strong> <strong>in</strong> Insulat<strong>in</strong>g <strong>Glass</strong><br />

DOE Requires <strong>Glass</strong> Certification<br />

In 2008 the Department of Energy moved to require <strong>in</strong>sulat<strong>in</strong>g<br />

glass certification for all glass used <strong>in</strong> Energy Star labeled<br />

fenestration products. The National Fenestration Rat<strong>in</strong>g<br />

Council (NFRC) accepted this challenge and effective July 1,<br />

2008 required Insulat<strong>in</strong>g <strong>Glass</strong> (IG) certification <strong>in</strong> accordance<br />

with NFRC 706. Insulat<strong>in</strong>g <strong>Glass</strong> Certification (IGC) programs<br />

are recognized by NFRC and adm<strong>in</strong>istered by the Certification<br />

Policy Committee (CPC). IGC programs must meet the<br />

requirements of ISO Guide 65 or ISO 9001, use laboratories<br />

accredited to ISO 17025, and to test and verify compliance<br />

to ASTM E2190 (or CGSB 12.8) at least one time every two years.<br />

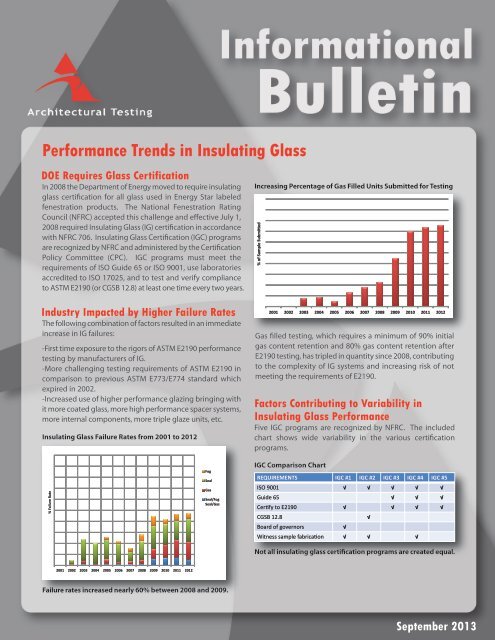

Increas<strong>in</strong>g Percentage of Gas Filled Units Submitted for Test<strong>in</strong>g<br />

% of Sample Submitted<br />

Industry Impacted by Higher Failure Rates<br />

The follow<strong>in</strong>g comb<strong>in</strong>ation of factors resulted <strong>in</strong> an immediate<br />

<strong>in</strong>crease <strong>in</strong> IG failures:<br />

-First time exposure to the rigors of ASTM E2190 performance<br />

test<strong>in</strong>g by manufacturers of IG.<br />

-More challeng<strong>in</strong>g test<strong>in</strong>g requirements of ASTM E2190 <strong>in</strong><br />

comparison to previous ASTM E773/E774 standard which<br />

expired <strong>in</strong> 2002.<br />

-Increased use of higher performance glaz<strong>in</strong>g br<strong>in</strong>g<strong>in</strong>g with<br />

it more coated glass, more high performance spacer systems,<br />

more <strong>in</strong>ternal components, more triple glaze units, etc.<br />

Insulat<strong>in</strong>g <strong>Glass</strong> Failure Rates from 2001 to 2012<br />

2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012<br />

Gas filled test<strong>in</strong>g, which requires a m<strong>in</strong>imum of 90% <strong>in</strong>itial<br />

gas content retention and 80% gas content retention after<br />

E2190 test<strong>in</strong>g, has tripled <strong>in</strong> quantity s<strong>in</strong>ce 2008, contribut<strong>in</strong>g<br />

to the complexity of IG systems and <strong>in</strong>creas<strong>in</strong>g risk of not<br />

meet<strong>in</strong>g the requirements of E2190.<br />

Factors Contribut<strong>in</strong>g to Variability <strong>in</strong><br />

Insulat<strong>in</strong>g <strong>Glass</strong> <strong>Performance</strong><br />

Five IGC programs are recognized by NFRC. The <strong>in</strong>cluded<br />

chart shows wide variability <strong>in</strong> the various certification<br />

programs.<br />

% Failure Rate<br />

Fog<br />

Seal<br />

Gas<br />

Seal/Fog<br />

Seal/Gas<br />

IGC Comparison Chart<br />

REQUIREMENTS IGC #1 IGC #2 IGC #3 IGC #4 IGC #5<br />

ISO 9001 √ √ √ √ √<br />

Guide 65 √ √ √<br />

Certify to E2190 √ √ √ √<br />

CGSB 12.8<br />

√<br />

Board of governors<br />

√<br />

Witness sample fabrication √ √ √<br />

Not all <strong>in</strong>sulat<strong>in</strong>g glass certification programs are created equal.<br />

2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012<br />

Failure rates <strong>in</strong>creased nearly 60% between 2008 and 2009.<br />

September 2013

-Even the tests used to comply with NFRC 706 are vastly<br />

different. CGSB 12.8, recognized <strong>in</strong> Canada, is completely<br />

different than ASTM E2190. Which test is more severe, CGSB<br />

12.8 or ASTM E2190? When considered <strong>in</strong> their entirety<br />

most experts will agree that E2190 is a more severe test.<br />

-Based on our review of over 3,000 data po<strong>in</strong>ts our research<br />

shows a wide variance <strong>in</strong> a given spacer/sealant system's<br />

ability to pass the E2190 test.<br />

Variability <strong>in</strong> Spacer / Sealant Systems<br />

% Failure Rate<br />

A B C D E F G H I J K L M N O P<br />

Spacer / Sealant Systems<br />

This chart shows significant variability <strong>in</strong> the risk of failure between spacer/sealant systems.<br />

Summary<br />

The pre-2002 method of IG test<strong>in</strong>g (ASTM E773/E774) had<br />

provisions for progressive levels of IG performance: Level C,<br />

Level CB, and Level CBA. ASTM E2190, conta<strong>in</strong>s all the<br />

provisions of CBA level plus a more challeng<strong>in</strong>g volatile fog<br />

test. Comb<strong>in</strong>e this with the NFRC mandate and the result<strong>in</strong>g<br />

<strong>in</strong>creased failure rate should not be a surprise. Because IG<br />

is so <strong>in</strong>strumental <strong>in</strong> the energy efficiency of fenestration<br />

products we should not expect the pressure for superior<br />

performance of IG systems to be relaxed any time soon. It is<br />

imperative that the <strong>in</strong>dustry promote and develop systems<br />

that meet the ever more robust requirements of the market<br />

we serve.<br />

About ATI<br />

Founded <strong>in</strong> 1975, <strong>Architectural</strong> Test<strong>in</strong>g, Inc. (ATI) is a<br />

lead<strong>in</strong>g ISO/IEC 17025 accredited build<strong>in</strong>g products<br />

test<strong>in</strong>g laboratory provid<strong>in</strong>g more than 2000 def<strong>in</strong>ed test<br />

protocols at one or more of its fifteen full-service laboratories.<br />

<strong>Architectural</strong> Test<strong>in</strong>g offers a Complete Solution for evaluation,<br />

test<strong>in</strong>g and certification.<br />

About The Author<br />

Dan Braun - Senior Vice President, <strong>Architectural</strong> Test<strong>in</strong>g<br />

Dan Braun has over 22 years of experience with the <strong>in</strong>dustry with expertise <strong>in</strong> build<strong>in</strong>g component<br />

and fenestration product test<strong>in</strong>g. He is responsible for regional laboratories and offices throughout<br />

the United States and is a member of IGCC and WDMA Technical Committees.<br />

717.764.7700 . dbraun@archtest.com . www.archtest.com<br />

September 2013