Gas Chromatography (GC) (IUPAC Compendium of Chemical Terminology):

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Lecture 3. <strong>Gas</strong> chromathography.<br />

<strong>Gas</strong> <strong>Chromatography</strong> (<strong>GC</strong>)<br />

(<strong>IUPAC</strong> <strong>Compendium</strong> <strong>of</strong> <strong>Chemical</strong> <strong>Terminology</strong>):<br />

A separation technique in which the mobile phase is a gas. <strong>Gas</strong> chromatography<br />

is always carried out in a column.<br />

<strong>Gas</strong>-liquid chromatography, GLC.<br />

Comprises all gas-chromatographic methods in which the stationary phase is a<br />

liquid dispersed on a solid support. Separation is achieved by partition <strong>of</strong> the<br />

components <strong>of</strong> a sample between the phases. Mostly used nowadays.<br />

<strong>Gas</strong>-solid chromatography, GSC.<br />

Comprises all gas chromatographic methods in which the stationary phase is an<br />

active solid (e.g. charcoal, molecular sieves). Separation is achieved by adsorption<br />

<strong>of</strong> the components <strong>of</strong> a sample. In gas chromatography the distinction between gasliquid<br />

and gas-solid may be obscure because liquids are used to modify solid<br />

stationary phases, and because the solid supports for liquid stationary phases<br />

affect the chromatographic process. For classification by the phases used, the term<br />

relating to the predominant effect should be chosen.<br />

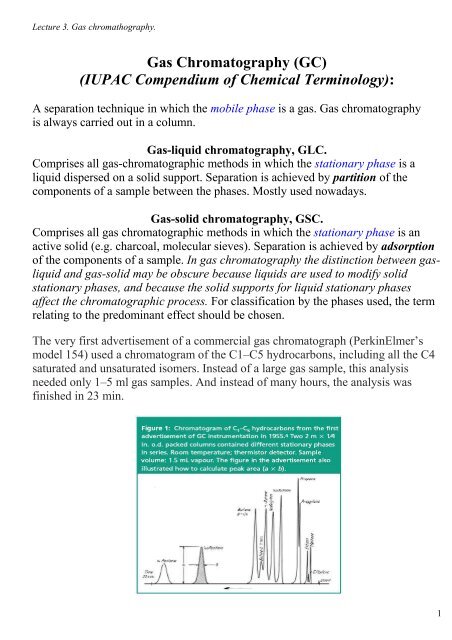

The very first advertisement <strong>of</strong> a commercial gas chromatograph (PerkinElmer’s<br />

model 154) used a chromatogram <strong>of</strong> the C1–C5 hydrocarbons, including all the C4<br />

saturated and unsaturated isomers. Instead <strong>of</strong> a large gas sample, this analysis<br />

needed only 1–5 ml gas samples. And instead <strong>of</strong> many hours, the analysis was<br />

finished in 23 min.<br />

1

Lecture 3. <strong>Gas</strong> chromathography.<br />

Application area and Instrumentation.<br />

Mobile phase: carrier gas.<br />

He, N 2 , H 2, CO 2 , Ar. The carrier gas must be chemically inert. The choice <strong>of</strong> carrier<br />

gas is <strong>of</strong>ten dependent upon the type <strong>of</strong> detector which is used. The carrier gas<br />

system also contains a molecular sieve to remove water and other impurities.<br />

Stationary phase: nonvolatile liquid, sometimes solid.<br />

Two kinds <strong>of</strong> column are used: packed and open tubular (capillary).<br />

Packed columns contain a finely divided, inert, solid support material (commonly<br />

based on diatomaceous earth) coated with liquid stationary phase. Most packed<br />

columns are 1.5 - 10m in length and have an internal diameter <strong>of</strong> 2 – 4mm.<br />

Capillary columns have an internal diameter <strong>of</strong> a few tenths <strong>of</strong> a millimeter. The<br />

inner walls are coated with thin layer <strong>of</strong> stationary phase.<br />

Analyte: gas or volatile liquid.<br />

Hydrocarbons, fatty acids, flavor compounds, essential oils, environmental<br />

pollutants (pesticides), especially modified substances. It is estimated that 10-20%<br />

<strong>of</strong> the known compounds can be analyzed by <strong>GC</strong>. To be suitable for <strong>GC</strong> analysis, a<br />

compound must have sufficient volatility and thermal stability. If all or some <strong>of</strong> a<br />

compound or molecules are in the gas or vapor phase at 400-450°C or below, and<br />

they do not decompose at these temperatures, the compound can probably be<br />

analyzed by <strong>GC</strong>.<br />

Flow controller<br />

Injection port<br />

Recorder<br />

Carrier<br />

gas<br />

Column oven<br />

Detector<br />

2

Lecture 3. <strong>Gas</strong> chromathography.<br />

Advantages <strong>of</strong> <strong>GC</strong><br />

●<br />

●<br />

●<br />

●<br />

●<br />

non-destructive method <strong>of</strong> analysis;<br />

analysis is fast;<br />

analysis is sensitive;<br />

high resolution;<br />

method is compatible with many types <strong>of</strong> detectors, including MS.<br />

Drawbacks <strong>of</strong> <strong>GC</strong><br />

●<br />

●<br />

suitable mostly for analytical purposes;<br />

restricted choice <strong>of</strong> eluent “polarity”;<br />

Variable parameters in <strong>GC</strong>:<br />

●<br />

●<br />

●<br />

●<br />

column;<br />

carrier gas;<br />

gas flow rate;<br />

temperature.<br />

3

Lecture 3. <strong>Gas</strong> chromathography.<br />

Columns.<br />

Open tubular (capillary) columns.<br />

Typical length is 15 to 100 m. Inner diameter is 0.10 to 0.53 mm. Narrow columns<br />

provide higher resolution but require higher operation pressure and have less<br />

sample capacity.<br />

WCOT (wall-coated open tubular) columns.<br />

Column wall<br />

Stationary<br />

liquid phase<br />

This type <strong>of</strong> columns features a 0.1 to 5 μm thick film <strong>of</strong> stationary liquid phase on<br />

inner wall <strong>of</strong> the column. Decreasing the thickness <strong>of</strong> the stationary phase increases<br />

resolution, decrease retention time, and decrease sample capacity. Most capillary<br />

columns are made <strong>of</strong> fused-silica with a polyimide outer coating. These columns are<br />

flexible, so a very long column can be wound into a small coil.<br />

SCOT (support-coated open tubular) columns.<br />

Column wall<br />

Solid support<br />

coated with<br />

stationary<br />

liquid phase<br />

This type <strong>of</strong> columns has solid particles coated with stationary liquid phase and<br />

attached to the inner wall.<br />

4

Film thickness, μm<br />

Lecture 3. <strong>Gas</strong> chromathography.<br />

PLOT (porous-layer open tubular) columns.<br />

Column wall<br />

Stationary<br />

solid-phase<br />

particles<br />

In this type <strong>of</strong> columns the porous layer is the stationary phase. The surface area is<br />

higher, and larger samples can be handled. the performance <strong>of</strong> PLOT columns is<br />

between wall-coated and packed columns.<br />

Internal diameter, μm<br />

100 200 320 530<br />

1<br />

10<br />

Narrowbore<br />

FSWCOT<br />

Ultra-high resolution<br />

{ Small sample capacity<br />

0.3<br />

Capacity, ng<br />

100<br />

Conventional<br />

FSWCOT<br />

1.0<br />

1000<br />

Low resolution<br />

High sample capacity}<br />

Wide-bore<br />

FSWCOT<br />

2.5<br />

10000 5000 3000 1500<br />

Efficiency, N/m<br />

5

Lecture 3. <strong>Gas</strong> chromathography.<br />

Stationary phases – capillar columns.<br />

Polarity and Selectivity.<br />

Polarity:<br />

physical characteristic <strong>of</strong> stationary phase. Polarity is determined by stationary<br />

phase structure, polarity <strong>of</strong> functional groups and amount <strong>of</strong> each group.<br />

Polarity<br />

Stability<br />

Temperature range<br />

Selectivity:<br />

solute interactions and separations. Determined by dispersion, dipole-dipole and<br />

hydrogen bonding interactions.<br />

Dispersion interaction is determined by differences in solute heat <strong>of</strong> vaporization<br />

ΔH vap . The value can be approximated from vapor pressure <strong>of</strong> the solute.<br />

Dipole-dipole interaction is determined by dipole moment <strong>of</strong> the molecule. Smaller<br />

differences require a stronger dipole phase.<br />

Cl<br />

Cl Cl Cl<br />

Hydrogen bonding interactions. Strong: alcohols, carboxylic acids, primary and<br />

secondary amines. Moderate: aldehyde, ketones, esters. Weak: hydrocarbons,<br />

halocarbons, ethers.<br />

6

Lecture 3. <strong>Gas</strong> chromathography.<br />

POLYSILOXANES:<br />

R<br />

* Si O<br />

R<br />

n<br />

*<br />

Polysiloxanes are the most common stationary phases. They are available in the<br />

greatest variety and are the most stable, robust and versatile.<br />

The most basic polysiloxane is the 100% methyl substituted. When other groups are<br />

present, the amount is indicated as the percent <strong>of</strong> the total number <strong>of</strong> groups.<br />

Cyanopropylphenyl percent values can be misleading. A 14% cyanopropylphenyldimethyl<br />

polysiloxane contains 7% cyanopropyl and 7% phenyl (along with 86%<br />

methyl). The cyanopropyl and phenyl groups are on the same silicon atom, thus<br />

their amounts are summed.<br />

POLYETHYLENE GLYCOLS:<br />

* CH 2<br />

CH 2<br />

O *<br />

n<br />

Polyethylene glycols (PEG) are widely used as stationary phases. Stationary phases<br />

with "wax" or "FFAP" in their name are some type <strong>of</strong> polyethylene glycol.<br />

Polyethylene glycols stationary phases are not substituted, thus the polymer is<br />

100% <strong>of</strong> the stated material. They are less stable, less robust and have lower<br />

temperature limits than most polysiloxanes.<br />

With typical use, they exhibit shorter lifetimes and are more susceptible to damage<br />

upon over heating or exposure to oxygen.<br />

The unique separation properties <strong>of</strong> polyethylene glycol makes these liabilities<br />

tolerable. Polyethylene glycol stationary phases must be liquids under <strong>GC</strong><br />

temperature conditions.<br />

7

Lecture 3. <strong>Gas</strong> chromathography.<br />

Selectivity – Interaction strength<br />

Phase Dispersion Dipole H-Bonding<br />

Methyl -CH 3 Strong None None<br />

Phenyl -C 6 H 5 Strong None Weak<br />

Cyanopropyl -C 3 H 6 CN Strong Strong Moderate<br />

Trifluoropropyl -C 2 H 4 CF 3 Strong Moderate Weak<br />

PEG -OCH 2 CH 2 O- Strong Strong Moderate<br />

Compounds – Properties<br />

Compounds Polar Aromatic H-Bonding Dipole<br />

Toluene No Yes No Induced<br />

Hexanol Yes No Yes Yes<br />

OH<br />

Phenol Yes Yes Yes Yes<br />

OH<br />

Decane No No No No<br />

Naphtalene No Yes No Induced<br />

Dodecane No No No No<br />

8

Lecture 3. <strong>Gas</strong> chromathography.<br />

Nonpolar to intermediate polarity stationary phases.<br />

BONDED PHASE Temp °C GENERAL USE OF PHASE<br />

O<br />

CH 3<br />

Si *<br />

*<br />

X<br />

CH 3<br />

Methyl polysiloxane<br />

Methyl 5% Phenyl Polysiloxane<br />

CH 3<br />

* O Si O Si *<br />

X<br />

CH 3<br />

Y<br />

50-325<br />

50-325<br />

Nonpolar. Optima 1.<br />

Most frequently used phase in <strong>GC</strong>. Low<br />

selectivity, separates compounds according to<br />

boiling points. Excellent thermal stability.<br />

Nonpolar. Optima 5.<br />

Similar to methyl polysiloxane but slightly<br />

more selective due to phenyl content. Excellent<br />

thermal stability.<br />

Methyl 50% Phenyl Polysiloxane<br />

CH 3<br />

* O Si O Si *<br />

6% Cyanopropylphenyl 94%<br />

Methylpolysiloxane<br />

X<br />

CN<br />

CH 3<br />

CH 3<br />

* O Si O Si *<br />

X<br />

Y<br />

CH 3<br />

Y<br />

40-325<br />

30-320<br />

Intermediate polarity. Optima 17.<br />

Added selectivity due to higher phenyl content.<br />

Usually retains similar compounds longer than<br />

methyl silicone. Provides efficient separations<br />

<strong>of</strong> PAHS and biomedical samples such as<br />

drugs, sugars and steroids. Good thermal<br />

stability.<br />

Intermediate polarity. Optima 1701.<br />

An additional choice for a general purpose<br />

phase with nominal selectivity for polarizable<br />

and polar compounds. Good thermal stability.<br />

9

Lecture 3. <strong>Gas</strong> chromathography.<br />

Intermediate polarity to strongly polar stationary phases.<br />

BONDED PHASE Temp °C GENERAL USE OF PHASE<br />

Methyl 7% Cyanopropyl 7%<br />

Phenyl Polysiloxane<br />

CN<br />

CH 3<br />

* O Si O Si *<br />

X<br />

CH 3<br />

Y<br />

280<br />

Intermediate polarity.<br />

Unique selectivity <strong>of</strong> cyanopropyl and phenyl<br />

groups provide efficient separations <strong>of</strong><br />

derivitized sugars and many environmental<br />

samples. Not truly a polar phase. Good thermal<br />

stability<br />

Methyl 25% Cyanopropyl 25%<br />

Phenyl Polysiloxane<br />

CN<br />

CH 3<br />

* O Si O Si *<br />

X<br />

CH 3<br />

Y<br />

40-240<br />

Polar. Optima 225<br />

Provides efficient separations <strong>of</strong> polar<br />

molecules such as fatty acids and alditol<br />

acetate derivatives <strong>of</strong> sugars. Fair thermal<br />

stability.<br />

50% Trifluoropropyl 50% Methyl<br />

polysiloxane<br />

*<br />

CF 3<br />

CH 3<br />

Si O Si<br />

Y<br />

X<br />

*<br />

CH 3<br />

CF 3<br />

Polyethylene Glycol<br />

* CH 2<br />

CH 2<br />

O *<br />

n<br />

40-300<br />

20-260<br />

Polar. Optima 210<br />

Selectivity for compounds with lone pair<br />

electrons or carbonyl groups. Retains<br />

oxygenated compounds in the order ether,<br />

hydroxy, ester and keto Widely used as a<br />

confirmatory phase for chlorinated pesticides.<br />

Also suitable for PCB’s, phenols and<br />

nitroaromatics. Good thermal stability.<br />

Carbowax 20M is a polyethylene glycol phase<br />

which demonstrates unique selectivity<br />

hydrogen bonding-type molecules. Particularly<br />

useful for the analysis <strong>of</strong> complex oxygenated<br />

samples but is susceptible to oxygen<br />

degradation. Not recommended for the<br />

analysis <strong>of</strong> mixtures containing silylating<br />

reagents<br />

10

Lecture 3. <strong>Gas</strong> chromathography.<br />

11

Lecture 3. <strong>Gas</strong> chromathography.<br />

Column dimensions. Diameter, length, film thickness.<br />

Resolution= N<br />

−1<br />

k ' av<br />

4 1k '<br />

e.g. resolution is proportional to square root <strong>of</strong> plates<br />

av<br />

number<br />

Diameter.<br />

I. D. mm Common Name<br />

0.53 Megabore<br />

0.45 High speed Megabore<br />

0.32 Wide<br />

0.20-0.25 Narrow<br />

0.18 Minibore<br />

for high flow situations<br />

for low flow situations, e.g.<br />

<strong>GC</strong>-MS<br />

12

Lecture 3. <strong>Gas</strong> chromathography.<br />

Column length.<br />

Most common 15 – 60 m. Available 5 – 150 m.<br />

Column cost is rising with column length.<br />

Film thickness.<br />

Most common 0.1 – 3 μm. Available 0.1 – 10 μm.<br />

The effect <strong>of</strong> film thickness is described by Van Deemter equation:<br />

H mass transfer =Cu x =C s C m u x<br />

where C s describe the rate <strong>of</strong> mass transfer trough stationary phase<br />

C s =<br />

where d is the thickness <strong>of</strong> stationary phase.<br />

2 k '<br />

3k '1 2 d 2<br />

D s<br />

13

Lecture 3. <strong>Gas</strong> chromathography.<br />

Examples <strong>of</strong> film thickness effects.<br />

To get the same retention, the temperature should be increased for thicker film.<br />

14

Lecture 3. <strong>Gas</strong> chromathography.<br />

Effect <strong>of</strong> film thickness and capacity factor.<br />

For low k resolution is rising when film thickness increased:<br />

For high k resolution is decreasing when film thickness increased:<br />

15

Lecture 3. <strong>Gas</strong> chromathography.<br />

BONDED AND CROSS-LINKED STATIONARY PHASES:<br />

Cross-linked stationary phases have the individual polymer chains linked via<br />

covalent bonds.<br />

Bonded stationary phases are covalently bonded to the surface <strong>of</strong> the tubing.<br />

Both techniques impart enhanced thermal and solvent stability to the stationary<br />

phase. Also, columns with bonded and cross-linked stationary phases can be<br />

solvent rinsed to remove contaminants.<br />

Most polysiloxanes and polyethylene glycol stationary phases are bonded and<br />

cross-linked.<br />

A few stationary phases are available in an nonbonded version; some stationary<br />

phases are not available in bonded and cross-linked versions. Use a bonded and<br />

cross-linked stationary phase if one is available.<br />

16

Lecture 3. <strong>Gas</strong> chromathography.<br />

GAS – SOLID: PLOT Columns.<br />

<strong>Gas</strong>-solid stationary phases are comprised <strong>of</strong> a thin layer (usually

Lecture 3. <strong>Gas</strong> chromathography.<br />

The Retention Index.<br />

Each chromatographic setup will vary to some degree. Retention times for a known set <strong>of</strong><br />

species can be hard to reproduce even from instrument to another.<br />

Retention indexing helps to standardize the results.<br />

For alkanes C n H 2n+2 : n is proportional to log t' R<br />

By agreement, Kovats retention index for linear alkanes equals 100 times the number <strong>of</strong><br />

carbon atoms. For the compound eluted between two linear alkanes with number <strong>of</strong> atoms n<br />

and N=n+1, is:<br />

I =100<br />

[ nN −n log t ' Runknown−log t ' R n<br />

log t ' R N −log t ' R n ]<br />

Example:<br />

t R (methane) = 0.5 min<br />

t R (octane) = 14.3 min<br />

t R (unknown) = 15.7 min<br />

t R (nonane) = 18.5 min<br />

Find the retention index for unknown.<br />

SOLUTION:<br />

t' R (octane) = 14.3 – 0.5 = 13.8 min<br />

t' R (unknown) = 15.7 – 0.5 = 15.2 min<br />

t' R (nonane) = 18.5 – 0.5 = 18.2 min<br />

[<br />

log 15.2−log 13.8<br />

]<br />

I unknown =100 89−8<br />

log 18.0−log 13.8 =836<br />

Kovats retention indexes must be compared on the same or very similar phases. For phases<br />

with different polarity the order <strong>of</strong> elution and, therefore, the retentions indexes are very<br />

different!<br />

18

Lecture 3. <strong>Gas</strong> chromathography.<br />

Temperature programming.<br />

By definition, programmed-temperature chromatography (temperature programming)<br />

A procedure in which the temperature <strong>of</strong> the column is changed systematically during a part or<br />

the whole <strong>of</strong> the separation.<br />

As stated before, the retention time <strong>of</strong> homologues increases exponentially with the number <strong>of</strong><br />

carbon. With longer retention time, the peaks are broad and wide, making detection difficult or<br />

even impossible.<br />

C 10<br />

C 9<br />

C 12<br />

C 8<br />

C 11<br />

C 13<br />

C Isotermal 150 ºC<br />

14<br />

C 15<br />

0 10 20 30 40 50 60 70 80 90 100<br />

time, min<br />

Raising the column temperature:<br />

● decrease retention time;<br />

● sharpens peak.<br />

Factors to take into account for temperature programming:<br />

● Stability <strong>of</strong> stationary phase<br />

● Stability <strong>of</strong> solutes<br />

● Changes in flow rates<br />

● Changes in solute volatility<br />

● Changes in solute solubility<br />

Steps to create a temperature program:<br />

1. Determine initial temperature and time according to best possible separation <strong>of</strong> fast peaks.<br />

2. Determine final temperature according to best possible separation <strong>of</strong> last peaks.<br />

3. Find experimentally the optimal temperature gradient to account the middle peaks.<br />

C 10<br />

C 11<br />

C 14<br />

C 15<br />

C 12<br />

C 13<br />

C 8<br />

C 9<br />

Programmed temperature<br />

50 – 250 ºC at 8º/min<br />

C 16<br />

C 17C18<br />

C 19 C 20 C 21<br />

C 6 C 7<br />

0 4 8 12 20 36<br />

16 24 28 32<br />

time, min<br />

19

Lecture 3. <strong>Gas</strong> chromathography.<br />

Example <strong>of</strong> temperature programming:<br />

20

Lecture 3. <strong>Gas</strong> chromathography.<br />

Sample injection.<br />

For optimum column efficiency, the sample should not be too large, and should be introduced<br />

onto the column as a "plug" <strong>of</strong> vapour - slow injection <strong>of</strong> large samples causes band<br />

broadening and loss <strong>of</strong> resolution. The most common injection method is where a microsyringe<br />

is used to inject sample through a rubber septum into a flash vapouriser port at the head <strong>of</strong> the<br />

column.<br />

Worn Septum<br />

An injection port septum should last between 100 and 200 injections. Higher injection port<br />

temperatures shorten the septum's lifespan. A leaking septum adversely affects the <strong>GC</strong><br />

instrument's sensitivity.<br />

If a portion <strong>of</strong> the specimen leaks back out <strong>of</strong> the septum, the amount <strong>of</strong> the specimen is not<br />

recorded. This event makes any eventual quantitative result erroneous. If air should leak into<br />

the injection port through a worn septum, the oxygen and water contained in air may skew the<br />

results. Any oxygen may react with the specimen components. If this happens, the <strong>GC</strong><br />

instrument will provide results indicating the presence <strong>of</strong> this unintended reaction product,<br />

instead <strong>of</strong> the original compounds present in the specimen vial. Any water in the column<br />

adversely affects the <strong>GC</strong> instrument's ability to separate components.<br />

Injection Port Temperature.<br />

The temperature <strong>of</strong> the <strong>GC</strong> injection port must be high enough to vaporize a liquid specimen<br />

instantaneously. The temperature <strong>of</strong> the sample port is usually about 50°C higher than the<br />

boiling point <strong>of</strong> the least volatile component <strong>of</strong> the sample. If the temperature is too low,<br />

separation is poor and broad spectral peaks should result or no peak develops at all. If the<br />

injection temperature is too high, the specimen may decompose or change its structure. If this<br />

occurs, the <strong>GC</strong> results will indicate the presence <strong>of</strong> compounds that were not in the original<br />

specimen.<br />

For packed columns, sample size ranges from 0.1 to 20 μl. Capillary columns, on the other<br />

hand, need much less sample, typically around 10 -3 ml.<br />

Types <strong>of</strong> injection for capillary <strong>GC</strong>:<br />

●<br />

●<br />

●<br />

●<br />

split injection<br />

splitless injection<br />

on-column injection<br />

21

Lecture 3. <strong>Gas</strong> chromathography.<br />

Split Injection.<br />

Used for samples with analyte concentration > 0.1 %.<br />

Only 0.2 – 2 % <strong>of</strong> the sample is delivered to column.<br />

Injector temperature is high, e.g. 350 ºC.<br />

102 ml/min<br />

1 ml/min<br />

100 ml/min<br />

1ml/min<br />

The sample is injected rapidly through the septum into evaporation zone. The injector<br />

temperature is kept high to promote fast evaporation. A brisk flow <strong>of</strong> the carrier gas sweeps<br />

the sample through the mixing chamber. At the split point, small fraction <strong>of</strong> vapors enters the<br />

column but most passes to waste vent. Split ratio (the proportion <strong>of</strong> the sample that does not<br />

reach the column) is typically 50:1 to 600:1.<br />

Septum purge gas flow: prevents the column during injection and chromatography from hot<br />

rubber septum gases and the excess <strong>of</strong> the sample vapors.<br />

●<br />

●<br />

●<br />

Advantages <strong>of</strong> split injection:<br />

narrow solute peaks;<br />

suitable for qualitative analysis;<br />

minimize the solvent effect.<br />

Drawbacks:<br />

●<br />

●<br />

●<br />

requires rather high concentration <strong>of</strong> analyte;<br />

split ratio makes the quantitative analysis more complex;<br />

not suitable for very expensive or toxic compounds.<br />

22

Lecture 3. <strong>Gas</strong> chromathography.<br />

Splitless injection.<br />

Used for traces analysis with analyte concentration < 0.01%.<br />

Volume <strong>of</strong> solution injected is ~ 2 μl.<br />

Injection time is ~ 2 sec (SLOW INJECTION).<br />

Injector temperature ~220 ºC.<br />

~ 80% <strong>of</strong> the sample is applied to the column.<br />

2 ml/min<br />

0 ml/min<br />

1 ml/min<br />

1ml/min<br />

Solvent trapping. The initial column temperature is set 40 ºC below the boiling point <strong>of</strong> the<br />

solvent. Therefore the solvent condenses in the beginning <strong>of</strong> the column and traps the analyte<br />

to produce a narrow plug in the beginning <strong>of</strong> the column. For solvent trapping, the analyte<br />

concentration should be < 0.01%.<br />

Cold trapping. The initial column temperature is 150 ºC than the boiling points <strong>of</strong> analytes <strong>of</strong><br />

interest. Solvent and low-boiling components are eluted rapidly, whereas high-boiling solutes<br />

remain as narrow band. The column is then rapidly warmed to initiate chromatography <strong>of</strong> highboiling<br />

solutes. Stationary-phase film thickness must be ≥2 μm.<br />

Cryogenic focusing is the variation <strong>of</strong> cold trapping for low-boiling solutes. The column is<br />

initially cooled with N 2 or CO 2 .<br />

●<br />

●<br />

●<br />

●<br />

●<br />

Advantages <strong>of</strong> splitless injection:<br />

suitable for quantitative and qualitative analysis;<br />

narrow peaks <strong>of</strong> analyte.<br />

Drawbacks:<br />

broad solvent peak;<br />

retention times depend on solvent evaporation speed;<br />

solvent affects the shape <strong>of</strong> the peaks.<br />

23

Lecture 3. <strong>Gas</strong> chromathography.<br />

On-Column injection.<br />

Used for samples that decompose above their boiling point.<br />

Preferred for quantitative analysis.<br />

Syringe needle<br />

1 ml/min<br />

0 ml/min<br />

0 ml/min<br />

At initial oven temperature, e.g. 50ºC<br />

1ml/min<br />

Solution is injected directly into column, without going through a hot injector.<br />

Initial column temperature is low enough to condense solutes in narrow zone. Warming the<br />

column initiate chromatography.<br />

The special thin-needle syringe is required to use good resolution columns (column diameter<br />

0.2 - 0.32 mm).<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

Advantages <strong>of</strong> on-column injection:<br />

narrow peaks <strong>of</strong> analyte;<br />

good accuracy and precision for quantitative analysis;<br />

no thermal destruction <strong>of</strong> the sample;<br />

little loss <strong>of</strong> high-boiling components.<br />

Drawbacks:<br />

non-volatile impurities harm the column;<br />

shape <strong>of</strong> the peaks depends on solvent.<br />

24

Lecture 3. <strong>Gas</strong> chromathography.<br />

Comparison <strong>of</strong> different injection methods.<br />

Solvent<br />

A<br />

Solvent<br />

B<br />

3<br />

2 3<br />

2<br />

Split injection<br />

Split vent closed<br />

3<br />

Solvent<br />

C<br />

Solvent<br />

2<br />

D<br />

2<br />

3<br />

Split vent opened<br />

after 30 s<br />

Solvent trapping<br />

A: standard Split injection, peaks are sharp.<br />

B: split vent closed, injection liner was purged slowly, sample was applied over a long time,<br />

peaks are broad and tail badly.<br />

C: same as B, but split vent was opened after 30 s to rapidly purge all the vapors from the<br />

injector liner.<br />

D: same as C, but the column was initially cooled to r.t. to trap solvent and solutes; to be<br />

proper splitless injection, the sample should be much more diluted.<br />

25

Lecture 3. <strong>Gas</strong> chromathography.<br />

Solid phase microextraction (SPME).<br />

Minimizes sample preparation and concentrates volatile analytes in a solvent-free manner.<br />

SPME was developed by Pawliszyn's research group at the University <strong>of</strong> Waterloo in the late<br />

1980s. SPME is a sensitive, reproducible, cost efficient, solventless technique that incorporates<br />

extraction, concentration, and sample introduction into a single step.<br />

A syringe-like device with an outer septum piercing needle and a plunger houses a fused silica<br />

fiber coated with a stationary phase.<br />

The fiber can be inserted into the sample matrix (aqueous samples) or the gaseous phase above<br />

the sample (headspace).<br />

Liquid sampling can be performed by inserting the fiber directly into the solution. Volatile<br />

analytes from solids can be sampled by inserting the fiber into the headspace region above the<br />

sample.<br />

Analytes are partitioned between the stationary phase coating and the gas phase when<br />

equilibrium is established.<br />

After concentration <strong>of</strong> analytes on the fiber, the syringe assembly is inserted into the injection<br />

port <strong>of</strong> a gas chromatograph where the analytes are thermally desorbed from the fiber and coldtrapped<br />

on the head <strong>of</strong> the capillary column. If an unknown sample has volatile components<br />

that can be detected by the human nose, SPME coupled to <strong>GC</strong> or <strong>GC</strong>/MS might be employed<br />

to identify and quantitate those compounds. Applications <strong>of</strong> SPME have included extraction<br />

<strong>of</strong> environmental contaminants from aqueous matrices, headspace extraction <strong>of</strong> flavor and<br />

fragrance compounds, and forensic investigations <strong>of</strong> drugs <strong>of</strong> abuse in biological fluids.<br />

26

Lecture 3. <strong>Gas</strong> chromathography.<br />

Purge and trap.<br />

Purge-and-trap is the method <strong>of</strong> choice for extracting and concentrating volatile organic<br />

compounds (VOCs) from almost any matrix.<br />

This procedure is particularly useful for concentrating VOCs that are insoluble or poorly<br />

soluble in water and have boiling points below 200°C.<br />

The procedure can also be used with water soluble VOCs, but quantification limits are<br />

generally much higher for these analytes, because <strong>of</strong> their poor purging efficiency.<br />

Generally, longer purging times and heating the sample are required to increase the purging<br />

efficiency <strong>of</strong> water soluble, <strong>of</strong>ten polar compounds.<br />

The purge-and-trap procedure involves bubbling an inert gas, such as nitrogen or helium,<br />

through an aqueous sample (solids must be suspended in water) at ambient temperature. This<br />

liberates the VOCs, which are efficiently transferred from the aqueous phase to the vapor<br />

phase. During this purge step, the inert gas flow sweeps the vapor through a trap containing<br />

adsorbent materials which retain the VOCs.<br />

A few systems <strong>of</strong>fer the ability to dry purge the trap after the purging step. The dry purge step<br />

continues to pass the purging gas through the trap, bypassing the purge vessel, for a set time to<br />

remove water that may have accompanied the VOCs into the trap during the purging process.<br />

Next, the adsorbent trap is rapidly heated to the desorb temperature and the valve is switched<br />

to align the carrier gas flow in-line with the trap. The trap is then held at the desorb<br />

temperature for an optimal time to thermally desorb the analytes into the carrier gas. The<br />

vaporized contents are swept into the <strong>GC</strong> column in a tight band, ensuring superior<br />

chromatographic separation <strong>of</strong> analyte.<br />

27

Lecture 3. <strong>Gas</strong> chromathography.<br />

Derivatization.<br />

●<br />

●<br />

●<br />

Aim <strong>of</strong> derivatization:<br />

improved volatility;<br />

better thermal stability;<br />

lower limit <strong>of</strong> detection due to improved peak symmetry.<br />

●<br />

●<br />

●<br />

●<br />

Derivatization demands:<br />

quantitative;<br />

rapid;<br />

reproducible;<br />

formation <strong>of</strong> only one derivative.<br />

●<br />

●<br />

●<br />

●<br />

●<br />

alcohols;<br />

phenols;<br />

amines;<br />

amides;<br />

carboxylic acids<br />

Derivatization subjects:<br />

●<br />

●<br />

●<br />

acylation;<br />

alkylation;<br />

silylation;<br />

Derivatization methods:<br />

28

Lecture 3. <strong>Gas</strong> chromathography.<br />

Derivatization reagents.<br />

Function method derivative recommended reagents<br />

Alcohols, silylation R'O tms BSA, MSTFA, MSHFBA,<br />

TSIM<br />

Phenols, R'OH acylation O TFAA, HFBA, MBTFA,<br />

R'O C R<br />

MBHFBA<br />

alkylation<br />

TMSH<br />

sterically hindered silylation R'O tms TSIM, BSTFA<br />

Amines<br />

primary, secondary<br />

silylation<br />

R'<br />

R'O R<br />

N tms<br />

R''<br />

BSA, MSTFA, MSHFBA<br />

R'<br />

N H R''<br />

acylation<br />

R'<br />

O<br />

N C<br />

R''<br />

R<br />

TFAA, HFBA, MBTFA,<br />

MBHFBA<br />

hydrochlorides silylation R' N tms MSTFA<br />

R''<br />

Amides silylation NOT STABLE<br />

O acylation<br />

O O<br />

R' C NH 2<br />

R' C N C<br />

H<br />

R<br />

TFAA, HFBA, MBTFA,<br />

MBHFBA<br />

Amino acids silylation H O BSA, BSTFA, MSTFA,<br />

R' C C tms MSHFBA<br />

H O<br />

N<br />

R' C C OH<br />

H<br />

tms<br />

NH 2<br />

alkylation (a)<br />

+ acylation (b)<br />

R'<br />

H O<br />

C C<br />

N<br />

H R<br />

OR<br />

a) MeOH/TMCS, TMSH<br />

b) TFAA, HFBA, MBTFA,<br />

MBHFBA<br />

29

Lecture 3. <strong>Gas</strong> chromathography.<br />

Function method derivative recommended reagents<br />

Carboxylic acids<br />

salts<br />

silylation<br />

alkylation<br />

silylation<br />

susceptible to hydrolysis<br />

susceptible to hydrolysis<br />

BSA, MSTFA, MSHFBA,<br />

TMCS, TSIM<br />

DMF-DMA, MeOH/TMCS,<br />

TMSH<br />

TMCS<br />

Carbohydrates silylation MSTFA, TSIM, HMDS<br />

acylation<br />

TFAA, MBTFA,<br />

Steroids silylation BSA, TSIM<br />

acylation<br />

R'<br />

R'<br />

R'<br />

O<br />

C O<br />

O<br />

O<br />

C O<br />

tms<br />

C O R<br />

tms<br />

TFAA, HFBA, MBTFA,<br />

MBHFBA<br />

F 3<br />

C<br />

F 3<br />

C<br />

F 7<br />

C 3<br />

F 7<br />

C 3<br />

F 3<br />

C<br />

F 3<br />

C<br />

F 7<br />

C 3<br />

F 7<br />

C 3<br />

O<br />

O<br />

O<br />

O<br />

O<br />

O<br />

O<br />

N<br />

O<br />

O<br />

N<br />

O<br />

Reagents for acylation.<br />

TFAA – trifluoroacetic anhydride. Used for alcohols, phenols, carboxylic<br />

acids, amines, amino acids and steroids, forming volatile, stable derivatives<br />

suited for FID and ECD detection.<br />

HFBA – heptafluorobutyric acid anhydride. Used for alcohols, phenols,<br />

carboxylic acids, amines, amino acids and steroids, forming volatile, stable<br />

derivatives suited for FID and ECD detection.<br />

MBTFA – N-methyl-bis(trifluoroacetamide). Recommended for alcohols,<br />

primary and secondary amines, as well for thiols under mild, neutral<br />

conditions. MBTFA forms very volatile derivatives with carbohydrates.<br />

MBHFBA – N-methyl-bis(heptafluorobutyramide). Recommended for<br />

alcohols, primary and secondary amines, as well for thiols under mild,<br />

neutral conditions.<br />

30

Lecture 3. <strong>Gas</strong> chromathography.<br />

Reagents for alkylation.<br />

H C<br />

N CH 3 3<br />

H O O CH 3<br />

C<br />

3<br />

DMF-DMA – N,N-dimethylformamidedimethylacetal. Methylation<br />

with DMF-DMA can be applied for fatty acids, primary amines and<br />

(partially) amino acids forming N-dimethylaminomethylene amino acid<br />

methyl esters.<br />

H 3<br />

C<br />

S + CH 3<br />

H 3<br />

C<br />

OH<br />

TMSH – 0.2 M trimethylsulfoniumoxide in methanol. Methylation with<br />

TMSH is recommended for free acids e.g. fatty acids ,<br />

chlorophenoxycarboxylic acids , their salts and derivatives as well as<br />

for phenols and chlorophenols, which can be detected in very small<br />

amounts. One great advantage is simplification <strong>of</strong> the sample<br />

preparation. Lipids or triglycerides can be converted to the<br />

corresponding fatty acid methyl esters (FAMEs) by a simple<br />

transesterification.<br />

31

Lecture 3. <strong>Gas</strong> chromathography.<br />

O<br />

N<br />

Si(CH 3<br />

) 3<br />

Si(CH 3<br />

) 3<br />

Reagents for sylilation.<br />

BSA – N,O-bis(trimethylsilyl)acetamide. BSA is a strong silylation<br />

reagent, which can be used to form very stable TMS derivatives <strong>of</strong> a<br />

wide variety <strong>of</strong> compounds such as alcohols, amines, carboxylic acids,<br />

phenols, steroids, biogenic amines and alkaloids.<br />

F 3<br />

C<br />

(CH 3<br />

) 3<br />

Si<br />

O<br />

O<br />

N<br />

H<br />

N<br />

N<br />

Si(CH 3<br />

) 3<br />

Si(CH 3<br />

) 3<br />

Si(CH 3<br />

) 3<br />

F 3<br />

C Si(CH 3<br />

) 3<br />

X H<br />

O<br />

X Si(CH 3<br />

) 3<br />

O<br />

+<br />

N<br />

F 3<br />

C Si(CH 3<br />

) 3<br />

N<br />

+<br />

O<br />

F 3<br />

C<br />

N<br />

H<br />

F 7<br />

C 3<br />

Si(CH 3<br />

) 3<br />

Si Cl<br />

BSTFA – N,O-bis(trimethylsilyl)trifluoroacetamide. BSTFA is a<br />

powerful trimethylsilyl donor with approximately the same donor<br />

strength as the unfluorinated analog BSA. Reactions <strong>of</strong> BSTFA are<br />

similar to those <strong>of</strong> BSA. The major advantage <strong>of</strong> BSTFA over BSA is<br />

the greater volatility <strong>of</strong> its reaction products.<br />

HMDS – hexamethyldisilazane. HMDS is a weak TMS donor. Used<br />

alone its action is slow and not very effective. However, after addition<br />

<strong>of</strong> catalytic quantities <strong>of</strong> TMCS (e.g. 1%) it becomes a fast and<br />

quantitative reagent for trimethylsilylation <strong>of</strong> organic compounds.<br />

MSTFA – N-methyl-N-trimethylsilyl-trifluoroacetamide. MSTFA is the<br />

most volatile trimethylsilyl amide available. BSA and BSTFA, which<br />

have been used most frequently in <strong>GC</strong> silylation, can <strong>of</strong>ten be replaced<br />

by MSTFA. MSTFA <strong>of</strong>fers the following advantages:<br />

1. For almost all compounds the reaction proceeds to the right side <strong>of</strong><br />

the equation<br />

2. Even without a catalyst the reaction rate is several times higher than<br />

with other TMS donors such as hexamethyldisilazane (HMDS).<br />

3. As for BSTFA, the by-product <strong>of</strong> the silylation reaction (Nmethyltrifluoroacetamide)<br />

features the advantage <strong>of</strong> high volatility and<br />

short retention time.<br />

MSHFBA – N-methyl-N-trimethylsilyl-heptafluorobutyramide.<br />

MSHFBA is similar to MSTFA in reactivity and chromatography. It<br />

may be used for the general purpose trimethylsilylation <strong>of</strong> carboxylic<br />

acids, alcohols, phenols, primary and secondary amines and amino<br />

acids.<br />

TMCS – trimethylchlorosilane. TMCS is <strong>of</strong>ten used as a catalyst with<br />

other trimethylsilyl reagents. Without additives it can be used for<br />

preparing TMS derivatives <strong>of</strong> organic acids.<br />

Si N<br />

N<br />

TSIM – N-trimethylsilyl-imidazole. TSIM is considered to be the<br />

strongest hydroxyl silylator and is the reagent <strong>of</strong> choice for<br />

carbohydrates and most steroids (even highly hindered steroids react).<br />

The reagent is unique in that it reacts quickly and smooth with<br />

hydroxyl (even tert. OH) and carboxyl groups, but not with amines.<br />

TSIM is used in the trimethylsilylation <strong>of</strong> alcohols, phenols, organic<br />

acids, steroids, hormones, glycols, nucleotides and narcotics.<br />

32

Lecture 3. <strong>Gas</strong> chromathography.<br />

33