Degelman Cutting Equipment Brochure

Degelman Cutting Equipment Brochure

Degelman Cutting Equipment Brochure

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

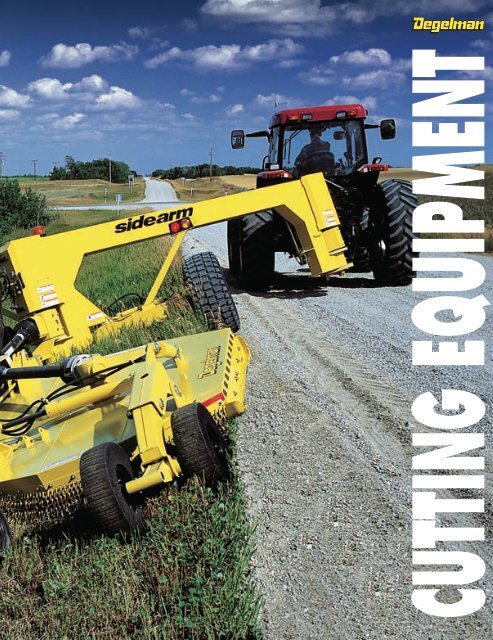

CUTTING EQUIPMENT

“ The use of the <strong>Degelman</strong> SIDEARM ® 1800<br />

allows the operator to offset the<br />

mower to make a second pass without<br />

removing the tractor off the right-ofway.<br />

The SIDEARM ® allows the operator to<br />

“steer” the mower to cut those extreme<br />

up-slopes and down-slopes. The SIDEARM ®<br />

holds to the terrain very well. The<br />

SIDEARM ® also allows the operator to<br />

cut the opposite side of the road if a<br />

meridian is present with out going<br />

against the flow of traffic. ”<br />

- Terry Eleniak<br />

Lamont County, AB

CUT WHERE YOU’VE NEVER CUT BEFORE.<br />

With the new <strong>Degelman</strong> Sidearm ®<br />

an operator can now cut where<br />

it’s never been possible to cut before - safely.<br />

The operator can stay on the highway and<br />

pull the cutter 50 degrees to either side<br />

of the road. Cut from the right, the left or<br />

straight back. The options are wide open.<br />

SAFETY FIRST<br />

The Sidearm ® completely eliminates the fear<br />

of tractor rollovers when encountering steep<br />

embankments because it allows the tractor<br />

to stay on the road - level and safe - while<br />

operating.<br />

TIGHTER<br />

TURNING RADIUS<br />

As a result of the in-line feature, the Sidearm<br />

® has a radically tighter turning radius<br />

than pulling a cutter directly with a tractor.<br />

The user can cut right to signs and power<br />

poles and save time and cost on secondary<br />

cuts and passes.<br />

REDUCED<br />

OPERATOR FATIGUE<br />

Drive level and smooth. By being straight on<br />

the road and out of the ditch, the operator<br />

also benefits from increased visibility and full<br />

command over the cutter.<br />

BACK UP WITH EASE<br />

Signs…fence posts…culverts…if operators<br />

find themselves in a tight spot, the Sidearm ®<br />

gives them the maneuverability to back up<br />

easily and get out quickly.<br />

MANEUVERABLE<br />

A fast-steering mechanism gives the entire<br />

unit a secure, safe and<br />

quick response to turns.<br />

A BETTER CUT<br />

When the tractor’s on the road, it’s not pressing<br />

down the grass making it harder to lift<br />

and cut. Using the Sidearm ® means all the<br />

grass is cut evenly without patches or strips.<br />

EASY MAINTENANCE<br />

All driveline bearings and cross-joints are<br />

easy to service. Drivelines are in-line and<br />

designed for handling misalignment and<br />

therefore require less servicing. Parts are<br />

easily replaceable such as spindles that can<br />

be removed with just one bolt. The frame<br />

swivel points and wheel axle are sandwiched<br />

between two layers of low wear composite for<br />

smooth operation and easy maintenance.<br />

QUICK<br />

CONNECTIONS<br />

Quick disconnect features are<br />

standard throughout the<br />

Sidearm ® , including a quick<br />

disconnect coupler in between<br />

the gearboxes. We<br />

include three sets of<br />

hoses that can be<br />

adapted<br />

easily<br />

to a four-hose arrangement<br />

if needed. And switching from<br />

one wing to the other can be<br />

done at the touch of a switch.<br />

REDUCED TRACTOR<br />

MAINTENANCE<br />

Long-term off-level operation is hard on a<br />

tractor’s transmission and engine lubrication.<br />

By remaining level and out of the ditch,<br />

tractors last longer. Less vibration. Less<br />

damaged tires and rims.<br />

WIDE-OPEN ACCESS<br />

We believe wide-open shielding makes<br />

things that much easier. We designed the<br />

Sidearm ® for easy routine maintenance.<br />

Operators can access components without<br />

tools in seconds. We equipped our shielding<br />

with two doors that swing open at least<br />

180 degrees. We also placed easy-toaccess<br />

shielding around all the input<br />

and output shafts. Getting at all the<br />

components is a snap. Fast. Easy.<br />

And accessible.<br />

COMPATIBLE<br />

Not only can the Sidearm ® hook up<br />

to <strong>Degelman</strong> cutters, but it can also<br />

easily connect to most other brands with<br />

a simple adapter plate.<br />

HEAVY-DUTY HITCH<br />

The Sidearm ® is equipped with a standard,<br />

heavy-duty V-Clamp compatible to more<br />

than 30 different makes and models of<br />

tractor drawbars.<br />

STAY HOOKED UP<br />

With the Sidearm ® there’s no need to<br />

unhook to move from mowing offset to<br />

straight. It can remain hooked up as the<br />

Sidearm ® can cut straight behind the tractor<br />

or from side to side easily.

“ After using the SIDEARM ® for almost 900 hours we found<br />

that the level of operator comfort alone justified the<br />

cost of the arms. There are many positive aspects in<br />

using the <strong>Degelman</strong> SIDEARM ® such as shorter turning<br />

radius, greater visibility, being able to cut closer<br />

to obstacles and wet areas in the ditches and above all<br />

operator safety. We also found that being able to cut<br />

on either the right or left or directly behind the<br />

tractor eliminates moving from place to place empty.<br />

The use of the <strong>Degelman</strong> SIDEARM ® has increased our<br />

miles mowed by at least 20% per day. Cheryl and I<br />

think that the SIDEARM ® is a great piece of equipment,<br />

well designed and built to last.”<br />

- Fred and Cheryl Peppler<br />

MacNutt, SK

DRIVE STRAIGHT. STRAIGHT DRIVE.<br />

To increase the life of the Sidearm ® even<br />

more, all our drive shafts are in-line to<br />

each other. This design feature significantly<br />

reduces wear and tear of the components<br />

and ensures a direct transfer of power<br />

without wearing drive train components.<br />

As the cutter is always directly in-line<br />

with the Sidearm’s output shaft, the life<br />

expectancy of the input drive of the<br />

cutter is extended exponentially. This<br />

increases the versatility of the equipment and<br />

keeps everything straight no matter what<br />

direction the unit is going in. The two vertical<br />

cross-joints also absorb any misalignment<br />

or deviation from 90 degrees. These extras<br />

mean the Sidearm ® goes farther, lasts longer<br />

and can take<br />

on practically<br />

anything put in<br />

its path.<br />

HIGH CARBON<br />

SHAFTING<br />

We use cold-rolled, high carbon hex shafting<br />

for maximum torque transmission. To<br />

increase the ease of maintenance, we designed<br />

the shafting and the bearings as one<br />

sub-assembly. That means<br />

they’re both contained in<br />

the same tray. If long term<br />

servicing is required, the entire<br />

bearing tray can be pulled out.<br />

OVER-SIZED FRAME<br />

It’s made up of quarter-inch steel and<br />

8”X12” hollow-structural<br />

tubing. It’s<br />

big. It’s<br />

wide. And<br />

it’s strong.<br />

AVERAGE LIFE (Hours)<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

Driveline Joint Life Expectancy<br />

0<br />

5 10 15 20 25 30<br />

JOINT ANGLE (Degrees o )<br />

HIGH HORSEPOWER<br />

GEARBOXES<br />

Our gearboxes are made<br />

right here in Canada<br />

using a splined shaft<br />

design versus a keyway.<br />

The splined shaft<br />

increases the surface area<br />

of all contact points for increased<br />

strength, power transfer and life expectancy.<br />

To go even further, we use gearboxes with a<br />

1:1 ratio - the maximum strength that can be<br />

extracted from a gearbox.<br />

THE SIDEARM<br />

ADVANTAGE<br />

In-line drive train…heavy-duty hitch…wide<br />

open shielding…all the components we<br />

put into the Sidearm ® are unequalled in<br />

design and quality. The result is a tool that<br />

maximizes the control the operator has over<br />

cutting ditches while minimizing the stress<br />

and danger associated with challenging<br />

angles and hard-to-get to places.

“ The service of <strong>Degelman</strong><br />

does not stop. . . the<br />

Territory Managers and the<br />

Research and Development<br />

Department are continuously<br />

exploring ideas on different<br />

techniques. It has been a<br />

pleasure to work with<br />

<strong>Degelman</strong> Industries and I am<br />

confident that it will be a<br />

pleasure in the future. ”<br />

- Terry Eleniak<br />

Lamont County, AB

IT’S ALL ABOUT THE DETAILS.<br />

A ROCK SOLID<br />

PHILOSOPHY<br />

In 1963 Wilf <strong>Degelman</strong> created his first<br />

rock picker and an unrivalled company<br />

philosophy: The fewer number of parts and<br />

complexity the better. And when you build<br />

something, build it right, build it heavy and<br />

build it to last from top to bottom. This is the<br />

same philosophy we use in every piece of<br />

machinery we make to this very day.<br />

No bolt is left unexamined. No<br />

piece of steel goes without scrutiny.<br />

No detail is too small to be engineered to<br />

perfection. That’s the thought process behind<br />

every <strong>Degelman</strong> Rotary Cutter. And that’s<br />

the unmatched standard that provides<br />

durable, easy-to-maintain machinery that<br />

holds its value year in and year out.<br />

NEW HINGE PINS<br />

2 TO 6X STRONGER<br />

HYDRAULIC<br />

CYLINDERS<br />

We manufacture our own industrial cylinders<br />

with induction hardened chrome shafting,<br />

urethane seals and wear bands to eliminate<br />

scarring and oil contamination. Shorter<br />

strokes translate into rapid movements and<br />

more wear, so we developed our center<br />

cylinder with a longer, smoother<br />

stroke to increase life expectancy<br />

and reduce<br />

wear and<br />

tear.<br />

INCREASED<br />

WING CONTROL<br />

Flow restricted hydraulic fittings allow<br />

increased control over the speed that the<br />

wings go up and down to reduce the risk of<br />

damage.<br />

SURFACE AREA<br />

INCREASED 19-58%<br />

We’re obsessed with making our equipment<br />

better in every way and in every detail.<br />

Include in that list – our Wing Hinge Pins.<br />

More steel equals more strength: so of course<br />

we added more steel to our wing hinge pins.<br />

They are now 1 3/16” in diameter, which<br />

makes them two to six times stronger than<br />

conventional hinge pins. In addition, the<br />

increased diameter enlarges the surface area<br />

up to 58% to make them twice as tough as<br />

1” diameter hinge pins.<br />

AR400 SKID SHOES<br />

Our AR400 plated skid shoes boast eight<br />

times the abrasion resistance of regular<br />

steel. They’re also reversible—the shoes can<br />

move from ditchside to roadside when wear<br />

appears.<br />

SAFETY CHAINS<br />

We redesigned our safety chains. Stronger<br />

and more robust. Our new design reduces<br />

chain upswing so the chains stay where they<br />

are supposed to…and so does debris.<br />

THICK SIDE SKIRTS<br />

The skirts take a beating in the ditches<br />

so we build ours with thick laminated<br />

steel plating so they<br />

contain debris and<br />

rocks better. Plus, if the<br />

skid shoe is<br />

replaced, part of the<br />

skirt ends up being<br />

replaced as well, so it<br />

ends up lasting even<br />

longer.<br />

<strong>Degelman</strong> Skirt Thickness<br />

Up to 1/2”<br />

Up to<br />

50%<br />

Thicker<br />

Typical Skirt<br />

Thickness - 1/4”<br />

PRECISION HITCH<br />

Our single bolt clamp hitch is<br />

machined and heat-treated from<br />

hardened steel to make our hitch<br />

superior in quality. Most grease<br />

points are designed for easy<br />

through the head access.<br />

Added safety comes into<br />

play with our lock up pin<br />

connection so one person<br />

can do the hook up without<br />

worry of hand<br />

injury.<br />

3/4”<br />

1”<br />

1-3/16”<br />

COMPETITOR HINGE<br />

PIN DIAMETERS<br />

DEGELMAN HINGE<br />

PIN DIAMETER

“. . . most durable mower I’ve ever run. My two<br />

machines have 3000 miles of road ditch on them and<br />

they look as good as the day I got them.”<br />

- Trevor Pollard<br />

Gladstone, MB

PROTECT YOUR INVESTMENT.<br />

Our goals are to build equipment that<br />

set the standard for strength and<br />

substantially reduce maintenance time. Our<br />

patented double-layer construction helps<br />

us achieve both these goals. The result is a<br />

Rotary Cutter of unparalleled strength that’s<br />

easy to maintain, holds its appearance and<br />

ensures a solid resale value.<br />

BOXED IN DECK<br />

STRENGTH<br />

Our box frame results in a deck strength like<br />

no other. Using the inherent strength of an<br />

I-beam design, combined with double-layer<br />

technology, our box frame is tougher and<br />

more durable. Add internal channels that<br />

create a reinforced rib system and the<br />

result is a cutter that can take on any<br />

challenge put in its path.<br />

INTEGRATED LUG<br />

DESIGN<br />

Our engineers didn’t stop with the<br />

box frame. They conducted experiments<br />

on lug design and found that<br />

when they welded the lugs through<br />

both layers of the deck - top and<br />

bottom - it increased the<br />

strength of the<br />

HIGH IMPACT<br />

RESISTANT STEEL<br />

It all starts with the steel. The tougher the<br />

steel the tougher the equipment deck<br />

– the backbone of the whole machine.<br />

So, we went back to the manufacturer and<br />

asked them to come up with even better<br />

steel. They did. The outcome is impactresistant<br />

steel with three to four times the<br />

lifespan of standard grade A36. It resists<br />

rusting better and can withstand shock<br />

loading with less or no damage. With<br />

3 TO 4 TIMES<br />

MORE LIFE<br />

design dramatically. An extra thick steel<br />

pad is integrated where loads are greatest.<br />

The lugs are also generally placed in the<br />

direction of travel for ease of cleaning.<br />

improved steel, the <strong>Degelman</strong> Cutter will<br />

last longer, endure more punishment in the<br />

field and retain a higher resale value like<br />

nothing else out there.<br />

UNI-BODY DESIGN<br />

We use an integrated uni-body structure<br />

design. There are no tubes welded on<br />

and no channels for debris to collect in<br />

and around. Just a continuous surface<br />

that reduces maintenance time and<br />

retains its value.<br />

LESS MAINTENANCE<br />

Our box frame is manufactured with<br />

continuous welds and without pockets that<br />

collect debris. As the cutter<br />

operates, debris sheds off<br />

in four directions. Maintenance<br />

is quick, easy and<br />

weeds are not transferred<br />

from one location to<br />

another.<br />

RESALE VALUE<br />

It’s no surprise that a <strong>Degelman</strong> cutter<br />

holds its value. Our uni-body, box-frame<br />

design means that the bottom takes all the<br />

punishment while the topside looks like it did<br />

when it was first bought. And because we<br />

don’t put framing on top there is no place<br />

for water to collect and rust to start. Plus,<br />

the Rotary Cutter’s ability to shed debris and<br />

to stay clean substantially reduces the likelihood<br />

of weeds heating on top,<br />

discoloring or rotting the<br />

surface.

“ We added <strong>Degelman</strong> cutters and<br />

a SIDEARM ® to our program in 2004<br />

with great results. The<br />

versatility of the SIDEARM ® is<br />

unmatched and our <strong>Degelman</strong><br />

cutters proved to be reliable<br />

and efficient in our program. The<br />

rugged design really reduced<br />

down time this past summer.”<br />

- Keith Boras<br />

Lacombe County, AB

NO GUTS. NO GLORY.<br />

SQUARE IS BETTER<br />

Why do all impact and socket wrenches<br />

use square adaptors? - Torque.<br />

Again,<br />

we go a step further.<br />

For easy blade<br />

replacement and<br />

increased resiliency, we<br />

use hardened square bolts.<br />

Because of the increased<br />

surface area, the square<br />

blade bolts have a tighter<br />

tolerance and a better contact fit than keyed<br />

or hex shaped bolts. This prevents the bolts<br />

from spinning and<br />

wearing out sooner.<br />

Because of this smart<br />

design, replacing<br />

our bolts is truly a<br />

one-person job.<br />

BOLT PROFILES<br />

Square Bolts<br />

- high resistance to<br />

torque due to<br />

increased contact<br />

area.<br />

- proven design.<br />

Other Bolts<br />

- less resistance to<br />

torque.<br />

- corners wear,<br />

bolts spin.<br />

Bolt & Key<br />

- low resistance<br />

to torque.<br />

- keys get lost or<br />

damaged.<br />

TAPERED BOLTS.<br />

TIGHT FIT.<br />

It’s an engineering fact that two perfectlymachined<br />

conical surfaces will centre to<br />

each other (a design the automotive<br />

industry uses for tie-rods). We applied this<br />

thinking to our nuts and bolts. Tapering<br />

centers the nut<br />

and the<br />

bolt, thus<br />

eliminating<br />

play and<br />

reducing<br />

wear.<br />

WIDE-OPEN ACCESS<br />

All of our clutches are under one gas<br />

assisted shield that’s ergonomically accessible<br />

with minimal lifting for easy maintenance.<br />

The drive shields are heavy walled,<br />

robust, supported by steel backing plates,<br />

free from vibration and can be popped off<br />

in seconds for maintenance.<br />

COMMON PARTS<br />

We know small details can make a huge<br />

difference. That is why we designed our<br />

bolts, pans and blades with common parts.<br />

The result is increased versatility, less<br />

downtime and reduced parts inventory.<br />

INDUCTION HARDENED<br />

BLADE COLLAR<br />

Small things make a big difference. Like<br />

tough bolts. Bolt collars are quenched and<br />

tempered to make them as hard as industrially<br />

possible. This improvement lengthens<br />

the lifespan of the blade itself and the bolts<br />

at the same time. With tougher bolts there’s<br />

less in-the-field maintenance and<br />

more uptime.<br />

GUARANTEED<br />

GEARBOXES<br />

Bondioli cut and heat treat gear sets inhouse<br />

to ensure a superior product. The<br />

boxes are made from a one-piece cast<br />

and painted inside and out to reduce<br />

corrosion. The gears and<br />

shafts are either forged as<br />

one piece or splined<br />

together without<br />

the use of keyways<br />

and heat<br />

treated for<br />

strength.<br />

LONGER LASTING<br />

MILLED BLADES<br />

Our blades have milled cutting edges and<br />

milled holes for strength and safety. Expect<br />

longer life than forged-edge blades. Blades<br />

are heat treated only once so the carbon<br />

content remains high and durability is the<br />

end result. Our blades stay sharp longer and<br />

undergo less chipping and breakage. Most<br />

blade breakage occurs at the hole,<br />

so instead of punching out a<br />

blade hole <strong>Degelman</strong> blades<br />

are milled square and true<br />

for more contact material.<br />

A better fit and less wear.<br />

THICK HEAVY-DUTY<br />

BLADE CARRIERS<br />

Three-quarter-inch steel. Our new blade carrier<br />

is three times thicker than its predecessor<br />

and four times as thick as conventional pans.<br />

The redesign also includes less parts; the less<br />

parts, the less there is to break or fix. Add to<br />

that our exclusive square & tapered bolts to<br />

reduce play to almost nil and<br />

the result is a tight,<br />

tough and safe<br />

blade carrier.<br />

Unrivaled by<br />

anything else<br />

out there.

“ Your SIDEARM ® is easy to operate and very<br />

responsive for ditch mowing around culverts<br />

and road signs . . . mower quality of cut is<br />

excellent. I could trim a golf course.”<br />

- David Boklaschuk<br />

Prince Albert, SK

MAXIMUM SHOCK ABSORPTION.<br />

Vibration. The largest single contributor<br />

to metal fatigue, stress-cracking<br />

and structural failures. Reduce the vibration.<br />

Reduce the wear and tear. In the design<br />

of our Rotary Cutter we’ve integrated a<br />

series of vibration dampening systems that<br />

collectively absorb the vibrations before they<br />

can go any further. The end advantage is<br />

that our equipment’s lifespan is exponentially<br />

extended. Sound smart? It is.<br />

WALKING WHEELS<br />

Our walking wheels are the other half of<br />

the equation. They add to the reduction of<br />

vibrations by dampening fifty per cent of<br />

movement and terrain shock. They stabilize<br />

the movement to ensure smooth and even<br />

cutting.<br />

REPLACEABLE PARTS<br />

RUGGED KNEE<br />

ACTION SUSPENSION<br />

Rubber. There’s no better substance on<br />

earth for absorbing and reducing impact.<br />

The rubber we use is top of<br />

the line, self-dampening<br />

and UV-protected to<br />

ensure the longevity and<br />

performance of the entire<br />

machine. Plus, our active<br />

suspension is held in place<br />

by a one and-a-quarter-inch<br />

Grade 8 grease-accessible<br />

hex bolt.<br />

ROBUST ROCKSHAFT<br />

Talk about long life. Our rockshaft is<br />

over-sized and over-built, with lugs that are<br />

wrapped all the way around for strength<br />

and made with our extra-wide boxed<br />

strut construction. Unmatched in<br />

the industry.<br />

Our walking axle has common parts<br />

between both sides to<br />

make part replacement<br />

that much<br />

easier. We also<br />

built the axle<br />

component so<br />

that changing<br />

parts is done<br />

with a single bolt<br />

to reduce maintenance<br />

time.<br />

LARGE DIAMETER<br />

SPINDLES<br />

Every detail counts. No matter how small.<br />

We make our spindles out of one and threequarter-inch<br />

diameter to guarantee less<br />

breaking and less bending.<br />

LOW MAINTENANCE<br />

BUSHING DESIGN<br />

Steel on steel results in more wear and<br />

tear on equipment. To minimize negative<br />

impact on the components, our wheels pivot<br />

on tough Nylatron bushings. This helps<br />

maximize the shock impact the system<br />

can absorb, and reduces maintenance and<br />

chance of rust penetration.

“ From an experienced<br />

operator to a second year<br />

summer student, there were<br />

no complaints about the<br />

operation or performance of<br />

the hitches or mowers. Our<br />

Council and Staff are<br />

extremely pleased with the<br />

performance of both the<br />

mower and SIDEARM ® hitch. We<br />

are equally impressed with<br />

<strong>Degelman</strong>’s willingness to<br />

address any questions or<br />

concerns that we have had with<br />

their equipment. ”<br />

- JAYE LEMIEUX<br />

ALIDA, SK

SPECIFICATIONS AND OPTIONS.<br />

SIDEARM 1820 OFFSET HITCH<br />

Overall Dimensions:<br />

Overall Height 74”<br />

Overall Width (with wheels) 116”<br />

Overall Length 22’-6”<br />

Weight: Standard<br />

3607 lbs<br />

Hitch Weight: (standard)<br />

1500 lbs<br />

Hitch Weight: (cutter attached)<br />

approx. 450 lbs<br />

Angling:<br />

Maximum 50° (left or right)<br />

Offset:<br />

166” (drawbar centre to cutter centre)<br />

Main Frame Construction:<br />

8” x 12” (.250 wall)<br />

Hitch:<br />

Swivel Type<br />

Pivoting Points:<br />

Protected by Nylon Bushings/discs<br />

Grease Fittings:<br />

Easy Access<br />

Tires:<br />

16.5 x 16.1 All Terrain<br />

Hydraulic Cylinder: 2-1/2” x 16”<br />

PTO requirement:<br />

(100 or 540 PTO)<br />

Drivelines:<br />

Weasler<br />

DIL Gear Box:<br />

1 : 1 ratio<br />

Drive Shaft:<br />

1-1/2” Hex Bar<br />

Heavy Duty Shielding:<br />

Easy Swing-Away<br />

Optional Accessories:<br />

Light Kit, Selector Valve Kit, Strobe Kit, Trailer Coupler, Cutter Adapter<br />

ROTARY CUTTER RC1520 & RC1020<br />

1020 model specs. shown in ( )’s.<br />

Field Position:<br />

<strong>Cutting</strong> Height 1” to 17”<br />

<strong>Cutting</strong> Width 180” (122”)<br />

Overall Width 188” (135”)<br />

Overall Length 191”<br />

Transport Position:<br />

Overall Height 86”<br />

Overall Width (no wheels) 90” (87”)<br />

Overall Width (with wheels) 120” (102”)<br />

Overall Length 180”<br />

Ground Clearance: 16”<br />

Weight: Standard 5985 lbs (6100 lbs)<br />

Hitch Weight:<br />

Field Position 2100 lbs (2125 lbs)<br />

Transport Position 1950 lbs (1975 lbs)<br />

Wing Flex: 24° down, 85° up<br />

Deck Thickness - Double Frame Construction:<br />

Top Deck 3/16”<br />

Bottom Deck (High Impact Resistant Steel) 3/16”<br />

Skid Shoes:<br />

Wing<br />

3/8” x 3” AR400<br />

Center Section 3/8” x 5-1/2” AR400<br />

Deck Rings: 1/2” x 3” Standard<br />

Side Skirt Thickness: Laminated up to 1/2” thick<br />

Chain Shield:<br />

Standard Double Row 5/16” GR 30<br />

Optional Cable through Chain 1/4” Cable<br />

Minimum Tractor PTO Power: 65 hp<br />

Recommended Tractor PTO Power: 85 hp<br />

Drivelines:<br />

540 RPM Machine Gearcases<br />

Tractor to Transfer<br />

CAT 6 with 80° CV<br />

Transfer to Center/Wing CAT 4<br />

1000 RPM Machine Gearcases<br />

Tractor to Transfer<br />

CAT 4 with 80° CV<br />

Transfer to Center/Wing CAT 4<br />

Driveline Protection: Preset Friction Torque Limiters<br />

Gearcase Power Rating:<br />

Transfer Gearcase:<br />

200 hp - continuous<br />

240 hp - peak<br />

Center and Wing Gearcase: 175 hp - continuous<br />

190 hp - peak<br />

Brush <strong>Cutting</strong> Capacity: 3-1/2”<br />

Blade Holder:<br />

Standard 3/4” Blade Carrier<br />

Optional 1/4” Reinforced Skid Pan<br />

Blades: Milled, 6-1/4” Overlap<br />

Standard 1/2” x 5”<br />

Optional 1/2” x 4”<br />

Blade Tip Speed:<br />

540 PTO<br />

Center 15,500 ft/minute<br />

Wing 15,700 ft/minute<br />

1000 PTO<br />

Center 16,750 ft/minute<br />

Wing 15,950 ft/minute<br />

Wing Lift Hydraulics: (Routing for combined circuit included)<br />

Standard<br />

Single acting individual circuits<br />

Hitch: Self-leveling<br />

Standard 1-1/4” Precision Clamping System<br />

Optional<br />

1-1/8” Clevis Hitch<br />

Suspension:<br />

Center:<br />

Walking Axle and Rubber Spring<br />

Wings: Standard<br />

Single Wheel and Rubber Spring<br />

Optional<br />

Walking Axle and Rubber Spring<br />

Wheels/Tires:<br />

Standard<br />

5 Bolt 20x5.5 Laminated<br />

Optional<br />

5 Bolt 22x6.6 Aircraft (foam filled)<br />

Optional<br />

5 Bolt 22x6.6 Aircraft (air filled)<br />

Optional Accessories:<br />

Light Kit, Winch Kit, Tow Hitch, Wing Gauge Wheel, Toolbox

“ In 2004, we purchased another <strong>Degelman</strong> mower and after<br />

attending a demonstration on their SIDEARM ® hitch, we<br />

also purchased two hitches. The combination of the new<br />

hitches with the <strong>Degelman</strong> mowers was amazing. We were<br />

able to mow in areas that we could not even come close<br />

to in previous years. The reach and maneuverability of<br />

the hitches makes them very operator friendly. ”<br />

- Jaye Lemieux<br />

Alida, SK<br />

W W W . D E G E L M A N . C O M<br />

1 800 667 3545 (306) 543 4447<br />

Protected by US patent 6,546,707 and CDN patent 102785. Other<br />

foreign and domestic patents are pending. <strong>Degelman</strong> Industries Ltd.<br />

is constantly striving to improve its products and reserves the right to change<br />

design, material and specifications without notice. Printed in Canada