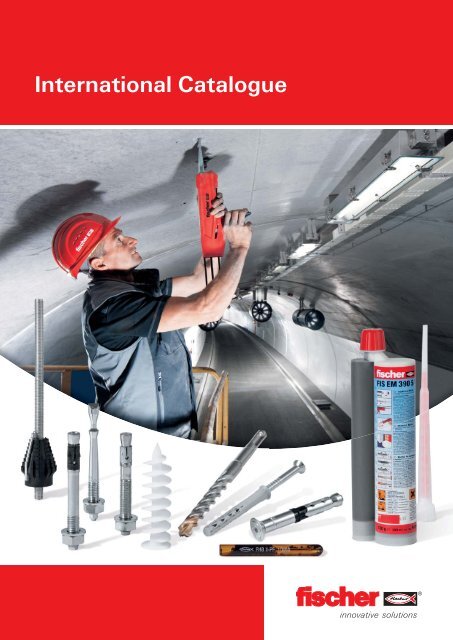

International Catalogue

International Catalogue

International Catalogue

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>International</strong> <strong>Catalogue</strong>

Dear Partners,<br />

fischer is a specialist for secure and economical construction fittings.<br />

Our product spectrum consists of chemical systems and steel anchors<br />

up to plastic fixings. Innovative facade systems, a comprehensive screw<br />

program, special assortments for external thermal insulation composite<br />

systems, sanitary, heating, ventilation and electrical installation, adhesives,<br />

sealants and foams: fischer has the right solution for every fixing problem.<br />

We deliver the highest quality, the best security and ease of installation.<br />

We aim at delivering every optimal technical solution for your current<br />

fixing task quickly and flexibly.<br />

fischer caters to customers all around the globe – with 35 foreign<br />

subsidiaries and sales partners in over 100 countries. We also develop<br />

and deliver customer-specific solutions on request. We strive to produce<br />

excellent and innovative products as well as provide an excellent range of<br />

services: Qualified field engineers can also be provided at your disposal on<br />

site. Our hotline connects you directly to fischer application engineering<br />

which offers you quick and professional help for all your fixing tasks.<br />

Finally, we also offer internally designed assessment programmes as<br />

well as the technical hand books about special and general applications<br />

in case of earthquake-prone areas, for fire protection or numerous other<br />

fields of application.<br />

The fischer ACADEMY is also one-of-a-kind. In our 4000 square-meter<br />

customer center at our Tumlingen headquarters, we provide ideal<br />

training conditions for practical implementation with our products and<br />

its numerous areas of application. However, we don’t offer you the most<br />

modern training in fixing technology just at our company headquarters.<br />

fischer trainers are active worldwide.<br />

Our fixing products catalogue is also a part of our comprehensive<br />

service offer. In 2012 it was revised and completely reworked. The quick<br />

overview at the beginning simplifies searching for the desired products.<br />

The following detailed product selection guide is clearly classified in the<br />

most important parameters: Product types, designs, building materials,<br />

approvals and an application recommendation.<br />

The application selection guide, which is arranged according to instances<br />

of application, is also new. This overview defines the most important<br />

sections with their typical requirements: Instance of application, product,<br />

substrate (building material), type of installation, approval, fire protection<br />

and corrosion.<br />

The individual product pages were overwritten with the main characteristic<br />

features of the products and the text as well as the technical tables<br />

were newly structured. Optimisations are also provided which will help<br />

you to orient to and choose the appropriate product.<br />

Please let us know your thoughts and suggestions about the new concept<br />

of the main fischer catalogue. We look forward to your response and wish<br />

you a lot of success with our products.<br />

Yours, Klaus Fischer<br />

3

Good reasons to choose fischer<br />

A brand and its promise to perform<br />

Whoever chooses fischer receives more than a range of safe<br />

products. The aim is to always develop the best solutions for<br />

our customers across the globe. This does not just mean<br />

innovative products, but also user-orientated support and a<br />

reliable service.<br />

With the fischer ProcessSystem (fPS), we ensure that we are<br />

adapting and optimising our processes in line with customer<br />

requirements in a flexible manner and on a continuous basis.<br />

Always with its finger on the pulse of the times<br />

At fischer, innovation is more than just a sum of the patents.<br />

We are open to new things and are prepared for change –<br />

always with the aim of offering our customers the greatest<br />

possible benefits. Over the years, our own development and<br />

production sites have been developing numerous fixing<br />

solutions for the most wide-ranging applications.<br />

Be it new production procedures or materials, such as<br />

renewable raw materials: We are carrying out the research for<br />

your safety and will continue to do so in the future. This gives<br />

us such great flexibility that we can even develop tailor-made<br />

customer solutions. This power to innovate has seen fischer<br />

become market leader in anchor technology and the fixing<br />

industry.<br />

Safety that connects – Decisive quality<br />

The fischer product range is well-positioned in all sectors of<br />

fixing technology – Steel, Nylon and Chemical fixings.<br />

2009 saw a complete range of wooden screws be made<br />

available on the market for the very first time.<br />

4

We take responsibility<br />

Our active environment management policy means that we<br />

are helping to maintain an intact environment for our<br />

generation and for those that follow. We deal responsibly<br />

with energy resources and raw materials. The environment<br />

management policy at the Tumlingen site has been certified<br />

in line with DIN EN ISO 14001. We are a member of the<br />

German Sustainable Building Council (DGNB), and our<br />

products have been successively certified in line with the<br />

guidelines provided by the Institute for Construction and the<br />

Environment (IBU).<br />

Our service to you<br />

We are a reliable partner, one that will stand at your side<br />

and address your individual requirements with advice and<br />

actions:<br />

• global presence and active sales service in over<br />

100 countries<br />

• training sessions, some with accreditation, at your<br />

premises or in the fischer ACADEMY – our company's<br />

own training and customer service centre<br />

• qualified, technical support and advice regarding<br />

economical fixing solutions, taking the latest building<br />

materials, standards and guidelines into account; we can<br />

even come to your building site if required<br />

• convenient calculations with modern software<br />

5

Innovations to inspire professionals<br />

Injection mortar FIS VT 300 T<br />

The solid injection mortar for anchorings<br />

in non-cracked concrete, now in a new<br />

cartridge size.<br />

You can find details on page 83.<br />

High-performance anchor FH II A4<br />

The push-through anchor for fixings with<br />

sophisticated design, now also available in<br />

stainless steel.<br />

You can find details on page 161.<br />

Anchor bolt FBN II A4<br />

The cost-efficient fixing for flexible<br />

use in non-cracked concrete, now<br />

also available in stainless steel..<br />

You can find details on page 195.<br />

6

Content<br />

Product selection guide<br />

• Quick overview<br />

• Detailed overview<br />

8<br />

1a<br />

Application selection guide<br />

24<br />

1b<br />

Chemical fixings<br />

41<br />

2<br />

High performance steel anchors<br />

Frame fixings / Stand-off installation<br />

General fixings<br />

Cavity fixings<br />

Electrical fixings<br />

Sanitary fixings<br />

Scaffold and eye screw fixings<br />

Insulation fixings / Façade fixings<br />

Foams and sealants<br />

Adhesives<br />

Drills and bits<br />

Basic knowledge<br />

Service<br />

151<br />

223<br />

275<br />

309<br />

323<br />

353<br />

363<br />

373<br />

395<br />

425<br />

431<br />

450<br />

470<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

7

Products - Quick overview<br />

Selection guide<br />

Chemical fixings<br />

Highbond-System FHB II<br />

Highbond anchor FHB II-A S<br />

Highbond anchor FHB II-A L<br />

2<br />

Page<br />

45<br />

49<br />

53<br />

Highbond anchor dynamic FHB dyn<br />

UMV multicone dynamic bonded<br />

anchor<br />

Stand-off installation Thermax<br />

Remedial wall tie VBS 8<br />

Page<br />

128<br />

132<br />

135<br />

140<br />

Resin anchor R with RG M<br />

57<br />

Remedial wall tie VBS-M<br />

140<br />

Resin anchor R with RG MI<br />

63<br />

Weather facing reconstruction<br />

system FWS<br />

144<br />

Injection mortar FIS EM<br />

67<br />

Can System FCS<br />

146<br />

Injection mortar FIS V<br />

71<br />

fill & fix injection fixing<br />

148<br />

1<br />

Injection mortar FIS VW<br />

Injection mortar FIS VS<br />

Injection mortar FIS VT<br />

75<br />

79<br />

83<br />

High performance steel anchors<br />

Bolt anchor FAZ II<br />

3<br />

Page<br />

154<br />

Injection mortar FIS P<br />

86<br />

Bolt anchor FAZ II GS<br />

158<br />

Injection for cracked concrete<br />

with FIS A<br />

89<br />

High performance anchor<br />

FH II<br />

161<br />

Injection for cracked concrete<br />

with RG MI<br />

94<br />

ZYKON undercut anchor<br />

FZA<br />

167<br />

Injection for non-cracked concrete<br />

with FIS A<br />

97<br />

ZYKON undercut anchor<br />

FZA-I<br />

173<br />

Injection for non-cracked concrete<br />

with RG MI<br />

103<br />

ZYKON hammerset anchor<br />

FZEA II<br />

176<br />

Injection in solid brick masonry<br />

106<br />

Concrete screw FBS<br />

179<br />

Injection in perforated brick masonry<br />

111<br />

Hammerset anchor EA II<br />

182<br />

Push-through installation in masonry<br />

116<br />

Nail anchor FNA II<br />

185<br />

Injection for aerated concrete<br />

119<br />

Ceiling nail FDN<br />

189<br />

Rebar connections<br />

123<br />

Bolt anchor FBN II<br />

Bolt anchor FBN II GS<br />

193<br />

195<br />

Bolt anchor EXA<br />

202<br />

8

Products - Quick overview<br />

Heavy-duty anchor TA M<br />

Heavy-duty anchor TA M-T<br />

Sleeve anchor FSA<br />

Fixing set for diamond drills<br />

FDBB<br />

Page<br />

206<br />

210<br />

212<br />

214<br />

General fixings<br />

Universal plug UX<br />

Expansion plug SX<br />

Expansion plug S<br />

Metal expansion anchor FMD<br />

5<br />

Page<br />

277<br />

280<br />

283<br />

286<br />

Selection guide<br />

Wall screw MR<br />

216<br />

Expansion plug M-S<br />

288<br />

Hollow-ceiling anchor FHY<br />

218<br />

Anchor M<br />

290<br />

Frame fixings / Stand-off installation<br />

4<br />

Brass fixing MS<br />

292<br />

Page<br />

Aircrete anchor GB<br />

294<br />

Frame fixing SXR<br />

225<br />

Turbo aircrete anchor FTP K<br />

296<br />

Universal frame fixing FUR<br />

Frame fixing SXS<br />

232<br />

237<br />

Turbo aircrete anchor FTP M<br />

Brass fixing PA 4<br />

298<br />

300<br />

1<br />

Hammerfix N<br />

242<br />

Balcony cladding fixing P9K<br />

302<br />

Nail sleeve FNH<br />

246<br />

Stair-tread fixing TB / TBB<br />

304<br />

Window frame fixing F-S<br />

248<br />

Repair pad FIX.it<br />

305<br />

Metal frame fixing F-M<br />

250<br />

Doorstop TS<br />

306<br />

Window frame screws FFSZ and FFS<br />

252<br />

Wall tie VB<br />

255<br />

Cavity fixings<br />

6<br />

Adjustable fixing S10J<br />

256<br />

Page<br />

Self-drilling adjustable screw JUSS<br />

258<br />

Metal cavity fixing HM<br />

310<br />

Universal spacing screw ASL<br />

259<br />

Gravity- and spring toggle<br />

K, KD, KDH, KM<br />

312<br />

Stand-off installation<br />

Thermax 8 / 10<br />

261<br />

Board fixing PD<br />

315<br />

Stand-off installation<br />

Thermax 12 / 16<br />

264<br />

Plasterboard fixing GK<br />

317<br />

Remedial wall tie VBS-M<br />

269<br />

Plasterboard fixing metal GKM<br />

319<br />

Remedial wall tie VBS 8<br />

264<br />

9

Products - Quick overview<br />

Selection guide<br />

Electrical fixings<br />

ClipFix plus LS/ES/ZS<br />

ClipFix plus SD<br />

Cable clasp KB<br />

Cable harness SHA<br />

7 9<br />

Scaffold and eye screw fixings<br />

Page<br />

Page<br />

324 Scaffold anchoring GS 12 + plug<br />

364<br />

326 Scaffold anchoring FI G<br />

366<br />

328 Eye screw GS<br />

368<br />

330 Ring nut RI<br />

370<br />

Pipe clip RC<br />

332<br />

Pipe clip FC<br />

Saddle clip SCH<br />

334<br />

336<br />

Insulation fixings / Façade fixings<br />

10<br />

Page<br />

Nail clip NS / MNS<br />

338<br />

Insulation support DHK<br />

374<br />

Nail disc NSB<br />

340<br />

Insulation support DHM<br />

376<br />

1<br />

Spacer pipe clamp AM<br />

Conduit clip BSM<br />

342<br />

344<br />

Render fixing DIPK<br />

Render fixing FIF-K<br />

378<br />

380<br />

Impact nail ED<br />

346<br />

Render fixing FIF-S<br />

382<br />

Cable tie BN / UBN<br />

348<br />

Insulation discs<br />

384<br />

Wireclip<br />

350<br />

Holding clamp DVN<br />

386<br />

Retaining disc with screw DHT S<br />

387<br />

Insulation fixing FID<br />

389<br />

Sanitary fixings<br />

Sanitary fixings for board materials<br />

8<br />

Page<br />

354<br />

Insulation disc FATB<br />

Fibre cement panel screw FAFZ H<br />

391<br />

393<br />

Ceramic fixings<br />

356<br />

Wash basin and urinal fixings<br />

358<br />

Foams and sealants<br />

11<br />

Page<br />

One-component gun foam PUP B2<br />

396<br />

One-component gun foam PUP G B2<br />

397<br />

One-component gun foam PUBS B2<br />

398<br />

10

Products - Quick overview<br />

One-component gun foam PUP B3<br />

One-component gun foam PUFS B1<br />

One-component gun foam PUPP G B2<br />

One-component rapid installation<br />

foam PU1<br />

Page<br />

399<br />

400<br />

401<br />

402<br />

Adhesives<br />

Assembly adhesive MK<br />

Construction adhesive KK<br />

All-round adhesive gluing and sealing KD<br />

PVC adhesive<br />

12<br />

Page<br />

426<br />

427<br />

428<br />

429<br />

Selection guide<br />

2-component rapid foam PU2<br />

403<br />

2-component fixing foam<br />

404<br />

Drills and bits<br />

13<br />

Accessories<br />

405<br />

Page<br />

Premium sanitary silicone DSSA<br />

407<br />

Hammer drill bit SDS Plus IV Quattric<br />

432<br />

Sanitary silicone DSSI<br />

408<br />

Hammer drill bit SDS Plus II Pointer<br />

434<br />

Multi-silicone DMS<br />

Premium high temperature silicone DHS<br />

409<br />

410<br />

Hammer drill bit SDS Max II /<br />

SDS Max IV<br />

Chisel<br />

437<br />

439<br />

1<br />

Premium construction silicone DBSA<br />

411<br />

Profi-bit FPB<br />

440<br />

Roof and wall silicone DBSI<br />

412<br />

Diamond bit FDB<br />

443<br />

Premium silicone for natural stone DNS<br />

413<br />

Stainless steel bit FSB<br />

446<br />

Premium B1 silicone DFS<br />

414<br />

Bit holder FBH<br />

448<br />

Premium painting acrylic DMA<br />

415<br />

Acrylic sealant DA<br />

416<br />

Premium structured acrylic DSA<br />

417<br />

Premium ventilation duct sealant DLK<br />

418<br />

Premium all-weather sealant DDK<br />

419<br />

Roof sealing compound DD<br />

420<br />

Accessories<br />

421<br />

Sealant selection matrix<br />

and colour boards<br />

422<br />

11

Products - Detailed overview<br />

Selection guide<br />

Chemical fixings<br />

Type<br />

Product<br />

Image<br />

zinc plated<br />

hdy<br />

A4<br />

C (1.4529)<br />

Principles of function<br />

Type of installation<br />

Anchoring base<br />

Concrete Masonry<br />

Approval<br />

ETA ICC<br />

Application recommendation<br />

Page<br />

Highbond anchor<br />

FHB II<br />

- a)<br />

b)<br />

1)<br />

2)<br />

3)<br />

- ■<br />

steel construction, railings, consoles,<br />

machines, staircases, gates,<br />

facades<br />

45<br />

Resin anchor R with RG M a)<br />

1)<br />

2)<br />

3)<br />

- ■<br />

steel constructions, railings,<br />

consoles, facade, cable-trays, high<br />

racks, ladders<br />

57<br />

Resin anchor R with RG MI - a) 1) - ■ machines, benches, consoles<br />

63<br />

Injection mortar<br />

FIS EM with FIS A<br />

a)<br />

1)<br />

2)<br />

3)<br />

- ■ ▲<br />

steel constructions, consoles,<br />

machines, gates<br />

67<br />

1<br />

Injection mortar<br />

FIS EM with<br />

reinforcement bar<br />

- - - - a) 1) - ■ ▲ post installed rebars<br />

123<br />

Injection mortar<br />

FIS EM with FRA<br />

- - a)<br />

1)<br />

2)<br />

- ■<br />

steel constructions, consoles,<br />

machines<br />

123<br />

Injection mortar<br />

FIS V with FIS A<br />

a)<br />

1)<br />

2)<br />

3)<br />

■ ▲<br />

steel constructions, consoles,<br />

machines, reinforcement bars,<br />

gates<br />

71<br />

Injection mortar<br />

FIS V with<br />

reinforcement bar<br />

- - - - a)<br />

1)<br />

2)<br />

- ■ ▲ post installed rebars<br />

123<br />

Injection mortar<br />

FIS V with FRA<br />

- - a) 1) - ■<br />

steel constructions, consoles,<br />

machines, gates<br />

123<br />

Injection mortar<br />

FIS VT with FIS A<br />

a)<br />

1)<br />

2)<br />

3)<br />

- ■<br />

steel constructions, railings,<br />

consoles, facade, cable-trays, high<br />

racks, ladders<br />

83<br />

Injection mortar<br />

FIS P with FIS A<br />

a)<br />

1)<br />

2)<br />

3)<br />

- <br />

steel construction, facades,<br />

cable trays, consoles<br />

128<br />

Injection mortar<br />

FIS HB with FHB dyn<br />

- - a)<br />

b)<br />

2) -<br />

Dibt<br />

machines, cranes, elevators<br />

132<br />

UMV multicone dynamic a)<br />

1)<br />

2)<br />

-<br />

Dibt<br />

machines, cranes, elevators<br />

132<br />

Remedial wall tie VBS 8<br />

<br />

a)<br />

b)<br />

2) - facing masonry<br />

146<br />

1) Pre-positioned installation 2) Push-through installation 3) Stand-off installation<br />

a) Adhesive locking b) Interlocking c) Friction locking<br />

12

Products - Detailed overview<br />

High performance fixings / steel anchors<br />

Product<br />

Anchoring base<br />

Concrete Masonry<br />

Type<br />

Image<br />

zinc plated<br />

hdy<br />

A4<br />

C (1.4529)<br />

Principles of function<br />

Type of installation<br />

Approval<br />

ETA ICC<br />

Application recommendation<br />

Page<br />

Selection guide<br />

Bolt anchor<br />

FAZ II<br />

Bolt anchor<br />

FAZ II GS<br />

High performance anchor<br />

FH II<br />

ZYKON undercut anchor<br />

FZA, FZA-D<br />

ZYKON undercut anchor<br />

FZA-I<br />

ZYKON hammerset anchor<br />

FZEA II<br />

Concrete screw<br />

FBS<br />

Hammerset anchor<br />

EA II<br />

Nail anchor<br />

FNA II<br />

Ceiling nail<br />

FDN<br />

Bolt anchor<br />

FBN II<br />

Bolt anchor<br />

FBN II GS<br />

Bolt anchor<br />

EXA<br />

Heavy-duty anchor<br />

TA M<br />

Heavy-duty anchor<br />

TA M-T<br />

Sleeve anchor<br />

FSA<br />

Fixing set for diamond drills<br />

FDBB<br />

Wall screw<br />

MR<br />

Hollow-ceiling anchor<br />

FHY<br />

- c) 2) ■ ▲<br />

c) 2) ■ ▲<br />

- - c) 2) ■ ▲<br />

- b)<br />

b)<br />

1)<br />

2)<br />

1)<br />

3)<br />

- b) 1) ■<br />

b) 2) ■<br />

<br />

■<br />

steel construction, facades,<br />

cable trays, consoles<br />

steel construction, facades,<br />

wooden seams<br />

steel construction, machines,<br />

gates, aircondition, handrails<br />

steel construction, facades,<br />

window elements, railings<br />

■ railings, window elements<br />

c) 1) ■ M+E, sprinkler<br />

- c) 2) ■<br />

steel construction, consoles,<br />

cable trays, sprinkler systems<br />

formwork supports, steel construction,<br />

railings<br />

pipes, fire protection panels,<br />

suspended ceilings<br />

- - - c) 2) ■ suspended ceilings<br />

- c)<br />

2)<br />

3)<br />

<br />

■<br />

steel construction, machines, gates,<br />

aircondition, handrails<br />

c) 2) ■ wooden beams, steel construcion<br />

- c) 2) ■ steel construction, facades, railings<br />

- - - c) 1) ■<br />

c)<br />

1)<br />

2)<br />

<br />

- - - c) 2) <br />

c)<br />

1)<br />

2)<br />

<br />

■<br />

steel construction, consoles,<br />

cable trays, gates<br />

steel construction, consoles,<br />

cable trays, gates<br />

metal shelves, wooden elements,<br />

metal sheets<br />

core drilling machines<br />

c) 2) metal sheets, light-steel construction 216<br />

b) 1) <br />

Dibt<br />

pipes, M + E, suspende ceilings<br />

154<br />

158<br />

161<br />

167<br />

173<br />

176<br />

179<br />

185<br />

189<br />

193<br />

195<br />

200<br />

202<br />

206<br />

210<br />

212<br />

214<br />

218<br />

1<br />

1) Pre-positioned installation 2) Push-through installation 3) Stand-off installation<br />

a) Adhesive locking b) Interlocking c) Friction locking<br />

13

Products - Detailed overview<br />

Selection guide<br />

Frame fixings / stand-off installation<br />

Product<br />

Type<br />

Image<br />

zinc plated<br />

hdy<br />

A4<br />

C (1.4529)<br />

Principles of function<br />

Type of installation<br />

Anchoring base<br />

Concrete Masonry<br />

Approval<br />

ETA ICC<br />

Application recommendation<br />

Page<br />

Frame fixing SXR - -<br />

b)<br />

c)<br />

2) ■<br />

squared timbers gates,<br />

kitchen cabines, facade, windows<br />

225<br />

Universal frame fixing<br />

FUR<br />

- -<br />

b)<br />

c)<br />

2) <br />

Dibt<br />

fire protection doors, gates, facades,<br />

cabinets<br />

232<br />

Frame fixing SXS - c) 2) ■<br />

squared timbers gates,<br />

kitchen cabines, facade, windows<br />

237<br />

Hammerfix<br />

N<br />

- A2 - c) 2) <br />

sheet metal, cable clips, pipe clamps,<br />

squared timbers<br />

242<br />

Nail sleeve<br />

FNH<br />

c) 2) boards, battens<br />

246<br />

1<br />

Window frame fixing<br />

F-S<br />

Metal frame fixing<br />

F-M<br />

- - - c) 2) <br />

- - - c) 2) <br />

windows, door frames,<br />

squared timbers<br />

windows, door frames,<br />

squared timbers<br />

248<br />

250<br />

Window frame screws<br />

FFSZ and FFS<br />

- - - b) 2) <br />

fire protection doors, windows,<br />

door frames, squared timbers<br />

252<br />

Wall tie<br />

VB<br />

faced brickwork<br />

255<br />

Adjustable fixing<br />

S 10 J<br />

c) 2) <br />

substractures for walls facings and<br />

bottoms<br />

256<br />

Self-drilling adjustable<br />

screw JUSS<br />

b) 2)<br />

substractures for walls facings and<br />

bottoms<br />

258<br />

Universal spacing screw<br />

ASL<br />

b) 2)<br />

substractures for walls facings and<br />

bottoms<br />

259<br />

Stand-off installation<br />

Thermax 8 / 10<br />

- - - c) 1) lamps, detectors, mailboxes<br />

261<br />

Stand-off installation<br />

Thermax 12 / 16<br />

- - a) 1) <br />

Dibt<br />

awning, french balcony, marquee<br />

264<br />

Remedial wall tie<br />

VBS M<br />

<br />

<br />

a)<br />

b)<br />

2) <br />

Dibt<br />

faced masonry<br />

269<br />

1) Pre-positioned installation 2) Push-through installation 3) Stand-off installation<br />

a) Adhesive locking b) Interlocking c) Friction locking<br />

14

Products - Detailed overview<br />

General fixings<br />

Product<br />

Type Image Material<br />

Principles of function<br />

Type of installation<br />

Anchoring base<br />

Concrete Masonry<br />

Approval<br />

ETA ICC<br />

Application recommendation<br />

Page<br />

Selection guide<br />

Universal plug<br />

UX<br />

PA 6 (nylon)<br />

b)<br />

c)<br />

1) <br />

Images, lights, skirtings, wall<br />

cabinets, towel rails, mirror cabinets,<br />

curtain rails, wash basin fixings,<br />

TV consoles, plumbing and heating<br />

fixings<br />

277<br />

Expansion plug<br />

SX<br />

Expansion plug<br />

S<br />

Metal expansion anchor<br />

FMD<br />

Expansion plug<br />

M-S<br />

Anchor<br />

M<br />

Brass fixing<br />

MS<br />

PA 6 (nylon) c)<br />

1)<br />

2)<br />

<br />

PA 6 (nylon) c) 1) <br />

zinc plated. b) 1) <br />

PA 6 (nylon) c) 1) <br />

PA 6 (nylon) c) 1) <br />

zinc plated. c) 1) <br />

Lights, wall cabinets, wardrobes,<br />

letterboxes, TV consoles, trellis, folding<br />

shutters, hand-rails, light wells,<br />

bath and toilet installations<br />

Images, lights, skirtings, wallmounted<br />

shelves, mirror cabinets,<br />

letterboxes, motion sensors, information<br />

boards, curtain rails, electric<br />

installations<br />

Gas pipes, water pipes, cable and<br />

pipe clamps<br />

Hand-rails, folding shutters, trellis,<br />

downpipes, stand-off installation,<br />

light wells<br />

Machines, protective grilles,<br />

control boxes<br />

Cellar shelves, wooden and metal<br />

substructures, boilers, aggregates,<br />

control boxes<br />

280<br />

283<br />

286<br />

288<br />

290<br />

292<br />

1<br />

Aircrete anchor<br />

GB<br />

PA 6 (nylon) b) 1)<br />

Dibt<br />

Suspended ceilings, Cable trays,<br />

pipes, premises, wooden and metal<br />

façade and roof constructions,<br />

awning consoles, letterboxes, trellis<br />

294<br />

Turbo Aircrete anchor<br />

FTP-K<br />

Turbo Aircrete anchor<br />

FTP-M<br />

PA 6 (nylon) b) 1)<br />

zinc plated. b) 1)<br />

Images, lights, wall-mounted shelves,<br />

mirror cabinets, letterboxes, boards,<br />

motion sensors, cable and pipe<br />

clamps, stand-off installations<br />

Images, lights, wall-mounted shelves,<br />

mirror cabinets, curtain rails, cable<br />

and pipe clamps, stand-off installations,<br />

radiators, TV consoles<br />

296<br />

298<br />

Brass fixing<br />

PA 4<br />

zinc plated. c) 1) <br />

Handles, angle brackets,<br />

furniture fittings<br />

300<br />

Balcony cladding fixing P9K b) 1)<br />

Balcony claddings, fittings,<br />

electric switches<br />

302<br />

Stair-tread fixing<br />

TB / TBB<br />

Door stop<br />

TS<br />

Repair pad<br />

FIX.it<br />

1) Pre-positioned installation 2) Push-through installation 3) Stand-off installation<br />

a) Adhesive locking b) Interlocking c) Friction locking<br />

b) 1) Wooden step treads<br />

c) 1) Doorstop with flexible positioning<br />

To repair over-sized or damaged<br />

drill holes in combination with<br />

plastic plugs.<br />

304<br />

306<br />

305<br />

15

Products - Detailed overview<br />

Selection guide<br />

Cavity fixings<br />

Type<br />

Product<br />

Image<br />

zinc plated<br />

hdy<br />

A4<br />

C (1.4529)<br />

Principles of function<br />

Type of installation<br />

Anchoring base<br />

Gypsum<br />

plasterboard<br />

Panel building<br />

materials<br />

Approval<br />

ETA ICC<br />

Application recommendation<br />

Page<br />

Metal cavity fixing<br />

HM<br />

- - - b) 1) <br />

pictures, lamps, detectors, hooks,<br />

curtain rails<br />

310<br />

Toggle fixing<br />

K, KD, KDH, KM<br />

- - - b) 1) <br />

lamps, curtain rails,<br />

pictures, detectors, hooks,<br />

312<br />

Board fixing<br />

PD<br />

- - - - b) 1) <br />

mirror cabinets, lamps, detectors,<br />

pictures, curtain rails<br />

315<br />

Plasterboard fixing<br />

GK<br />

- - - - b) 1) <br />

skirting, key boxes, pictures,<br />

lamps, detectors<br />

317<br />

Plasterboard fixing metal<br />

GKM<br />

- - - - b) 1) <br />

key boxes, pictures, lamps,<br />

detectors, skirting<br />

319<br />

1<br />

1) Pre-positioned installation 2) Push-through installation 3) Stand-off installation<br />

a) Adhesive locking b) Interlocking c) Friction locking<br />

16

Products - Detailed overview<br />

Electrical fixings<br />

Type<br />

product<br />

Image<br />

zinc plated<br />

hdy<br />

A4<br />

C (1.4529)<br />

Principles of function<br />

Type of installation<br />

Anchoring base<br />

Concrete Masonry<br />

Approval<br />

ETA ICC<br />

Application recommendation<br />

Page<br />

Selection guide<br />

ClipFix plus<br />

LS ,ZS, ES<br />

c) conduits, flexible pipes<br />

324<br />

ClipFix plus<br />

SD<br />

c) 2) trunking, strips, profiles<br />

326<br />

Cable clasp<br />

KB<br />

c) 2) conduits<br />

328<br />

Cable harness<br />

SHA<br />

conduits, flexible and rigid plastic<br />

pipes<br />

330<br />

Pipe clip<br />

RC<br />

rigid plastic pipes<br />

332<br />

Pipe clip<br />

FC<br />

Saddle clip<br />

SCH<br />

conduits, flexible and rigid plastic<br />

pipes<br />

conduits, flexible and rigid plastic<br />

pipes<br />

334<br />

336<br />

1<br />

Nail clip<br />

NS / MNS<br />

c) conduits<br />

338<br />

Nail disc<br />

NSB<br />

c) cables in wall slots<br />

340<br />

Spacer pipe clamp<br />

AM<br />

<br />

metal conduits according to<br />

DIN 49020<br />

342<br />

Conduit clip<br />

BSM<br />

<br />

conduits, flexible and rigid plastic<br />

pipes, metal conduits<br />

344<br />

Impact nail<br />

ED<br />

Cable tie<br />

BN, UBN<br />

Wireclip<br />

c) conduit clips<br />

conduits, flexible and rigid plastic<br />

pipes<br />

for suspension of lighting, trunking,<br />

busbar<br />

346<br />

348<br />

350<br />

1) Pre-positioned installation 2) Push-through installation 3) Stand-off installation<br />

a) Adhesive locking b) Interlocking c) Friction locking<br />

17

Products - Detailed overview<br />

Selection guide<br />

Sanitary fixings<br />

Type<br />

Product<br />

Image<br />

zinc plated<br />

hdy<br />

A4<br />

C (1.4529)<br />

Principles of function<br />

Type of installation<br />

Anchoring base<br />

Concrete Masonry<br />

Approval<br />

ETA ICC<br />

Application recommendation<br />

Page<br />

Sanitary fixings for board<br />

materials<br />

<br />

b)<br />

c)<br />

2) Wash basins and urinals<br />

354<br />

Ceramic fixings c)<br />

1)<br />

2)<br />

Free-standing toilets<br />

356<br />

Wash basins and urinal<br />

fixings<br />

c)<br />

1)<br />

2)<br />

Wash basins and urinals<br />

358<br />

Installation tool<br />

HED<br />

Tool for installing stud screws with<br />

four thread sizes<br />

354<br />

Accessories Flanged nut and cover cap 354<br />

1<br />

1) Pre-positioned installation 2) Push-through installation 3) Stand-off installation<br />

a) Adhesive locking b) Interlocking c) Friction locking<br />

Scaffold and eye screw fixings<br />

Product<br />

Anchoring base<br />

Concrete Masonry<br />

Approval<br />

Application recommendation<br />

Page<br />

Type<br />

Image<br />

zinc plated<br />

hdy<br />

A4<br />

C (1.4529)<br />

Principles of function<br />

Type of installation<br />

ETA ICC<br />

Scaffold anchoring<br />

S 14 ROE + GS 12<br />

c) 1) <br />

Facade and climbing scaffolds,<br />

Tensioning ropes, Chains<br />

364<br />

Scaffold anchoring<br />

FI G<br />

<br />

with metric thread M12 for combination<br />

with internal-threaded fixings.<br />

366<br />

Cover caps<br />

AD<br />

Cover cap for closing off remaining<br />

drill holes<br />

366<br />

Ring nut<br />

RI<br />

<br />

connection piece for fixings with<br />

threaded studs<br />

370<br />

Eye screw<br />

GS<br />

<br />

Climbing scaffolds ,Cables Chains,<br />

Lamps, Clotheslines Hanging flower<br />

baskets<br />

368<br />

1) Pre-positioned installation 2) Push-through installation 3) Stand-off installation<br />

a) Adhesive locking b) Interlocking c) Friction locking<br />

18

Products - Detailed overview<br />

Insulation fixings / Facade fixings<br />

Product Material Anchoring base<br />

Concrete Masonry<br />

Type<br />

Image<br />

Principles of function<br />

Type of installation<br />

Approval<br />

ETA ICC<br />

Application recommendation<br />

Page<br />

Selection guide<br />

Insulation support<br />

DHK<br />

Insulation support<br />

DHM<br />

c) 2) <br />

c) 2) <br />

material soft and pressure resistant<br />

insulating materials, as e.g. for the<br />

underside of the ceiling for underground<br />

car parks<br />

with depth stop, soft insulating<br />

materials<br />

374<br />

376<br />

Render fixing<br />

DIPK<br />

Render fixing<br />

FIF-K<br />

c) 2) <br />

c) 2) <br />

with plastic nail, plaster facade with<br />

pressure-resistant insulating materials<br />

with plastic nail, plaster facade with<br />

pressure-resistant insulating materials<br />

378<br />

380<br />

Render fixing<br />

FIF-S<br />

c) 2) with coated steel nail with plastic nail<br />

382<br />

Insulation discs<br />

DT<br />

Holding clamp DVN b)<br />

Retaining disk with screw<br />

DHT-S<br />

Insulation fixing<br />

FID<br />

b) 2)<br />

pressure-resistant insulating materials,<br />

roof sealing sheets for flat roofs<br />

material pressure-resistant insulating<br />

materials as e.g. polystyrene,<br />

PU-expanded plastic slab<br />

material pressure-resistant insulating<br />

materials as e.g. polystyrene, PU-expanded<br />

panels, foamglass, rock wool<br />

b) 1) lamps, mailboxes, labels, detectors<br />

384<br />

386<br />

387<br />

389<br />

1<br />

Insulation disc<br />

FATB<br />

c) 2) <br />

with steel nail, to fix pressureresistant<br />

insulation materials<br />

391<br />

Fibre cement panel screw<br />

FAFZ-H<br />

b) 2) fibre cement panels<br />

393<br />

1) Pre-positioned installation 2) Push-through installation 3) Stand-off installation<br />

a) Adhesive locking b) Interlocking c) Friction locking<br />

19

Products - Detailed overview<br />

Selection guide<br />

Foams<br />

Type<br />

Product<br />

Image<br />

1 component<br />

2 component<br />

Building material B1<br />

(general test certificate from building authorities)<br />

Building material B2<br />

(general test certificate from building authorities)<br />

Building material class B3<br />

Tested<br />

joint soundproofing<br />

Tested<br />

thermal conductivity<br />

Tested airtightness<br />

Tested watertightness<br />

(suitable as mirror adhesive)<br />

Colour<br />

Application recommendation<br />

Page<br />

One-component gun foam<br />

PUP 750 B2<br />

● ● ● ● ● beige<br />

Insulating and filling window connection<br />

joints, around window sills and shutter<br />

boxes, in roofing work and dry construction,<br />

finished elements, wall connections, wall<br />

penetrations and cavities, pipe penetrations<br />

and ventilation ducts<br />

396<br />

One-component gun foam<br />

PUP 500 G B2<br />

● ● ● ● ●<br />

concrete<br />

grey<br />

Installing and filling component joints,<br />

wall connections and wall penetrations,<br />

in roofing work and dry construction (e.g. in<br />

the ceiling area), window connection joints,<br />

around window sills and shutter boxes, pipe<br />

penetrations and ventilation ducts<br />

397<br />

1<br />

One-component gun foam<br />

PUP 750 B3<br />

● ● ● beige<br />

Insulating and filling in roofing work and<br />

dry construction, window connection joints,<br />

around window sills and shutter boxes,<br />

finished elements, wall penetrations and<br />

cavities, pipe penetrations and ventilation<br />

ducts<br />

399<br />

One-component gun foam<br />

PUFS 750 B1<br />

●<br />

●<br />

concrete<br />

grey<br />

As a hardly flammable PU to be used<br />

between massive, mineral or metallic<br />

materials, high-efficiency thermal insulation<br />

on façades, installing and filling in window<br />

connection joints, around window sills<br />

and shutter boxes, finished elements,<br />

wall connections<br />

400<br />

One-component gun foam<br />

PUP P 750 G B2<br />

●<br />

●<br />

concrete<br />

grey<br />

Bonding expanded polystyrene panels,<br />

installing and filling wall penetrations,<br />

foaming in electrical installations,<br />

filling joints and cavities in all internal<br />

constructions, fixing and sealing walls<br />

and ceilings<br />

401<br />

One-component rapid<br />

installation foam<br />

PU 1<br />

● ● ● ● beige<br />

Bonding and sealing manhole rings,<br />

insulating and filling in roofing work and<br />

dry construction, window connection joints,<br />

around window sills and shutter boxes,<br />

finished elements, wall connections and<br />

wall penetrations<br />

402<br />

2-component rapid<br />

installation foam<br />

PU 2/402<br />

●<br />

●<br />

light<br />

blue<br />

Installation of door frames, filling and<br />

insulating cavities in walls and ceilings,<br />

foaming in windows, bath tubs and<br />

showers, fixing insulating elements, wooden<br />

cladding, sheet metal panels, control boxes<br />

403<br />

2-component rapid<br />

installation foam<br />

PU 2/403<br />

●<br />

●<br />

light<br />

green<br />

Installation of door frames, filling and<br />

insulating cavities in walls and ceilings,<br />

foaming in windows, bath tubs and<br />

showers, fixing insulating elements, wooden<br />

cladding, sheet metal panels, control boxes<br />

403<br />

Foam guns<br />

PUP<br />

Suitable for all standard systems<br />

403<br />

PU cleaner<br />

PUR<br />

For the save removal of fresh<br />

PU-foam<br />

403<br />

20

Products - Detailed overview<br />

Sealants and adhesives<br />

Product<br />

Type<br />

Picture<br />

Chemical base<br />

Frost-resistant up to -15 °C<br />

during transportation<br />

Odourless / low-odour<br />

Suitable in the interior and<br />

exterior area<br />

Adhesive, even on a damp base<br />

Immediately rainproof<br />

Fungus-inhibiting (fungicidal)<br />

Silicon-free<br />

Solvent-free<br />

Free from isocyanate (MDI-free)<br />

Compatible with paint<br />

paintable 1)<br />

Suitable for natural stone /<br />

marple<br />

Compatible with bitumen<br />

Suitable for use as mirror<br />

adhesive<br />

No stress cracks 3)<br />

Resistant to chemicals, ageing<br />

and weathering<br />

Page<br />

Selection guide<br />

Premium sanitary silicone<br />

DSSA<br />

Silicone<br />

Acetate<br />

● ● / ● ● ● ● ● ● ●<br />

407<br />

Sanitary silicone<br />

DSSI<br />

Silicone<br />

Acetate<br />

● ● / ● ● ● ● ● ● ●<br />

408<br />

Multi-silicone<br />

DMS<br />

Silicone<br />

Acetate<br />

● ● / ● ● ● ● ● ●<br />

409<br />

Premium high temperature<br />

silicone DHS<br />

Silicone<br />

Acetate<br />

● ● / ● ● ● ● ● ●<br />

410<br />

Construction silicone<br />

DBSA<br />

Silicone-<br />

Alkoxy<br />

● ● ● / ● ● ● ● ● ●<br />

●<br />

(only in transparent)<br />

●<br />

●<br />

411<br />

Roof and wall silicone<br />

DBSI<br />

Premium silicone for<br />

natural stone<br />

DNS<br />

Silicone<br />

Oxim<br />

Silicone<br />

Oxim<br />

● ● / ● ● ● ● ● ● ●<br />

● ● / ● ● ● ● ● ● ● ●<br />

412<br />

413<br />

1<br />

B1 Premium silicone<br />

DFS<br />

Silicone-<br />

Alkoxy<br />

● ● ● / ● ● ● ● ● ●<br />

414<br />

Premium painting acrylic<br />

DMA<br />

Dispersionacrylic<br />

● ● ● / ● ● ● ● ● ● ● ●<br />

415<br />

Acrylic sealant<br />

DA<br />

Dispersionacrylic<br />

●<br />

● / ●<br />

2)<br />

● ● ● ● ● ●<br />

416<br />

Premium structured acrylic<br />

DSA<br />

Dispersionacrylic<br />

● ● ● / ●<br />

2)<br />

● ● ● ● ● ●<br />

417<br />

Ventilation duct sealant<br />

DLK<br />

418<br />

Premium all-weather sealant<br />

DDK<br />

MS-Polymer®<br />

● ● ● / ● ● ● ● ● ● ● ● ● ● ●<br />

419<br />

Roof sealing<br />

DD<br />

Synthesekautschuk<br />

● ● / ● ● ● ● ● ● ● ● ● ●<br />

420<br />

Assembly adhesive<br />

MK<br />

Dispersionacrylic<br />

● ● / - ● ● ● ● ● ● ●2)<br />

426<br />

Construction adhesive<br />

KK<br />

Polyurethan<br />

● ● / ● ● ● ● ● ● ● ●1)<br />

427<br />

All-round adhesive gluing<br />

and sealing KD<br />

MS-Polymer®<br />

● ● ● / ● ● ●<br />

●<br />

(not in black)<br />

● ● ● ● ●<br />

●<br />

(not in transparent)<br />

●<br />

(not in transparent)<br />

●<br />

●<br />

428<br />

PVC adhesive<br />

PVC +<br />

Dissolver<br />

● ● / ● ● ● ●<br />

429<br />

21

Products - Detailed overview<br />

Selection guide<br />

Drills and bits<br />

Type<br />

Product<br />

Image<br />

zinc plated<br />

hdy<br />

A4<br />

C (1.4529)<br />

Principles of function<br />

Type of installation<br />

Anchoring base<br />

Concrete Masonry<br />

Approval<br />

ETA ICC<br />

Application recommendation<br />

Page<br />

Hammer drill bit<br />

SDS Plus IV Quattric<br />

<br />

for drilling in concrete and reinforced<br />

concrete<br />

432<br />

Hammer drill bit<br />

SDS Plus II Pointer<br />

<br />

for drilling in solid building materials<br />

434<br />

Hammer drill bit<br />

SDS Max II / SDS Max IV<br />

<br />

for drilling in masonry<br />

437<br />

Chisel<br />

<br />

suitable for concrete, natural stone<br />

and masonry<br />

439<br />

Profi-bit<br />

FPB<br />

suitable for ¼“ drives<br />

440<br />

1<br />

Diamond bits<br />

FDB<br />

Stainless steel bit<br />

FSB<br />

suitable for ¼“ drives<br />

suitable for ¼“ drives<br />

443<br />

446<br />

Bit holder<br />

FBH<br />

suitable for ¼“ drives<br />

448<br />

22

fischer hammer drill bits<br />

Unstoppable.<br />

Selection guide<br />

1<br />

The fischer bit product range<br />

Perfect shape. Optimum drive.<br />

modified<br />

23

Application selection guide<br />

Selection guide<br />

1<br />

Metal construction<br />

Balcony railings<br />

Banisters<br />

Canopies<br />

Consoles<br />

Heavy doors/ gates<br />

Core drilling devices<br />

Awnings<br />

Application product * Anchoring base Type of installation<br />

Concrete Solid brick Hollow block<br />

perforated<br />

brick<br />

Panel<br />

building<br />

materials<br />

Natural stone<br />

dense<br />

structure<br />

Type<br />

FAZ II ▯ ○ <br />

FHB II ▯ ○ <br />

FBN II ▯ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FAZ II ▯ ○ <br />

FHB II ▯ ○ <br />

FH II ▯ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FHB II ▯ ○ <br />

FAZ II ▯ ○ <br />

FBN II ▯ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FHB II ▯ ○ <br />

FAZ II ▯ ○ <br />

FH II ▯ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FAZ II ▯ ○ <br />

FBN II ▯ ○ <br />

SXR ○ ○ ○ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

EA II D ▯ ○ ○ <br />

EA-N ○ ○ ○ <br />

FDBB ○ ○ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FAZ II ▯ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

Thermax ▯ ▯ ▯ ○ <br />

FUR ○ ○ ○ ○ <br />

Pre-positioned installation<br />

Push-through installation<br />

Stand-off installation<br />

▯ permitted<br />

○ fischer recommendation<br />

* The cited product is solely recommended without guarantee. The fixing elements must always be adjusted to suit the local conditions<br />

and the materials used in an individual case.<br />

24

cracked<br />

Approval<br />

ESR-2948<br />

See ICC-ES<br />

Evaluation Report<br />

at www.ic-es.org<br />

Inspection agency:<br />

AA-707<br />

Concrete Masonry Concrete<br />

uncracked<br />

solid brick<br />

perforated<br />

brick<br />

cracked<br />

uncracked<br />

Certification of<br />

fire protection<br />

Inner area<br />

Corrosion<br />

<br />

45<br />

195<br />

71<br />

154<br />

45<br />

161<br />

71<br />

45<br />

154<br />

195<br />

71<br />

45<br />

154<br />

161<br />

71<br />

154<br />

195<br />

zp<br />

Outer area<br />

A4<br />

Page<br />

154<br />

225<br />

71<br />

185<br />

185<br />

214<br />

71<br />

154<br />

71<br />

264<br />

232<br />

Selection guide<br />

1<br />

25

Application selection guide<br />

Selection guide<br />

1<br />

Carpentry and roofers<br />

Support beam<br />

Application product * Anchoring base Type of installation<br />

Concrete Solid brick Hollow block<br />

perforated<br />

brick<br />

Panel<br />

building<br />

materials<br />

Natural stone<br />

dense<br />

structure<br />

Threshold anchoring systems<br />

Threshold anchoring while framing<br />

Column bases<br />

Wooden canopies<br />

Type<br />

FAZ II GS ▯ ○ <br />

FBN II GS ▯ ○ <br />

FIS V / FIS H K ▯ ▯ ▯ ○ <br />

FUR ○ ○ ○ ○ <br />

FAZ II GS ▯ ○ <br />

FBN II GS ▯ ○ <br />

R ▯ ○ <br />

FIS V / FIS H K ▯ ▯ ▯ ○ <br />

FAZ II ▯ ○ <br />

FBN II ▯ ○ <br />

R ▯ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FAZ II ▯ ○ <br />

FBN II ▯ ○ <br />

FH II ▯ ○ <br />

FSA ○ ○ ○ <br />

FIS V / FIS H K ▯ ▯ ▯ ○ <br />

FAZ II GS ▯ ○ <br />

FBN II GS ▯ ○ <br />

Thermax ▯ ▯ ▯ ○ <br />

DHK 45 ○ ○ ○ ○ <br />

DHK ○ ○ ○ ○ <br />

DHM ○ ○ ○ ○ <br />

Pre-positioned installation<br />

Push-through installation<br />

Stand-off installation<br />

Insulation boards in the present facades<br />

Facades<br />

Balcony claddings<br />

SXR ▯ ▯ ▯ ○ <br />

SXS ▯ ▯ ▯ ○ <br />

FUR ▯ ▯ ▯ ○ <br />

N ○ ○ ○ <br />

SXR ○ ○ ○ ○ <br />

FUR ○ ○ ○ ○ <br />

P 9 K ○ <br />

Wood screws<br />

Refer to fischer's range of screws.<br />

▯ permitted<br />

○ fischer recommendation<br />

* The cited product is solely recommended without guarantee. The fixing elements must always be adjusted to suit the local conditions<br />

and the materials used in an individual case.<br />

26

cracked<br />

Approval<br />

ESR-2948<br />

See ICC-ES<br />

Evaluation Report<br />

at www.ic-es.org<br />

Inspection agency:<br />

AA-707<br />

Concrete Masonry Concrete<br />

uncracked<br />

solid brick<br />

perforated<br />

brick<br />

cracked<br />

uncracked<br />

Certification of<br />

fire protection<br />

Inner area<br />

zp<br />

Corrosion<br />

Outer area<br />

A4<br />

Page<br />

Selection guide<br />

158<br />

200<br />

71<br />

232<br />

158<br />

200<br />

57<br />

71<br />

154<br />

195<br />

57<br />

71<br />

154<br />

195<br />

161<br />

212<br />

1<br />

71<br />

158<br />

200<br />

264<br />

374<br />

374<br />

376<br />

225<br />

237<br />

232<br />

242<br />

225<br />

232<br />

232<br />

27

Application selection guide<br />

Selection guide<br />

1<br />

Sanitary - heating - climate - ventilation (SHKL)<br />

Pipeline routes<br />

Individual pipes<br />

Ventilation ducts<br />

Sanitary fixings<br />

Air conditioning devices<br />

Application product * Anchoring base Type of installation<br />

Concrete Solid brick Hollow block<br />

perforated<br />

brick<br />

Panel<br />

building<br />

materials<br />

Natural stone<br />

dense Fittings<br />

Type<br />

EA II ▯ ○ <br />

FBS ▯ ○ <br />

FIS V / FIS E ▯ ▯ ▯ ○ <br />

EA-N ○ ○ <br />

EA II ▯ ○ <br />

FZEA II ▯ ○ <br />

FIS V / FIS E ▯ ▯ ▯ ○ <br />

EA-N ○ ○ <br />

EA II ▯ ○ <br />

FBS ▯ ○ <br />

FIS V / FIS A / FIS E ▯ ▯ ▯ ○ <br />

EA-N ○ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FIS P / FIS A ○ ○ ○ ○ <br />

SXR ○ ○ ○ ○ <br />

UX ○ ○ ○ ○ ○ <br />

FAZ II ▯ ○ <br />

FBN II ▯ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FIS P / FIS A ○ ○ ○ ○ <br />

Pre-positioned installation<br />

Push-through installation<br />

Stand-off installation<br />

▯ permitted<br />

○ fischer recommendation<br />

* The cited product is solely recommended without guarantee. The fixing elements must always be adjusted to suit the local conditions<br />

and the materials used in an individual case.<br />

28

cracked<br />

Approval<br />

ESR-2948<br />

See ICC-ES<br />

Evaluation Report<br />

at www.ic-es.org<br />

Inspection agency:<br />

AA-707<br />

Concrete Masonry Concrete<br />

uncracked<br />

solid brick<br />

perforated<br />

brick<br />

cracked<br />

uncracked<br />

Certification of<br />

fire protection<br />

Inner area<br />

zp<br />

Corrosion<br />

Outer area<br />

A4<br />

Page<br />

Selection guide<br />

185<br />

179<br />

71<br />

185<br />

185<br />

176<br />

71<br />

185<br />

185<br />

179<br />

71<br />

185<br />

1<br />

71<br />

86<br />

225<br />

277<br />

154<br />

195<br />

71<br />

86<br />

29

Application selection guide<br />

Selection guide<br />

1<br />

Plant construction<br />

Hoist rails<br />

Machines<br />

Pumps<br />

Containers<br />

Platform lifts<br />

High racks<br />

Application product * Anchoring base Type of installation<br />

Concrete Solid brick Hollow block<br />

perforated<br />

brick<br />

Panel<br />

building<br />

materials<br />

Natural stone<br />

dense<br />

structure<br />

Type<br />

FHB dyn ▯ <br />

FAZ II ▯ <br />

FH II ▯ <br />

FBN II ▯ <br />

R ▯ ○ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FH II ▯ ○ <br />

FBN II ▯ ○ <br />

R ▯ ○ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FH II ▯ ○ <br />

FBN II ▯ ○ <br />

R ▯ ○ ○ <br />

FHB II ▯ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FBN II ▯ ○ <br />

FH II ▯ ○ <br />

FSA ▯ ○ ○ <br />

FAZ II ▯ ○ <br />

FBN II ▯ ○ <br />

R ▯ ○ ○ <br />

FHB II ▯ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FIS VT ▯ ○ ○ <br />

Pre-positioned installation<br />

Push-through installation<br />

Stand-off installation<br />

▯ permitted<br />

○ fischer recommendation<br />

* The cited product is solely recommended without guarantee. The fixing elements must always be adjusted to suit the local conditions<br />

and the materials used in an individual case.<br />

30

cracked<br />

Approval<br />

ESR-2948<br />

See ICC-ES<br />

Evaluation Report<br />

at www.ic-es.org<br />

Inspection agency:<br />

AA-707<br />

Concrete Masonry Concrete<br />

uncracked<br />

solid brick<br />

perforated<br />

brick<br />

cracked<br />

uncracked<br />

Certification of<br />

fire protection<br />

Inner area<br />

zp<br />

Corrosion<br />

Outer area<br />

A4<br />

Page<br />

Selection guide<br />

128<br />

154<br />

161<br />

195<br />

57<br />

71<br />

161<br />

195<br />

57<br />

71<br />

161<br />

195<br />

57<br />

45<br />

71<br />

195<br />

161<br />

212<br />

154<br />

195<br />

57<br />

45<br />

71<br />

83<br />

1<br />

31

Application selection guide<br />

Selection guide<br />

1<br />

Concrete construction<br />

Application product * Anchoring base Type of installation<br />

Concrete Solid brick Hollow block<br />

perforated<br />

brick<br />

Panel<br />

building<br />

materials<br />

Natural stone<br />

dense<br />

structure<br />

Formwork and support fixings<br />

Scaffold fixings<br />

Light wells<br />

Type<br />

FBS ▯ ○ ○ <br />

EA II ▯ ○ <br />

EA-N ○ ○ ○ <br />

FBN II ▯ ○ <br />

GS 12 + S 14 ROE ○ ○ ○ ○ <br />

FIS V / FIG ▯ ▯ ▯ ○ <br />

Thermax ▯ ▯ ▯ ○ <br />

GS 12 / UX 14 ○ ○ ○ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FAZ II ▯ ○ <br />

FBN II ▯ ○ <br />

SXR ○ ○ ○ ○ <br />

FIS V ▯ <br />

FIS VS ▯ <br />

FIS EM ▯ <br />

Pre-positioned installation<br />

Push-through installation<br />

Stand-off installation<br />

Additional reinforcement connections<br />

Core drilling devices<br />

▯ permitted<br />

○ fischer recommendation<br />

EA II D ▯ ○ ○ <br />

EA-N ○ ○ ○ <br />

FDBB ○ ○ ○ <br />

FIS V / FIS-A ▯ ▯ ▯ ○ <br />

* The cited product is solely recommended without guarantee. The fixing elements must always be adjusted to suit the local conditions<br />

and the materials used in an individual case.<br />

32

cracked<br />

Approval<br />

ESR-2948<br />

See ICC-ES<br />

Evaluation Report<br />

at www.ic-es.org<br />

Inspection agency:<br />

AA-707<br />

Concrete Masonry Concrete<br />

uncracked<br />

solid brick<br />

perforated<br />

brick<br />

cracked<br />

uncracked<br />

Certification of<br />

fire protection<br />

Inner area<br />

zp<br />

Corrosion<br />

Outer area<br />

A4<br />

Page<br />

Selection guide<br />

179<br />

185<br />

185<br />

195<br />

368<br />

71<br />

135<br />

368<br />

71<br />

154<br />

195<br />

225<br />

1<br />

71<br />

79<br />

67<br />

185<br />

185<br />

214<br />

71<br />

33

Application selection guide<br />

Selection guide<br />

1<br />

Plastered and dry construction<br />

Application product * Anchoring base Type of installation<br />

Concrete Solid brick Hollow block<br />

perforated<br />

brick<br />

Panel<br />

building<br />

materials<br />

Natural stone<br />

dense<br />

structure<br />

Fixings for dry construction<br />

Underceilings<br />

Insulation board fixings<br />

Façade sub-structures<br />

Scaffold fixings<br />

Type<br />

HM ○ ○ <br />

UX ○ ○ ○ ○ ○ <br />

PD ○ ○ ○ ○ ○ <br />

GKM ○ ○ ○ ○ <br />

FNA II ▯ ○ <br />

FDN ▯ ○ <br />

FBS ▯ ○ ○ <br />

EA II ▯ ○ <br />

FIF-A ○ ○ ○ ○ <br />

DIPK ○ ○ ○ ○ <br />

DHT S<br />

<br />

SXR ▯ ▯ ▯ ○ <br />

SXS ▯ ▯ ▯ ○ <br />

FUR ▯ ▯ ▯ ○ <br />

N ○ ○ ○ <br />

GS 12 / S 14 ROE ○ ○ ○ ○ <br />

FIS V / FIG ▯ ▯ ▯ ○ <br />

Thermax ▯ ▯ ▯ <br />

GS 12 / UX ○ ○ ○ ○ <br />

Pre-positioned installation<br />

Push-through installation<br />

Stand-off installation<br />

▯ permitted<br />

○ fischer recommendation<br />

* The cited product is solely recommended without guarantee. The fixing elements must always be adjusted to suit the local conditions<br />

and the materials used in an individual case.<br />

34

cracked<br />

Approval<br />

ESR-2948<br />

See ICC-ES<br />

Evaluation Report<br />

at www.ic-es.org<br />

Inspection agency:<br />

AA-707<br />

Concrete Masonry Concrete<br />

uncracked<br />

solid brick<br />

perforated<br />

brick<br />

cracked<br />

uncracked<br />

Certification of<br />

fire protection<br />

Inner area<br />

zp<br />

Corrosion<br />

Outer area<br />

A4<br />

Page<br />

Selection guide<br />

310<br />

277<br />

315<br />

319<br />

189<br />

193<br />

179<br />

185<br />

380<br />

378<br />

387<br />

1<br />

225<br />

237<br />

232<br />

242<br />

368<br />

71<br />

264<br />

368<br />

35

Application selection guide<br />

Selection guide<br />

Electrical installation<br />

Application product * Anchoring base Type of installation<br />

Concrete Solid brick Hollow block<br />

perforated<br />

brick<br />

Panel<br />

building<br />

materials<br />

Natural stone<br />

dense<br />

structure<br />

Type<br />

Pre-positioned installation<br />

Push-through installation<br />

Stand-off installation<br />

1<br />

Cable support systems<br />

Cable ducts<br />

Light strips<br />

Lighting<br />

External lighting<br />

Motion sensors<br />

Satellite antennas<br />

Screen consoles<br />

▯ permitted<br />

○ fischer recommendation<br />

FAZ II ▯ <br />

FBN II ▯ ○ <br />

EA II ▯ ○ <br />

EA-N ○ ○ ○ <br />

FNA II ▯ ○ <br />

SXR ▯ ▯ ▯ ○ <br />

UX ○ ○ ○ ○ ○ <br />

SX ○ ○ ○ ○ ○ <br />

FNA II ▯ <br />

EA II ▯ <br />

EA-N ○ ○ ○ <br />

UX ○ ○ ○ ○ ○ <br />

FIS P ○ ○ ○ ○ <br />

Fill & Fix ○ ○ ○ ○ <br />

HM ○ ○ <br />

UX ○ ○ ○ ○ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

Thermax ○ ○ ○ ○ <br />

SXR ○ ○ ○ ○ ○ <br />

UX ○ ○ ○ ○ ○<br />

SXR ○ ○ ○ ○ ○ <br />

Thermax ○ ○ ○ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FIS P / FIS A ○ ○ ○ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FIS P / FIS A ○ ○ ○ ○ <br />

Thermax ▯ ▯ ▯ ○ <br />

SXR ○ ○ ○ ○ <br />

FIS V ▯ ▯ ▯ ○ <br />

FIS P ○ ○ ○ ○ <br />

SXR ○ ○ ○ ○ <br />

UX ○ ○ ○ ○ ○ <br />

* The cited product is solely recommended without guarantee. The fixing elements must always be adjusted to suit the local conditions<br />

and the materials used in an individual case.<br />

36

cracked<br />

Approval<br />

ESR-2948<br />

See ICC-ES<br />

Evaluation Report<br />

at www.ic-es.org<br />

Inspection agency:<br />

AA-707<br />

Concrete Masonry Concrete<br />

uncracked<br />

solid brick<br />

perforated<br />

brick<br />

cracked<br />

uncracked<br />

Certification of<br />

fire protection<br />

Inner area<br />

zp<br />

Corrosion<br />

Outer area<br />

A4<br />

Page<br />

Selection guide<br />

154<br />

195<br />

185<br />

185<br />

189<br />

225<br />

277<br />

280<br />

189<br />

185<br />

185<br />

277<br />

86<br />

148<br />

310<br />

277<br />

71<br />

264<br />

225<br />

277<br />

225<br />

264<br />

71<br />

86<br />

1<br />

71<br />

86<br />

135<br />

225<br />

71<br />

86<br />

225<br />

277<br />

37

Application selection guide<br />

Selection guide<br />

1<br />

Joiners<br />

Application product * Anchoring base Type of installation<br />

Concrete Solid brick Hollow block<br />

Perforated<br />

brick<br />

Panel<br />

building<br />

materials<br />

Natural stone<br />

dense<br />

structure<br />

Small wall-mounted shelves<br />

Handrails<br />

Skirtings<br />

Room doors<br />

Wardrobes<br />

Jalousies/ folding shutters<br />

Windows<br />

Store and inn fittings<br />

Type<br />

UX ○ ○ ○ ○ ○ <br />

HM ○ <br />

FIS V / FIS E K ○ ○ ○ ○ <br />

SXR ○ ○ ○ ○ <br />

UX ○ ○ ○ ○ ○ <br />

HM ○ <br />

FIS V / FIS E K ○ ○ ○ ○ <br />

SXR ○ ○ ○ ○ <br />

SXR ○ ○ ○ ○ <br />

UX ○ ○ ○ ○ ○ <br />

SX ○ ○ ○ <br />

fill & fix ○ ○ ○ ○ ○ <br />

SXR ○ ○ ○ ○ <br />

UX ○ ○ ○ ○ ○ <br />

SX ○ ○ ○ <br />

PU 2 ○ ○ ○ ○ ○<br />

SXR ○ ○ ○ ○ <br />

UX ○ ○ ○ ○ ○ <br />

HM ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

SXR ○ ○ ○ ○ <br />

Thermax ▯ ▯ ▯ ○ <br />

UX ○ ○ ○ ○ ○ <br />

FFSZ ○ ○ ○ ○ <br />

FFS ○ ○ ○ ○ <br />

F-M ○ ○ ○ ○ <br />

F-S ○ ○ ○ ○ <br />

FIS V / FIS A ▯ ▯ ▯ ○ <br />

FAZ II ▯ ○ <br />

FBN II ▯ ○ <br />

UX ○ ○ ○ ○ ○ <br />

Pre-positioned installation<br />

Push-through installation<br />

Stand-off installation<br />

▯ permitted<br />

○ fischer recommendation<br />

* The cited product is solely recommended without guarantee. The fixing elements must always be adjusted to suit the local conditions<br />

and the materials used in an individual case.<br />

38

cracked<br />

Approval<br />

ESR-2948<br />

See ICC-ES<br />

Evaluation Report<br />

at www.ic-es.org<br />

Inspection agency:<br />

AA-707<br />

Concrete Masonry Concrete<br />

uncracked<br />

solid brick<br />

perforated<br />

brick<br />

cracked<br />

uncracked<br />

Certification of<br />

fire protection<br />

Inner area<br />

zp<br />

Corrosion<br />

Outer area<br />

A4<br />

Page<br />

Selection guide<br />

277<br />

310<br />

71<br />

225<br />

277<br />

310<br />

71<br />

225<br />

225<br />

277<br />

280<br />

148<br />

1<br />

225<br />

277<br />

280<br />

225<br />

277<br />

310<br />

71<br />

71<br />

403<br />

225<br />

264<br />

277<br />

252<br />

252<br />

250<br />

248<br />

71<br />

154<br />

195<br />

277<br />

39

Chemical fixings<br />

40

Chemical fixings<br />

Chemical fixings<br />

▪ Highbond-System FHB II ............................................................................................<br />

▪ Highbond anchor FHB II-A S ....................................................................................<br />

▪ Highbond anchor FHB II-A L.....................................................................................<br />

▪ Resin anchor R with RG M (threaded rod) ..........................................................<br />

▪ Resin anchor R with RG MI (internal threaded anchor) .................................<br />

▪ Injection mortar FIS EM .............................................................................................<br />

▪ Injection mortar FIS V .................................................................................................<br />

▪ Injection mortar FIS VW .............................................................................................<br />

▪ Injection mortar FIS VS ..............................................................................................<br />

▪ Injection mortar FIS VT ..............................................................................................<br />

▪ Injection mortar FIS P .................................................................................................<br />

▪ Injection technology for cracked concrete with FIS A (threaded rod) ......<br />

▪ Injection technology for cracked concrete with RG MI ..................................<br />

▪ Injection technology for non-cracked concrete with FIS A ...........................<br />

▪ Injection technology for non-cracked concrete with RG MI .........................<br />

▪ Injection technology in solid brick masonry .......................................................<br />

▪ Injection technology in perforated brick masonry ...........................................<br />

▪ Push-through installation in masonry....................................................................<br />

▪ Injection technology for aerated concrete ..........................................................<br />

▪ Rebar connections .......................................................................................................<br />

▪ Highbond anchor dynamic FHB dyn .....................................................................<br />

▪ UMV multicone dynamic bonded anchor ...........................................................<br />

▪ Stand-off installation Thermax .................................................................................<br />

▪ Remedial wall tie VBS 8 .............................................................................................<br />

▪ Remedial wall tie mechanical VBS-M ...................................................................<br />

▪ Weather facing reconstruction system FWS .....................................................<br />

▪ Can System FCS ...........................................................................................................<br />

▪ fill & fix injection fixing ...............................................................................................<br />

45<br />

49<br />

53<br />

57<br />

63<br />

67<br />

71<br />

75<br />

79<br />

83<br />

86<br />

89<br />

94<br />

97<br />

103<br />

106<br />

111<br />

116<br />

119<br />

123<br />

128<br />

132<br />

135<br />

140<br />

142<br />

144<br />

146<br />

148<br />

41

Chemical fixings<br />

Range of chemical fixings<br />

For fixings in cracked concrete<br />

FIS EM mortar<br />

The powerful injection mortar for cracked concrete<br />

Page 67<br />

Highbond FHB II System<br />

The best performance in cracked concrete<br />

FIS HB mortar<br />

from Page 45 on<br />

with threaded rod FIS A<br />

The variable fixing system for cracked concrete<br />

Page 89<br />

with internal threaded anchor RG MI<br />

The fixing system with internal threaded anchor<br />

for cracked concrete<br />

Page 94<br />

FHB II-P standard version<br />

FHB II-PF quick version<br />

with FHB II-A S<br />

with the least installation effort<br />

with FHB II-A L<br />

for maximum tensile loads<br />

For fixings in masonry<br />

FIS V Injection mortar<br />

The versatile injection mortar for anchorings in<br />

non-cracked concrete and masonry<br />

Page 71<br />

FIS P Injection mortar<br />

The reliable injection mortar for fixings in masonry<br />

Page 86<br />

FIS VW Injection mortar<br />

The versatile injection mortar with reduced curing<br />

time for non-cracked concrete and masonry<br />

FIS VS Injection mortar<br />

The versatile injection mortar with extended open time<br />

for non-cracked concrete and masonry<br />

FIS VT Injection mortar<br />

The solid injection mortar for anchorings in<br />

non-cracked concrete<br />

Page 75<br />

Page 79<br />

Page 83<br />

with threaded rod FIS A and<br />

internal threaded anchor FIS E<br />

The versatile fixing system for solid brick masonry<br />

for perforated brick masonry with injection<br />

anchor sleeves<br />

The versatile fixing system with injection anchor<br />

sleeves<br />

for push-through installation with FIS H K<br />

Simple push-through installation in masonry<br />

Page 106<br />

Page 111<br />

Page 116<br />

42

Resin anchor R<br />

with threaded rod RG M<br />

The proven bonded anchor<br />

for non-cracked concrete<br />

For fixings in non-cracked concrete<br />

Page<br />

57<br />

FIS V mortar<br />

The versatile injection mortar for anchorings<br />

in non-cracked concrete and masonry<br />

Page 71<br />

FIS VW mortar<br />

The versatile injection mortar with reduced<br />

curing time for non-cracked concrete and masonry<br />