Jenkins Cast Steel Valves - Associated Valve

Jenkins Cast Steel Valves - Associated Valve

Jenkins Cast Steel Valves - Associated Valve

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Cast</strong> <strong>Steel</strong> <strong><strong>Valve</strong>s</strong><br />

SINCE 1864<br />

JENKINS<br />

®<br />

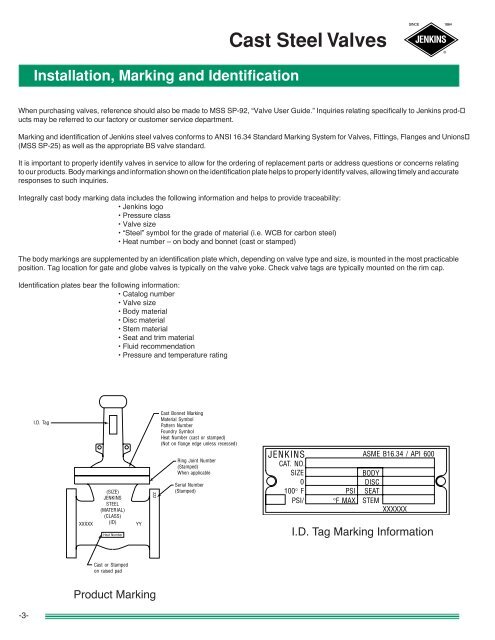

Installation, Marking and Identification<br />

When purchasing valves, reference should also be made to MSS SP-92, “<strong>Valve</strong> User Guide.” Inquiries relating specifically to <strong>Jenkins</strong> prod-<br />

ucts may be referred to our factory or customer service department.<br />

Marking and identification of <strong>Jenkins</strong> steel valves conforms to ANSI 16.34 Standard Marking System for <strong><strong>Valve</strong>s</strong>, Fittings, Flanges and Unions<br />

(MSS SP-25) as well as the appropriate BS valve standard.<br />

It is important to properly identify valves in service to allow for the ordering of replacement parts or address questions or concerns relating<br />

to our products. Body markings and information shown on the identification plate helps to properly identify valves, allowing timely and accurate<br />

responses to such inquiries.<br />

Integrally cast body marking data includes the following information and helps to provide traceability:<br />

• <strong>Jenkins</strong> logo<br />

• Pressure class<br />

• <strong>Valve</strong> size<br />

• “<strong>Steel</strong>” symbol for the grade of material (i.e. WCB for carbon steel)<br />

• Heat number – on body and bonnet (cast or stamped)<br />

The body markings are supplemented by an identification plate which, depending on valve type and size, is mounted in the most practicable<br />

position. Tag location for gate and globe valves is typically on the valve yoke. Check valve tags are typically mounted on the rim cap.<br />

Identification plates bear the following information:<br />

• Catalog number<br />

• <strong>Valve</strong> size<br />

• Body material<br />

• Disc material<br />

• Stem material<br />

• Seat and trim material<br />

• Fluid recommendation<br />

• Pressure and temperature rating<br />

I.D. Tag<br />

XXXXX<br />

(SIZE)<br />

JENKINS<br />

STEEL<br />

(MATERIAL)<br />

(CLASS)<br />

(ID)<br />

Heat Number<br />

YY<br />

zzz<br />

<strong>Cast</strong> Bonnet Marking<br />

Material Symbol<br />

Pattern Number<br />

Foundry Symbol<br />

Heat Number (cast or stamped)<br />

(Not on flange edge unless recessed)<br />

Ring Joint Number<br />

(Stamped)<br />

When applicable<br />

Serial Number<br />

(Stamped)<br />

JENKINS<br />

CAT. NO.<br />

SIZE<br />

0<br />

100° F<br />

PSI/<br />

PSI<br />

°F MAX<br />

ASME B16.34 / API 600<br />

BODY<br />

DISC<br />

SEAT<br />

STEM<br />

XXXXXX<br />

I.D. Tag Marking Information<br />

<strong>Cast</strong> or Stamped<br />

on raised pad<br />

Product Marking<br />

-3-

SINCE 1864<br />

JENKINS<br />

®<br />

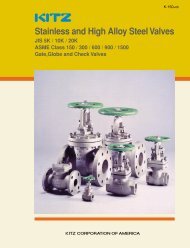

<strong>Cast</strong> <strong>Steel</strong> Gate <strong><strong>Valve</strong>s</strong><br />

General Information • Class 150, 300 and 600 <strong><strong>Valve</strong>s</strong><br />

Features<br />

Flexible Wedge<br />

• Compensates for deformation of body due to pipe stresses<br />

• Will not stick when valve is closed hot and allowed to cool<br />

Welded-in Seat Ring<br />

• Seat ring is seal welded to eliminate leak path.<br />

Basic Standards<br />

These valves comply with the applicable requirements of the following standards:<br />

• API 600<br />

• API 598<br />

• ANSI B16.34<br />

• ANSI B16.10<br />

• ANSI B16.5<br />

Inspection Policy for <strong>Jenkins</strong> <strong><strong>Valve</strong>s</strong><br />

Every <strong>Jenkins</strong> cast steel valve is subjected to a 100% pressure test according to API 598 requirements.<br />

Manufacturer’s material test reports and Inspection and Test Certifications are available upon request.<br />

Some of the additional inspections and tests performed are:<br />

• Random Radiograph Inspection of Body and Bonnet <strong>Cast</strong>ings to ASME B16.34 Appendix B.<br />

• Random Chemical Composition and Mechanical Properties Verification of Fasteners to ASTMA A-193/A-194.<br />

• Liquid Penetrate Inspection of Seat Rings.<br />

• Visual Inspection of <strong>Cast</strong>ing to MSS-SP-55.<br />

• Receiving, In-process, and Final Dimensional Inspections to Relevant <strong>Valve</strong> Standards.<br />

Other inspections or tests can be performed or evaluation criteria applied when specified by the customer.<br />

Notes<br />

• Standard material is ASTM A216 Grade WCB.<br />

• Standard trim is XU (13% CR to hardface) which is suitable for a wide range of applications.<br />

• See Engineering Data section for end flange dimensions and drilling templates.<br />

-4-

<strong>Cast</strong> <strong>Steel</strong> Gate <strong><strong>Valve</strong>s</strong><br />

SINCE 1864<br />

JENKINS<br />

®<br />

Typical Bolted Bonnet Gate <strong>Valve</strong> Features<br />

<strong>Jenkins</strong> gate valves offer the ultimate in dependable service for steam, air, gas, oil, oil vapor, and high pressure installations. All have<br />

straight-through ports to assure minimum turbulence, erosion, and resistance to flow. They are available in a wide variety of trims.<br />

-5-<br />

1. Body: Body is cast to provide liberal strength to meet operating<br />

conditions and to permit unobstructed flow. Turbulence, erosion<br />

and pressure drop are minimized.<br />

Flanged End-<strong>Jenkins</strong> cast steel gate valves are available in<br />

flanged end and butt weld ends. All flanged and butt welding<br />

end valves are designed to conform to ANSI B16.5 and ANSI<br />

B16.34 standards.<br />

2. Integral Yoke & Bonnet: Some designs incorporate a twopiece<br />

bonnet and yoke. All bonnet assemblies are cast and<br />

finished to the same exacting tolerances as the bodies for<br />

accurate alignment of stems and ease of sealing. Bonnet joint<br />

varies from flat face gasket-joint to ring-type bonnet joint,<br />

depending on class.<br />

3. Seat Rings: Seat rings are seal welded to eliminate leak path<br />

behind rings and for long trouble-free service. The surfaces are<br />

precision ground to fit accurately with the disc.<br />

4. Disc: One piece flexible disc provides accurate alignment of<br />

mating seating surfaces so the valve can absorb piping strains<br />

without leakage. Also, it avoids any tendency to stick in the<br />

seated position. <strong><strong>Valve</strong>s</strong> are also furnished with solid wedge<br />

discs that have proved successful in millions of applications.<br />

5. Stem: The tee-head disc-stem connection prevents lateral<br />

strain on the stem for smooth, easy operation. Accurately cut<br />

threads engage the yoke sleeve for positive control of disc<br />

position.<br />

6. Yoke Sleeve<br />

7. Handwheel Nut<br />

8. Yoke Sleeve Retaining Nut<br />

9. Packing: Packing contains corrosion inhibitor to avoid stem<br />

pitting. Stuffing box is deep, assuring long packing life.<br />

10. Gland: Gland is a two-piece ball-type which exerts even pressure<br />

on the packing without binding the stem.<br />

11. Gland Flange<br />

12. Gland Eye Bolts: Eyebolts swing aside for ease in repacking<br />

the stuffing box.<br />

13. Gland Eye Bolt Nuts<br />

14. Bonnet Gasket<br />

15. Bonnet Studs: Number is dependent on valve size and class.<br />

16. Bonnet Nuts: Number is dependent on valve size and class.<br />

17. Groove-Pin<br />

18. Bonnet Bushing<br />

19.<br />

20.<br />

Handwheel: Gate valves can also be supplied with gear or<br />

motor operators.<br />

Hydraulic Grease Fitting: Hydraulic grease fitting provides<br />

for lubrication of yoke sleeve bearing surfaces (not shown).

SINCE 1864<br />

JENKINS<br />

®<br />

<strong>Cast</strong> <strong>Steel</strong> Gate <strong><strong>Valve</strong>s</strong><br />

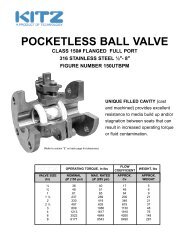

Figure J1009B8F<br />

Class 150 • Outside Screw & Yoke • Flexible Wedge Disc<br />

Material of Construction<br />

Description<br />

Material<br />

Body<br />

WCB<br />

Bonnet<br />

WCB<br />

Seat Rings<br />

Hardfaced<br />

Disc<br />

13% CR Overlay<br />

Stem<br />

410 SS<br />

Packing<br />

Graphite<br />

Bonnet Gasket<br />

Soft Iron<br />

Back Seat<br />

410 SS<br />

Yoke Sleeve<br />

D2 Ni-Resist<br />

Retaining Nut<br />

Malleable<br />

Gland<br />

<strong>Steel</strong><br />

Gland Flange<br />

<strong>Steel</strong><br />

Eye Bolt<br />

<strong>Steel</strong><br />

Eye Bolt Nuts<br />

A563 Gr. A or O<br />

Pins<br />

<strong>Steel</strong><br />

Bonnet Studs<br />

A193 Gr. B7<br />

Bonnet Nuts<br />

A194 Gr. 2H<br />

Handwheel<br />

Malleable or Ductile<br />

Handwheel Nut<br />

Ductile or <strong>Steel</strong><br />

I.D. Tags<br />

SS<br />

I.D. Pins<br />

<strong>Steel</strong><br />

Spacer<br />

<strong>Steel</strong><br />

Figure J1009B8F<br />

Flanged<br />

Size Range:<br />

2 through 12 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

285 psi @ -20°F to 100°F<br />

Note<br />

• 2" only-solid wedge<br />

C<br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ANSI B16.34<br />

Face-to-Face/End-to-End ANSI B16.10<br />

Flange Dimensions ANSI B16.5<br />

Basic Design API 600<br />

Testing API 598<br />

A<br />

B<br />

Dimensions and Weights<br />

<strong>Valve</strong><br />

Size<br />

Weight<br />

(pounds)<br />

Dimensions (inches)<br />

A B C<br />

2 40 7.00 14.88 7.87<br />

2 1 /2 57 7.50 18.11 7.87<br />

3 75 8.00 20.47 9.84<br />

4 114 9.00 23.90 9.84<br />

5 155 10.00 27.88 12.00<br />

6 189 10.50 31.61 13.78<br />

8 310 11.50 38.19 13.78<br />

10 455 13.00 45.59 15.75<br />

12 650 14.00 54.84 17.72<br />

-6-

Figure J1010B8F<br />

<strong>Cast</strong> <strong>Steel</strong> Gate <strong><strong>Valve</strong>s</strong><br />

SINCE 1864<br />

JENKINS<br />

®<br />

Class 300 • Outside Screw & Yoke • Flexible Wedge Disc<br />

Figure J1010B8F<br />

Flanged<br />

Size Range:<br />

2 through 12 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

740 psi @ -20°F to 100°F<br />

Note<br />

• 2" only-solid wedge<br />

Material of Construction<br />

Description<br />

Material<br />

Body<br />

WCB<br />

Bonnet<br />

WCB<br />

Seat Rings<br />

Hardfaced<br />

Disc<br />

13% CR Overlay<br />

Stem<br />

410 SS<br />

Packing<br />

Graphite<br />

Bonnet Gasket<br />

Spiral Wound<br />

Back Seat<br />

410 SS<br />

Yoke Sleeve<br />

D2 Ni-Resist<br />

Retaining Nut<br />

Malleable<br />

Gland<br />

<strong>Steel</strong><br />

Gland Flange<br />

<strong>Steel</strong><br />

Eye Bolt<br />

<strong>Steel</strong><br />

Eye Bolt Nuts<br />

A563 Gr. A or O<br />

Pins<br />

<strong>Steel</strong><br />

Bonnet Studs<br />

A193 Gr. B7<br />

Bonnet Nuts<br />

A194 Gr. 2H<br />

Handwheel<br />

Malleable or Ductile<br />

Handwheel Nut<br />

Ductile or <strong>Steel</strong><br />

I.D. Tags<br />

SS<br />

I.D. Pins<br />

<strong>Steel</strong><br />

Spacer<br />

<strong>Steel</strong><br />

Grease Fittings<br />

<strong>Steel</strong><br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ANSI B16.34<br />

Face-to-Face/End-to-End ANSI B16.10<br />

Flange Dimensions ANSI B16.5<br />

Basic Design API 600<br />

Testing API 598<br />

C<br />

Dimensions and Weights<br />

-7-<br />

<strong>Valve</strong><br />

Size<br />

Weight<br />

(pounds)<br />

Dimensions (inches)<br />

A B C<br />

2 48 8.50 15.75 7.87<br />

2 1 /2 79 9.50 18.98 9.84<br />

3 114 11.12 21.42 9.84<br />

4 172 12.00 24.80 11.81<br />

5 235 15.00 28.38 12.00<br />

6 339 15.88 32.48 15.75<br />

8 500 16.50 39.57 15.75<br />

10 760 18.00 49.50 18.00<br />

12 1020 19.75 57.25 20.00<br />

A<br />

B

SINCE 1864<br />

JENKINS<br />

®<br />

<strong>Cast</strong> <strong>Steel</strong> Gate <strong><strong>Valve</strong>s</strong><br />

Figure J1012B8F<br />

Class 600 • Outside Screw & Yoke • Flexible Wedge Disc<br />

Material of Construction<br />

Description<br />

Material<br />

Body<br />

WCB<br />

Bonnet<br />

WCB<br />

Seat Rings<br />

Hardfaced<br />

Disc<br />

13% CR Overlay<br />

Stem<br />

410 SS<br />

Packing<br />

Graphite<br />

Bonnet Gasket<br />

Ring Joint<br />

Back Seat<br />

410 SS<br />

Yoke Sleeve<br />

D2 Ni-Resist<br />

Retaining Nut<br />

Malleable<br />

Gland<br />

<strong>Steel</strong><br />

Gland Flange<br />

<strong>Steel</strong><br />

Eye Bolt<br />

<strong>Steel</strong><br />

Eye Bolt Nuts<br />

A563 Gr. A or O<br />

Pins<br />

<strong>Steel</strong><br />

Bonnet Studs<br />

A193 Gr. B7<br />

Bonnet Nuts<br />

A194 Gr. 2H<br />

Handwheel<br />

Malleable or Ductile<br />

Handwheel Nut<br />

Ductile or <strong>Steel</strong><br />

I.D. Tags<br />

SS<br />

I.D. Pins<br />

<strong>Steel</strong><br />

Spacer<br />

<strong>Steel</strong><br />

Grease Fittings<br />

<strong>Steel</strong><br />

Figure J1012B8F<br />

Flanged<br />

Size Range:<br />

2 through 12 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

1480 psi @ -20°F to 100°F<br />

Note<br />

• 2" only-solid wedge<br />

C<br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ANSI B16.34<br />

Face-to-Face/End-to-End ANSI B16.10<br />

Flange Dimensions ANSI B16.5<br />

Basic Design API 600<br />

Testing API 598<br />

A<br />

B<br />

Dimensions and Weights<br />

<strong>Valve</strong><br />

Size<br />

Weight<br />

(pounds)<br />

Dimensions (inches)<br />

A B C<br />

2 84 11.50 18.00 10.00<br />

2 1 /2 130 13.00 20.50 10.00<br />

3 160 14.00 22.62 12.00<br />

4 300 17.00 28.62 14.00<br />

6 640 22.00 38.62 18.00<br />

8 1080 26.00 47.25 20.00<br />

10 1550 31.00 58.25 25.00<br />

12 2100 33.00 68.12 28.00<br />

-8-

<strong>Cast</strong> <strong>Steel</strong> Globe <strong><strong>Valve</strong>s</strong><br />

SINCE 1864<br />

JENKINS<br />

®<br />

General Information • Class 150, 300 and 600 <strong><strong>Valve</strong>s</strong><br />

Features<br />

Welded-in Seat Ring<br />

• Seat ring is seal welded to eliminate leak path. behind rings<br />

Basic Standards<br />

These valves comply with the applicable requirements of the following standards:<br />

• API 598<br />

• ANSI B16.34<br />

• ANSI B16.10<br />

• ANSIB16.5<br />

Notes<br />

• Standard material is ASTM A216 Grade WCB.<br />

• Standard trim is XU (13% CR to hardface) which is suitable for a wide range of applications.<br />

• See Engineering Data section for end flange dimensions and drilling templates.<br />

-9-

SINCE 1864<br />

JENKINS<br />

®<br />

<strong>Cast</strong> <strong>Steel</strong> Globe <strong><strong>Valve</strong>s</strong><br />

Typical Globe <strong>Valve</strong> Features<br />

<strong>Jenkins</strong> globe valves are highly efficient for services requiring frequent operation and throttling when pressure drop across the valve is about<br />

20% of inlet pressure. Closer throttling, creating higher pressure drops may cause cavitation or excessive velocities which could cause high<br />

noise levels, vibration and possible damage to the valve or adjacent piping. Globe valves can be equipped with optional operators and are<br />

available with a variety of trims to match service requirements.<br />

1. Body: Body is cast with heavy sections reinforced at points<br />

subjected to the greatest stress. <strong><strong>Valve</strong>s</strong> are available in both<br />

flanged and butt welding ends. All conform to ANSI specifications.<br />

2. Bonnet<br />

3. Bonnet Seat Ring<br />

4. Disc<br />

5. Disc Stem Ring: Disc Stem Ring connects the disc to the stem,<br />

permitting the disc to swivel and aid in securing tight seating for<br />

trouble-free service.<br />

6. Disc Washer<br />

7. Stem: Stem has long engagement with yoke bushing for accurate<br />

seating.<br />

8. Bonnet Bushing<br />

9. Yoke Bushing<br />

10. Wheel Nut<br />

11. Packing<br />

12. Gland: Gland is a two-piece, ball-type which exerts even<br />

pressure on the packing without binding the stem.<br />

13. Gland Flange<br />

14. Gland Eye Bolts: Eye bolts are securely fastened to the bonnet<br />

yet swing away to permit easy access to the stuffing box.<br />

15. Bonnet Gasket: Bonnet gasket provides a positive seal against<br />

leakage. Class 150 and 300 valves have a male/female bonnet<br />

joint. A ring-type gasket is employed in Class 600.<br />

16. Bonnet Studs<br />

17. Bonnet Nuts<br />

18. Pin<br />

19. Handwheel<br />

-10-

Figure J1040B2<br />

<strong>Cast</strong> <strong>Steel</strong> Globe <strong><strong>Valve</strong>s</strong><br />

SINCE 1864<br />

JENKINS<br />

®<br />

Class 150 • Outside Screw & Yoke • Bolted Bonnet<br />

Figure 1040B2<br />

Flanged<br />

Size Range:<br />

2 through 12 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

285 psi @ -20°F to 100°F<br />

Material of Construction<br />

Description<br />

Material<br />

Body<br />

WCB<br />

Bonnet<br />

WCB<br />

Seat Rings<br />

Hardfaced<br />

Disc<br />

13% CR Overlay<br />

Stem<br />

410 SS<br />

Packing<br />

Graphite<br />

Bonnet Gasket<br />

Soft Iron<br />

Back Seat<br />

410 SS<br />

Disc Stem Nut<br />

410 SS<br />

Disc Washer<br />

Carbon <strong>Steel</strong><br />

Gland<br />

410 SS<br />

Gland Flange<br />

WCB<br />

Eye Bolt<br />

<strong>Steel</strong><br />

Eye Bolt Nuts<br />

A563 Gr. A or O<br />

Pins –<br />

Bonnet Studs<br />

A193 Gr. B7<br />

Bonnet Nuts<br />

A194 Gr. 2H<br />

Handwheel<br />

WCB<br />

Handwheel Nut<br />

A194 Gr. 2H<br />

I.D. Tags<br />

SS<br />

I.D. Pins<br />

<strong>Steel</strong><br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ANSI B16.34<br />

Face-to-Face/End-to-End ANSI B16.10<br />

Flange Dimensions ANSI B16.5<br />

Testing API 598<br />

C<br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B C<br />

B<br />

2 51 8.00 13.62 7.87<br />

2 1 /2 62 8.50 15.16 7.87<br />

3 75 9.50 16.61 9.84<br />

4 132 11.50 19.84 11.81<br />

5 199 14.00 23.00 12.00<br />

6 231 16.00 23.62 15.75<br />

8 525 19.50 24.65 15.75<br />

10 900 24.50 28.03 17.72<br />

12 900 27.50 39.50 24.00<br />

A<br />

-11-

SINCE 1864<br />

JENKINS<br />

®<br />

<strong>Cast</strong><br />

<strong>Steel</strong> Globe <strong><strong>Valve</strong>s</strong><br />

Figure J1042B2<br />

Class 300 • Outside Screw & Yoke • Bolted Bonnet<br />

Material of Construction<br />

Description<br />

Material<br />

Body<br />

WCB<br />

Bonnet<br />

WCB<br />

Seat Rings<br />

Hardfaced<br />

Disc<br />

13% CR Overlay<br />

Stem<br />

410 SS<br />

Packing<br />

Graphite<br />

Bonnet Gasket<br />

Spiral Wound<br />

Back Seat<br />

410 SS<br />

Disc Stem Nut<br />

410 SS<br />

Disc Washer<br />

Carbon <strong>Steel</strong><br />

Gland<br />

410 SS<br />

Gland Flange<br />

WCB<br />

Eye Bolt<br />

<strong>Steel</strong><br />

Eye Bolt Nuts<br />

A563 Gr. A or O<br />

Pins –<br />

Bonnet Studs<br />

A193 Gr. B7<br />

Bonnet Nuts<br />

A194 Gr. 2H<br />

Handwheel<br />

WCB<br />

Handwheel Nut<br />

A194 Gr. 2H<br />

I.D. Tags<br />

SS<br />

I.D. Pins<br />

<strong>Steel</strong><br />

Figure J1042B2<br />

Flanged<br />

Size Range:<br />

2 through 12 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

740 psi @ -20°F to 100°F<br />

Industry Standards<br />

C<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ANSI B16.34<br />

Face-to-Face/End-to-End ANSI B16.10<br />

Flange Dimensions ANSI B16.5<br />

Testing API 598<br />

Dimensions and Weights<br />

B<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B C<br />

A<br />

2 59 10.50 16.65 7.87<br />

2 1 /2 88 11.50 17.83 9.84<br />

3 128 12.50 20.31 9.84<br />

4 191 14.00 22.91 13.78<br />

5 290 15.75 27.50 12.00<br />

6 345 17.50 25.91 17.72<br />

8 750 22.00 36.00 20.00<br />

10 1100 24.50 41.65 34.02<br />

12 1100 28.00 37.25 24.00<br />

-12-

Figure J1044B2<br />

<strong>Cast</strong> <strong>Steel</strong> Globe <strong><strong>Valve</strong>s</strong><br />

SINCE 1864<br />

JENKINS<br />

®<br />

Class 600 • Outside Screw & Yoke • Bolted Bonnet<br />

Figure J1044B2<br />

Flanged<br />

Size Range:<br />

2 through 8 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

1480 psi @ -20°F to 100°F<br />

Material of Construction<br />

Description<br />

Material<br />

Body<br />

WCB<br />

Bonnet<br />

WCB<br />

Seat Rings<br />

Hardfaced<br />

Disc<br />

13% CR Overlay<br />

Stem<br />

410 SS<br />

Packing<br />

Graphite<br />

Bonnet Gasket<br />

Ring Joint<br />

Back Seat<br />

410 SS<br />

Disc Stem Nut<br />

410 SS<br />

Disc Washer<br />

Carbon <strong>Steel</strong><br />

Gland<br />

410 SS<br />

Gland Flange<br />

WCB<br />

Eye Bolt<br />

<strong>Steel</strong><br />

Eye Bolt Nuts<br />

A563 Gr. A or O<br />

Pins –<br />

Bonnet Studs<br />

A193 Gr. B7<br />

Bonnet Nuts<br />

A194 Gr. 2H<br />

Handwheel<br />

WCB<br />

Handwheel Nut<br />

A194 Gr. 2H<br />

I.D. Tags<br />

SS<br />

I.D. Pins<br />

SS<br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ANSI B16.34<br />

Face-to-Face/End-to-End ANSI B16.10<br />

Flange Dimensions ANSI B16.5<br />

Testing API 598<br />

C<br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B C<br />

B<br />

2 88 11.50 18.75 10.00<br />

2 1 /2 126 13.00 20.25 10.00<br />

3 160 14.00 23.00 14.00<br />

4 270 17.00 26.50 18.00<br />

6 550 22.00 27.00 20.00<br />

8 1000 26.00 28.50 22.00<br />

A<br />

-13-

SINCE 1864<br />

JENKINS<br />

®<br />

<strong>Cast</strong> <strong>Steel</strong> Check <strong><strong>Valve</strong>s</strong><br />

General Information • Class 150, 300 and 600 <strong><strong>Valve</strong>s</strong><br />

Features<br />

Disc Type<br />

• Class 150 valves-2"-12" and Class 300 valves-sizes 2"-8" feature an internally mounted hinge pin<br />

which eliminates a leak path<br />

• For class 600 valves, a ring joint bonnet gasket assures positive seal against leakage and accurate<br />

alignment of moving parts<br />

Welded-in Seat Ring<br />

• Seat ring is seal welded to eliminate leak path. behind rings<br />

Basic Standards<br />

These valves comply with the applicable requirements of the following standards:<br />

• API 598<br />

• ANSI B16.34<br />

• ANSI B16.10<br />

• ANSI B16.5<br />

Notes<br />

• Standard material is ASTM A216 Grade WCB.<br />

• Standard trim is XU (13% CR to hardface) which is suitable for a wide range of applications.<br />

• See Engineering Data section for end flange dimensions and drilling templates.<br />

-14-

<strong>Cast</strong> <strong>Steel</strong> Swing Check <strong>Valve</strong><br />

SINCE 1864<br />

JENKINS<br />

®<br />

Typical Swing Check <strong>Valve</strong> Features<br />

Check valves are automatically actuated. They are opened and sustained in the open position by the force of velocity pressure, and<br />

closed by the force of gravity. Seating load and resultant tightness is dependent upon back pressure. The disc and associated moving<br />

parts may be in a constant state of movement if the velocity pressure is not sufficient to hold the valve in a wide open and stable<br />

position. Premature wear and noisy operation or vibration of the moving parts can be avoided by selecting the size of check valve on the<br />

basis of flow conditions. The minimum velocity required to hold a swing check valve in the wide open and stable position has been<br />

developed by analysis of extensive test data and is expressed by the formula:<br />

v= 60 v<br />

The value for v is equal to flow in feet per second and v is the specific volume of fluid in cubic feet per pound. Sizing swing check valves<br />

on this basis may often result in the use of valves that are smaller than the pipe in which they are used, necessitating the use of reducers<br />

for installation. The pressure drop will be no greater than that of the larger valve that is only partially open, and valve life will be greatly<br />

extended. The added bonus, of course, is the lower cost of the smaller valve.<br />

There is no tendency for the seating surfaces of swing check valves to gall or score, because the disc meets the flat seat squarely<br />

without rubbing contact upon closing.<br />

<strong>Jenkins</strong> cast steel swing check valves can be furnished with outside lever and adjustable weight when so ordered. With the lever and<br />

weight mounted so that the weight assists the disc in closing, the valve closes more rapidly when flow stops, thus minimizing reversal of<br />

flow and resultant surge and shock. With the lever and weight mounted to balance the weight of the disc, the valve becomes more<br />

sensitive to low inlet velocities.<br />

Swing check valves are used to prevent reversal of flow in horizontal or vertical pipe lines. In vertical lines, or for any angle from horizontal<br />

to vertical, they can be used for upward flow only.<br />

1. Body: Strong construction assures<br />

maximum safety over the recommended<br />

pressure and temperature<br />

range. Both flange and butt weld ends<br />

are available.<br />

2. Cap: permits access to hinge and<br />

disc without removing valve from line.<br />

3. Disc: is designed to close on its own<br />

weight to stop backflow from gaining<br />

sufficient velocity to create damaging<br />

shock.<br />

4. Disc Nut Pin<br />

5. Hinge<br />

6. Cap Studs<br />

7. Cap Stud Nuts<br />

8. Cap Gasket<br />

9. Body Seat Ring (welded in)<br />

10. Disc Washer<br />

12. Disc Nut<br />

-15-

SINCE 1864<br />

JENKINS<br />

®<br />

<strong>Cast</strong> <strong>Steel</strong> Swing Check <strong>Valve</strong><br />

Figure<br />

J1025B2<br />

Class 150 • Bolted Cap<br />

Material of Construction<br />

Description<br />

Material<br />

Body<br />

WCB<br />

Cap<br />

WCB<br />

Seat Ring<br />

Hardfaced<br />

Disc<br />

13% CR Overlay<br />

Hinge<br />

WCB<br />

Pins, Hinge<br />

410 SS<br />

Disc Washer<br />

<strong>Steel</strong><br />

Cap Screw<br />

A307 Gr. B<br />

Cap Gasket<br />

Soft Iron<br />

Cap Studs<br />

A193 Gr. B<br />

Cap Nuts<br />

A194 Gr. 2H<br />

I.D. Tags<br />

SS<br />

I.D. Pins<br />

<strong>Steel</strong><br />

Figure J1025B2<br />

Flanged<br />

Size Range:<br />

2 through 12 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

285 psi @ -20°F to 100°F<br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ANSI B16.34<br />

Face-to-Face/End-to-End ANSI B16.10<br />

Flange Dimensions ANSI B16.5<br />

Testing API 598<br />

B<br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B<br />

A<br />

2 33 8.00 6.75<br />

2 1 /2 57 8.50 7.12<br />

3 59 9.50 7.38<br />

4 93 11.50 8.50<br />

5 152 13.00 9.50<br />

6 165 14.00 10.25<br />

8 275 19.50 11.88<br />

10 440 24.50 13.88<br />

12 680 27.50 15.75<br />

-16-

Figure<br />

J1026B2<br />

<strong>Cast</strong> <strong>Steel</strong> Swing Check <strong>Valve</strong><br />

SINCE 1864<br />

JENKINS<br />

®<br />

Class 300 • Bolted Cap<br />

Figure J1026B2<br />

Flanged<br />

Size Range:<br />

2 through 12 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

740 psi @ -20°F to 100°F<br />

Material of Construction<br />

Description<br />

Material<br />

Body<br />

WCB<br />

Cap<br />

WCB<br />

Seat Ring<br />

Hardfaced<br />

Disc<br />

13% CR Overlay<br />

Hinge<br />

WCB<br />

Pins, Hinge<br />

410 SS<br />

Disc Washer<br />

<strong>Steel</strong><br />

Cap Screw<br />

A307 Gr. B<br />

Cap Gasket<br />

Spiral Wound<br />

Cap Studs<br />

A193 Gr. B<br />

Cap Nuts<br />

A194 Gr. 2H<br />

I.D. Tags<br />

SS<br />

I.D. Pins<br />

<strong>Steel</strong><br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ANSI B16.34<br />

Face-to-Face/End-to-End ANSI B16.10<br />

Flange Dimensions ANSI B16.5<br />

Testing API 598<br />

Dimensions and Weights<br />

B<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B<br />

2 46 10.50 6.75<br />

2 1 /2 66 11.50 7.38<br />

3 86 12.50 8.50<br />

4 154 14.00 9.25<br />

5 255 15.75 10.62<br />

6 276 17.50 11.88<br />

8 420 21.00 13.38<br />

10 640 24.50 13.88<br />

12 1000 28.00 16.62<br />

A<br />

-17-

SINCE 1864<br />

JENKINS<br />

®<br />

<strong>Cast</strong> <strong>Steel</strong> Swing Check <strong>Valve</strong><br />

Figure<br />

J1028B2<br />

Class 600 • Bolted Cap<br />

Material of Construction<br />

Description<br />

Material<br />

Body<br />

WCB<br />

Cap<br />

WCB<br />

Seat Ring<br />

Hardfaced<br />

Disc<br />

13% CR Overlay<br />

Hinge<br />

WCB<br />

Pins, Hinge<br />

410 SS<br />

Disc Washer<br />

<strong>Steel</strong><br />

Cap Screw<br />

A307 Gr. B<br />

Cap Gasket<br />

Ring Joint<br />

Cap Studs<br />

A193 Gr. B<br />

Cap Nuts<br />

A194 Gr. 2H<br />

I.D. Tags<br />

SS<br />

I.D. Pins<br />

<strong>Steel</strong><br />

Figure J1028B2<br />

Flanged<br />

Size Range:<br />

2 through 12 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

1480 psi @ -20°F to 100°F<br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ANSI B16.34<br />

Face-to-Face/End-to-End ANSI B16.10<br />

Flange Dimensions ANSI B16.5<br />

Testing API 598<br />

B<br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B<br />

A<br />

2 62 11.50 6.88<br />

2 1 /2 84 13.00 7.88<br />

3 115 14.00 9.12<br />

4 192 17.00 11.62<br />

6 495 22.00 14.25<br />

8 780 26.00 15.75<br />

10 1400 31.00 18.12<br />

12 1750 33.00 20.50<br />

-18-

<strong>Cast</strong> <strong>Steel</strong> <strong><strong>Valve</strong>s</strong><br />

SINCE 1864<br />

JENKINS<br />

®<br />

Pressure-Temperature Ratings<br />

Pressure-Temperature Ratings<br />

(comply with ANSI B16.34-1981 – Standard Class)<br />

Bolted Bonnet <strong><strong>Valve</strong>s</strong><br />

Class Temp. Working Pressures, psig Class Temp. Working Pressures, psig<br />

A216 A217 A217 A217 A352 A352 A216 A217 A217 A217 A362 A362<br />

F WCB C5W C6 WC9 LCB LC3 F WCB C5W C6 WC9 LCB LC3<br />

-20 t0 100° 285 290 290 290 265 290 -20 to 100° 1480 1500 1500 1500 1390 1500<br />

200 260 260 260 260 250 260 200 1350 1500 1425 1430 1315 1500<br />

300 230 230 230 230 230 230 300 1315 1455 1345 1355 1275 1465<br />

400 200 200 200 200 200 200 400 1270 1410 1315 1295 1235 1410<br />

500 170 170 170 170 170 170 500 1200 1330 1285 1280 1165 1330<br />

600 140 140 140 140 140 140 600 1095 1210 1210 1210 1065 1210<br />

650 125 125 125 125 125 125 650 1075 1210 1210 1210 1065 1210<br />

700 110 110 110 110 – – 700 1065 1135 1135 1135 – –<br />

Class<br />

Class<br />

150 600<br />

800 80 80 80 80 – – 800 825 995 1015 1015 – –<br />

850 651 65 65 65 – – 850 5351 880 975 975 – –<br />

900 501 50 50 50 – – 900 3451 705 900 900 – –<br />

950 351 35 35 35 – – 950 2051 520 755 755 – –<br />

1000 201 20 20 20 – – 1000 1051 365 445 535 – –<br />

1050 – 202 20 20 – – 1050 _ 280 275 400 _ _<br />

1100 _ 202 _ _ _ _ 1150 _ 205 190 225 _ _<br />

1150 _ 202 _ _ _ _ 1150 _ 140 _ _ _ _<br />

1200 _ 202 _ _ _ _ 1200 _ 90 _ _ _ _<br />

-20 to 100° 740 750 750 750 695 750 -20 to 100° 2220 2250 2250 2250 2085 2250<br />

200 675 750 710 715 655 750 200 2025 2250 2135 2150 1970 2250<br />

300 655 730 675 675 640 730 300 1970 2185 2020 2030 1915 2185<br />

400 635 705 660 650 620 705 400 1900 2115 1975 1945 1850 2115<br />

500 600 665 640 640 585 665 500 1795 1995 1925 1920 1745 1995<br />

600 550 605 605 605 535 605 600 1640 1815 1815 1815 1600 1815<br />

650 535 590 590 590 525 590 650 1610 1765 1765 1765 1570 1765<br />

700 535 570 570 570 _ _ 700 1600 1705 1705 1705 _ _<br />

750 505 530 530 530 _ _ 750 1510 1595 1595 1595 _ _<br />

Class<br />

Class<br />

300 900<br />

800 410 500 510 510 _ _ 800 1235 1490 1525 1525 _ _<br />

850 2701 440 485 485 _ _ 850 8051 1315 1460 1460 _ _<br />

900 1701 355 450 450 _ _ 900 5151 1060 1350 1350 _ _<br />

950 1051 260 380 380 _ _ 950 3101 780 1130 1130 _ _<br />

1000 501 190 225 270 _ _ 1000 1551 575 670 805 _ _<br />

1050 _ 140 140 200 _ _ 1050 _ 420 410 595 _ _<br />

1100 _ 105 95 115 _ _ 1100 _ 310 290 340 _ _<br />

1150 _ 70 _ _ _ _ 1150 _ 205 _ _ _ _<br />

1200 _ 45 _ _ _ _ 1200 _ 135 _ _ _ _<br />

-20 to 100° 990 1000 1000 1000 925 1000 -20 to 100° 3705 3750 3750 3750 3470 3750<br />

200 900 1000 950 955 875 1000 200 3375 3750 3560 3580 3280 3750<br />

300 875 970 895 905 850 970 300 3280 3640 3365 3385 3190 3640<br />

400 845 940 880 865 825 940 400 3170 3530 3290 3240 3085 3530<br />

500 800 885 855 855 775 885 500 2995 3325 3210 3200 2910 3325<br />

600 730 805 805 805 710 805 600 2735 3025 3025 3025 2665 3025<br />

650 715 785 785 785 695 785 650 2685 2940 2940 2940 2615 2940<br />

700 710 755 755 755 _ _ 700 2665 2840 2840 2840 _ _<br />

750 670 710 710 710 _ _ 750 2520 2660 2660 2660 _ _<br />

Class<br />

Class<br />

400 1500<br />

800 550 665 675 675 _ _ 800 2060 2485 2540 2540 _ _<br />

850 3551 585 650 650 _ _ 850 13401 2195 2435 2435 _ _<br />

900 2301 470 600 600 _ _ 900 8601 1765 2245 2245 _ _<br />

950 1401 350 505 505 _ _ 950 5151 1305 1885 1885 _ _<br />

1000 701 255 300 355 _ _ 1000 2601 960 1115 1340 _ _<br />

1050 _ 190 185 265 _ _ 1050 _ 705 685 995 _ _<br />

1100 _ 140 130 150 _ _ 1100 _ 515 480 565 _ _<br />

1150 _ 90 _ _ _ _ 1150 _ 345 _ _ _ _<br />

1200 _ 60 _ _ _ _ 1200 _ 225 _ _ _ _<br />

-19-

SINCE 1864<br />

JENKINS<br />

®<br />

Technical Data<br />

Temperature Conversions<br />

Centigrade to Fahrenheit – Fahrenheit to Centigrade<br />

Locate temperature in middle column. If in degrees Centigrade, read Fahrenheit equivalent in <br />

right-hand column; if in degrees Fahrenheit, read Centigrade equivalent in left-hand column.<br />

Conversion Formulas: °C = 5/9 (°F-32)<br />

°F = 9/5 (°C+32)<br />

-20-

SINCE 1864<br />

JENKINS<br />

®<br />

Performance In Any Application<br />

In any fluid handling system, valves are the controlling element: starting or stopping flow, regulating or throttling<br />

flow, preventing backflow, or relieving and regulating pressure.<br />

<strong>Jenkins</strong> valves are universally accepted by industry for virtually every application ranging from vacuum pressures<br />

and cryogenic temperatures to elevated pressures and temperatures.<br />

Gate <strong><strong>Valve</strong>s</strong><br />

Since <strong>Jenkins</strong> valves are used in a variety of applications, the following descriptions may provide a basic guideline<br />

in the selection of steel valves.<br />

Gate valves serve as efficient stop valves with flow in either direction. They are commonly used where a minimum<br />

pressure drop is important. Throttling is not recommended because partially open gate valves exhibit flow<br />

characteristics not conducive to accurate and consistent flow control. Also, the valves may be damaged by the<br />

high velocity across the seats. They function best fully open or fully closed.<br />

Globe <strong><strong>Valve</strong>s</strong><br />

Swing Check <strong><strong>Valve</strong>s</strong><br />

Globe valves are ideal for throttling service. Their flow characteristics permit accurate and repeatable flow<br />

control. However, caution must be exercised to avoid extremely close throttling when pressure drop exceeds<br />

20%. This creates excessive noise, vibration and possible damage to valves and piping. When these conditions<br />

are anticipated, consult <strong>Jenkins</strong> for recommendations.<br />

Swing Check valves prevent reversal of flow through pipe lines. Most <strong>Jenkins</strong> swing check valves can be<br />

installed in horizontal or vertical, upward flow, piping. They offer low resistance to flow and are particularly suited<br />

to low velocity service.<br />

How to Specify and Order the Correct <strong><strong>Valve</strong>s</strong><br />

How to Specify and Order <strong><strong>Valve</strong>s</strong><br />

Size<br />

Nominal size of the pipeline into which the valve will be placed must be<br />

determined. Comprehensive data on flow characteristic and pipe properties<br />

are contained in the Engineering Data Catalog.<br />

<strong>Valve</strong> Material<br />

The following facts should be considered in determining the correct valve<br />

material.<br />

• The media to be controlled.<br />

• The temperature of the media.<br />

• The possible extraordinary stresses affecting the valve.<br />

• Safety standards and/or piping codes.<br />

Pressure/Temperature Rating<br />

Please pay careful attention that the PRESSURE/TEMPERATURE RATINGS<br />

shown on page 19 in this catalog are in keeping with the requirements of the<br />

service.<br />

<strong>Valve</strong> End Connections<br />

Considerations as to pipeline integrity, future maintenance, corrosion factors,<br />

field assembly, weight and safety should be given in determining the<br />

method of connecting the valve in the pipeline.<br />

CAUTION: When servicing, disassembling or disposing of valves containing asbestos gaskets or packing, avoid breathing dust or fibers from these parts.<br />

Disposal of asbestos and asbestos related products should comply with local, state and federal laws and regulations.<br />

-2-