Stockham Cast Steel Valves - Associated Valve

Stockham Cast Steel Valves - Associated Valve

Stockham Cast Steel Valves - Associated Valve

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Stockham</strong><br />

<strong>Cast</strong> <strong>Steel</strong> <strong><strong>Valve</strong>s</strong><br />

Setting The Standard In Service

<strong>Cast</strong> <strong>Steel</strong> <strong><strong>Valve</strong>s</strong><br />

Contents<br />

Performance in Any Application......................................................................................................................2<br />

How to Specify and Order <strong><strong>Valve</strong>s</strong>.....................................................................................................................2<br />

Installation, Marking, and Identification...........................................................................................................3<br />

Gate <strong><strong>Valve</strong>s</strong>......................................................................................................................................................4<br />

Globe <strong><strong>Valve</strong>s</strong> ...................................................................................................................................................9<br />

Check <strong><strong>Valve</strong>s</strong> .................................................................................................................................................14<br />

Figure Number Index<br />

Figure No.<br />

Page<br />

15-OF-U...........................................................................................................................................................6<br />

30-OF-U...........................................................................................................................................................7<br />

60-OF-U...........................................................................................................................................................8<br />

15-GPF-U.......................................................................................................................................................11<br />

30-GPF-U.......................................................................................................................................................12<br />

60-GPF-U.......................................................................................................................................................13<br />

15-SF-U.........................................................................................................................................................16<br />

30-SF-U.........................................................................................................................................................17<br />

60-SF-U.........................................................................................................................................................18<br />

Figure Number Cross Reference<br />

<strong>Valve</strong> Type Class <strong>Stockham</strong> Jenkins<br />

Gate 150 15-OF-U J1009B8F<br />

300 30-OF-U J1010B8F<br />

600 60-OF-U J1012B8F<br />

Globe 150 15-GPF-U J1040B2<br />

300 30-GPF-U J1042B2<br />

600 60-GPF-U J1044B2<br />

Check 150 15-SF-U J1025B2<br />

300 30-SF-U J1026B2<br />

600 60-SF-U J1028B2<br />

T: 800-STOCKHAM • F: 256-775-3860 • www.stockham.com

<strong>Cast</strong> <strong>Steel</strong> <strong><strong>Valve</strong>s</strong><br />

Performance in Any<br />

Application<br />

Gate <strong><strong>Valve</strong>s</strong><br />

Globe <strong><strong>Valve</strong>s</strong><br />

In any fluid handling system, valves are the controlling element: starting or stopping flow, regulating or throttling flow,<br />

preventing backflow, or relieving and regulating pressure.<br />

Since <strong>Stockham</strong> valves are used in a variety of applications, the following descriptions may provide a basic guideline in<br />

the selection of steel valves.<br />

Gate valves serve as efficient stop valves with flow in either direction. They are commonly used where a minimum pressure<br />

drop is important. Throttling is not recommended because partially open gate valves exhibit flow characteristics not<br />

conducive to accurate and consistent flow control. Also, the valves may be damaged by the high velocity across the seats.<br />

They function best fully open or fully closed.<br />

Globe valves are ideal for throttling service. Their flow characteristics permit accurate and repeatable flow control. However,<br />

caution must be exercised to avoid throttling close to the seat or when pressure drop exceeds 20% of the valve’s upstream<br />

pressure. This creates excessive noise, vibration, and possible damage to valves and piping. When these conditions are<br />

anticipated, consult <strong>Stockham</strong> sales personnel for recommendations.<br />

Swing Check <strong><strong>Valve</strong>s</strong><br />

Swing Check valves prevent reversal of flow through pipe lines. Most <strong>Stockham</strong> swing check valves can be installed in<br />

horizontal or vertical, upward flow, piping. They offer low resistance to flow and are particularly suited to low velocity<br />

service.<br />

How to Specify and Order the Correct <strong><strong>Valve</strong>s</strong><br />

Size<br />

Nominal size of the pipeline into which the valve will be placed must be determined.<br />

Comprehensive data on flow characteristic and pipe properties are contained in the<br />

Engineering Data Catalog.<br />

<strong>Valve</strong> Material<br />

The following facts should be considered in determining the correct valve body,<br />

trim, and packing material.<br />

• The media to be controlled.<br />

• The temperature of the media.<br />

• The possible extraordinary stresses affecting the valve.<br />

• Safety standards and/or piping codes.<br />

Type of <strong>Valve</strong><br />

A few minutes spent in reading some simple valve facts on pages 3 and 4 will<br />

prove helpful.<br />

Pressure/Temperature Rating<br />

Please pay careful attention that the PRESSURE/TEMPERATURE RATINGS are in<br />

keeping with the requirements of the application.<br />

<strong>Valve</strong> End Connections<br />

Considerations as to pipeline integrity, future maintenance, corrosion factors, field<br />

assembly, weight and safety should be given in determining the method of connecting<br />

the valve in the pipeline.<br />

CAUTION: When servicing, disassembling, or disposing of valves containing asbestos gaskets or packing, avoid breathing dust or fibers from these parts. Disposal of<br />

asbestos and asbestos related products should comply with local, state and federal laws and regulations.<br />

NOTE: In keeping with our policy of continuous product improvement, we reserve the right to institute changes in design, material, dimensions,<br />

and specifications without notice and without incurring any obligation to make such changes and modifications on the product previously<br />

or subsequently sold.<br />

<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

<strong>Cast</strong> <strong>Steel</strong> <strong><strong>Valve</strong>s</strong><br />

Installation, Marking, and<br />

Identification<br />

When purchasing valves, reference should also be made to MSS SP-92, “<strong>Valve</strong> User Guide.” Inquires relating specifically to<br />

<strong>Stockham</strong> products may be referred to our factory or customer service department.<br />

Marking and identification of <strong>Stockham</strong> steel valves conforms to ASME 16.34 Standard Marking System for <strong><strong>Valve</strong>s</strong>, Fittings, Flanges, and Unions (MSS<br />

SP-25) as well as the appropriate BS valve standard.<br />

It is important to properly identify valves in service to allow for the ordering of replacement parts or address questions or concerns relating to our<br />

products. Body markings and information shown on the identification plate helps to properly identify valves, allowing timely and accurate responses to<br />

such inquiries.<br />

Integrally cast body marking data includes the following information and helps to provide traceability:<br />

• <strong>Stockham</strong> name<br />

• Pressure class<br />

• <strong>Valve</strong> size<br />

• “<strong>Steel</strong>” symbol for the grade of material (i.e. WCB for carbon steel)<br />

• Heat number casted on body and bonnet<br />

The body markings are supplemented by an identification plate which, depending on valve type and size, is mounted in the most practicable position. Tag<br />

location for gate and globe valves is typically on the valve yoke. Check valve tags are typically mounted on the rim cap.<br />

Identification plates bear the following information:<br />

• Catalog number<br />

• <strong>Valve</strong> size<br />

• Body material<br />

• Disc material<br />

• Stem material<br />

• Seat and trim material<br />

• Pressure and temperature rating<br />

Product Marking<br />

I.D. Tag Marking Information<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

<strong>Cast</strong> <strong>Steel</strong> Gate <strong><strong>Valve</strong>s</strong><br />

General Information<br />

Class 150, 300, and 600 <strong><strong>Valve</strong>s</strong><br />

Features<br />

Flexible Wedge<br />

• Compensates for deformation of body due to pipe stresses.<br />

• Will not stick when the closed valve is subjected to temperature differentials.<br />

Welded-in Seat Ring<br />

• Seat ring is seal welded to eliminate leak path.<br />

Basic Standards<br />

These valves comply with the applicable requirements of the following standards:<br />

• API 600<br />

• API 598<br />

• ASME B16.34<br />

• ASME B16.10<br />

• ASME B16.5<br />

Pressure Temperature Ratings<br />

ASTM A216 Grade WCB<br />

ºF<br />

STANDARD CLASS B16.34 - 1996<br />

MAXIMUM NON-SHOCK WORKING PRESSURE - PSIG<br />

150 300 600<br />

HYDROSTATIC SHELL TEST 450 1,125 2,225<br />

HYDROSTATIC SEAT TEST 325 825 1,650<br />

-20 - 100 285 740 1,480<br />

200 260 675 1,350<br />

300 230 655 1,315<br />

400 200 635 1,270<br />

500 170 600 1,200<br />

600 140 550 1,095<br />

650 125 535 1,075<br />

700 110 535 1,065<br />

750 95 505 1,010<br />

800 80 410 825<br />

NOTE: Upon prolonged exposure to temperatures above 800 F, the carbide phase of carbon steel may be converted to graphite.<br />

Permissible, but not recommended for prolonged usage above 800 F.<br />

Notes<br />

• Standard material is ASTM A216 Grade WCB.<br />

• Standard trim is U (13% Cr to hardface) which is suitable for a wide range of applications.<br />

<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

<strong>Cast</strong> <strong>Steel</strong> Gate <strong><strong>Valve</strong>s</strong><br />

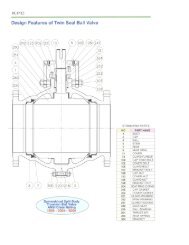

Typical Bolted Bonnet Gate <strong>Valve</strong> Features<br />

<strong>Stockham</strong> gate valves offer the ultimate in dependable service for steam, air, gas, oil, oil vapor, and high pressure installations.<br />

All have straight-through ports to assure minimum turbulence, erosion, and resistance to flow. The valves are available in a<br />

wide variety of trims.<br />

1. Body: Body is cast to provide liberal strength to meet operating<br />

conditions and to permit unobstructed flow. Turbulence, erosion, and<br />

pressure drop are minimized.<br />

<strong>Cast</strong> steel gate valves are available in flanged ends designed to conform<br />

to ASME B16.5 standards.<br />

2. Integral Yoke and Bonnet: Some designs incorporate a two-<br />

piece bonnet and yoke. All bonnet assemblies are cast and<br />

finished to the same exacting tolerances as the bodies for<br />

accurate alignment of stems and ease of sealing. Bonnet<br />

joint varies from flat face gasket-joint to ring-type bonnet<br />

joint, depending on class.<br />

3. Seat Rings: Seat rings are seal welded to eliminate leak<br />

path behind rings and for long, trouble-free service. The<br />

surfaces are precision ground to fit accurately to the disc.<br />

4. Wedge: The one-piece flexible wedge provides accurate<br />

alignment of mating seating surfaces so the valve can<br />

absorb piping stress without leakage. Also, it avoids any<br />

tendency to stick in the seated position.<br />

5. Stem: The T-head disc stem connection prevents lateral<br />

strain on the stem for smooth, easy operation. Accurately<br />

cut threads engage the yoke sleeve for positive control of<br />

disc position.<br />

6. Yoke Sleeve<br />

7. Handwheel Nut<br />

8. Yoke Sleeve Retaining Nut<br />

9. Packing: Packing contains corrosion inhibitor to avoid<br />

stem pitting. Stuffing box is deep, assuring long packing life<br />

10. Gland: Gland is two-piece ball-type which exerts even<br />

pressure on the packing without binding the stem.<br />

11. Gland Flange<br />

12. Gland Eye Bolts: Eyebolts swing aside for ease in repacking<br />

the stuffing box.<br />

13. Gland Eye Bolt Nuts<br />

14. Bonnet Gasket<br />

15. Bonnet Studs: Number is dependent on valve size and<br />

class.<br />

16. Bonnet Nuts: Number is dependent on valve size and<br />

class. The hydraulic grease fitting provides for lubrication of<br />

yoke sleeve bearing surfaces.<br />

17. Groove Pin<br />

18. Bonnet Bushing<br />

19. Handwheel: <strong>Cast</strong> steel gate valves can also be supplied<br />

with gear or motor operators.<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

Figure 15-OF-U<br />

Class 150 • Outside Screw & Yoke • Flexible Wedge Disc<br />

<strong>Cast</strong> <strong>Steel</strong> Gate <strong><strong>Valve</strong>s</strong><br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ASME B16.34<br />

Face-to-Face/End-to-End ASME B16.10<br />

Flange Dimensions ASME B16.5<br />

Basic Design API 600<br />

Testing API 598<br />

Figure 15-OF-U<br />

Flanged<br />

Size Range:<br />

2 through 24 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

285 psi @ -20°F to 100°F<br />

Materials of Construction<br />

Description Material<br />

Body<br />

ASTM A216 WCB<br />

Bonnet<br />

ASTM A216 WCB<br />

Seat Rings ASTM A105 + AWS CoCr-A<br />

Wedge<br />

ASTM A216 WCB + 13% Cr<br />

Stem<br />

ASTM A182 F6a<br />

Packing<br />

Graphite<br />

Bonnet Gasket Soft <strong>Steel</strong> + Flexible Graphite<br />

Back Seat ASTM A276 410<br />

Yoke Sleeve ASTM A439 D2<br />

Retaining Nut ASTM A216 WCB<br />

Gland ASTM A276 410<br />

Gland Flange ASTM A216 WCB<br />

Eye Bolt<br />

ASTM A307 B<br />

Eye Bolt Nuts ASTM A194 2H<br />

Pins<br />

AISI C1045<br />

Bonnet Studs ASTM A193 B7<br />

Bonnet Nuts ASTM A194 2H<br />

Handwheel Ductile Iron<br />

Handwheel Nut AISI C1020<br />

I.D. Tags ASTM A276 304<br />

I.D. Pins ASTM A276 304<br />

Spacer –<br />

Grease Fittings Carbon <strong>Steel</strong><br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B (open) C<br />

2 40 7.0 15.4 7.9<br />

2½ 51 7.5 18.1 7.9<br />

3 75 8.0 20.5 9.8<br />

4 115 9.0 23.9 9.8<br />

5 143 10.0 27.5 13.8<br />

6 187 10.5 31.6 13.8<br />

8 317 11.5 38.4 13.8<br />

10 434 13.0 45.7 15.7<br />

12 657 14.0 54.7 17.7<br />

14 895 15.0 61.2 22.0<br />

16 1155 16.0 71.3 23.6<br />

18 1587 17.0 77.2 25.2<br />

20 2579 18.0 90.6 26.8<br />

24 3231 20.0 99.2 29.9<br />

C<br />

A<br />

B<br />

<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

<strong>Cast</strong> <strong>Steel</strong> Gate <strong><strong>Valve</strong>s</strong><br />

Figure 30-OF-U<br />

Class 300 • Outside Screw & Yoke • Flexible Wedge Disc<br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ASME B16.34<br />

Face-to-Face/End-to-End ASME B16.10<br />

Flange Dimensions ASME B16.5<br />

Basic Design API 600<br />

Testing API 598<br />

Figure 30-OF-U<br />

Flanged<br />

Size Range:<br />

2 through 24 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

740 psi @ -20°F to 100°F<br />

Materials of Construction<br />

Description Material<br />

Body<br />

ASTM A216 WCB<br />

Bonnet<br />

ASTM A216 WCB<br />

Seat Rings ASTM A105 + AWS CoCr-A<br />

Wedge<br />

ASTM A216 WCB + 13% Cr<br />

Stem<br />

ASTM A182 F6a<br />

Packing<br />

Graphite<br />

Bonnet Gasket Soft <strong>Steel</strong> + Flexible Graphite<br />

Back Seat ASTM A276 410<br />

Yoke Sleeve ASTM A439 D2<br />

Retaining Nut ASTM A216 WCB<br />

Gland ASTM A276 410<br />

Gland Flange ASTM A216 WCB<br />

Eye Bolt<br />

ASTM A307 B<br />

Eye Bolt Nuts ASTM A194 2H<br />

Pins<br />

AISI C1045<br />

Bonnet Studs ASTM A193 B7<br />

Bonnet Nuts ASTM A194 2H<br />

Handwheel Ductile Iron<br />

Handwheel Nut AISI C1020<br />

I.D. Tags ASTM A276 304<br />

I.D. Pins ASTM A276 304<br />

Spacer ASTM A276 410<br />

Grease Fittings Carbon <strong>Steel</strong><br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B (open) C<br />

2 48 8.5 16.9 7.9<br />

2½ 79 9.5 19.9 9.8<br />

3 115 11.1 21.4 9.8<br />

4 166 12.0 24.8 9.8<br />

5 276 11.0 28.5 15.7<br />

6 324 15.9 32.5 15.7<br />

8 483 16.5 39.7 15.7<br />

10 776 18.0 48.8 17.7<br />

12 1040 19.8 57.9 19.7<br />

14 1530 30.0 63.0 22.0<br />

16 2380 33.0 70.5 25.2<br />

18 2722 36.0 77.1 26.8<br />

20 3648 39.0 85.8 29.9<br />

24 5510 45.0 104.5 36.0<br />

C<br />

A<br />

B<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

Figure 60-OF-U<br />

Class 600 • Outside Screw & Yoke • Flexible Wedge Disc<br />

<strong>Cast</strong> <strong>Steel</strong> Gate <strong><strong>Valve</strong>s</strong><br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ASME B16.34<br />

Face-to-Face/End-to-End ASME B16.10<br />

Flange Dimensions ASME B16.5<br />

Basic Design API 600<br />

Testing API 598<br />

Figure 60-OF-U<br />

Flanged<br />

Size Range:<br />

2 through 16 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

1480 psi @ -20°F to 100°F<br />

Materials of Construction<br />

Description Material<br />

Body<br />

ASTM A216 WCB<br />

Bonnet<br />

ASTM A216 WCB<br />

Seat Rings ASTM A105 + AWS CoCr-A<br />

Wedge<br />

ASTM A216 WCB + 13% Cr<br />

Stem<br />

ASTM A182 F6a<br />

Packing<br />

Graphite<br />

Bonnet Gasket Ring Type Joint<br />

Back Seat ASTM A276 410<br />

Yoke Sleeve ASTM A439 D2<br />

Retaining Nut ASTM A216 WCB<br />

Gland ASTM A276 410<br />

Gland Flange ASTM A216 WCB<br />

Eye Bolt<br />

ASTM A307 B<br />

Eye Bolt Nuts ASTM A194 2H<br />

Pins<br />

AISI C1045<br />

Bonnet Studs ASTM A193 B7<br />

Bonnet Nuts ASTM A194 2H<br />

Handwheel Ductile Iron<br />

Handwheel Nut AISI C1020<br />

I.D. Tags ASTM A276 304<br />

I.D. Pins ASTM A276 304<br />

Spacer ASTM A276 410<br />

Grease Fittings Carbon <strong>Steel</strong><br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B (open) C<br />

2 88 11.5 18.2 9.8<br />

2½ 119 13.0 20.3 9.8<br />

3 150 14.0 22.4 11.8<br />

4 282 17.0 27.2 13.8<br />

6 540 22.0 35.8 17.7<br />

8 923 26.0 44.3 19.7<br />

10 1433 31.0 50.5 23.6<br />

12 1962 33.0 58.7 26.8<br />

14 2900 35.0 65.2 34.0<br />

16 3685 39.0 73.7 36.0<br />

C<br />

A<br />

B<br />

<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

<strong>Cast</strong> <strong>Steel</strong> Globe <strong><strong>Valve</strong>s</strong><br />

General Information<br />

Class 150, 300, and 600 <strong><strong>Valve</strong>s</strong><br />

Features<br />

Disc Type<br />

• Plug type disc allows for close throttling control of flow.<br />

Welded-In Seat Ring<br />

• Seat ring is seal welded to eliminate leak path.<br />

Basic Standards<br />

These valves comply with the applicable requirements of the following standards:<br />

• API 598<br />

• ASME B16.34<br />

• ASME B16.10<br />

• ASME B16.5<br />

Notes<br />

• Standard material is ASTM A216 Grade WCB.<br />

• Standard trim is U (13% CR to hardface) which is suitable for a wide range of applications.<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

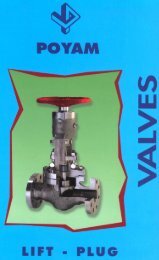

<strong>Cast</strong> <strong>Steel</strong> Globe <strong><strong>Valve</strong>s</strong><br />

Typical Globe <strong>Valve</strong> Features<br />

<strong>Stockham</strong> globe valves are highly efficient for services requiring frequent operation and throttling when pressure drop across the valve is<br />

about 20% of inlet pressure. Closer throttling, creating higher pressure drops, may cause cavitation or excessive velocities which could<br />

cause high noise levels, vibration, and possible damage to the valve or adjacent piping. Globe valves can be equipped with optional operators<br />

and are available with a variety of trims to match service requirements.<br />

1. Body: Body is cast with heavy sections reinforced at points subjected<br />

to the greatest stress. <strong><strong>Valve</strong>s</strong> are available in flanged ends<br />

that conform to ASME specifications.<br />

2. Bonnet<br />

3. Seat Ring<br />

4. Disc<br />

5. Disc Stem Nut: Disc Stem Ring connects the disc to the stem,<br />

permitting the disc to swivel and assist in securing tight seating for<br />

trouble-free service.<br />

6. Disc Washer<br />

7. Stem: Stem has a long engagement with yoke bushing for<br />

accurate seating.<br />

8. Bonnet Bushing<br />

9. Yoke Bushing<br />

10. Wheel Nut<br />

11. Packing<br />

12. Gland: Gland is two-piece ball-type which exerts even pressure<br />

on the packing without binding the stem.<br />

13. Gland Flange<br />

14. Gland Eye Bolts: Eye bolts are securely fastened to the bonnet<br />

yet swing away to permit easy access to the stuffing box.<br />

15. Bonnet Gasket: Bonnet gasket provides a positive seal against<br />

leakage. Class 150 and 300 valves have a male/ female bonnet<br />

joint. A ring-type gasket is employed in Class 600 valves.<br />

16. Bonnet Studs<br />

17. Bonnet Nuts<br />

18. Pin<br />

19. Handwheel<br />

10<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

<strong>Cast</strong> <strong>Steel</strong> Globe <strong><strong>Valve</strong>s</strong><br />

Figure 15-GPF-U<br />

Class 150 • Outside Screw & Yoke • Bolted Bonnet<br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ASME B16.34<br />

Face-to-Face/End-to-End ASME B16.10<br />

Flange Dimensions ASME B16.5<br />

Testing API 598<br />

Figure J1040B2<br />

Flanged<br />

Size Range:<br />

2 through 12 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

285 psi @ -20°F to 100°F<br />

Materials of Construction<br />

Description Material<br />

Body<br />

ASTM A216 WCB<br />

Bonnet<br />

ASTM A216 WCB<br />

Seat Rings ASTM A105 + AWS CoCr-A<br />

Disc<br />

ASTM A216 WCB + 13% Cr<br />

Stem<br />

ASTM A182 F6a<br />

Packing<br />

Graphite<br />

Bonnet Gasket Soft <strong>Steel</strong> + Flexible Graphite<br />

Back Seat ASTM A276 410<br />

Disc Nut ASTM A276 410<br />

Stem Nut ASTM A493 D2<br />

Disc Washer ASTM A276 410<br />

Gland ASTM A276 410<br />

Gland Flange ASTM A216 WCB<br />

Eye Bolt<br />

ASTM A307 B<br />

Eye Bolt Nuts ASTM A194 2H<br />

Pins<br />

AISI C1045<br />

Bonnet Studs ASTM A193 B7<br />

Bonnet Nuts ASTM A194 2H<br />

Handwheel Ductile Iron<br />

Handwheel Nut AISI C1020<br />

I.D. Tags ASTM A276 304<br />

I.D. Pins ASTM A276 304<br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B (open) C<br />

2 48 8.0 13.6 7.9<br />

2½ 71 8.5 15.2 7.9<br />

3 88 9.5 16.6 9.8<br />

4 132 11.5 19.8 11.8<br />

5 198 14.0 20.9 15.7<br />

6 223 16.0 23.3 15.7<br />

8 355 19.5 23.6 17.7<br />

10 639 24.5 32.5 19.7<br />

12 N/A 27.5 39.6 23.6<br />

C<br />

A<br />

B<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com 11

Figure 30-GPF-U<br />

Class 300 • Outside Screw & Yoke • Bolted Bonnet<br />

<strong>Cast</strong> <strong>Steel</strong> Globe <strong><strong>Valve</strong>s</strong><br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ASME B16.34<br />

Face-to-Face/End-to-End ASME B16.10<br />

Flange Dimensions ASME B16.5<br />

Testing API 598<br />

Figure 30-GPF-U<br />

Flanged<br />

Size Range:<br />

2 through 12 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

740 psi @ -20°F to 100°F<br />

Materials of Construction<br />

Description Material<br />

Body<br />

ASTM A216 WCB<br />

Bonnet<br />

ASTM A216 WCB<br />

Seat Rings ASTM A105 + AWS CoCr-A<br />

Disc<br />

ASTM A216 WCB + 13% Cr<br />

Stem<br />

ASTM A182 F6a<br />

Packing<br />

Graphite<br />

Bonnet Gasket Soft <strong>Steel</strong> + Flexible Graphite<br />

Back Seat ASTM A276 410<br />

Disc Nut ASTM A276 410<br />

Stem Nut ASTM A493 D2<br />

Disc Washer ASTM A276 410<br />

Gland ASTM A276 410<br />

Gland Flange ASTM A216 WCB<br />

Eye Bolt<br />

ASTM A307 B<br />

Eye Bolt Nuts ASTM A194 2H<br />

Pins<br />

AISI C1045<br />

Bonnet Studs ASTM A193 B7<br />

Bonnet Nuts ASTM A194 2H<br />

Handwheel Ductile Iron<br />

Handwheel Nut AISI C1020<br />

I.D. Tags ASTM A276 304<br />

I.D. Pins ASTM A276 304<br />

Spacer ASTM A276 410<br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B (open) C<br />

2 66 10.5 16.6 7.9<br />

2½ 95 11.5 17.8 9.8<br />

3 128 12.5 20.3 9.8<br />

4 190 14.0 22.9 13.8<br />

5 287 15.8 24.3 15.7<br />

6 331 17.5 25.9 17.7<br />

8 N/A 22.0 34.0 19.7<br />

10 N/A 24.5 37.7 23.6<br />

12 N/A 28.0 42.2 27.6<br />

C<br />

B<br />

A<br />

12<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

<strong>Cast</strong> <strong>Steel</strong> Globe <strong><strong>Valve</strong>s</strong><br />

Figure 60-GPF-U<br />

Class 600 • Outside Screw & Yoke • Bolted Bonnet<br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ASME B16.34<br />

Face-to-Face/End-to-End ASME B16.10<br />

Flange Dimensions ASME B16.5<br />

Testing API 598<br />

Figure 60-GPF-U<br />

Flanged<br />

Size Range:<br />

2 through 10 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

1480 psi @ -20°F to 100°F<br />

Materials of Construction<br />

Description Material<br />

Body<br />

ASTM A216 WCB<br />

Bonnet<br />

ASTM A216 WCB<br />

Seat Rings ASTM A105 + AWS CoCr-A<br />

Disc<br />

ASTM A216 WCB + 13% Cr<br />

Stem<br />

ASTM A182 F6a<br />

Packing<br />

Graphite<br />

Bonnet Gasket Ring Type Joint<br />

Back Seat ASTM A276 410<br />

Disc Nut ASTM A276 410<br />

Stem Nut ASTM A493 D2<br />

Disc Washer ASTM A276 410<br />

Gland ASTM A276 410<br />

Gland Flange ASTM A216 WCB<br />

Eye Bolt<br />

ASTM A307 B<br />

Eye Bolt Nuts ASTM A194 2H<br />

Pins<br />

AISI C1045<br />

Bonnet Studs ASTM A193 B7<br />

Bonnet Nuts ASTM A194 2H<br />

Handwheel Ductile Iron<br />

Handwheel Nut AISI C1020<br />

I.D. Tags ASTM A276 304<br />

I.D. Pins ASTM A276 304<br />

Spacer ASTM A276 410<br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B (open) C<br />

2 88 11.5 17.5 9.8<br />

2½ 110 13.0 18.5 9.8<br />

3 165 14.0 21.7 13.8<br />

4 276 17.0 25.6 17.7<br />

6 N/A 22.0 30.8 19.7<br />

8 N/A 26.0 37.7 23.6<br />

10 N/A 31.0 40.4 27.6<br />

C<br />

B<br />

A<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com 13

<strong>Cast</strong> <strong>Steel</strong> Check <strong><strong>Valve</strong>s</strong><br />

General Information<br />

Class 150, 300, and 600 <strong><strong>Valve</strong>s</strong><br />

Features<br />

Disc Type<br />

• Class 150 and 300 valves (2" to 12") and Class 600 valves (2" to 10") feature an internally mounted hinge pin which<br />

eliminates a leak path.<br />

• For Class 600 valves, a ring joint bonnet gasket assures positive seal against leakage and accurate alignment of<br />

moving parts.<br />

Welded-in Seat Ring<br />

• Seat ring is seal welded to eliminate leak path.<br />

Basic Standards<br />

These valves comply with the applicable requirements of the following standards:<br />

• API 598<br />

• ASME B16.34<br />

• ASME B16.10<br />

• ASME B16.5<br />

Notes<br />

• Standard material is ASTM A216 Grade WCB.<br />

• Standard trim is U (13% CR to hardface) which is suitable for a wide range of applications.<br />

14<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

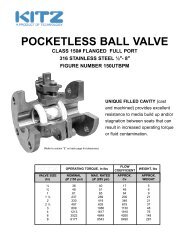

<strong>Cast</strong> <strong>Steel</strong> Check <strong><strong>Valve</strong>s</strong><br />

Typical Swing Check <strong>Valve</strong> Features<br />

Swing check valves are used to prevent reversal of flow in horizontal or vertical pipelines. In vertical lines, or for any angle<br />

from horizontal, they can be used for upward flow only.<br />

Check valves are automatically actuated. They are opened and sustained in the open position by the force of velocity pressure,<br />

and they are closed by the force of gravity. Seating load and resultant tightness is dependent upon back pressure.<br />

The disc and associated moving parts may be in a constant state of movement if the velocity pressure is not sufficient to<br />

hold the valve in a wide open and stable position. Premature wear and noisy operation or vibration of the moving parts can<br />

be avoided by selecting the size of check valve on the basis of flow conditions. The minimum velocity to hold a swing check<br />

valve in the wide open and stable position is expressed in the formula:<br />

The value for ν is equal to flow in feet per second and ν is the specific volume of fluid in cubic feet per pound. Sizing swing<br />

check valves on this basis may often result in the use of valves that are smaller than the pipe in which they are used,<br />

necessitating the use of reducers for installation. The pressure drop will be no greater than that of the larger valve that is<br />

only partially open, and the valve life will be greatly extended. An added bonus is the lower cost of the smaller valve.<br />

There is no tendency for the seating surfaces of swing check valves to gall or score because the disc meets the flat seat<br />

squarely without rubbing contact upon closing.<br />

<strong>Stockham</strong> cast steel swing check valves can be furnished with outside lever and adjustable weight if desired. With the lever<br />

and weight mounted so that the weight assists the disc in closing, the valve closes more rapidly when flow stops, thus<br />

minimizing reversal of flow and resultant surge and shock. With the lever and weight mounted to balance the weight of the<br />

disc, the valve becomes more sensitive to low inlet velocities.<br />

1. Body: Strong construction assures maximum<br />

safety over the recommended pressure and temperature<br />

range. Available in Flanged End body<br />

configuration.<br />

2. Cap: Cap permits access to hinge and disc<br />

without removing valve from line.<br />

3. Disc: Disc is designed to close on its own<br />

weight to stop backflow from gaining sufficient<br />

velocity to create damaging shock.<br />

4. Disc Nut Pin<br />

5. Hinge<br />

6. Hinge Pin Plug<br />

7. Cap Studs<br />

8. Cap Stud Nuts<br />

9. Cap Gasket<br />

10. Body Seat Ring (welded in)<br />

11. Disc Washer<br />

12. Hinge Pin<br />

13. Disc Nut<br />

ν = 60 √ ν<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com 15

<strong>Cast</strong> <strong>Steel</strong> Check <strong><strong>Valve</strong>s</strong><br />

Figure 15-SF-U<br />

Class 150 • Bolted Cap<br />

Figure 15-SF-U<br />

Flanged<br />

Size Range:<br />

2 through 24 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

285 psi @ -20°F to 100°F<br />

Materials of Construction<br />

Description Material<br />

Body<br />

ASTM A216 WCB<br />

Cap<br />

ASTM A216 WCB<br />

Seat Ring ASTM A105 + AWS CoCr-A<br />

Disc<br />

ASTM A216 WCB + 13% Cr<br />

Hinge<br />

ASTM A216 WCB<br />

Hinge Pin ASTM A182 F6a<br />

Disc Washer ASTM A276 410<br />

Cap Screw ASTM A307 B<br />

Cap Gasket Soft <strong>Steel</strong> + Flexible Graphite<br />

Cap Studs ASTM A193 B7<br />

Cap Nuts ASTM A194 2H<br />

I.D. Tags ASTM A276 304<br />

I.D. Pins ASTM A276 304<br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ASME B16.34<br />

Face-to-Face/End-to-End ASME B16.10<br />

Flange Dimensions ASME B16.5<br />

Testing API 598<br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B<br />

2 35 8.0 6.8<br />

2½ 48 8.5 6.9<br />

3 64 9.5 7.6<br />

4 101 11.5 8.7<br />

5 130 13.0 9.3<br />

6 148 14.0 11.3<br />

8 309 19.5 14.0<br />

10 485 24.5 17.9<br />

12 694 27.5 20.9<br />

14 970 31.0 23.6<br />

16 1256 32.9 24.8<br />

18 1653 38.5 27.2<br />

20 1829 38.5 29.1<br />

24 2997 51.0 32.3<br />

A<br />

B<br />

16<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

<strong>Cast</strong> <strong>Steel</strong> Check <strong><strong>Valve</strong>s</strong><br />

Figure 30-SF-U<br />

Class 300 • Bolted Cap<br />

Figure 30-SF-U<br />

Flanged<br />

Size Range:<br />

2 through 24 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

740 psi @ -20°F to 100°F<br />

Materials of Construction<br />

Description Material<br />

Body<br />

ASTM A216 WCB<br />

Cap<br />

ASTM A216 WCB<br />

Seat Ring ASTM A105 + AWS CoCr-A<br />

Disc<br />

ASTM A216 WCB + 13% Cr<br />

Hinge<br />

ASTM A216 WCB<br />

Hinge Pin ASTM A182 F6a<br />

Disc Washer ASTM A276 410<br />

Cap Screw ASTM A307 B<br />

Cap Gasket Soft <strong>Steel</strong> + Flexible Graphite<br />

Cap Studs ASTM A193 B7<br />

Cap Nuts ASTM A194 2H<br />

I.D. Tags ASTM A276 304<br />

I.D. Pins ASTM A276 304<br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ASME B16.34<br />

Face-to-Face/End-to-End ASME B16.10<br />

Flange Dimensions ASME B16.5<br />

Testing API 598<br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B<br />

2 44 10.5 6.9<br />

2½ 66 11.5 7.3<br />

3 86 12.5 8.4<br />

4 148 14.0 9.7<br />

5 287 15.8 10.6<br />

6 276 17.5 12.2<br />

8 463 21.0 16.7<br />

10 650 24.5 18.9<br />

12 857 28.0 21.7<br />

14 1499 33.0 25.8<br />

16 1840 34.0 28.1<br />

18 2193 38.5 29.9<br />

20 2909 40.0 31.7<br />

24 4188 53.0 35.6<br />

A<br />

B<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com 17

<strong>Cast</strong> <strong>Steel</strong> Check <strong><strong>Valve</strong>s</strong><br />

Figure 60-SF-U<br />

Class 600 • Bolted Cap<br />

Figure 60-SF-U<br />

Flanged<br />

Size Range:<br />

2 through 12 inches<br />

Pressure Temperature Rating<br />

Carbon <strong>Steel</strong><br />

ASTM A216 Grade WCB<br />

1480 psi @ -20°F to 100°F<br />

Materials of Construction<br />

Description Material<br />

Body<br />

ASTM A216 WCB<br />

Cap<br />

ASTM A216 WCB<br />

Seat Ring ASTM A105 + AWS CoCr-A<br />

Disc<br />

ASTM A216 WCB + 13% Cr<br />

Hinge<br />

ASTM A216 WCB<br />

Hinge Pin ASTM A182 F6a<br />

Disc Washer ASTM A276 410<br />

Cap Screw ASTM A307 B<br />

Cap Gasket Ring Type Joint<br />

Cap Studs ASTM A193 B7<br />

Cap Nuts ASTM A194 2H<br />

I.D. Tags ASTM A276 304<br />

I.D. Pins ASTM A276 304<br />

Industry Standards<br />

<strong>Steel</strong> <strong><strong>Valve</strong>s</strong> ASME B16.34<br />

Face-to-Face/End-to-End ASME B16.10<br />

Flange Dimensions ASME B16.5<br />

Testing API 598<br />

Dimensions and Weights<br />

<strong>Valve</strong> Weight Dimensions (inches)<br />

Size (pounds) A B<br />

2 82 11.5 7.3<br />

2½ 86 13.0 8.0<br />

3 126 14.0 9.1<br />

4 231 17.0 11.9<br />

6 485 22.0 16.8<br />

8 904 26.0 18.9<br />

10 1366 31.0 22.3<br />

12 1807 33.0 26.4<br />

A<br />

B<br />

18<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

<strong>Cast</strong> <strong>Steel</strong> <strong><strong>Valve</strong>s</strong><br />

Notes<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com 19

<strong>Cast</strong> <strong>Steel</strong> <strong><strong>Valve</strong>s</strong><br />

Notes<br />

20<br />

T: 1-800-STOCKHAM • F: 256-775-3860 • www.stockham.com

iii

“We wrote the book”<br />

www.tp410.com<br />

<strong>Stockham</strong><br />

2129 3rd Avenue, S.E.<br />

Cullman, Alabama 35055<br />

Tel: 1-800-STOCKHAM<br />

Fax: 1-256-775-3860<br />

www.stockham.com<br />

<strong>Stockham</strong> is a trademark of Crane Co. ©2007<br />

0207 CV-807