FCC Coordinates Team Effort on Diamond Jubilee Cruiseship ...

FCC Coordinates Team Effort on Diamond Jubilee Cruiseship ...

FCC Coordinates Team Effort on Diamond Jubilee Cruiseship ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

fall & winter 2012<br />

The biannual newsmagazine of the OSCO C<strong>on</strong>structi<strong>on</strong> Group<br />

<str<strong>on</strong>g>FCC</str<strong>on</strong>g> <str<strong>on</strong>g>Coordinates</str<strong>on</strong>g> <str<strong>on</strong>g>Team</str<strong>on</strong>g><br />

<str<strong>on</strong>g>Effort</str<strong>on</strong>g> <strong>on</strong> Diam<strong>on</strong>d<br />

<strong>Jubilee</strong> <strong>Cruiseship</strong><br />

Terminal<br />

Irving Oil Refinery • Broad Institute • Topping off 225 Binney<br />

Profile <strong>on</strong> Architectural Precast • Employee Recogniti<strong>on</strong> Awards

pg.10 pg.19 pg.32<br />

What’s fall<br />

Inside...<br />

& winter 2012<br />

3 Message from the President<br />

priorities<br />

30 Group Safety News<br />

31 Envir<strong>on</strong>mental Due Diligence<br />

projects<br />

4 Diam<strong>on</strong>d <strong>Jubilee</strong> Cruise Terminal<br />

6 Miscellaneous Metals Divisi<strong>on</strong><br />

7 Irving Oil Refinery<br />

Mid-C<strong>on</strong>tinental Crude project & East Campus Project<br />

15 Zi<strong>on</strong>ville Bridge<br />

16 225 Binney topping off<br />

17 351 Water Street<br />

18 Broad Institute<br />

20 Pouring it On: Ready Mix & Aggregates Updates<br />

Halifax Airport; Nova Scotia Power Dam Rebuilding; Kennebecasis<br />

Library Expansi<strong>on</strong>; Sewell-Carlet<strong>on</strong> Parking Garage; Waterside Centre;<br />

Le<strong>on</strong>’s; PEI Dental Clinic<br />

23 Dept of Nati<strong>on</strong>al Defence<br />

24 Port of Halifax Expansi<strong>on</strong><br />

25 Banking <strong>on</strong> <str<strong>on</strong>g>FCC</str<strong>on</strong>g><br />

Bank of M<strong>on</strong>treal; TD Waterhouse<br />

26 Rebar<br />

Maximum Security Detenti<strong>on</strong> Facility; Transportati<strong>on</strong> Discovery Center;<br />

Lansing Court Apartment Building; Misc Projects.<br />

28 Picadilly Update<br />

Raw Water Pumphouse; Diesel Storage Building; Ore Feed Pump; Mine<br />

Supply Air Complex.<br />

profiles<br />

10 Product Profile: Architectural Precast<br />

The Vincent Coleman; King’s Wharf; Royal View Apartments; The Grainery;<br />

The Trillium<br />

14 Customer Profile: Fares Inc.<br />

32 Company Profile: MacLean’s C<strong>on</strong>crete<br />

A warm hello to our newest Group members; A look back at 59 years of<br />

MacLean’s C<strong>on</strong>crete<br />

public & community<br />

34 C<strong>on</strong>necting with the Community<br />

Sculpture Saint John; Steel Day; Nati<strong>on</strong>al Precast Day; Touch a Truck;<br />

NSCC Award; Pte. David Greenslade Memorial Bursary<br />

people<br />

37 Hans O. Klohn H<strong>on</strong>oured with 2011 CPCI Fellow<br />

Award<br />

38 Employee Recogniti<strong>on</strong> Awards Dinner<br />

40 Dave Loomer Celebrates 50 Years of Service with<br />

Ocean Steel<br />

40 Retirement Lane<br />

Howard Dryden; John Myers; Douglas Cringan; James Milt<strong>on</strong>; Roger<br />

MacD<strong>on</strong>ald; Richard Thibodeaqu; Brian Case; Robert Taylor; Dale Card.<br />

42 Group Golf Tournament<br />

42 Group Picnic<br />

43 <str<strong>on</strong>g>FCC</str<strong>on</strong>g> Softball Champs<br />

43 OSCO Bursary Winners<br />

43 Fresh Faces<br />

43 C<strong>on</strong>gratulati<strong>on</strong>s<br />

44 Our Locati<strong>on</strong>s<br />

OSCO<br />

c<strong>on</strong>structi<strong>on</strong><br />

group<br />

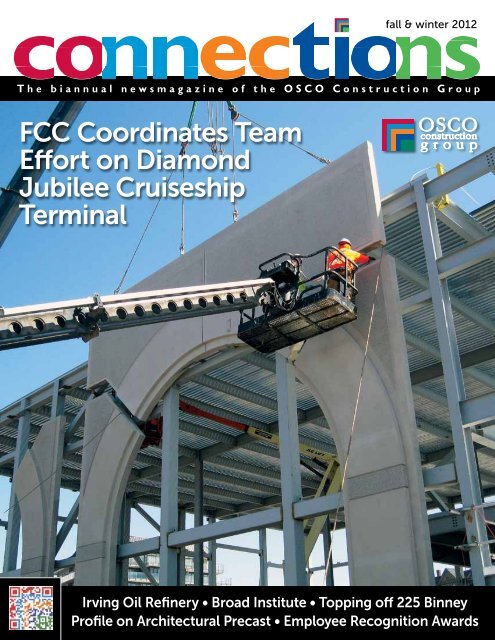

<strong>on</strong> the cover...<br />

Members of Stresc<strong>on</strong> Atlantic’s erecti<strong>on</strong> team set a<br />

piece of architectural precast in place for the facade<br />

of Saint John, New Brunswick’s Diam<strong>on</strong>d <strong>Jubilee</strong><br />

CONNECTIONS is the biannual magazine of the OSCO<br />

C<strong>on</strong>structi<strong>on</strong> Group, published every Spring and Fall to share<br />

news and informati<strong>on</strong> with our valued customers & employees<br />

Comments and submissi<strong>on</strong>s are greatly appreciated and may be sent to<br />

the editor/designer: Tammy Legacy, c/o OSCO C<strong>on</strong>structi<strong>on</strong> Group<br />

400 Chesley Drive, Saint John, NB • Canada • E2K 5L6<br />

2 CONNECTIONS • Fall & Winter Cruise 2012Terminal.<br />

email: legacy.tammy@oceansteel.com<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com

Message from the President<br />

Looking back<br />

over 2012, we’ve had a busy summer and<br />

fall. Our ready mix divisi<strong>on</strong> was very busy<br />

in the Halifax market with record volumes.<br />

Given the size of the Halifax market, we<br />

are in the midst of installing a GPS tracking<br />

system for all our trucks and pumps.<br />

At the same time, we are rec<strong>on</strong>figuring<br />

our dispatching system to integrate with<br />

this GPS tracking to upgrade our level<br />

of service and optimize the usage of our<br />

ready mix fleet.<br />

Although in New Brunswick<br />

the ready mix market slowed<br />

c<strong>on</strong>siderably, the market in<br />

PEI remained fairly steady.<br />

The acquisiti<strong>on</strong> of MacLean’s<br />

Ready Mix C<strong>on</strong>crete has g<strong>on</strong>e<br />

extremely well. We are very<br />

pleased to have this well run organizati<strong>on</strong><br />

join OSCO C<strong>on</strong>crete. Both Doug<br />

and John MacLean have stayed with the<br />

company and c<strong>on</strong>tinue to provide the<br />

great service they have been noted for in<br />

eastern PEI. At the same time, James Reid<br />

has assumed the duties of PEI Operati<strong>on</strong>s<br />

Manager and this has allowed our services<br />

in PEI to be coordinated throughout the<br />

province.<br />

In our structural steel and precast<br />

c<strong>on</strong>crete divisi<strong>on</strong>s, we have undertaken<br />

projects located in several geographic<br />

markets throughout Canada and the<br />

eastern United States: from Bost<strong>on</strong>; to<br />

Halifax; to St. John’s; to Fort McMurray.<br />

Geographic diversity c<strong>on</strong>tinues to play<br />

an important role to ensure we c<strong>on</strong>tinue<br />

to find profitable opportunities for our<br />

steel and precast c<strong>on</strong>crete sectors. As<br />

some markets slow down, like our local<br />

market in New Brunswick, other markets<br />

offer great promise, such as Labrador &<br />

Newfoundland.<br />

We’re also encouraged to see the significant<br />

activity in the Bost<strong>on</strong> area; particularly<br />

in the instituti<strong>on</strong>al, health science<br />

and high-rise residential segments. We<br />

anticipate that after the American presidential<br />

electi<strong>on</strong> more c<strong>on</strong>structi<strong>on</strong> will<br />

occur al<strong>on</strong>g the northeastern Atlantic<br />

seacoast in C<strong>on</strong>necticut, Rhode Island and<br />

New York. This should enable the Ocean<br />

<str<strong>on</strong>g>Team</str<strong>on</strong>g>work remains the most important attribute<br />

that we, as an organizati<strong>on</strong>, can improve. If any<br />

<strong>on</strong>e of us fails in fulfilling the important role we<br />

play, then we all fail as a group.<br />

Steel plant in New York State to stay busy;<br />

especially with the Canadian-to-American<br />

dollar projected to remain at par.<br />

The uncertain ec<strong>on</strong>omic times in North<br />

America and the European Uni<strong>on</strong> makes<br />

moving from <strong>on</strong>e c<strong>on</strong>structi<strong>on</strong> jurisdicti<strong>on</strong><br />

to another vitally important to our future<br />

success. For this reas<strong>on</strong>, we c<strong>on</strong>tinue<br />

to work hard at developing our skills to<br />

open and service more geographic markets.<br />

This starts with identifying opportunities<br />

in new markets, timely marketing &<br />

sales efforts to win c<strong>on</strong>tracts and building<br />

a str<strong>on</strong>g project management infrastructure<br />

to service these distant markets.<br />

Without good communicati<strong>on</strong> and teamwork<br />

between all of our departments &<br />

divisi<strong>on</strong>s, we would not have been successful<br />

in making this happen. I believe<br />

we need to develop even str<strong>on</strong>ger teambuilding<br />

skills between ourselves. To help<br />

with this, we have started m<strong>on</strong>thly “team<br />

building” management meetings in all of<br />

our Group Sectors. At the same time, we<br />

are revamping our MicroSoft SharePoint<br />

corporate networking website to allow for<br />

easier sharing of our instituti<strong>on</strong>al knowledge<br />

between all of our employees.<br />

<str<strong>on</strong>g>Team</str<strong>on</strong>g>work remains the most important<br />

attribute that we, as an organizati<strong>on</strong>, can<br />

improve. If any <strong>on</strong>e of us fails in fulfilling<br />

the important role we play, then we all<br />

fail as a group. It’s not about<br />

individuals with the best performance:<br />

it’s about how well<br />

the team works together!<br />

We want all team members<br />

to understand what role they<br />

can play in helping the entire<br />

OSCO Group to succeed. At<br />

the same time, we need to better explain<br />

what overall impact a team member’s acti<strong>on</strong><br />

may have bey<strong>on</strong>d just what happens<br />

in a particular department. For example,<br />

designing something that’s easy to fabricate<br />

but more expensive to ship or install<br />

is not necessarily a win for the team!<br />

I want to <strong>on</strong>ce again thank all of our team<br />

members for their significant c<strong>on</strong>tributi<strong>on</strong>s<br />

to making 2012 another successful<br />

<strong>on</strong>e for the OSCO C<strong>on</strong>structi<strong>on</strong> Group.<br />

I am looking forward to the challenges<br />

of 2013 and I know with the talent and<br />

dedicati<strong>on</strong> in our organizati<strong>on</strong> that it will<br />

be another successful year for us all!<br />

Hans O. Klohn<br />

President, OSCO C<strong>on</strong>structi<strong>on</strong> Group<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com CONNECTIONS • Fall & Winter 2012 3

projects<br />

The Saint John, New Brunswick<br />

waterfr<strong>on</strong>t c<strong>on</strong>tinues to grow<br />

with the c<strong>on</strong>structi<strong>on</strong> of the<br />

Diam<strong>on</strong>d <strong>Jubilee</strong> Cruise Terminal.<br />

Named in h<strong>on</strong>our of Queen Elizabeth’s<br />

60th anniversary <strong>on</strong> the<br />

British thr<strong>on</strong>e, this new project<br />

was initiated by the Port of Saint<br />

John to meet the growing needs<br />

of both the Disney cruise ship line<br />

and the cruise ship industry in<br />

general. C<strong>on</strong>structi<strong>on</strong> of the new<br />

terminal started in late November<br />

2011 and was completed in October<br />

2012. <str<strong>on</strong>g>FCC</str<strong>on</strong>g> C<strong>on</strong>structi<strong>on</strong>’s<br />

civil divisi<strong>on</strong> provided c<strong>on</strong>structi<strong>on</strong><br />

management services from<br />

the early design phase through<br />

project completi<strong>on</strong>.<br />

The new terminal is located <strong>on</strong><br />

Water St., just south of the existing<br />

Marco Polo Cruise Terminal.<br />

This c<strong>on</strong>temporary facility offers<br />

a number of amenities for tourists<br />

visiting Saint John. These<br />

features include a 400 ft. pedway,<br />

which is used to safely and<br />

efficiently offload cruise ship passengers,<br />

washroom facilities, and<br />

a large assembly area where passengers<br />

can sign up for tours of Southern<br />

New Brunswick. The terminal also<br />

c<strong>on</strong>tains space which will be accessible<br />

to the general public. The sec<strong>on</strong>d level<br />

has a rentable banquet room serviced<br />

by a full kitchen as well as a roof top<br />

Diam<strong>on</strong>d<br />

<strong>Jubilee</strong><br />

Cruise<br />

Terminal<br />

c<strong>on</strong>tributed by:<br />

Carl Blanchard,<br />

Tim MacD<strong>on</strong>ald, Dave Dunnett,<br />

STEWART TOTTEN & Stephane Belanger<br />

patio. The upper roof features a<br />

patio which is open to the public<br />

and provides a spectacular view<br />

of the Saint John waterfr<strong>on</strong>t<br />

and an opportunity for an up<br />

close view of visiting cruise ships.<br />

With the first ship scheduled to<br />

arrive at the terminal <strong>on</strong> September<br />

5th 2012; and design <strong>on</strong>ly<br />

beginning in the fall of 2011; it<br />

was recognized that this project<br />

was <strong>on</strong> a very tight schedule. It<br />

was critical that <str<strong>on</strong>g>FCC</str<strong>on</strong>g> C<strong>on</strong>structi<strong>on</strong><br />

work closely with both the<br />

Client and the design team to<br />

solve scheduling, cost c<strong>on</strong>trol,<br />

and c<strong>on</strong>structability issues. Despite<br />

many design details, added<br />

scope and working through<br />

winter weather <strong>on</strong> the Saint John<br />

waterfr<strong>on</strong>t, the ship arrival date<br />

remained unchanged.<br />

Through teamwork, careful planning<br />

and efficient work <strong>on</strong> site,<br />

the first Disney cruise ship was<br />

able to arrive as scheduled. Since<br />

then, the terminal has c<strong>on</strong>tinued<br />

to serve the various cruise lines<br />

and passengers who call <strong>on</strong> the<br />

Port of Saint John while <str<strong>on</strong>g>FCC</str<strong>on</strong>g><br />

C<strong>on</strong>structi<strong>on</strong> completed work<br />

<strong>on</strong> site.<br />

While the project was delivered<br />

both <strong>on</strong> schedule and within<br />

budget, “safety first” c<strong>on</strong>tinued<br />

to be the approach taken<br />

<strong>on</strong> site. Overall, this<br />

project was completed<br />

with zero lost time<br />

4 CONNECTIONS • Fall & Winter 2012<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com

projects<br />

accidents, which is a great accomplishment<br />

for a project of this size.<br />

Following the proper safety regulati<strong>on</strong>s,<br />

c<strong>on</strong>ducting <strong>on</strong>-site orientati<strong>on</strong>s<br />

and ensuring all site pers<strong>on</strong>nel<br />

wore proper PPE, were key<br />

strategies to meeting this target.<br />

The <str<strong>on</strong>g>FCC</str<strong>on</strong>g> Project <str<strong>on</strong>g>Team</str<strong>on</strong>g> c<strong>on</strong>sisted of<br />

C<strong>on</strong>structi<strong>on</strong> Manager Bill Woodhouse,<br />

General Site Supervisor<br />

Daryl Ross, Sitework Supervisor<br />

Rob Murphy and Site Administrator<br />

Robin Young. Project estimating<br />

and tendering was carried<br />

out by Shauna Miller and Kyle<br />

Blanchard.<br />

A special thanks to all of the site<br />

and office staff for pushing this<br />

project forward to it’s successful<br />

completi<strong>on</strong>. Special thanks<br />

especially goes out to Daryl Ross<br />

and Bill Woodhouse who spent<br />

many extra hours of their own time<br />

during the week and week-ends to<br />

make sure deadlines were met. We<br />

have built a great business relati<strong>on</strong>ship<br />

with our client and a great<br />

deal of thanks must go to Daryl<br />

and Bill for their efforts. Thanks<br />

guys!<br />

In additi<strong>on</strong> to the prominent role<br />

that <str<strong>on</strong>g>FCC</str<strong>on</strong>g>’s Civil Divisi<strong>on</strong> played in<br />

the c<strong>on</strong>structi<strong>on</strong> of the Diam<strong>on</strong>d<br />

<strong>Jubilee</strong> Cruise Terminal, other<br />

members of the OSCO C<strong>on</strong>structi<strong>on</strong><br />

Group c<strong>on</strong>tributed products,<br />

including: Ready-Mix C<strong>on</strong>crete &<br />

Precast C<strong>on</strong>crete <strong>on</strong> the building;<br />

as well as Precast Pipe and Rebar<br />

elsewhere <strong>on</strong> site.<br />

Precast C<strong>on</strong>crete<br />

The new Terminal was c<strong>on</strong>structed<br />

with a structural steel framework<br />

clad with mas<strong>on</strong>ry and precast<br />

panels. Stresc<strong>on</strong> Saint John was<br />

awarded the c<strong>on</strong>tract to supply and<br />

install 10,200 sq.ft. of architectural<br />

precast for the Saint John Cruise<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com<br />

Just wanted to send out a thank you<br />

for all the hard work and effort you<br />

and your teams have put into having the<br />

Terminal ready for today. It has been<br />

amazing to see it all come together in<br />

such a short time. The Port greatly<br />

appreciates what has been accomplished.<br />

Tyler O’Rourke P.Eng.<br />

Port Engineer, Saint John Port Authority<br />

•<br />

I just wanted to echo Tyler’s comments<br />

and pass al<strong>on</strong>g my thanks to each of you,<br />

not <strong>on</strong>ly from myself but also <strong>on</strong> behalf<br />

of the President and CEO. September<br />

5th was always a tough date to work<br />

towards, but it was critical that this not<br />

fall back for so many reas<strong>on</strong>s. The terminal<br />

looks fantastic, and you should all be<br />

very proud of your accomplishment.<br />

Andrew Dix<strong>on</strong>, CITT<br />

Sr. Vice President, Planning and Development<br />

& Acting President and CEO,<br />

Saint John Port Authority<br />

Terminal. The precast c<strong>on</strong>sisted of<br />

31 plinth panels, 6 large arches and<br />

3 small arches. Stresc<strong>on</strong> Quality<br />

C<strong>on</strong>trol department worked<br />

closely with <str<strong>on</strong>g>FCC</str<strong>on</strong>g>, Saint John Port<br />

Authority and Toss Architecture<br />

which resulted in a precast sample<br />

being approved for use <strong>on</strong> March<br />

13th. The approved sample<br />

c<strong>on</strong>sisted of two separate finishes<br />

and multiple pigments to achieve<br />

a blend between the architectural<br />

brick and reflective glass windows<br />

as seen <strong>on</strong> the building.<br />

Due to the building enclosure<br />

requirements, Stresc<strong>on</strong> engineering<br />

and Stresc<strong>on</strong> Atlantic devised<br />

c<strong>on</strong>necti<strong>on</strong>s that did not pierce<br />

the building exterior seal. All c<strong>on</strong>necti<strong>on</strong>s<br />

were located between<br />

the building exterior framing and<br />

the inside face of the precast.<br />

A successful precast fabricati<strong>on</strong><br />

was the result of Stresc<strong>on</strong>’s new<br />

batch plant being able to precisely<br />

batch repetitive mixes as well as<br />

Stresc<strong>on</strong>’s Quality C<strong>on</strong>trol department<br />

and shop pers<strong>on</strong>nel ensuring<br />

quality product was produced.<br />

Precast fabricati<strong>on</strong> began in late<br />

March and was completed by the<br />

end of May.<br />

Precast installati<strong>on</strong> c<strong>on</strong>sisted of 2<br />

phases, the first phase was to install<br />

the large and small arches in May<br />

and the sec<strong>on</strong>d phase to install the<br />

smaller plinth panels in July.<br />

Ready-Mix C<strong>on</strong>crete<br />

OSCO C<strong>on</strong>crete’s Stresc<strong>on</strong>-Saint<br />

John plant started supplying Ready<br />

Mix c<strong>on</strong>crete for this project in<br />

January 2012. The c<strong>on</strong>crete mixes<br />

used were of a normal variety, but<br />

the interior slabs utilized a c<strong>on</strong>crete<br />

mix which enabled it to be<br />

ground down and polished, leaving<br />

a terrazzo-look to the floors inside.<br />

c<strong>on</strong>tinued <strong>on</strong> next page...<br />

CONNECTIONS • Fall & Winter 2012 5

projects<br />

The exterior c<strong>on</strong>crete at the entrance<br />

incorporated an exposed aggregate mix<br />

chosen by the architect to blend in with<br />

the interior Polished c<strong>on</strong>crete look. In<br />

total, 2600 cubic metres of Ready-Mix<br />

was supplied over a period of 8 M<strong>on</strong>ths.<br />

Pipe<br />

Stresc<strong>on</strong>’s Pipe divisi<strong>on</strong> was also part of<br />

the Cruise Ship Terminal team, providing<br />

envir<strong>on</strong>mental<br />

products which<br />

included: four 750<br />

diameter catch<br />

basins; five 1050 diameter<br />

catch basins;<br />

<strong>on</strong>e standard 1050<br />

valve chamber; and four custom 1800<br />

diameter valve chambers with custom<br />

covers and custom valve chamber pads.<br />

www.sjport.com<br />

Rebar<br />

Ocean Steel’s Rebar divisi<strong>on</strong><br />

also played a role in this<br />

project, as a subc<strong>on</strong>tractor<br />

to Paul & Bruce Martin Limited.<br />

OSCO Rebar provided 36 T<strong>on</strong>s of rebar<br />

for five 175-T<strong>on</strong> bollards at the Diam<strong>on</strong>d<br />

<strong>Jubilee</strong> and L<strong>on</strong>g Wharf sites. Work <strong>on</strong><br />

the project began in July and the bollards<br />

were completed this fall.<br />

Miscellaneous Metals Divisi<strong>on</strong><br />

c<strong>on</strong>tributed by CHRIS BANKS, CET<br />

• Underground Material Handling<br />

Phase 1, Hoppers and Chutes c/w liner<br />

wear plates, Penobsquis, NB, PCS Potash,<br />

121.8 t<strong>on</strong>s of plate work.<br />

• New Transfer Bridge, Port aux<br />

Basques, NL, Brook C<strong>on</strong>structi<strong>on</strong>, 30.2<br />

t<strong>on</strong>s of misc. metals.<br />

• Extensi<strong>on</strong> to St. Andrews Wharf,<br />

St. Andrews, NB, GW Doucette C<strong>on</strong>structi<strong>on</strong>,<br />

20.2 t<strong>on</strong>s of struct. steel.<br />

• Craig Brook Bridge, Perth Andover,<br />

NB, E. Cummings C<strong>on</strong>tracting, 9.4 t<strong>on</strong>s of<br />

struct. steel.<br />

• Logging Bridge (21ft), Atholville, NB,<br />

AV Cell, 2.8 t<strong>on</strong>s of struct. steel.<br />

• Westmorland Substati<strong>on</strong>, Saint<br />

John, NB, Saint John Energy, 8.1 t<strong>on</strong>s of<br />

galvanized struct. steel.<br />

• Producti<strong>on</strong> Headframe Replacement<br />

Steel, Penobsquis, NB, PCS Potash<br />

(old site), 2.1 t<strong>on</strong>s of struct. steel.<br />

• House Beams, various locati<strong>on</strong>s in<br />

NB, General C<strong>on</strong>tractor, 7.2 t<strong>on</strong>s of struct.<br />

steel.<br />

6 CONNECTIONS • Fall & Winter 2012<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com

projects<br />

Around the Refinery<br />

On-Site With OSCO C<strong>on</strong>structi<strong>on</strong> Group Members at the Irving Oil Refinery<br />

Mid-C<strong>on</strong>tinental Crude:<br />

Ocean Steel<br />

c<strong>on</strong>tributed by MARIO LEBOUTHILLIER & BERNIE BLAKELY<br />

Cheap western crude prices are driving the North American<br />

oil industry to find creative ways to ship oil east where<br />

refineries are struggling to remain competitive.<br />

The Irving Oil refinery in Saint John, NB is working <strong>on</strong> their<br />

own soluti<strong>on</strong>. Canada’s largest oil refinery, Irving Oil has been<br />

bringing in crude from the west by rail to supply its 300,000<br />

barrel-per-day refinery in recent m<strong>on</strong>ths and is working <strong>on</strong><br />

inking l<strong>on</strong>g-term supply c<strong>on</strong>tracts for c<strong>on</strong>tinental crude.<br />

Ocean Steel’s Saint John, NB; Frederict<strong>on</strong>, NB; and C<strong>on</strong>klin,<br />

NY fabricati<strong>on</strong> plants have been working together to fabricate<br />

and install approximately 63 t<strong>on</strong>s of structural and miscellaneous<br />

steel for the Mid C<strong>on</strong>tinent Crude Offloading Project.<br />

The last porti<strong>on</strong>, comprising 302 pieces of handrails in various<br />

lengths, was delivered in mid-October. Irving Oil had some<br />

very urgent delivery requirements for this project, which<br />

required Ocean’s office, plant, and field employees to step<br />

up and work overtime hours, in order to meet the customer<br />

deadline.<br />

Marque C<strong>on</strong>structi<strong>on</strong><br />

c<strong>on</strong>tributed by PETER HIGSON<br />

In the last editi<strong>on</strong> of C<strong>on</strong>necti<strong>on</strong>s, we wrote about Marque’s<br />

involvement in the Mid-C<strong>on</strong>tinental Crude Project at the Irving<br />

Oil Refinery’s train car loading facility. The project required<br />

Marque to install thousands of feet of new cabling and cable<br />

tray. New motors and Variable Frequency Drive c<strong>on</strong>trollers<br />

were installed and commissi<strong>on</strong>ed. Thousands of feet of<br />

electric heat tracing was installed and is ready for operati<strong>on</strong>.<br />

New instrumentati<strong>on</strong> and c<strong>on</strong>trol systems have<br />

been placed in service.<br />

The project schedule required specific equipment becoming<br />

operati<strong>on</strong>al while other scope of work remained under c<strong>on</strong>structi<strong>on</strong><br />

in the same areas. This presented its own unique challenges,<br />

particularly with safety to all involved <strong>on</strong> site, as rail car<br />

traffic increased. As rail cars were shunted (moved into or out<br />

of positi<strong>on</strong>) worker access to the site was limited to n<strong>on</strong> train<br />

car areas. Marque employees needed to perform prefabricati<strong>on</strong><br />

work outside the area, in order to remain productive and <strong>on</strong><br />

schedule. At the time of this writing, Marque has just received<br />

the last work order for this project. The entire project will be<br />

completed within a few weeks, <strong>on</strong> budget and <strong>on</strong> schedule.<br />

ESJ Rail Spur Lines<br />

At the East Saint John Terminals, a major project called the ESJ<br />

Rail Spur Lines has transformed the face of the Irving property<br />

at the south-east corner of Courtenay Causeway and Bayside<br />

Drive into a brand new train car unloading facility. Spur lines are<br />

extensi<strong>on</strong>s from the main rail line. Irving Oil required this facility<br />

to become operati<strong>on</strong>al as so<strong>on</strong> as possible to take advantage<br />

of the increased availability of Mid-C<strong>on</strong>tinental Crude oil.<br />

Marque’s scope of work involved a total relocati<strong>on</strong> of the existing<br />

ESJ Terminal 12,470V electrical service. The new overhead<br />

cabling and hydro poles have been installed skirting the spur<br />

line unloading facility and are now c<strong>on</strong>nected to the newly<br />

installed underground service cabling. C<strong>on</strong>necti<strong>on</strong> and energizati<strong>on</strong><br />

of the new service involved major planning, permitting and<br />

scheduling with Saint John Energy, NB Dept of Public Safety, City<br />

c<strong>on</strong>tinued <strong>on</strong> next page...<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com<br />

CONNECTIONS • Fall & Winter 2012 7

projects<br />

of Saint John and <strong>on</strong>going ship traffic/operati<strong>on</strong>s at the ESJ Terminals.<br />

Marque employees endured inclement weather as well as<br />

a l<strong>on</strong>g, hard day and night as the final stages in the project were<br />

completed. The facility is now operati<strong>on</strong>al and Irving Oil operati<strong>on</strong>s<br />

will be receiving upwards of 40 rail cars per shunt. Marque’s<br />

scope of work will be <strong>on</strong>going, installing permanent lighting,<br />

c<strong>on</strong>trol systems and electric heat tracing. As was menti<strong>on</strong>ed in<br />

the Mid-C<strong>on</strong>tinental Crude project, the safety of Marque employees<br />

and all will be paramount as rail car traffic increased.<br />

Central Satellite Logic<br />

Manager Upgrade Project<br />

The annual Fall Turnaround (annual scheduled maintenance<br />

shutdown) at the IOR will start mid September. Marque is well<br />

into its pre-turnaround work <strong>on</strong> the Central Satellite Logic<br />

Manager Upgrade Project. The work in the Central Satellite,<br />

#3 Crude Unit and recently upgraded Visbreaker Unit involves<br />

installati<strong>on</strong> of thousands of feet of instrument cabling and cable<br />

tray as well as new instrument juncti<strong>on</strong> boxes, new instruments,<br />

and rework of pneumatic tubing. Marque has scheduled 8 days<br />

for final c<strong>on</strong>necti<strong>on</strong>s and commissi<strong>on</strong>ing of the equipment. This<br />

work will ensure the fail safe operati<strong>on</strong> of these units should an<br />

upset to daily operati<strong>on</strong>s occur. During the turnaround Marque<br />

will begin working <strong>on</strong> the F12601 Furnace Safety Upgrade Project<br />

located in the South Process Area. Although much of the<br />

scope of work will be performed post-turnaround, some installati<strong>on</strong><br />

such as cabling and cable tray must take place while the<br />

furnace is out of service as under normal operating c<strong>on</strong>diti<strong>on</strong>s it<br />

would be too hot and too dangerous to work <strong>on</strong>.<br />

Over the last several m<strong>on</strong>ths Marque has been successful in<br />

meeting the schedules for project completi<strong>on</strong> required by IOL.<br />

We would be remiss if we did not menti<strong>on</strong> the l<strong>on</strong>g hours and<br />

hard work performed by Marque employees, supervisi<strong>on</strong><br />

and IOL coordinati<strong>on</strong>s pers<strong>on</strong>nel.<br />

Many Thanks.<br />

www.irvingoil.com<br />

New East Campus Project Comes<br />

to Life at the Irving Oil Refinery<br />

c<strong>on</strong>tributed<br />

by<br />

ABBEY DUGUAY<br />

& DAN MAZEROLLE<br />

In the current ec<strong>on</strong>omic climate, small<br />

and large businesses alike must take the<br />

necessary steps and acti<strong>on</strong> to weather<br />

the storm. This is especially true for<br />

industries such as petroleum, where<br />

downturns in a specific market can have<br />

a debilitating effect <strong>on</strong> margins, profits<br />

and bottom lines.<br />

Irving Oil Limited, in resp<strong>on</strong>se to the<br />

challenges of the ec<strong>on</strong>omy, has targeted<br />

the reducti<strong>on</strong> of recurring costs to<br />

reduce overall expenditures. Four years<br />

ago, several groups working at the Refinery<br />

were relocated to a rental space<br />

in the Saint John city core. This was intended<br />

to be a temporary locati<strong>on</strong> until<br />

the completi<strong>on</strong> of the new Corporate<br />

Head Quarters <strong>on</strong> L<strong>on</strong>g Wharf. Once<br />

again the downturn in the ec<strong>on</strong>omy<br />

back in 2008 resulted in the new office<br />

structure being shelved. To allow the<br />

relocati<strong>on</strong> of pers<strong>on</strong>nel to a more permanent<br />

locati<strong>on</strong>, IOL made the decisi<strong>on</strong><br />

to c<strong>on</strong>struct a new office building <strong>on</strong><br />

Refinery property and c<strong>on</strong>tracted <str<strong>on</strong>g>FCC</str<strong>on</strong>g><br />

C<strong>on</strong>structi<strong>on</strong> to manage the project.<br />

The East Campus Engineering Facility<br />

is the latest and largest installment of a<br />

modular office c<strong>on</strong>cept at the Refinery.<br />

TOSS Soluti<strong>on</strong>s, the project Designers,<br />

developed a modular office approach<br />

to meet operati<strong>on</strong>al needs and align<br />

with the Refinery’s dynamic space<br />

requirements moving forward.<br />

The structure is composed<br />

of 18 office modules joined<br />

by two service modules. To<br />

add a twist to the project the<br />

Designers created three distinct<br />

secti<strong>on</strong>s, each offset from the<br />

other by 20 feet and 4 feet in elevati<strong>on</strong>.<br />

This allowed the structure to take advantage<br />

of the natural grade where the<br />

building is located, minimizing site work<br />

and foundati<strong>on</strong> depths.<br />

To support the new complex as well<br />

as the previous modular office directly<br />

south, new service infrastructure was<br />

installed for water and sewage as well<br />

as voice lines to Grandview Avenue. This<br />

new service will also provide for the<br />

new Guard House at the Gate 8 entry<br />

just north of the new building as well as<br />

future development to the west. A new<br />

8 inch fire line was also included for<br />

protecti<strong>on</strong> of all structures in the East<br />

Campus area.<br />

The exterior of the building has<br />

metal cladding to match the<br />

finish <strong>on</strong> surrounding structures.<br />

All building services are<br />

located in the three foot crawl<br />

space below each level, making<br />

installati<strong>on</strong> a difficult challenge.<br />

The project began in June 2012, with<br />

the first two modules arriving <strong>on</strong> site<br />

July 16th. Due to the scheduled Turnaround<br />

at the Refinery beginning mid<br />

September, IOL required the Project<br />

Soluti<strong>on</strong>s Group <strong>on</strong> site by September<br />

15th. The balance of pers<strong>on</strong>nel relocati<strong>on</strong>s<br />

would occur <strong>on</strong> October 15th and<br />

October 23rd. After much planning,<br />

8 CONNECTIONS • Fall & Winter 2012<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com

projects<br />

hard work and l<strong>on</strong>g hours, the design<br />

and c<strong>on</strong>structi<strong>on</strong> teams were able to<br />

complete the building <strong>on</strong> time to accommodate<br />

the aggressive schedule.<br />

Al<strong>on</strong>g with the East Campus Engineering<br />

Facility, another structure directly<br />

across Grandview Avenue (former Technico<br />

Building) was completely renovated<br />

to accommodate the Document<br />

Management Group. This group was<br />

relocated to the newly renovated office<br />

<strong>on</strong> September 8th, requiring many l<strong>on</strong>g<br />

hours by the c<strong>on</strong>structi<strong>on</strong> team.<br />

We are now in the final completi<strong>on</strong><br />

stage with pers<strong>on</strong>nel relocated, grass in<br />

place, trees planted, picnic tables ready<br />

and final yard lighting arriving. <str<strong>on</strong>g>FCC</str<strong>on</strong>g> is<br />

proud to have been involved with the<br />

development and c<strong>on</strong>structi<strong>on</strong> of the<br />

East Campus Project and look forward<br />

to assisting with future developments.<br />

OSCO Group <str<strong>on</strong>g>Team</str<strong>on</strong>g>work<br />

In additi<strong>on</strong> to the Project Management<br />

skills of <str<strong>on</strong>g>FCC</str<strong>on</strong>g>’s Civil Divisi<strong>on</strong>, other OSCO<br />

Group members involved in this project<br />

included: OSCO C<strong>on</strong>crete’s Stresc<strong>on</strong>-SJ<br />

plant, who supplied ready-mix for all<br />

foundati<strong>on</strong> work, and OSCO Rebar, who<br />

supplied and installed reinforcing steel<br />

for foundati<strong>on</strong>s.<br />

<str<strong>on</strong>g>FCC</str<strong>on</strong>g>’S Electrical divisi<strong>on</strong> provided the<br />

electrical <strong>on</strong> this project. In July, R<strong>on</strong><br />

Rathje and his team began the renovati<strong>on</strong><br />

at both buildings. With the September<br />

completi<strong>on</strong> date already in sight,<br />

his team wasted no time beginning the<br />

electrical interior demoliti<strong>on</strong> of the existing<br />

3,000 square foot Grandview Ave.<br />

building. This building was brought back<br />

to life with new suspended direct/indirect<br />

lighting throughout, new 200amp<br />

208volt distributi<strong>on</strong> panel and new<br />

decorative surface mounted c<strong>on</strong>vector<br />

heaters as well a<br />

sound masking system, network cabling,<br />

network cabinet and UPS back-up.<br />

Work <strong>on</strong> the East Campus building<br />

involved the installati<strong>on</strong> of new suspended<br />

direct/indirect interior lighting<br />

throughout, a 600amp 208volt service<br />

entrance, fire alarm system, sound<br />

masking system and new decorative<br />

surface mounted c<strong>on</strong>vector heaters as<br />

well as new floor communicati<strong>on</strong> rack<br />

and UPS back-up.<br />

In parallel with the installati<strong>on</strong> of the<br />

electrical equipment, over 28,000ft of<br />

Cat6 data cabling and 15,000ft Cat5e<br />

voice cabling was installed in the 3ft<br />

crawl space for the new workstati<strong>on</strong>s.<br />

An enormous amount of coordinati<strong>on</strong><br />

was needed to complete this project <strong>on</strong><br />

schedule. <str<strong>on</strong>g>FCC</str<strong>on</strong>g> electrical team supervisor<br />

R<strong>on</strong> Rathje and his lead hands<br />

Denny Lowe and Ben Kilpatrick as well<br />

as the other electricians, worked l<strong>on</strong>g<br />

days and multiple weekends to successfully<br />

complete this project <strong>on</strong> schedule.<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com<br />

CONNECTIONS • Fall & Winter 2012 9

product profile: architectural precast<br />

Product Profile:<br />

Architectural<br />

Precast<br />

No single c<strong>on</strong>structi<strong>on</strong> method lends itself<br />

to a more dazzling array of architectural<br />

treatments than precast prestressed<br />

c<strong>on</strong>crete. Rich aggregates, decorative<br />

shapes, reveals and attractive st<strong>on</strong>e and<br />

mas<strong>on</strong>ry veneers can all be employed to<br />

express a wealth of architectural detail.<br />

c<strong>on</strong>tributed by:<br />

KINNON BONA<br />

It<br />

is difficult to imagine an architectural<br />

style that cannot be<br />

expressed with this material. Precast<br />

c<strong>on</strong>crete is not <strong>on</strong>ly compatible with all<br />

structural systems, it can be designed<br />

to harm<strong>on</strong>ize with and complement all<br />

other materials. Precast has the design<br />

flexibility of shape, colour and size in<br />

virtually any finish or texture. Designs<br />

can range from historical to c<strong>on</strong>temporary<br />

and project a str<strong>on</strong>g distinctive<br />

image. The use of architectural precast<br />

c<strong>on</strong>crete projects a quality appearance<br />

and offers years of maintenance free<br />

operati<strong>on</strong>.<br />

Quality precast c<strong>on</strong>crete, produced and<br />

erected under stringent quality c<strong>on</strong>trols,<br />

effectively resists corrosi<strong>on</strong> and damage<br />

and retains its good looks for years with<br />

no significant staining, discolorati<strong>on</strong> or<br />

surface decay. Required maintenance is<br />

low - saving plenty of m<strong>on</strong>ey and inc<strong>on</strong>venience<br />

over the life of the structure.<br />

ADVANTAGES:<br />

VERSATILITY<br />

With Stresc<strong>on</strong> Limited’s architectural<br />

precast c<strong>on</strong>crete wall panels, the possibilities<br />

are endless. Adding a cornice, a<br />

bullnose, reveals, or various colour and<br />

texture opti<strong>on</strong>s, provides design flexibility<br />

to create unlimited looks for buildings.<br />

SPEED OF CONSTRUCTION<br />

The so<strong>on</strong>er a building is completed, the<br />

10 CONNECTIONS • Fall & Winter 2012<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com

product profile: architectural precast<br />

The Trillium<br />

so<strong>on</strong>er it can earn income for the owner.<br />

When using architectural precast c<strong>on</strong>crete,<br />

work can c<strong>on</strong>tinue <strong>on</strong> the job site<br />

throughout the year with minimal delays<br />

caused by weather or material schedules<br />

The building can be clad in a fracti<strong>on</strong><br />

of the time compared to other cladding<br />

materials - saving time and m<strong>on</strong>ey.<br />

HIGH QUALITY CONTROL<br />

Precast/Prestressed Architectural wall<br />

panels are manufactured in a climate<br />

c<strong>on</strong>trolled CSA/PCI certified plant under<br />

the highest quality c<strong>on</strong>trol standards.<br />

Our quality c<strong>on</strong>trol department ensures<br />

that every piece meets the customers<br />

specificati<strong>on</strong>s as well as the highest<br />

industry standards.<br />

ECONOMICAL<br />

There are many different opti<strong>on</strong>s for<br />

making architectural precast c<strong>on</strong>crete<br />

the ec<strong>on</strong>omical cladding choice for your<br />

building. By c<strong>on</strong>sulting with Stresc<strong>on</strong><br />

Limited in the early c<strong>on</strong>ceptual stages of<br />

design, we can help create an efficient<br />

and cost effective building while keeping<br />

with the design requirements. Making<br />

ec<strong>on</strong>omical choices such as textures, aggregates,<br />

panel-size and shapes, colours<br />

and panel repetiti<strong>on</strong> will help with the<br />

overall cost. The speed of c<strong>on</strong>structi<strong>on</strong><br />

also improves the cost by enclosing your<br />

building quicker.<br />

ENERGY EFFICIENCY<br />

Building green energy-efficient buildings<br />

are becoming a high priority in the<br />

c<strong>on</strong>structi<strong>on</strong> industry and using architectural<br />

precast c<strong>on</strong>crete panels will help<br />

you obtain that goal. The high thermal<br />

mass of c<strong>on</strong>crete keeps the fluctuati<strong>on</strong>s<br />

of temperature outside, while c<strong>on</strong>trolling<br />

the temperature inside. Precast c<strong>on</strong>crete<br />

can also help gain points towards LEED<br />

certificati<strong>on</strong> by producing little waste<br />

in our plants, using local materials and<br />

creating a low maintenance and durable<br />

cladding system.<br />

Precast c<strong>on</strong>crete offers many different<br />

colours and textures, from a basic form<br />

grey through to a stained formliner finish.<br />

Careful selecti<strong>on</strong> of finishes can turn<br />

a basic building design into an award<br />

winning masterpiece. It is not uncomm<strong>on</strong><br />

to have precast elements with<br />

more than <strong>on</strong>e finish. Some of the most<br />

comm<strong>on</strong> finishes are listed below.<br />

FINISHES:<br />

EXPOSED AGGREGATE<br />

Natural st<strong>on</strong>e used as an aggregate in<br />

c<strong>on</strong>crete can be a beautiful thing, and<br />

an exposed aggregate finish can accomplish<br />

that. When the architectural<br />

c<strong>on</strong>crete panel is set in the casting bed,<br />

a chemical retarder is put down so that<br />

the c<strong>on</strong>crete w<strong>on</strong>’t set at the face of<br />

the panel. This leaves the aggregated<br />

exposed with a very natural finish.<br />

HEAVY SANDBLAST<br />

A heavy sandblast will take away most of<br />

the c<strong>on</strong>crete, exposing more of the aggregate,<br />

giving the panel a natural look<br />

with a very c<strong>on</strong>sistent colour.<br />

MEDIUM SANDBLAST<br />

A medium sandblast has the same<br />

process as the heavy sandblast but it<br />

exposes less aggregate and shows more<br />

c<strong>on</strong>crete and sand. This allows for the<br />

colour in the sand al<strong>on</strong>g with the colour<br />

in the aggregate to be showcased.<br />

LIGHT SANDBLAST<br />

After the architectural c<strong>on</strong>crete panel<br />

is set and taken out of the bed, it is<br />

sandblasted. A light sandblast gives the<br />

architectural c<strong>on</strong>crete panel a completely<br />

different look. By exposing very<br />

little of the aggregate and more sand<br />

and c<strong>on</strong>crete, it gives the panel a very<br />

smooth finish, showcasing the colour<br />

of the sand. While this finish can be very<br />

attractive, it is more difficult to achieve a<br />

c<strong>on</strong>sistent colour throughout the panel.<br />

RECENT PROJECTS:<br />

Halifax, NS is currently experiencing the<br />

biggest apartment building boom in<br />

decades. Not surprisingly, many developers<br />

are turning to Stresc<strong>on</strong>’s precast<br />

c<strong>on</strong>crete for their projects, such as the<br />

high-profile examples below.<br />

The Vincent Coleman<br />

Sitting next to <strong>on</strong>e of the major railways<br />

into Halifax, it’s fitting that this upscale<br />

apartment building is named after a train<br />

dispatcher and <strong>on</strong>e of the many heroes<br />

from the Halifax explosi<strong>on</strong> – Vincent<br />

Coleman.<br />

This 9-storey, 124 unit building was<br />

c<strong>on</strong>structed in 2010-2011 <strong>on</strong> an open site<br />

next to the St. Andrew’s Community Centre<br />

<strong>on</strong> Bayer’s Road. It now acts as <strong>on</strong>e of<br />

the first and most welcoming views when<br />

entering Halifax from the highway.<br />

c<strong>on</strong>tinued <strong>on</strong> next page...<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com<br />

CONNECTIONS • Fall & Winter 2012 11

product profile: architectural precast<br />

Royal View Apartments<br />

the grainery<br />

The Vincent Coleman<br />

King’s Wharf Buildings A and B<br />

12 CONNECTIONS • Fall & Winter 2012<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com

product profile: architectural precast<br />

C<strong>on</strong>crete was introduced by the ancient<br />

Romans and was used as a primary material<br />

in Roman architecture. Although<br />

a very old material, c<strong>on</strong>crete is still very<br />

relevant to modern architecture. The<br />

Vincent Coleman exhibits a lot of Roman<br />

style references, such as arches,<br />

cornices and columns, to create a very<br />

Romanesque looking building - a classic<br />

look that never goes out of style.<br />

In order to achieve this look, the architect<br />

worked with Stresc<strong>on</strong> Limited to<br />

provide the precast c<strong>on</strong>crete - a product<br />

known for its quality and c<strong>on</strong>sistency<br />

as well as design flexibility needed<br />

to create the architectural features.<br />

Stresc<strong>on</strong> provided 262 (51,636 sq.ft.) architectural<br />

precast c<strong>on</strong>crete wall panels,<br />

with 96 of those pieces being decorative<br />

cornice panels.<br />

King’s Wharf<br />

Buildings A and B<br />

The King’s Wharf development is located<br />

<strong>on</strong> the waterfr<strong>on</strong>t of Dartmouth,<br />

Nova Scotia. Sitting directly <strong>on</strong> the edge<br />

of Halifax Harbour this neighborhood<br />

is quickly becoming <strong>on</strong>e of the most<br />

cutting-edge and sought after neighborhoods<br />

in the city. The development<br />

is designed to have all amenities located<br />

in <strong>on</strong>e c<strong>on</strong>venient area, making a new<br />

definiti<strong>on</strong> for high-end urban living.<br />

There will be a marina, boutiques, a<br />

boardwalk al<strong>on</strong>g the water, as well as 4<br />

new luxury apartment buildings.<br />

Buildings A and B, located <strong>on</strong> the eastern<br />

side of the property are known as<br />

“The Anchorage” and “The Keels<strong>on</strong>”.<br />

These buildings are sitting al<strong>on</strong>g the<br />

Shubenacadie Canal and Halifax Harbour<br />

and are going to be the first buildings<br />

to be completed and occupied.<br />

Using architectural precast c<strong>on</strong>crete <strong>on</strong><br />

the exterior of these buildings allowed<br />

the blending of the c<strong>on</strong>temporary and<br />

modern themes of King’s Wharf. It also<br />

gave them an efficient and sustainable<br />

exterior cladding system.<br />

For “The Anchorage (Building ‘A’)<br />

Stresc<strong>on</strong> provided 126 – 6” solid architectural<br />

precast pieces. Included in<br />

those, were radius panels that were installed<br />

<strong>on</strong> the fr<strong>on</strong>t face of the building.<br />

For “The Keels<strong>on</strong>” (Building ‘B’) Stresc<strong>on</strong><br />

provided 56 – 6” solid architectural<br />

precast pieces. Both buildings used<br />

white cement, al<strong>on</strong>g with local sand and<br />

aggregate providing a clean and modern<br />

look for the new development.<br />

Royal View Apartments<br />

Located in an up-and-coming area<br />

of Halifax, Mount Royale, Royal View<br />

apartments will be ready for occupancy<br />

by the end of 2012. Located between<br />

the new entrance to Bayers Lake and<br />

Dunbrack St., Mount Royale has been<br />

developing quickly over the past few<br />

years, with high-end homes and apartments.<br />

The market for high quality rental<br />

accommodati<strong>on</strong>s has been very competitive<br />

in the Halifax area and they are<br />

in high demand. The name Royal View<br />

Apartments is very fitting, c<strong>on</strong>sidering<br />

the building is located <strong>on</strong> the highest<br />

peak in Halifax, giving the occupants <strong>on</strong>e<br />

of the best views in the city.<br />

In order to make this apartment stand<br />

out am<strong>on</strong>g the rest, the architect and<br />

developer chose architectural precast<br />

for the exterior of the building. Working<br />

with Stresc<strong>on</strong>, the developer and the<br />

architect came up with a final design<br />

which included 164 pieces of solid 6”<br />

wall panels and 38 pieces of solid 6”<br />

cornice panels with a buff medium<br />

sandblast finish and light sandblast<br />

bands. The bands around the window<br />

as well as the cornice feature add a very<br />

distinguished look to the precast wall<br />

panels. These features, combined with<br />

the access to all amenities, the spacious<br />

and modern apartment features and the<br />

emerging surrounding area, gives this<br />

building a new level of luxury.<br />

The Grainery<br />

State-of-the-art and sustainable designs<br />

are quickly becoming the most essential<br />

requirements when designing an<br />

urban, upscale apartment building. The<br />

Grainery, located in the South end of<br />

Halifax, has c<strong>on</strong>tinued with this trend. It<br />

is within walking distance of downtown<br />

Halifax, and close to all amenities. The<br />

building is the first privately developed,<br />

LEED registered, multi-unit residential<br />

development in Atlantic Canada.<br />

To achieve the LEED points necessary<br />

for that distincti<strong>on</strong>, the developer<br />

and the architect chose to incorporate<br />

miscellaneous architectural precast <strong>on</strong><br />

the exterior of the building. Precast gave<br />

them points both for using local materials<br />

that produce very little amounts of<br />

waste, and for being a product with<br />

such a l<strong>on</strong>g life-span.<br />

Altogether, Stresc<strong>on</strong> Limited and<br />

Borcherdt C<strong>on</strong>crete provided 184 - precast<br />

architectural panels and 435 - Miscellaneous<br />

precast comp<strong>on</strong>ents including<br />

accent squares and balc<strong>on</strong>y covers.<br />

The light sandst<strong>on</strong>e colour grounds the<br />

building and blends very nicely with the<br />

brick exterior.<br />

The Trillium<br />

Named after a flower that is found in<br />

Halifax’s Public Gardens, The Trillium<br />

was completed in early 2012. A 19-storey,<br />

84 unit residential and commercial<br />

building, The Trillium brings new meaning<br />

to upscale urban living in Halifax.<br />

With beautiful views from all sides and<br />

a locati<strong>on</strong> within walking distance of<br />

any amenity, this building has brought<br />

new life to <strong>on</strong>e of Halifax’s most popular<br />

areas.<br />

The Trillium was designed and built<br />

by W.M. Fares. During the c<strong>on</strong>ceptual<br />

stage of the design, W.M. Fares turned<br />

to Roy Willworth, <strong>on</strong>e of Halifax’s most<br />

renowned architects (in associati<strong>on</strong> with<br />

DRKR Architects) and an avid supporter<br />

of the precast c<strong>on</strong>crete industry, to help<br />

with the design of the building.<br />

W.M. Fares approached Stresc<strong>on</strong> about<br />

using Architectural precast c<strong>on</strong>crete<br />

panels as an exterior cladding <strong>on</strong> the<br />

upper floors. Stresc<strong>on</strong> worked closely<br />

with the architects during the design<br />

phase to ensure that the most efficient<br />

design was achieved, without taking<br />

anything away from the appearance<br />

of the building. In the end, the precast<br />

blended perfectly with the glass and<br />

brick used <strong>on</strong> the rest of the building. In<br />

all, Stresc<strong>on</strong> provided 152 solid architectural<br />

panels and 23 cornice panels.<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com<br />

CONNECTIONS • Fall & Winter 2012 13

customer profile:<br />

Customer Profile:<br />

Fares Inc.<br />

Fares Inc. has been transforming addresses<br />

into destinati<strong>on</strong>s for over 20<br />

years and has a reputati<strong>on</strong> for c<strong>on</strong>sistently<br />

developing and managing sophisticated,<br />

high-end real estate projects.<br />

Fares’ current project, King’s Wharf in<br />

Dartmouth, is a $500 milli<strong>on</strong>, mixeduse<br />

residential community, designed to<br />

feature: 1,300 residential units; a 200<br />

room hotel and c<strong>on</strong>venti<strong>on</strong> centre; and<br />

230,000 square feet of retail, dining,<br />

entertainment, office and commercial<br />

space, <strong>on</strong> the Halifax Harbour.<br />

Set in what used to be the Dartmouth<br />

shipyards, developer Francis Fares’ plan<br />

was to bring a new upscale development<br />

to the coastal town of Dartmouth.<br />

Francis first came up with the idea for<br />

this project in 2006. It was <strong>on</strong>e of those<br />

incredible opportunities that have never<br />

been seen before, and Francis brought<br />

a visi<strong>on</strong> to the project that was about<br />

youth, vigor, excitement and a modern<br />

internati<strong>on</strong>al way of living in our city.<br />

“We’re building a community where people<br />

of all ages and groups can work, live<br />

and enjoy the harbour. The future has<br />

arrived for Dartmouth, it is so exciting.<br />

The potential for ec<strong>on</strong>omic development<br />

in downtown Dartmouth is incredible.”<br />

Changing the Skyline of Halifax Harbour<br />

As the developer of Dartmouth, Nova<br />

Scotia’s most high-profile development<br />

in years, Fares Inc. is garnering a lot of<br />

attenti<strong>on</strong>. The King’s Wharf project is not<br />

<strong>on</strong>ly creating an entire “community” <strong>on</strong> a<br />

piece of previously under utilized waterfr<strong>on</strong>t<br />

property, but it is changing both the<br />

shoreline and the skyline of the city.<br />

Headquartered in Dartmouth, Nova Scotia,<br />

Fares Inc. is lead by Francis Fares. Raised<br />

in Leban<strong>on</strong>; Francis Fares immigrated to<br />

Canada in the late 1980’s, where he has<br />

lived for the past 23 years. He holds a<br />

Masters Degree in Business Administrati<strong>on</strong><br />

from Saint Mary’s University and currently<br />

sits <strong>on</strong> the Board of Directors for the Halifax<br />

Chamber of Commerce.<br />

Working with key partners, Fares Inc’s<br />

fully integrated team manages all critical<br />

comp<strong>on</strong>ents required to undertake<br />

large-scale, mixed-use developments<br />

including financing, design, c<strong>on</strong>structi<strong>on</strong>,<br />

marketing and sales.<br />

The King’s Wharf site has southern exposure<br />

to the harbour entrance and great<br />

views, but the special, unique feature of<br />

this property is the water. Because the<br />

property included 20 acres of pre-c<strong>on</strong>federati<strong>on</strong><br />

water, regulati<strong>on</strong>s allow Fares to<br />

build right out <strong>on</strong>to the water - something<br />

which couldn’t be d<strong>on</strong>e anyplace else.<br />

“We envisi<strong>on</strong> this development as a<br />

mixed use community where people can<br />

work and play. They can walk down and<br />

buy their fresh produce, they can go to<br />

the baker, do their banking, or be close<br />

to health care facilities. It is like building<br />

a community <strong>on</strong>e piece at a time. It will<br />

have all the services of a small town. It’s<br />

a sustainable community. It’s residential,<br />

office, retail and instituti<strong>on</strong>al all put<br />

together in the right proporti<strong>on</strong>s. It will<br />

be alive in the day time and alive in the<br />

night time. The quality of life is all there,<br />

everything that you need, will be built<br />

right in.”<br />

King’s Wharf has been designed to<br />

experience, first and foremost the view,<br />

14 CONNECTIONS • Fall & Winter 2012<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com

projects<br />

but the idea was also to bring the view<br />

and the oceanfr<strong>on</strong>t feel inside. “There<br />

is a lot of interest in being able to have<br />

your own boat outside your door. Kings<br />

Wharf will have its own marina, including<br />

a high speed water taxi.”<br />

“It will be quite a unique live, work, play<br />

experience that we d<strong>on</strong>’t have right now.<br />

I can’t imagine any<strong>on</strong>e who wouldn’t<br />

want to live at Kings Wharf. This certainly<br />

will be an ic<strong>on</strong>ic development.<br />

We’ve designed an ic<strong>on</strong>ic tower that is<br />

33 stories high <strong>on</strong> Halifax Harbour with<br />

360 degrees of views, nothing but water<br />

from all angles.”<br />

This development shows c<strong>on</strong>fidence in<br />

Greater Halifax, which is very positive<br />

in terms of l<strong>on</strong>g term stability. The time<br />

is now right for a development like this<br />

<strong>on</strong>e. It’s a win, win for everybody. It will<br />

be a win, win for the residents in the<br />

new project. It will be a win, win for the<br />

businesses in the project. .<br />

There are a lot of post cards out there<br />

that will have to be reprinted, because<br />

there will be a new view of Halifax Harbour<br />

around the world and it will include<br />

and feature the tower at Kings Wharf.<br />

<str<strong>on</strong>g>Team</str<strong>on</strong>g>ing up with Stresc<strong>on</strong><br />

Kings Wharf Buildings A and B are<br />

Stresc<strong>on</strong>’s first jobs with Fares Inc.. For<br />

Fares, the reas<strong>on</strong>s for going with Precast<br />

was speed of erecti<strong>on</strong> “They were able<br />

to enclose their building quicker allowing<br />

them to get started <strong>on</strong> the interior<br />

work”; and aesthetics “They were<br />

looking for a sleek modern appearance<br />

which precast was able to achieve”<br />

According to Fares, they have received<br />

many positive comments <strong>on</strong> the design<br />

of their first two buildings.<br />

<str<strong>on</strong>g>Team</str<strong>on</strong>g>ing up with AllStar Rebar<br />

Zi<strong>on</strong>ville Bridge<br />

c<strong>on</strong>tributed by: Mario LeBouthillier & Bernie Blakely<br />

The Saint John, NB plant has become very efficient over the last few years in<br />

fabricating plate girders, which are becoming increasingly comm<strong>on</strong> in commercial<br />

building frames as architects become more creative. This development has<br />

allowed us to revisit the local bridge market where recently we were awarded the<br />

Penniac Stream bridge, and the McAdam Railway Line bridge (see C<strong>on</strong>necti<strong>on</strong>s<br />

Spring & Summer 2011).<br />

Our latest additi<strong>on</strong> to this list is the Zi<strong>on</strong>ville Road Route 8 Underpass, located a<br />

few kilometers North of Frederict<strong>on</strong>, NB for the company Dunbar C<strong>on</strong>structi<strong>on</strong><br />

Ltd. Ocean Steel’s Saint John shop supplied four main girders with shop attached<br />

shear studs. The main girders were six feet deep and 148 feet l<strong>on</strong>g after field<br />

splicing.<br />

In additi<strong>on</strong> to the main girders, Ocean also fabricated six abutment diaphragm<br />

plate girders, intermediate WT K-frames, and WT lateral braces required to complete<br />

the structure. The total weight was 121 t<strong>on</strong>s.<br />

Detailing started in December 2011 with fabricati<strong>on</strong> starting near the end of February<br />

2012. The steel was delivered mid August 2012.<br />

AllStar Rebar, Kings Wharf buildings are<br />

not their first work with the developer. In<br />

additi<strong>on</strong> to supplying over 1000 t<strong>on</strong>s of<br />

rebar for Buildings A & B combined, they<br />

had previously supplied rebar for both a<br />

14-unit apartment building and a 27-unit<br />

c<strong>on</strong>do building <strong>on</strong> Crown Drive in Halifax.<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com<br />

CONNECTIONS • Fall & Winter 2012 15

projects<br />

225 Binney topping off<br />

c<strong>on</strong>tributed by: JASON PRESLEY<br />

Ocean Steel is currently wrapping up work <strong>on</strong> the 225 Binney<br />

building in Cambridge, MA for Alexandria Real Estate Equities<br />

Inc., in cooperati<strong>on</strong> with the c<strong>on</strong>tractor C<strong>on</strong>sigli C<strong>on</strong>structi<strong>on</strong> Inc..<br />

The Binney Street Building will be an office space for client Biogen<br />

Idec Inc., and is being built as a combinati<strong>on</strong> of new structure and<br />

the retrofit of existing structures as part of an overall Binney Street<br />

rehabilitati<strong>on</strong> currently underway in Cambridge.<br />

Ocean Steel began work <strong>on</strong> the project in October of 2011,<br />

including detailing, c<strong>on</strong>sulting and fabricati<strong>on</strong> (which began in<br />

January 2012) and Steel Erecti<strong>on</strong> (which commenced June 7, 2012).<br />

Ocean Steel supplied and installed close to 1600 t<strong>on</strong>s of structural<br />

steel, 800 t<strong>on</strong>s of joists and 4200 square feet of deck including all<br />

accessories. Erecti<strong>on</strong> of the main new building ended in mid October<br />

2012, with some retrofit inside of an existing building and the<br />

tower crane infill steel work to follow.<br />

This project was OSCO’s first BIM (Building Informati<strong>on</strong> Modeling)<br />

project. What makes this process unique is that all work was<br />

completed 100% in our steel model and the model was then issued<br />

to the EOR for approval of the pieces within the model for use in<br />

fabricati<strong>on</strong>. No shop drawings or erecti<strong>on</strong> plans were required.<br />

Since there are joists <strong>on</strong> this 8 floor project OSCO received and imported<br />

model files from the joist manufacturer into weekly model<br />

uploads. Not <strong>on</strong>ly were the models used in the steel fabricati<strong>on</strong> approval<br />

process but also in the coordinati<strong>on</strong> process for clash detecti<strong>on</strong><br />

with all of the various trades who running their ducts, piping or<br />

electrical comp<strong>on</strong>ents around and through our steel and joists.<br />

On September 10, 2012 C<strong>on</strong>sigli C<strong>on</strong>structi<strong>on</strong> Co., Inc. held<br />

the customary topping off Cerem<strong>on</strong>y where a white painted beam<br />

signed by all of the workers was hoisted into positi<strong>on</strong> in fr<strong>on</strong>t of a<br />

large crowd of <strong>on</strong>lookers including upper management from Alexandria<br />

Real Estate Equities, Inc. and the Mayor. The new building is<br />

expected to be ready for it’s tenants in late 2013.<br />

16 CONNECTIONS • Fall & Winter 2012<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com

projects<br />

351<br />

Water<br />

Street<br />

Stresc<strong>on</strong><br />

Supplies Precast<br />

Parking Garage<br />

for Downtown<br />

Newfoundland<br />

Development<br />

c<strong>on</strong>tributed by: J.P. LaCHANCE<br />

www.threefifty<strong>on</strong>e.ca<br />

fall of 2011 marked the official ground-breaking of 351<br />

The - the first new office building in downtown St. John’s<br />

Newfoundland in more than 25 years. Developed by East Port<br />

Properties Limited and designed by PHB Group, 351 marks the<br />

beginning of a new age in the city’s waterfr<strong>on</strong>t development. “We<br />

are pleased to offer downtown St. John’s a building that incorporates<br />

the latest sustainable practices, for a truly healthy, efficient<br />

and interesting working envir<strong>on</strong>ment.” says East Port Properties<br />

President John W. Lindsay.<br />

While architecturally designed to encompass the l<strong>on</strong>g-standing<br />

heritage of Water Street charm, 351 will also incorporate the best<br />

of today’s newest technologies. It is the first sea water heated and<br />

cooled building in Newfoundland and Labrador. A Canada Green<br />

Building Council LEED® registered building, 351 has been designed<br />

to achieve Gold level certificati<strong>on</strong>.<br />

This stunning new development includes an innovative six-storey,<br />

165,000-square-foot office tower above prime retail and commercial<br />

space, and a 446-car garage.<br />

Stresc<strong>on</strong> Limited’s Precast Divisi<strong>on</strong> supplied the parking garage.<br />

Producti<strong>on</strong> <strong>on</strong> the precast comp<strong>on</strong>ents started <strong>on</strong> September<br />

29th, 2011 and was completed <strong>on</strong> April 11th, 2012.<br />

In total, Stresc<strong>on</strong> supplied 1061 precast pieces and 22 steel Deltabeams.<br />

The precast pieces supplied included: 351 double tees; 85<br />

columns; 61 inverted tee beams; 1 rectangular beam; 42 shearwalls;<br />

49 load-bearing spandrels; 48 n<strong>on</strong> load-bearing spandrels;<br />

54 stairs & landings; 101 load-bearing walls; 9 curved spandrels;<br />

and 260 Strescore planks.<br />

This project was truly a team effort. The inverted tee beams and<br />

Strescore planks were produced at the Stresc<strong>on</strong> Saint John Plant; the<br />

stairs & landings were produced at the Borcherdt Plant; and the rest<br />

of the precast pieces were produced at the Stresc<strong>on</strong> Bedford Plant.<br />

Precast installati<strong>on</strong> and erecti<strong>on</strong> was d<strong>on</strong>e by American Steel &<br />

Precast Erectors and began <strong>on</strong> April 2nd. Erecti<strong>on</strong> finished <strong>on</strong> June<br />

22nd and is now open for cars. Completi<strong>on</strong><br />

of the 351 project is<br />

set for 2013.<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com<br />

CONNECTIONS • Fall & Winter 2012 17

projects<br />

new Broad Institute Project at 75 Ames Street in<br />

The Cambridge MA is located in the heart of Kendall<br />

Square. Formally affiliated with the Massachusetts Institute<br />

of Technology as well as Harvard University and its affiliated<br />

hospitals, the Broad Institute is a genomic medicine research<br />

center. The institute is named after Eli and Edythe Broad, and<br />

allows collaborative, cross-disciplinary research between<br />

physicians, geneticists, and biologists.<br />

www.broadinstitute.org<br />

www.suffolkc<strong>on</strong>structi<strong>on</strong><br />

.com<br />

The new facility will c<strong>on</strong>sist of a 15-story building<br />

accounting for more than 375,000 sq ft.<br />

Of this, 250,000 square feet of research and<br />

administrative space will be provided, through<br />

a series of c<strong>on</strong>nector bridges, to Broad’s existing<br />

headquarters at 7 Cambridge Center.<br />

The development will also include ground<br />

level retail space.<br />

STRUCTURAL STEEL<br />

In early January 2012, Ocean Steel was awarded the c<strong>on</strong>tract<br />

by Suffolk C<strong>on</strong>structi<strong>on</strong> Company Inc. of Danvers, MA<br />

to supply and erect: 5400 t<strong>on</strong>s of Structural Steel and Plate<br />

Work; 350,000 square feet of decking; and 3700 square feet<br />

of grating. The expansi<strong>on</strong> is being built adjacent to and over<br />

an existing parking garage.<br />

One of the more complex features of the new structure is<br />

the use of 12 super columns, each measuring 80 feet l<strong>on</strong>g,<br />

being carefully placed down through 6 existing floors of the<br />

parking garage. Built in halves weighing in at approximately<br />

20 t<strong>on</strong>s per piece, the super columns support the porti<strong>on</strong> of<br />

the new structure that overhangs the existing parking garage<br />

at the 6th floor. This floor is framed with 19 plate girders, the<br />

heaviest secti<strong>on</strong>s being 60 feet l<strong>on</strong>g and weighing 57 t<strong>on</strong>s.<br />

Aside from site logistics, another major challenge was the<br />

aggressive schedule. This was overcome by having all three<br />

of our fabricati<strong>on</strong> plants (C<strong>on</strong>klin, NY; Saint John, NB, &<br />

18 CONNECTIONS • Fall & Winter 2012<br />

www.oscoc<strong>on</strong>structi<strong>on</strong>group.com

projects<br />