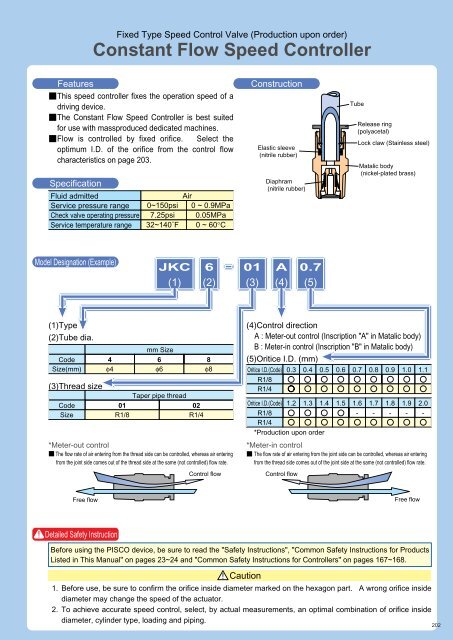

Constant Flow Speed Controller

Constant Flow Speed Controller

Constant Flow Speed Controller

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

How to select Orifice Inside DiameterWhen controlling the cylinder speed with a constant flow speed controller, determine the orifice inside diameter as follows:(1)Using the following formula, obtain the air flow rate necessary for cylinder operation at desired speed.(Formula for calculation of air flow rate)D 2 ×LQ=4.7 × 10 -5 × ×tP+1.031.03Q= air flow rate (N /min)D=cylinder I.D. (mm)L=cylinder stroke (mm)t=time for one-way stroke (sec)P=working pressure (kgf/cm 2 )(2)Using the graph of control flow (flow characteristics) on page 203, locate the intersecting point of flow rate and working pressure. Select2 or 3 samples whose orifice I.D. provides characteristcs closest to the above. Then choose the optimal model from actual measurements.(Example,1)D (Inside diam.)=25mmL (Stroke)=60mmt (Time)=0.1 secP (Pressure)=5kgf/cm 2 (A)Calculate the necessary air flow, using the formula of (1):Q=100N /min (B)Find the inside diameter of the fixed orifice from Fig1.Inside diameter of fixed orifice=φ1.45mm (C)The range of selection is : φ1.6mm~φ1.4mm*The formula of (1)does not take load on cylinder andair consumption in piping into consideration.Fig.2 shows a graphic representation of the calculation formula of (1).By use of the graph, the air flow rate can be obtained quite easily.It is necessary, however, to obtain the cylinder speed beforehand.(Formula for calculation of cylinder speed)Control flowLV=t0V=cylinder speed (mm/sec)L=cylinder stroke (mm)t=time for one-way stroke (sec)<strong>Flow</strong> rate(N /min)200150(B)100501 2 3 4 5Pressure (kgf/cm 2 ) (C)[Fig.1]6 7φ1.9φ1.8φ1.7φ1.6φ1.5φ1.45 (A)φ1.4φ1.3φ1.2φ1.1φ1φ0.9φ0.8φ0.7φ0.6φ0.5φ0.40.3Fized oritice I.D.(mm)203(Example 2)How to Use the Graph (Example)Cylinder I.D.=25mm (a)Cylinder stroke=60mmTime for one-way stroke=0.1sec (Cylinder speed:600mm/sec) (c)Working pressure=5kgf/cm 2 (b)Air flow rate=100N /minDetermine the air flow, then the inside diameter of the <strong>Constant</strong> <strong>Flow</strong> <strong>Controller</strong> can be selected.

[Fig.2] Graph for calculation of required air flow of Air CylinderCylinder <strong>Speed</strong> (mm/sec)10205020050010002000(c)5000φ200φ180φ16010000φ125φ100φ80φ75φ50φ40φ30cylinder I.D. (mm)(a) φ25φ20φ15φ10φ6105 4(b)3210.020.1110100(d)100010000100000Working air pressure (kgf/cm 2 )Air flow rate (N /min)204

Control Series <strong>Constant</strong> <strong>Flow</strong> <strong>Speed</strong> <strong>Controller</strong>CADJKCStraightφPφDCModelJKC 4-01JKC 6-01JKC 6-02JKC 8-01JKC 8-02Tube dia.φD468RR1/8R1/8R1/4R1/8R1/4A B L φP C H881181123.52427.5303319.519.521.5262710101114111218.510101414Mass(g)9.58.5171720.5unit:mmFree flow Eff. a.(mm 2 )3.1 ~ 3.53.9 ~ 4.66.7 ~ 7.33.4 ~ 4.56.4 ~ 71BALHROrifice I.D.(mm)Control flow Eff. a.(mm 2 )φ0.3 φ0.4 φ0.5 φ0.6 φ0.7 φ0.8 φ0.9 φ1.0 φ1.10.06 0.11 0.16 0.2 0.3 0.4 0.5 0.65 0.8Orifice I.D.(mm)φ1.2 φ1.3 φ1.4 φ1.5 φ1.6 φ1.7 φ1.8 φ1.9 φ2.0Control flow Eff. a.(mm 2 )0.9 1.1 1.25 1.5 1.8 2 2.3 2.55 2.8CADJKLElbowECφDφPModelJKL 4-01JKL 6-01JKL 6-02JKL 8-01JKL 8-02Tube dia.φD468RR1/8R1/8R1/4R1/8R1/4A B L φP C E H881181126 26.525.5 27.528.5 28.528.5 31.531.5 32.510.51315151718.517202310121414Mass(g)11.513.51918.522.5unit:mmFree flow Eff. a.(mm 2 )3.1 ~ 3.53.9 ~ 4.66.7 ~ 7.33.4 ~ 4.56.4 ~ 71BLARHOrifice I.D.(mm)Control flow Eff. a.(mm 2 )φ0.3 φ0.4 φ0.5 φ0.6 φ0.7 φ0.8 φ0.9 φ1.0 φ1.10.06 0.11 0.16 0.2 0.3 0.4 0.5 0.65 0.8Orifice I.D.(mm)φ1.2 φ1.3 φ1.4 φ1.5 φ1.6 φ1.7 φ1.8 φ1.9 φ2.0Control flow Eff. a.(mm 2 )0.9 1.1 1.25 1.5 1.8 2 2.3 2.55 2.8<strong>Flow</strong> characteristicsControl flowφ2φ1.9Free flow<strong>Flow</strong> rate (N /min)200150100φ1.8φ1.7φ1.6φ1.5φ1.4φ1.3φ1.2Orifice I. D. (mm)<strong>Flow</strong> rate (N /min)6005004003002001006-02,8-026-01,8-014-010 1 2 3 4 5 6 7Pressure (kgf/cm 2 )2055001 2 3 4 5 6 7Pressure (kgf/cm 2 )φ1.1φ1φ0.9φ0.8φ0.7φ0.6φ0.5φ0.4φ0.3