Issue 1, 2005 - Repak

Issue 1, 2005 - Repak

Issue 1, 2005 - Repak

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

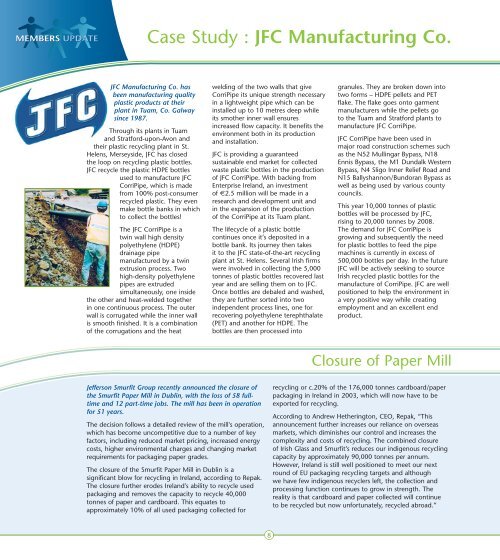

MEMBERS UPDATECase Study : JFC Manufacturing Co.JFC Manufacturing Co. hasbeen manufacturing qualityplastic products at theirplant in Tuam, Co. Galwaysince 1987.Through its plants in Tuamand Stratford-upon-Avon andtheir plastic recycling plant in St.Helens, Merseyside, JFC has closedthe loop on recycling plastic bottles.JFC recycle the plastic HDPE bottlesused to manufacture JFCCorriPipe, which is madefrom 100% post-consumerrecycled plastic. They evenmake bottle banks in whichto collect the bottles!The JFC CorriPipe is atwin wall high densitypolyethylene (HDPE)drainage pipemanufactured by a twinextrusion process. Twohigh-density polyethylenepipes are extrudedsimultaneously, one insidethe other and heat-welded togetherin one continuous process. The outerwall is corrugated while the inner wallis smooth finished. It is a combinationof the corrugations and the heatwelding of the two walls that giveCorriPipe its unique strength necessaryin a lightweight pipe which can beinstalled up to 10 metres deep whileits smother inner wall ensuresincreased flow capacity. It benefits theenvironment both in its productionand installation.JFC is providing a guaranteedsustainable end market for collectedwaste plastic bottles in the productionof JFC CorriPipe. With backing fromEnterprise Ireland, an investmentof €2.5 million will be made in aresearch and development unit andin the expansion of the productionof the CorriPipe at its Tuam plant.The lifecycle of a plastic bottlecontinues once it’s deposited in abottle bank. Its journey then takesit to the JFC state-of-the-art recyclingplant at St. Helens. Several Irish firmswere involved in collecting the 5,000tonnes of plastic bottles recovered lastyear and are selling them on to JFC.Once bottles are debaled and washed,they are further sorted into twoindependent process lines, one forrecovering polyethylene terephthalate(PET) and another for HDPE. Thebottles are then processed intogranules. They are broken down intotwo forms – HDPE pellets and PETflake. The flake goes onto garmentmanufacturers while the pellets goto the Tuam and Stratford plants tomanufacture JFC CorriPipe.JFC CorriPipe have been used inmajor road construction schemes suchas the N52 Mullingar Bypass, N18Ennis Bypass, the M1 Dundalk WesternBypass, N4 Sligo Inner Relief Road andN15 Ballyshannon/Bundoran Bypass aswell as being used by various countycouncils.This year 10,000 tonnes of plasticbottles will be processed by JFC,rising to 20,000 tonnes by 2008.The demand for JFC CorriPipe isgrowing and subsequently the needfor plastic bottles to feed the pipemachines is currently in excess of500,000 bottles per day. In the futureJFC will be actively seeking to sourceIrish recycled plastic bottles for themanufacture of CorriPipe. JFC are wellpositioned to help the environment ina very positive way while creatingemployment and an excellent endproduct.Closure of Paper MillJefferson Smurfit Group recently announced the closure ofthe Smurfit Paper Mill in Dublin, with the loss of 58 fulltimeand 12 part-time jobs. The mill has been in operationfor 51 years.The decision follows a detailed review of the mill's operation,which has become uncompetitive due to a number of keyfactors, including reduced market pricing, increased energycosts, higher environmental charges and changing marketrequirements for packaging paper grades.The closure of the Smurfit Paper Mill in Dublin is asignificant blow for recycling in Ireland, according to <strong>Repak</strong>.The closure further erodes Ireland's ability to recycle usedpackaging and removes the capacity to recycle 40,000tonnes of paper and cardboard. This equates toapproximately 10% of all used packaging collected forrecycling or c.20% of the 176,000 tonnes cardboard/paperpackaging in Ireland in 2003, which will now have to beexported for recycling.According to Andrew Hetherington, CEO, <strong>Repak</strong>, “Thisannouncement further increases our reliance on overseasmarkets, which diminishes our control and increases thecomplexity and costs of recycling. The combined closureof Irish Glass and Smurfit’s reduces our indigenous recyclingcapacity by approximately 90,000 tonnes per annum.However, Ireland is still well positioned to meet our nextround of EU packaging recycling targets and althoughwe have few indigenous recyclers left, the collection andprocessing function continues to grow in strength. Thereality is that cardboard and paper collected will continueto be recycled but now unfortunately, recycled abroad.”8