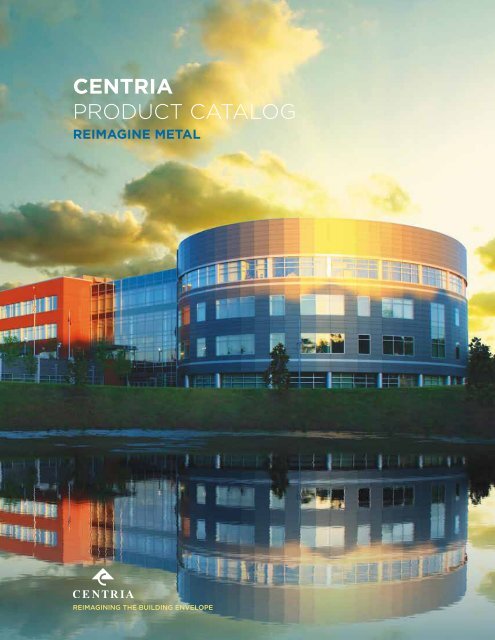

CENTRIA PRODUCT CATALOG

CENTRIA PRODUCT CATALOG

CENTRIA PRODUCT CATALOG

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Contents4 Formawall® Dimension Series®6 Formawall® Dimension Series® Product Details8 Formawall® Graphix Series10 Formawall® Graphix Series Product Details11 Formavue Integrated Window System12 Smart-R Wall SolutionReimagine PerformanceReimagine AestheticsReimagine SustainabilityReimagine Value14 Formawall® Integrated Options16 Versawall® & Versapanel® Wall & Roof Panel Systems18 FormaBond® & FormaBond® IIMetal Composite Wall Systems20 MetalWrap Series Insulated Composite Backup Panel22 Profile Series Concept Series®24 Profile Series IW Series25 Profile Series Exposed Fastener Panels25 Profile Series Liner Panels26 Profile Series Concept Series® Product Details27 Profile Series IW Series Product Details28 Profile Series Exposed Fastener PanelsProduct Details28 Profile Series Liner Panels Product Details29 EcoScreen® Perforated Screenwall30 Profile Series Design Options31 Quietwall & Firewall Systems32 SRS® Structural Standing Seam Roof Systems34 Ventilation Systems35 Coating Systems & Substrates36 Prismatic Series, Sundance Series & Duracast37 Kolorshift Series & Allusion38 Product Finish Availability39 Project Index<strong>CENTRIA</strong>’s collection of metal wall and roof systemsoffers the highest levels of performance, aesthetics,sustainability and value — and are designed to helparchitects, building owners and contractorsReimagine Metal.We offer one of the widest product ranges of anymetal wall and roof manufacturer — many thatincorporate our innovative Advanced Thermal andMoisture Protection (ATMP®) technology for thehighest levels of performance. Our products alsooffer beautiful aesthetics with a wide range of panellengths, widths, reveals and textures—creating clean,crisp lines, shadows and reliefs. Many panels alsooffer seamless integration with our wide selectionof accessories. Manufactured using recycledcontent, and with our recycle, reuse, repurposeprogram for our foam insulated products, <strong>CENTRIA</strong>demonstrates our commitment to sustainabilityand helps ensure the built environment doesn’tharm the natural one. Finally, our products provideoutstanding value, both at the jobsite and over thelong term with reduced maintenance costs and longlife-cycles.From a support standpoint, our national andinternational sales network provides a consultativeapproach that leads to innovative project solutions.Their expertise helps architects and other membersof the building team achieve excellence with:• A commitment to exceeding expectations andcustomer satisfaction• An in-house design and development groupto assist in selecting the best options whenconsidering metal wall and roofs• Unique project details and specifications• Access to our trained installer network for qualityinstallations• Thermal efficiency and moisture control• Consulting services for substrates, coatingsand coils• Comprehensive in-house coil coating services

North Carolina National Guard HeadquartersRaleigh, NCO’Brien Atkins Architecture

FORMAWALL ®The Complete Wall SystemDevon Boathouseand Finish Line TowerOklahoma City, OKElliot and AssociatesFormawall Dimension Seriesreimagines metal as a wallsystem that provides thermalefficiency and moisturecontrol in a single panelizedcomponent.Compared to traditional multicomponentwall construction,which typically requires five ormore separate components, suchas a rainscreen, an air barrier,exterior gypsum sheathing,fiberglass insulation and a vaporbarrier, Formawall DimensionSeries’ single panel has a factoryfoamed-in-place core, minimizinginsulation gaps. Combined with<strong>CENTRIA</strong>’s ATMP® technology,Formawall Dimension Seriesprovides thermal performance andvalue that is second to none.With a wide range of lengths,thicknesses, reveals and profiles,along with integrated wallcomponents like windows,louvers and sunshades, FormawallDimension Series provides virtuallyunlimited design possibilities.Features & Benefits• May be installed horizontally or vertically• Available in a variety of interchangeable reveals, thicknessand profile configurations• Concealed clips, fasteners and sealants plus vertical drygaskets or insulated metal vertical joints provide a clean,uninterrupted appearance• Factory foamed-in-place core to ensure no insulation gapswithin the panel• Panels integrate with <strong>CENTRIA</strong> Formavue windowsystems and are compatible with most other glass walland window systems• Pressure-equalized horizontal joinery to help preventwater infiltration• Optional Pressure Equalized Vertical Seal Plate• Extruded aluminum or factory-formed metal trim available• Panels can be easily curved• Mitered panels permit clean, sharp corners, beam andcolumn wraps• Trimless ends eliminate overlapping trim at panel enddetails• Thermal break between face and liner offers efficient panelR-values• High strength panels offer increased span capability andsave support costs with less framing required• Lightweight — as low as 2.7 psf — easy to handle and installand minimizes foundation load• Striated, variable striated, smooth, embossed and precastlikesurface treatments available• Integrated louvers and sunshades available4 Formawall

FORMAWALLDIMENSION SERIES ®2-1/2" [64mm]Horizontal FlatFor product details refer to pages 6-7.DescriptionFactory foam-insulated architecturalwall panel systemSUBSTRATE & CORE• Standard — 22/26 gage G-90 galvanizedsteel face and liner with HCFC-freepolyurethane or polyisocyanurate foaminsulatedcore• Optional gages available — consult<strong>CENTRIA</strong>• Optional stainless steel face sheet, 304stainless steel, 22 or 20 gage, smooth,embossed or striated*• Optional .040" [1mm] Aluminum Face(2" [51mm] thick only), flat embossed orsmooth striated*JOINERY• Horizontal oriented panel — Rainscreen,pressure-equalized and drainablejoinery, 1/2" [13mm] nom.joint — standard• Vertical oriented panel — Doubletongue-and-groove, 1/8" [3mm] nom.joint — standard• Optional Pressure Equalized VerticalSeal Plate• Optional Formawall IMV insulatedmetal vertical joint 5/8" [16mm] joint —standardSURFACE FINISH• Exterior–Non-directional embossed flator striated– Smooth flat or striated• Interior– Non-directional embossed plankedor flat– Smooth plankedCOATINGS & COLORS• Advanced Fluorofinish PVDF, metallicand mica color coatings in standard &custom colors• Duragard & Duragard Plus premium highbuild architectural coatings• Duracast® — a natural appearingtextured finish• Versacor® Ultra PremiumMulti-Layered Coating System• Kolorshift Iridescent Coating Systemm• AllusionPANEL WIDTH• Flat panels available from 10" [254mm]to 40" [1016mm]Consult <strong>CENTRIA</strong> for profiled panelinformation.PANEL LENGTH• Smooth — 16' [4.88m] max.• Embossed striated — 37' [11.28m] max.• Embossed — 37' [11.28m] max.• Smooth striated — 20' [6.10m] max.• Duracast — 28' [8.53m] max.• Stainless — 16' [4.88m] max.• Aluminum — 12' 6" [3.81m] max.PANEL THICKNESS/DEPTHOF REVEAL• 2" [51mm] with 1-3/16" [30mm]deep reveal — standard• 2.5" [63.5mm] with 1-3/16"[30mm] reveal• 3" [76mm] with 2-3/16" [56mm]deep reveal• 3"-T [76mm] with 1-3/16" [30mm]deep reveal“R” VALUE• 2" [51mm] panel with 1/2" [13mm]reveal — R14• 2" [51mm] DS-59 panel with 1/2" [13mm]reveal — R10• 2" [51mm] DS-60 panel with 1/2" [13mm]reveal — R10• 2.5" [63.5mm] panel with 1/2" [13mm]reveal — R17• 2.5" [63.5mm] DS-59 panel with 1/2"[13mm] reveal — R13• 2.5" [63.5mm] DS-60 panel with 1/2"[13mm] reveal — R13• 3" [76mm] panel with 1/2" [13mm]reveal — R21• 3"-T [76mm] panel with 1/2" [13mm]reveal — R22• 3"-T [76mm] DS-59 panel with 1/2"[13mm] reveal — R16• 3"-T [76mm] DS-60 panel with 1/2"[13mm] reveal — R16R-Values are based on ASTM C1363 testing.Air films are included.All data shown for flat panels only.Patent No.: US 6.253.511; 6.627.128;6.968.659; 8.261.494 Canada 2.351.846*Length restrictions apply, please consult<strong>CENTRIA</strong>FORMAWALLDIMENSION SERIESFWDSVS.TRADITIONALMULTI-COMPONENT WALL1 component required 7 components requiredTRADITIONALStud insulatedmulti-componentwall construction1 installer requiredWorks for all climatesSuperiorthermal efficiencyTotal air& moisture controlContains no moldfood sourcesIntegrated windows,louvers and sunshadesProven systematizedlong-term performanceVS.VS.VS.VS.VS.VS.Up to 3 installersrequiredClimate specificdesign requiredThermally inefficientQuestionable air& moisture controlMay containmold food sourcesNo integratedcomponentsUnknown — dependanton installation quality<strong>CENTRIA</strong>performance.comFormawall5

FORMAWALL DIMENSION SERIES Product Details675342" [51mm]Horizontal FlatDS59 2" [51mm]Horizontal Profile12The Complete Wall System1 Pressure-equalized horizontal joint with concealedsealant protects against water penetration2 Variable reveal sizes, 1/2" [13mm] to 6" [152mm]34567Concealed clips and fasteners provide a sleek exteriorappearance with proven long-term performanceHigh performance coatings offer long-term coverage,minimal maintenance and excellent color selection foryour building’s exteriorDurable metal skins provide impact resistance, strengthfor increased span capability and a built-in vapor barrieron the interior linerInsulating foam core, factory foamed-in-place, providesa thermally efficient exterior wall in either 2" [51mm],2-1/2" [64mm], or 3" [76mm] thicknessUnique Insulated Metal Vertical joint (IMV)BUILDING CODE APPROVALSFire Tests:• Tunnel Test, ASTM E84;a. Flame Spread 25 max.b. Smoke Developed 450 max.• UL Room Corner Test, UL 1715• Factory Mutual Approval: FM 4880• Factory Mutual Approval: FM 4881• SwRI: Multistory Fire Test, NFPA 285(ISMA)• ASTM D2015; BTU Content Test• ASTM D1929; Ignition Properties• UL Fire Wall Designs: 1 hr, 2 hr, 3 hr, U017, U617,U645, U605Special Approvals:• Dade County (Missile Impact Resistance)2-1/2" [64mm]Horizontal Flat3"-T [76mm]Horizontal Flat3" [76mm]Horizontal FlatDS59 2-1/2" [64mm]Horizontal ProfileDS59 3"-T [76mm]Horizontal Profile3" [76mm]Vertical FlatConsult <strong>CENTRIA</strong> for test reports.For more information about<strong>CENTRIA</strong>’s high performance wall system,watch our video, The Rainscreen Principleof Performance.6 Formawall

FORMAWALL DIMENSION SERIES Product DetailsDS60 2" [51mm]Horizontal Profile2" [51mm]Vertical FlatDS59 2" [51mm]Vertical ProfileDS60 2" [51mm]Vertical ProfileDS60 2-1/2" [64mm]Horizontal Profile2-1/2" [64mm]Vertical FlatDS59 2-1/2" [64mm]Vertical ProfileDS60 2-1/2" [64mm]Vertical ProfileDS60 3"-T [76mm]Horizontal Profile3"-T [76mm]Vertical FlatDS59 3"-T [76mm]Vertical ProfileDS60 3"-T [76mm]Vertical ProfileWolfe Center for Performing ArtsBowling Green State UniversityBowling Green, OHSnohetta/The Collaborative

North Seattle Community CollegeSeattle, WASchacht Aslani Architects

FORMAWALLGRAPHIX SERIES 2" (51mm) Horizontal FlatFormawall Graphix Series wall system provides outstanding performance in a single panelizedcomponent. Graphix Series reimagines innovative aesthetics and value and takes them to the next levelby making a single panel look like 12 smaller ones—and by offering the ability to choose how the panellength is segmented. This segmented construction makes distinctive designs both easy and economical.For product details refer to page 10.Features & Benefits• Graphix Series panels can be segmented as frequentlyas every 12" [305mm] and can be installed bothvertically and horizontally• Distinguish your design further by adding horizontalpanel to panel reveals of varying widths — from 1/2"[13mm] to 6" [152mm]• Customization continues as you select panel finisheswith enough options that your Graphix Series designmay never be duplicated• <strong>CENTRIA</strong> offers advanced coating systems thatprovide outstanding durability and corrosionresistance — available in over 70 standard colors,including micas and metallics, and unlimitedcustom colors• Formawall Graphix Series is a single-component wallsystem — a steel face and liner, using foamed-inplaceCFC-free foam insulation. Panels are joined with<strong>CENTRIA</strong>’s proven pressure equalized vented anddry-sealed joinery. The result is the most advancedthermal and moisture protection available• Combined with Formawall’s integrated componentsincluding windows, louvers and sunshades, it’s all youneed to build the complete wall in any climate• Optional Pressure Equalized Vertical Seal PlateDescriptionSUBSTRATE & CORE• Standard —22/26 gage G-90galvanized steel faceand liner with HCFCfreepolyurethane orpolyisocyanuratefoam-insulated core• Optional gagesavailable — consult<strong>CENTRIA</strong>• Optional .040"[1mm] Aluminumface (2" [51mm] thickonly), embossed andsmoothJOINERY• Horizontal oriented panel — Rainscreen, pressureequalizedand drainable joinery, 1/2" [13mm] nom.joint — standard• Vertical oriented panel — Double tongue-and-groove,1/8" [3mm] nom. joint — standard• Segmented joint — 5/8" x 3/4" [16mm x 19mm] deepembossment with factory applied black gasket,standard– Max. segments per panel — 12– Min. length of segment — 1' [305mm]• Formawall IMV insulated metal vertical joint 5/8"[16mm] joint — standardSURFACE FINISH• Exterior– Non-directional embossed– Smooth flat• Interior– Non-directional embossed, planked or flat– Smooth plankedCOATINGS AND COLORS• Advanced Fluorofinish PVDF, metallic, and mica colorcoating systems are available in standard and customcolors• Duragard® & Duragard® Plus premium high buildarchitectural coatings• Duracast® a natural appearing textured finish• Versacor® Ultra Premium Multi-LayeredCoating System• Kolorshift Iridescent Coating SystemPANEL WIDTH• Available from 10" [254mm] to 40" [1016mm]PANEL LENGTH (Steel Face)• 20' [6.10m] max.PANEL LENGTH (Aluminum Face)• Embossed, Flat — Overall Max. Length — 12'6" [3.81m]- Max. Length of Segment — 11'6" [3.51m]- Min. Length of Segment — 12" [305mm]- Max. Number of Segments — 12• Smooth, Flat — Overall Max. Length — 12'6" [3.81m]- Max. Length of Segment — 4' [1.22m]- Min. Length of Segment — 12" [305mm]- Max. Number of Segments — 12PANEL THICKNESS• 2" [51mm] standard• 2-1/2" [64mm] (Steel face)• 3"-T [76mm] standard (Steel face)“R” VALUE• 2" [51mm] panel with 1/2" [13mm] reveal — R14• 2-1/2" [63.5mm] panel with 1/2" [13mm] reveal — R17• 3"-T [76mm] panel with 1/2" [13mm] reveal — R22R-Values are based on ASTM C1363 testing.Air films are included.Patent No.: 7.895.807; 7.678.219<strong>CENTRIA</strong>performance.comFormawall9

FORMAWALL GRAPHIX SERIES Product Details1243567891234High performance coatings offer longtermperformance, minimal maintenanceand excellent color selection for yourbuilding’s exteriorInsulating foam core, factory foamedin-place,provides a thermally efficientexterior wall in either 2" [51mm] or3" [76mm] thicknessConcealed clips and fasteners provide asleek exterior appearance with provenlong-term performanceDurable metal skins provide impactresistance, strength for increased spancapability and a built-in vapor barrier56789Gasketed Joint or InsulatedMetal Vertical (IMV) Joint (optional)Placement of segments arespecified by designerOptional reveals of varying widthsSegmented joints are treated to matchactual jointVented, pressure-equalized anddrainable joinery with concealedsealant prohibits water penetration2" (51mm) Horizontal FlatRunning Bond Option2" (51mm) Vertical FlatGrid Option10 Formawall

FORMAWALLFORMAVUE Formavue window systems reimagine integration and are designed to provide a high performance, thermallyefficient window/panel interface with Formawall Dimension Series and Formawall Graphix Series panels.The Formavue window system offers integrated head, sill and jamb details that feature large thermal breaksaligned with the panel insulation, as well as additional insulation in the head of the window frame for one of themost efficient systems on the market today.SystemFV 100Window DescriptionsVertical Panels with Spandrel SupportsStrip Window applications and PunchedWindows with single lite and stacked glassoptions. Full and vertical structural glazedmullions.IntegratesWith2"FormawallVerticalor 2"VersawallpanelsExteriorSightlines3" [76mm]FV 600 Formavue WindowFV 200Horizontal Panels with Spandrel SupportsStrip Window applications and PunchedWindows with single lite and stacked glassoptions. Full and vertical structural glazedmullions.2" & 3"panels3" [76mm]1FV 300Horizontal Panels with Steel or AluminumThru-Tube Supports Strip Windowapplications and Punched Windows withsingle lite and stacked glass options. Fulland vertical structural glazed mullions.2" & 3"panels3" [76mm]FV 400Horizontal Panels with Steel or AluminumThru-Tube Supports Strip Windowapplications and Punched Windows withsingle lite and stacked glass options. Fulland vertical structural glazed mullions.Exterior pressure bar glazing with snap-oncovers. Unique integral gutter at head isstandard.2" & 3"panels2-1/2" [64mm]32FV 500FV 600FV 650Horizontal Panels with Spandrel Supportsfor Punched Windows Horizontal Panelswith Thru-Tube Supports for StripWindows, Shop-assembled frames forfaster installation. Single lite and stackedglass options, full mullions.Horizontal Panels with Spandrel or Thru-Tube Support Systems, Punched or StripWindows, Shop-assembled frames forfaster installation. Single lite, stacked glassor ribbon windows. Full and structuralsilicone glazed mullions. Seamlesslyintegrates with FWDS 3"-T only and FWGS3"-T only.Horizontal Panels with Spandrel or Thru-Tube Support Systems, Punched or StripWindows, Shop-assembled frames forfaster installation. Single lite, stacked glassor ribbon windows. Full and structuralsilicone glazed mullions. Integrates withFWDS and FWGS 2-1/2" only.2" & 3"panels3"-Tpanels2-1/2"panels3" [76mm]3" [76mm]3" [76mm]123Window system eliminates receptorextrusions, provides easier andfaster jobsite coordination, and issystem tested to ensure superiorweather resistanceInside glazing options allow easieraccess for installation or glassreplacement; R-value up to 3.5Advanced, thermally-improveddesign features a thermal barrierthat minimizes through-metalconductivity, while maintainingstructural integrity tested CRFvalue of 65All Formavue window systems are designed to accept 1" [25mm] insulating glass.FV 100-FV 500 integrate with 2" [51mm] and 3" [76mm] Formawall Dimensionand Graphix Series.<strong>CENTRIA</strong>performance.comFormawall11

FORMAWALLSMART-R WALL SOLUTION<strong>CENTRIA</strong>’s Smart-R Wall Solution offers the ultimate combination of aesthetics, sustainability and value, alongwith the best metal wall thermal performance on the market today. This superior thermal efficiency is achievedthrough a combination of innovative components and integrated solutions, such as wall panels, windows,louvers and sunshades.Families, Inc.Jonesboro, ARCahoon Steiling Studio ArchitectureThe Smart-R Wall Solution incorporates <strong>CENTRIA</strong>’sAdvanced Thermal and Moisture Protection (ATMP®)technology by utilizing factory foamed-in-place insulatedcomposite metal panels, pressure-equalized vertical andhorizontal joinery and integrated components specificallyengineered to work together to maintain a high levelof thermal and moisture protection. The system alsospecifically addresses air infiltration through the use ofshop and field-applied concealed sealants that will notdegrade over time.The aesthetics of the system feature a myriad of optionsin color, texture, profile and shape. Consistent sight linesare maintained without the use of additional receptorswhen integrating system components such as Formawallpanels and Formavue windows.Finally, the Smart-R Wall Solution is a sustainable choice,providing a high performance thermal envelope byminimizing the amount of materials used to build a wallwhile reducing scrap generated at the jobsite.Features & BenefitsDesign• Systems approach to high-performancearchitectural cladding• Seamless integration of panels, windows, louvers andsunshades provides sleek sightlines at componentjoinery intersections• All-metal joinery provides unrivaled architectural foampanel aesthetics• Design flexibility with 2.5" [64mm] and 3"-T [76mm]thick Formawall Dimension Series DS-59 and DS-60profiles and Formawall Graphix Series panelsPerformance• The 2.5" [64mm] FWDS panels and FV 650 windowplatform along with the 3"-T [76mm] FWDS panelsand FV 600 window platform offer enhancedthermal performance• A combination of concealed shop and field appliedsealants as well as the PE Seal plate specifically addresscritical air and water seals by providing consistency andredundancy as well as a degree of post inspection.• Shop-assembled windows reduce the risk of air andwater failures by simplifying the installation processSustainability• Integrated wall system reduces the amount ofmaterial used• Engineered composite foam panels, integratedaccessories and factory-assembled windows reducejobsite waste• High-performance wall system improves the overall air,water and thermal performance12 Formawall

Smart-R Wall Components1Formawall IMV insulatedmetal vertical joint• Offers a 4-sided metaljoint option• Added aesthetic flexibility• Added insulation at thevertical joint• Also available withpressure-equalized (PE)seal plate2 2.5" [64mm] and 3"-T[76mm] FormawallDimension Series insulatedmetal panels• Available with all popularFormawall profiles• Seamlessly integrateswith louvers andsunshades• 2.5" [64 mm] panelsintegrate with FV 650windows and 3"-T [76mm] panels integratewith FV 600 windows• Pressure-equalized,thermally maximizedhorizontal joinery• 2.5” [64 mm] – R17 and3”-T [76 mm] – R22 perASTME C 13633 FV 600 and FV 650Formavue windows• Shop-assembled,integrated punchedor strip window system• Available on studs orthru-tube supports• Seamlessly integrateswith 2.5" [64mm] and3"-T [76mm] Formawall• Enhanced thermalperformance• R3.5*4* 1" IGU with soft coat Low-Eand argon gas2.5" [64 mm] and3"-T [76 mm] FormawallGraphix Series insulatedmetal panels• Aesthetic flexibility• Reduced chance of airand water infiltration• Installation savings23Smart-R Wall14Performance OptionFor 3"-T, FV 600 AND IMVFormawall PE Seal Plate*• Multiple lines of defenseagainst water infiltration• Vented, pressure-equalizeddrain channel minimizes theforce that may drive waterthrough the wall system• An inspectable seal on theinterior after the panels areinstalledPatent No.: US 8.261.499*Available only with 3" [76 mm] panels andFV 600 windows. Contact <strong>CENTRIA</strong> for availability.<strong>CENTRIA</strong>performance.comFormawall13

FORMAWALLINTEGRATED OPTIONS<strong>CENTRIA</strong>’s performance, aesthetics, sustainability and value extend beyond the wall panel — we offer a completewall system with integration options that include windows, sunshades and louvers; finishes like Duracast®, stainlesssteel and aluminum; design options like variable striations; and performance options like Formawall DimensionSeries PE for two lines of defense against water intrusion.Integrated OptionsFORMAVUE WINDOWSSeven distinct styles of Formavue windowsintegrate seamlessly with Dimension Series panelsand accommodate a variety of fenestrations andconstruction types.C/S SUNSHADES<strong>CENTRIA</strong> and Construction Specialties, Inc. (C/SGroup) join forces to provide a wide selection ofsunshades, engineered for seamless and thermallyisolated integration with Formavue windows andDimension Series panels.C/S LOUVERS<strong>CENTRIA</strong> and C/S Group also provide a full lineof fixed, drainable and storm-resistant louversengineered for seamless integration withDimension Series panels.KALWALL® TRANSLUCENT WINDOWS<strong>CENTRIA</strong> and Kalwall Corporation haveco-designed this Formawall DimensionSeries Integrated Translucent WindowSystem. Designed to install easily with<strong>CENTRIA</strong> 2", 2-1/2", 3" or 3"-T FormawallDimension Series panels, these lightweightand strong window systems combine thebeauty and good sense of diffused, naturalinterior lighting with the functional qualitiesof high insulation, shatterproof constructionand low maintenance.14 Formawall

finish optionsDURACAST® TEXTURED FINISH SYSTEMDimension Series panels coated with <strong>CENTRIA</strong>Duracast finish, which uses a silica aggregate,provides a rugged, natural look. Duracastis available in eight natural earthtones andcomes with an exclusive 20-year warranty.STAINLESS STEELChoice of:• No. 4 — A brushed finish• Embossed, smooth or striatedAluminum• 0.040" [1mm] face• Available on 2" [51mm] FormawallDimension Series and Graphix Series• Non-directional embossed flat or smoothstriated• Lengths up to 12'6" [3.81m]Design optionsVARIABLE STRIATIONS• Striation bands are 6" [152mm] wide• A minimum 1" [25mm] smooth bandbetween striation bands• Striations can run outto both edges• Striations can be as far from the face edgeas desired in 1/4" [6mm] incrementsAesthetic OptionsVariable REVEALSA variable reveal adds visual appeal andaccentuates scale for <strong>CENTRIA</strong>’s FormawallDimension Series metal wall panels. The abilityto adjust the width of the reveals from 1/2"[13mm] to 6" [152mm] in half inch increments isone more way <strong>CENTRIA</strong> helps architects createtruly innovative aesthetics.<strong>CENTRIA</strong>performance.comFormawall15

VERSAWALL & VERSAPANELWall & Roof SystemsFaribault Energy ParkFaribault, MNNelson ArchitectsVersawall and Versapanelreimagine versatility andflexibility by offering a metalpanel solution for both wallsand roofs.The lightweight insulated metalcomposite panels feature concealedfasteners and can be installedvertically for long, sleek sight lines.The wall panels can also be coatedwith <strong>CENTRIA</strong>’s Duracast finish for anatural textured look. Designed withdouble tongue-and-groove joinery,both sytems provide outstandingweather resistance and can beinstalled quickly and easily.Versapanel’s bold standing seamoffers an outstanding seamlessinsulated roofing solution with awater-tight snap-on batten capthat conceals the joint for a sleek,continuous visual.Versawall 2"[51mm] StriatedVersawall 2.75"[70mm] StriatedVersawall 2.75"[70mm] PlankedVersapanel 1.75"[44mm] Planked16 Versawall & Versapanel

Features & Benefits• Lightweight panels lower installation costs• Increased span capability reduces supportsteel requirements• CFC-free foam insulation• Thermal break between face and liner saves energy• Versawall can be used for interior partitions• Available with factory-formed sheet metal flashingor extruded aluminum trim• Versapanel’s snap-on cap conceals joint for aseamless appearance (required on roofs)DescriptionFactory foam-insulated wall and roof panel systemSUBSTRATES• Standard — 26/26 G-90 galvanized steel face andliner with HCFC-free foam insulated core• Optional gages available, consult <strong>CENTRIA</strong>JOINERY• Double tongue-and-groove joinery with factoryappliedair and vapor sealSURFACE FINISH• Versawall Exterior — Non-directional embossing,flat, striated or planked.• Versapanel Exterior — Non-directional embossing,planked or flat• Interior — Non-directional embossing, planked• Optional Duracast textured finish is available forVersawall and Versapanel wall applications, consult<strong>CENTRIA</strong> for panel length optionsPANEL WIDTH• Versawall — 30" [762mm], 36" [914mm]• Versapanel — 36" [914mm]PANEL LENGTH• 6' to 40' [1.83m to 12.19m] standard• 48' [14.63m] max. Consult <strong>CENTRIA</strong>PANEL THICKNESS• Versawall — 2" [51mm], 2-3/4" [70mm],4" [102mm] nom.• Versapanel — 1-3/4" [44mm], 2-1/2" [64mm],4" [102mm]“R” VALUEVersawall• 2" [51mm] depth — R14• 2-3/4" [70mm] — R20• 4" [102mm] — R26Versapanel• 1-3/4" [44mm] — R14• 2-1/2" [64mm] — R19• 4" [102mm] — R32R-values are based on ASTM C1363 testing.Air films are included.Coatings & Colors• Advanced Fluorofinish PVDF, metallic and mica colorcoatings in standard & custom colors• Duragard & Duragard Plus premium high buildarchitectural coatings• Duracast® — a natural appearing textured finish• Versacor Ultra, multi-layered coating system• Kolorshift Iridescent Coating SystemVERSAWALL FLATVERSAWALL STRIATEDVERSAWALL PLANKEDVERSAPANEL PLANKED<strong>CENTRIA</strong>performance.com Versawall & Versapanel 17

FORMABOND ® & FORMABOND ® IIMetal Composite Wall SystemBaylor Charles A. Sammons Cancer CenterDallas, TXPerkins + Will<strong>CENTRIA</strong> reimagines metalcomposite material (MCM)wall panel systems withFormaBond and FormaBond II.FormaBond<strong>CENTRIA</strong>’s FormaBond revolutionizesthe thin aluminum composite panel(ACM) industry. Unlike the traditionalACM process that involves laminationand then fabrication into panelsby a second party, FormaBond ismanufactured entirely by <strong>CENTRIA</strong>using a proprietary reaction injectionmolding process. This means thatthe panels are stronger and flatterwith excellent bond strength andsuperior impact resistance, along withhaving pressure-equalized joinery.Plus, <strong>CENTRIA</strong>’s patented dry joineryeliminates wet seals and providesoptimum venting. This process meansthat wall cavities dry effectively andkeep rainwater out, thereby reducingthe chance of entrapped moisture,material degradation and mold.FormaBond II<strong>CENTRIA</strong>’s FormaBond II is acomplete metal composite material(MCM) wall system that deliversdependability, convenience and value.A smooth, sleek panel, FormaBondII offers superior flatness and sharp,crisp sight lines, and is availablewith a fire resistant core. Plus, it’slightweight, installation ready, and,with its dry seal construction, costlyexterior wet seal maintenance isn’trequired.FormaBond II also incorporates<strong>CENTRIA</strong>’s unique horizontal dryseal joinery to minimize waterpenetration and maximize ventilation.This innovative design improvesthe integrity of the application byreducing the chance of entrappedmoisture behind the rainscreen, whichminimizes the potential for materialdegradation and mold.

FormaBondFeatures & Benefits• Provides super-flat, sharp andcrisp exterior sight lines• Value-added dry seal installation• Low maintenance and no costlyre-caulking• Pressure-equalized rainscreenwith no water entry behind thescreen at 15 psf.• Ventilated cavity along eachhorizontal joint• Excellent bond strength andsuperior impact resistance•Proprietary polymeric core meetsfire code requirements for allbuilding heights• 8mm sheet thickness providessuperior impact resistanceDescriptionPre-formed aluminum compositearchitectural wall panel systemSUBSTRATE & CORE• Metal — 0.032" [.8mm] nominalaluminum face and liner• Core — Highly cross-linkedpolymer that meets fire corerequirements• 8mm sheet thickness• Smooth — flat ACM panel systemJOINERY• All dry construction that ispressure equalized and providesventilation to the inner wall cavitySURFACE FINISH• Smooth, Embossed, Braided orFusion Surface FinishPANEL WIDTH• Up to 60" [1.52m] Smooth• Up to 45" [1.14m] for Fusion,Braided and Embossed texturesPANEL LENGTH• Up to 180" [4.57m]VARIABLE REVEALS• From 1/2" [13mm] to 6" [152mm]in 1/2" [13mm] increments.May also be colorizedCOATINGS• Available in micas, metallics,Fluorofinish and KolorshiftPERFORMANCE• High performance air andwater ratings• Pressure-equalized joinery• AAMA 508-05PRESSURE-EQUALIZEDRAINSCREENJOINERYFusionBraidedEmbossedSmooth*Patent No.: US 7.007.433 B2SURFACE FINISHFormaBond IIFeatures & Benefits• Superior flatness• Sharp, crisp sight lines• Fire resistant core available• Lightweight• No maintenance dry seal joinery• Metal spline or gaskets availableat vertical jointDescriptionAvailable in a variety of colorsand coating systems, <strong>CENTRIA</strong>FormaBond II is a smooth panelwith a sleek, flat design offeringcrisp corner transitions or soft,flowing curves.SUBSTRATE & CORE• Metal — 0.020" [.5mm] nominalthickness aluminum face and liner• Polyethylene and fire-ratedcores available• 4mm panel thickness, 2-1/2"[64mm] system• 6mm panel thickness, 2-1/2"[64mm] system• Flat MCM panelJOINERY• All dry construction• High performance drained andback ventilated system• Open side joint allows ventilationbehind the rainscreen• Drain shelf at top edge of panelminimizes water penetration• Metal spline and gasket verticaljoint optionsSURFACE FINISH• SmoothPANEL WIDTH• Up to 60" [1.52m]Panel Length• Up to 180" [4.57m]Panel Reveals• 1/2" [13mm] Horiz., 1/2" [13mm]Vert.Contact <strong>CENTRIA</strong> for other size options.PERFORMANCE• High performance air andwater ratings• AAMA 508-07• AAMA 509-09COATINGS• Fluorofinish — Durable PVDFcoating system• Sundance MICA — 2-coatpearlescent PVDF coating system• Sundance AM — 3-coat metallicPVDF coating systemContact <strong>CENTRIA</strong> for coating options.<strong>CENTRIA</strong>performance.comFormaBond19

METALWRAP SERIESInsulated Composite Backup Panel System<strong>CENTRIA</strong>’s MetalWrap Seriesreimagines building envelopetechnology.MetalWrap Series is more thanan insulated composite backuppanel—it’s the ultimate backupwall that provides superior thermalperformance and minimizes moistureand air penetration for nearly any typeof exterior rainscreen system, fromsingle skin metal and ACM to brick,terra cotta and others.Designed with <strong>CENTRIA</strong>’s innovativeATMP® building envelope science,MetalWrap Series includes an air andvapor barrier, along with insulationand a metal drain plane—controllingmoisture without sacrificing thermalefficiency.Heart of the City Health SystemGrand Rapids, MIDesign Plus

MetalWrap Series1 2 3 3 MetalWrap12ExteriorRainscreenSubgirtsSeries withintegralattachmentsystemTypical Backup System1 2 3 4 512345ExteriorRainscreenZee Support& verticalsubgirts (Maycause thermalshort circuits)InsulationAir and VaporBarrierExteriorSheathingMetal Brick Terra CottaFEATURES & Benefits• Provides an air barrier, vapor andmoisture control, drain plane andthermal performance in onecomposite assembly.• Minimizes the potential for waterpenetration, air infiltration andthermal bridges.Description• Encloses the building faster in allweather conditions.• Works well for all building types inall climates.• The flexibility to be installed bothhorizontally and vertically.• Assembly thermal performanceachieves U-factors that meet orexceed ASHRAE requirements.• MetalWrap with different wallassemblies meets requirementsfor NFPA 285 multi-story fire test.• Fully tested for air and waterinfiltration.HORIZONTAL INSTALLATIONThickness 2", 3"Width 36" | 32" | 36"METAL | BRICK | TERRA COTTALength (Std.)* 12' or 20'Face29 gage Galvalume with primerLiner29 gage Galvalume with primerFoam Insulation Min. 2.4 pcf polyisocyanurateR Value 2" – R-143" – R-21VERTICAL INSTALLATIONMETAL | TERRA COTTAThickness 2.75", 4"Width 36"Length (Std.)* 12' or 20'Face26 gage G90 galvanized steel with primerLiner26 gage G90 galvanized steel with primerFoam Insulation Min. 2.4 pcf polyisocyanurateR Value 2.75" – R-204" – R-26*Custom lengths 6' – 45' available. Consult <strong>CENTRIA</strong>.<strong>CENTRIA</strong>performance.comMetalWrap21

PROFILE SERIESReimagining Contemporary DesignSherwood Middle SchoolShrewsbury, MALamoureaux Pagano ArchitectsProfile Series takes thesingle-skin profile panel andelevates it to new levels ofaesthetics, innovation andperformance—in a highlycost-effective way.With <strong>CENTRIA</strong> Profile Series,which includes Concept Series®, IWSeries, Exposed Fastener Profiles,as well the unique fabrication ofEcoScreen® Perforated Screenwall,your creativity knows no bounds.You have complete access to ourfull range of standard and customcolors, along with unlimitedcombinations of articulations,shadows, sight lines, and detailoptions—plus all of the panels canbe installed vertically or horizontally.In addition, the panels work well forboth new construction and retrofitprojects, along with having theall-weather installation capabilitythat keeps projects on time and onbudget.As part of a comprehensive system,additional design options includethe Quietwall System, FirewallSystem, MicroSeam® Corners,MicroLine Extrusions, ProfileLouvers and unique curved panels.Together, these are just a fewmore ways <strong>CENTRIA</strong> helps youreimagine contemporary design byreimagining metal.

CS-200PROFILE SERIESCONCEPT SERIES ®Concealed Fastener ProfilesConcept Series single-skin panels have concealed fasteners and a common lock joint thatallows the panels to be interchanged for interesting custom aesthetics.Available in a wide range of profiles, Concept Series panels are perfect for insulated oruninsulated field-assembled walls.For product profile options refer to page 26.Features & Benefits• Panels may be installed vertically andhorizontally*• Common lock joint allows panels to be mixedfreely for custom-like aesthetics• Concealed clips and fasteners• Cost effective with a clean, unbroken appearanceallowing for interesting visual effects• Excellent for new construction and retrofitprojects• All-weather installation capability shortensinstallation time, permits fast-track scheduling• Panels are available with stucco-embossedor smooth finishes• May be insulated to meet many levels of thermalprotection• Concealed extended leg option• EcoScreen for CS-260 and CS-660 profiles• Profile Louvers for CS-260 and CS-660 profilesDavie West BuildingFlorida Atlantic University/University of FloridaDavie, FLSchenkel Shultz*Horizontal applications require a backup with exteriorsheathing and a weather-resistant air barrier.DescriptionSubstrates• Standard 24**–18 gage G-90 galvanized steel• Galvanized steel, galvalume® steel, aluminumor stainless steel — optional• Smooth or embossed surface textureConcept Series Profiles• Lengths up to 30' [9.14m]• Concealed clips and fasteners• Stand-off clips provide ventilation cavity andcontinuous drain plane behind panel• Horizontal or vertical wall installation• Common joint design permits multiple profileintegration• Concealed extended leg optionPatent No.: US D538.948; D527.834“Oil canning” is an inherent part of light gage cold-formedmetal products, particularly those with broad flat areas.<strong>CENTRIA</strong> takes every precaution, as defined by MCA, tominimize the effects of oil canning. Lack of flatness orwaviness due to oil canning is not sufficient cause forrejection of material** 24 gage only available in certain profiles.Consult <strong>CENTRIA</strong>.<strong>CENTRIA</strong>performance.comProfile Series23

IW-10APROFILE SERIESIW SERIESConcealed Fastener ProfilesIW Series panels have no exposed fasteners for a clean, unbroken aesthetic in a variety of finishes.The panels also feature a common lock-joint design that makes interesting visual effects possible.For product profile options refer to page 27.Mazda DealershipElk Grove, CAMartin Consulting GroupFeatures & Benefits• No exposed panel fasteners• Cost effective, with a clean, unbrokenappearance• All panels are interchangeable because of thecommon lock-joint design which allows forinteresting visual effects• Excellent for new construction and retrofitprojects• All-weather installation capability shortensinstallation time; permits fast-track scheduling• May be insulated to meet many levels ofthermal protection• Panels are available with stucco-embossed orsmooth finishes and in flush, ribbed, striatedand stepped profilesNOTE: Swaged ends of 2" [51mm] length are available in20 and 22 gages only. Not available in IW-12A, IW-14A,and IW-15A.DescriptionSubstrate• Standard 22-18 gage G-90 galvanized steel• Galvalume® steel, aluminum or stainless steel –optional• Smooth or embossed surface texturesIW SERIES PROFILES• Lengths up to 30' [9.14m]• Horizontal or vertical wall installation• Lock-joint design of IW-10A through IW-41Amakes panels interchangeable• Horizontal applications require a backupwith exterior sheathing and a weather-resistantair barrier• Now available with MicroSeam® corners24 Profile Series

MR3-36PROFILE SERIESEXPOSED FASTENERPROFILESExposed Fastener Profiles are extremely versatile panels that can be used as exterioror interior walls, roofs and soffits with ribs that run horizontally or vertically.For product profile options refer to page 28.Features & Benefits• Extremely versatile panels can be used asexterior or interior walls, roofs and soffits• Ribs can be run either horizontally* orvertically• May be insulated to meet many levels ofthermal protection• Excellent negative wind load properties• All-weather installation capability minimizesdelays; permits fast-track scheduling• Panels are available in stucco-embossedor smooth finishesLincoln ElementaryLouisville, KYBravura Architects* Horizontal applications require a backup with exteriorsheathing and a weather-resistant air-barrier.DescriptionSubstrates• Standard 24** – 18 gage G90 Galvanized Steel• Galvalume® Steel, aluminum or stainless steel –optional• Smooth or embossed surface texturesEXPOSED FASTENER PROFILES• Horizontal or vertical wall installation• Wall and roof installation• Lengths up to 40' [12.19m], consult <strong>CENTRIA</strong>** 24 gage only available in certain profiles. Consult <strong>CENTRIA</strong>PROFILE SERIESLINER PANELSFor product profile options refer to page 28.L2-3Features & Benefits• Incorporate liner panel, subgirts, varying thicknesses ofnoncombustible fiberglass insulation and any <strong>CENTRIA</strong>exposed fastener or concealed fastener panel for acomplete field assembled wall system• High “R” Values, depending upon insulation• Provides a flush appearance to building interiors• Perforated liner panels available for tested acousticalperformance• Firewall systemsDescriptionMinimize heat loss or gain to conservevaluable energy with <strong>CENTRIA</strong> liner panelsSUBSTRATE• 24-18 gage G-90 galvanized steelPANEL WIDTH• 24" [610mm]PANEL LENGTH• 30'-0" [9.14m] max.PANEL THICKNESS• L2 — 1-3/8" [35mm]• L2-2 — 2" [51mm]• L2-3 — 3" [76mm]• L-21A — 1-1/2" [38mm] (for interior partitions)<strong>CENTRIA</strong>performance.comProfile Series25

PROFILE SERIES CONCEPT SERIES Product DetailsCS-200CS-210CS-220ConcealedClip Fastener(standard)CS-260CS-610CS-620ConcealedExtendedFastener Leg(optional)CS-630CS-660South Texas Research FacilitySan Antonio, TXRafael Vinoly Architects26 Profile Series

PROFILE SERIES IW SERIES Product DetailsIW-10AIW-11AIW-12AIW-13AIW-14AIW-15AIW-20AIW-21AIW-30AIW-31AIW-40AIW-41AFor information about product width in metric, please consult <strong>CENTRIA</strong> or visit <strong>CENTRIA</strong>.com.<strong>CENTRIA</strong>performance.comProfile Series27

PROFILE SERIES EXPOSED FASTENER PROFILES Product DetailsECONOLAP 1/2" ECONOLAP 3/4"MR3-36TR4-36 STYLE-RIB BR5-36PROFILE SERIES LINER PANELS Product DetailsSUPER-RIBL2L2-2 L2-3L-21AL2 L2 -2L2-3Interior Finish Side Interior Finish Side Interior Finish SideL-21AInterior Finish Side28 Profile Series

PROFILE SERIESECOSCREEN ®Perforated ScreenwallThrough the use of a unique fabrication process, EcoScreen perforated screen walls provide an airy aesthetic andoutstanding performance that elegantly blends industrial and other applications with their surroundings.BR5-36CS-260Interurban Transit PartnershipWealthy Street Operations ExpansionGrand Rapids, MIProgressive AECS-660ECONOLAP 3/4"MR3-36STYLE-RIBImages showing standard 40% open area staggered pattern,3/8" [10mm] diameter, 9/16" [14mm] spacing.ECOSCREEN PERFORATION PATTERN OPTIONSOpen/FreeAreaPatternDiameter(in)Spacing(in)10 Reverse 1/8 3/823 Staggered 1/8 1/423 Reverse 1/4 1/230 Staggered 1/8 7/3233 Staggered 3/16 5/1640 Staggered 1/8 3/1640 Staggered 3/8 9/16Bold lines are standard. For additional patterns, contact <strong>CENTRIA</strong>.<strong>CENTRIA</strong>performance.comProfile Series29

PROFILE SERIESDESIGN OPTIONSMICROSEAM® CORNERSMicroSeam Corners use cutting edge structural bondingtechniques to produce corners that appear virtuallyseamless. Manufactured from the same metal substrate coilas the panels, MicroSeam corners employ no welding and nopop rivets. Like all <strong>CENTRIA</strong> panels, they are fully tested forperformance. MicroSeam Corners are available on BR5-36,Econolap 3/4", MR3-36, Style-Rib, Super-Rib, TR4-36, allConcept Series profiles and all IW Series profiles. They arealso available in <strong>CENTRIA</strong>’s full palette of nearly 100 colors,including metallics and Versacor Ultra.MICROLINE EXTRUSIONSMicroLine details incorporate aluminum extrusions designedto integrate visually and mechanically with <strong>CENTRIA</strong> ProfileSeries Concept Series panels. Slim 2" [51mm] wide MicroLineextrusions make it a snap to trim and finish around windowsand doors, inside or outside corners, and at the base ofwalls; or to create clean vertical joints. MicroLine detailsenable you to replace wide obtrusive flashing and exposedfasteners with narrower, crisper and cleaner finished lines,and can be finished to match or complement wall panels.Also available for horizontal IW Series, Style-Rib, BR5-36,Econolap 3/4" and TR4-36. MicroLine details are availablefor Concept Series profiles in horizontal and verticalapplications.PROFILE LOUVERS<strong>CENTRIA</strong> Profile Louvers come in gages, colors and finishesto match corresponding panels and blend invisibly into awall, eliminating visual breaks in site lines. Profile Louversare available for horizontal installation with BR5-36, InvertedBR5-36, MR3-36, CS-260, CS-660, Style-Rib or Super-Ribwall panels. Variable blade depths from 1-1/2" to 8" [38mmto 203mm] create free area from 10% to 49% for air intakeor exhaust.CURVED PANELSWith <strong>CENTRIA</strong> curved panels you can add radius designelements to your projects. Available in a wide selectionof exposed fastener profiles, finishes and colors to matchvirtually any architectural, commercial or industrialapplication. Curved panels are ideal for canopies andawnings, roofing, fascia, walls, curved parapets, curved trim,column and beam wraps, where they can be used to addbold visual statements or innovative special effects.<strong>CENTRIA</strong> fabricates curved panels from a variety ofarchitectural panel profiles. They are available in anumber of finishes to match your application, and in thefull <strong>CENTRIA</strong> color palette.30 Profile Series

PROFILE SERIESQUIETWALL & FIREWALLSystemsQUIETWALL SYSTEM<strong>CENTRIA</strong> Quietwall systemshelp you select a wall systemwith specific sound absorptionor transmission loss values thatyour design requires — moreeconomically and more efficiently.FIREWALL SYSTEMWith the <strong>CENTRIA</strong> firewallsystem, layers of gypsum boardbetween the exterior Profile paneland the insulation and liner panelcreate UL one-hour through fourhourfirewalls based on ASTME119 fire tests.OTHER SYSTEMS• Explosion Release• RF Shielding<strong>CENTRIA</strong>performance.comProfile Series31

SRS ®Structural Standing Seam Roof SystemsHarrison County HospitalCorydon, INLaughlin Millea Hillman Architecture, Inc.Walker Architects, Inc.<strong>CENTRIA</strong> reimagines theclassic structural standingseam roof system (SRS)Designed to provide clean, unbrokenlines with minimal exposed fasteners,continuous transitions and longpanel lengths, <strong>CENTRIA</strong>’s SRS offersdynamic aesthetic possibilities.<strong>CENTRIA</strong>’s SRS also providesoutstanding performance witha unique concealed clip andpanel interlock design that allowsunimpeded thermal movementwithout damage. In addition, themechanical seaming of roof panelsin the field ensures superior weatherresistance.

Features & Benefits• Long panel lengths eliminate transitionflashing, enhance weather resistance• Unique concealed clip and panel interlockdesign allows unimpeded thermal movementwithout damage• Mechanical seaming of roof panels in the fieldensures weather resistance and enhancesappearance• UL 580 Class 90 listing• FM 1-90 and FM-180 for SRS 3• Dade County NOA for SRS 3• Low slope applications:1/2:12 [2.40°] without endlaps1:12 [4.76°] with endlaps• Can be field roll-formed, eliminating endlaps• SRS 3 can be curved to various radiiSRS 3 Curved• SRS 3 mechanical curving process• Available in 12" [305mm], 16" [406mm] and 18"[457mm] widths• Curving performed on-site or in the plant, using<strong>CENTRIA</strong>-supplied equipment• Consult <strong>CENTRIA</strong> for the minimum radius availablefor each gageSRS 3 PlankedDescriptionStructural standing seam roof systemsSUBSTRATES• SRS 3 — 24-18 gage• G90 galvanized steel, Galvalume, stainlesssteel*, and aluminumPANEL WIDTH• 12" [305mm], 16" [406mm], 18" [457mm]PANEL DEPTHS• SRS 3 — 3" [76mm]PANEL LENGTH• Factory-formed — up to 48'0" [14.63m] max.– standard, up to 60'0" [18.29m] — optional• Field-formed — 220'0" [67.06m] max.Oil canning within industry standard guidelines asdefined by MCA is not a cause for rejection.Architect ural Design PanelsADP 100ADP 100BADP 100CStructural Design PanelsSDP 175SDP 200Parkway Central High School Science LabChesterfield, MOParsons Brinkerhoff<strong>CENTRIA</strong>performance.comSRS33

VENTILATIONSystemsUniversity of Louisville Ralph Wright NatatoriumLouisville, KYBrowning Day Mullins Dierdorf Architects<strong>CENTRIA</strong> offers a rangeof ventilation systems tocomplete any wall system.Choose from profile louvers, c/slouvers, continuous ridge ventilators,continuous clamshell ventilators andsmall streamline ventilators.Features & BenefitsPROFILE LOUVERSMatched to <strong>CENTRIA</strong> BR5-36, Inverted BR5-36, MR3-36, Concept Series, CS-260/CS-660,Style-Rib and Super-Rib panels.• Integrate architecturally with horizontalbuilding panel linesC/S LOUVERS<strong>CENTRIA</strong> and C/S Group also provide a full lineof fixed, drainable and storm-resistant louversengineered for seamless integration withDimension Series panels.CONTINUOUS RIDGE VENTILATORS (CRV)Energy-saving products that use gravityto provide maximum air flow• Available with throat openings from 2'-0"[610mm] to 20'-0" [6.10m]• Weathertight, low maintenance, self-cleaning• Available accessories include dampers,screens and operatorsCONTINUOUS CLAMSHELL VENTILATORS (CSV)Function like CRVs while offering increasedcapabilities• For extreme heat areas, throat openings of upto 32'-0" [9.75m] are possible using doubleCSVs on a monitor roof• Available from 8'-0" [2.44m] through 16'-0"[4.88m]SMALL STREAMLINE VENTILATORS (SSV)Factory-assembled in 10' [3.05m] sectionswith fixed or operable dampers• Factory assembled in 10'-0" [3.05m] sections• Fixed or operable dampers

COATING SYSTEMS& SUBSTRATES<strong>CENTRIA</strong> has been reimagining the art and science of producing richly hued and textured, high performance, high value colorcoated metal walls and roofs. This includes a wide variety of innovative coating systems, a full range of colors including customcolor matching, and an array of substrates and surface textures to meet the most challenging environmental conditions.3432321211FLUOROFINISH®*A Kynar 500® or Hylar 5000® coating thatprovides good durability.0.8 mil [20 micron] nominal Color Coat0.2 mil [5.1 micron] nominal PrimerSubstrateDURAGARD® PLUSA premium, high build architectural coatingthat provides the ultimate in color retentionand fade resistance.0.8 mil [20 micron] nominalPolyvinylidene Fluoride Clear Coat*0.8 mil [20 micron] nominalPolyvinylidene Fluoride Color Coat*0.8 mil [20 micron] nominal PrimerSubstrateDuragard®0.8 mil [20 micron] nominal PolyvinylideneFluoride Color Coat*0.8 mil [20 micron] nominal PrimerSUNDANCE MICA* 2-COAT FINISHA high performance PVDF coating thatprovides good durability.0.8 mil [20 micron] nominal Color Coat0.2 mil [5.1 micron] nominal PrimerSubstrateVERSACOR® ULTRAA premium, high build, multi-layer coating for applicationswhere corrosion and abrasion resistance is more important.332211VERSACOR® ULTRA PF and MXExcellent coatings for corrosivearchitectural applications.Versacor Ultra MX has a PVDFcoat with mica, providing apearlescent appearance.0.8 mil [20 micron] nominalPVDF Coat3.0 mil [75 micron] nominalVersacor Ultra BarrierCoat PrimerSubstrateVERSACOR® ULTRA TF and HFA coating merging thesuperior corrosion resistanceof the Versacor Barrier CoatPrimer with the durability ofa Urethane Finish.1.5 or 3.0 mil [38 or 75micron] nominal UrethaneCoat3.0 mil [75 micron] nominalVersacor Ultra Barrier CoatPrimerSubstrate44332121SUNDANCE AM–ALUMINIUM METALLIC3-COAT FINISHA quality, durable coating that providesthe iridescence and reflectivity of a metallicsurface.0.5 mil [12.7 micron] nominalPolyvinylidene Fluoride Clear Coat*0.8 mil [20 micron] nominalPolyvinylidene Fluoride Color Coat*0.2 mil [5.1 micron] nominal PrimerSubstrateDURACAST® TEXTURED FINISH SYSTEM**Factory-applied coating with naturalaggregate matrix providing the look andfeel of precast. Available exclusively forFormawall Dimension Series, FormawallGraphix Series and Versawall panels.Acrylic and Natural Aggregate Matrix0.8 mil [20 micron] nominal Polyester0.2 mil [5.1 micron] nominal PrimerSubstrateWhat is Reverse Side Coating Protection?On <strong>CENTRIA</strong>’s Profile Series panels with a Versacor UltraCoating System, an additional Versacor Ultra Barrier CoatPrimer is applied to the interior of the metal substrate. A washcoat is applied over the barrier coat and other top coats areavailable, such as PVDF, urethane or polyester. This additionalcoating provides superior protection against corrosion fromthe interior and at lap conditions.AVAILABLE SUBSTRATES• Standard G-90 hot-dip galvanized steel conforming to ASTMA924 and ASTM A653 structural quality• Galvalume steel, unpainted hot-dip coated with aluminumzincalloy conforming to ASTM A924 and ASTM A792• Stainless Steel**, Type 304 AISI architectural grade alloy;austenitic, non-magnetic, non-glare surface; slight variationin surface finish• Aluminum Alloy 3003 or 5052 and for standing seam roofpanels, 3004**, available in smooth surface as a substrate• Galvalume steel not available with Versacor Ultra* Polyvinylidene Fluoride (PVDF) coat contains 70% Kynar500 or Hylar 5000 resin. Kynar 500 is a Reg. TM of AtofinaChemicals, Inc. Hylar 5000 is a Reg. TM of Solvay Solexix,Inc. Galvalume is a Reg. TM of BIEC International, Inc.** Subject to minimum quantity requirements.<strong>CENTRIA</strong>performance.comCoating Systems & Substrates35

COLORSPrismatic Series Colors — Fluorofinish, Duragard and Duragard PlusUnless specified otherwise, <strong>CENTRIA</strong>will provide a standard backer coat onthe reverse side of single skin panels.Color may vary.Polyester Arctic Ice is the standardfinish offering for the interior surfacesof foam panels. Other finishes availableupon request.nThese colors meet the low-slope and steep slopeSRI requirements for LEED-NC SS Credit 7.2.sThese colors meet the steep-slope SRIrequirements for LEED-NC SS Credit 7.2.† Standard Duracast finish color. Consult <strong>CENTRIA</strong>for custom colors.Colors shown are for preliminary selectiononly. Printed colors can vary from actualpainted material.Contact <strong>CENTRIA</strong> for painted metal samplesbefore final selection.NOTE: Because of the differences in theformulation and application properties ofspray-applied coatings versus coil coatings,a slight color variation is likely to occur whenmatching coatings of these different types..Sundance Series ColorsSundance Mica2-coatSundance AMAluminumMetallic 3-coatCustom colors may require an additional clear and/or barrier coat.Consult <strong>CENTRIA</strong> for details.Duracast®Off-WhiteLimestoneLee Ivory Surrey Beige Light Seawolf Dove Gray Light Gray Slate GrayNOTE: Galvalume, Stainless and Aluminum may not be available for allproduct profiles or coating systems. Consult <strong>CENTRIA</strong> sales. Galvalumeoffers improved heat resistance only when used unpainted.36 Coating Systems & Substrates

KOLORSHIFT SERIESThe KolorShift Series truly reimagines the design possibilities ofcolor with exterior metal walls that shift in color depending on theviewing angle or direction of sunlight. The end result isa continuous iridescent color gradient.KolorShift Series paints are formulated as a polyvinylidene fluoride(PVDF) coating system with 70% Kynar 500®/Hylar 5000® resins,which provide lasting durability. They are available with a standard20-year warranty.Colors AvailableBase Color Flop Color731 Hemlock32KolorshiftAn iridescent polyvinylidene(PVDF) architectural coating40.8 mil [20 micron]nominal PVDF Color Coat732 Dusty Rose10.5 mil [12.7 micron]Polyester Base Coat0.2 mil [5.1 micron]Polyester PrimerSubstrate733 Green ShimmerKynar 500 is a Registered Trademark of Atofina Chemicals, Inc.Hylar 5000 is a Registered Trademark of Solvay Solvents, Inc.Kolorshift paints are applied by coil coating to provide consistency ofcolor. Spray coating matches are not available. It is recommended thattrim required for Kolorshift coated projects use brake-formed trim or acomplimentary color in a standard PVDF for extrusions. Contact <strong>CENTRIA</strong>for availability of MicroSeam® corners with a Kolorshift finish.734 Purple Rain735 Lightning StormALLUSION The Allusion pre-finished decorative paint system is one more way<strong>CENTRIA</strong> helps architects reimagine metal for their designs. Thesystem accurately simulates expensive natural finishes, includingwood and specialty metals, using high performance print coatingtechnology that is less expensive and lower maintenance thannatural materials.A precoated finish system usingpolyvinylidine (PVDF) print patterncolors761 Light Oak762 Dark Oak432145 mil [11.475 micron]nominal PVDF Clear Top Coat05 mil nominal PVDF ink763 Rust764 Slate65 mil [16.575 micron] nominalColor Base Coat (also acts asprimer)Metal Substrate765 Antique Bronze<strong>CENTRIA</strong>performance.comCoating Systems & Substrates37

Product Finish AvailabilityPANELS FINISHES SUBSTRATESFluorofinishDuragardDuragard PlusSundance MicaSundance AM-MetallicDuracastVersacor Ultra PF, TF,HF, MXKolorshiftAllusionG90 GalvanizedGalvalumeAluminumStainless SteelFW DimensionSeriesX X X X X X X 2 X X X X 1 X 1FW Graphix Series X X X X X X X 2 X X X X 1Formavue X X X X X X X XFWDS Louvers X X X X X X X XFWDS Sunshades X X X X X X X XVersapanel X X X X X X X 2 X X XVersawall X X X X X X X 2 X X XFormaBond X X X X X XFormaBond II X X X XConcept Series X X X X X X 2 X X X X X XIW Series X X X X X X 2 X X X X X XBR5-36 X X X X X X 2 X X X X X XEconolap 1/2" X X X X X X 2 X X X X X XEconolap 3/4" X X X X X X 2 X X X X X XMR3-36 X X X X X X 2 X X X X X XStyle-Rib X X X X X X 2 X X X X X XSuper-Rib X X X X X X X X X XTR4-36 X X X X X X 2 X X X X X XProfile Louvers X X X X X X 2 X X X XL2 X X X X X X 2 X X X XL2-2 X X X X X X 2 X X X XL2-3 X X X X X X 2 X X X XL-21A X X X X X X 2 X X X XADP-100 X X X X X XADP-100B X X X X X XADP-100C X X X X X XSDP-175 X X X X 2 X X X XSDP-200 X X X X 2 X X X XSRS 3 X X X X X X 2 X X X X X XCertain panel profiles and options may not be available in all finish and gage combinations. Contact <strong>CENTRIA</strong> for availability.1Stainless and aluminum are available for face elements only and not liner elements.2Consult <strong>CENTRIA</strong> for profile, gage and finish availability.38

Project IndexCover, Page 3North Carolina National GuardHeadquartersRaleigh, NCA: O’Brien Atkins ArchitectureC: Shelco Inc.D: Steel CladPage 4Devon Boathouse and Finish Line TowerOklahoma City, OKA: Elliot and AssociatesC: Timberlake Construction/Smith & PickelD: W.J. Coe & Company, Inc.Page 7Wolfe Center for Performing ArtsBowling Green State UniversityBowling Green, OHA: Snohetta/The CollaborativeC: Rudolph LibbeD: C.L. RieckhoffPage 8North Seattle Community CollegeSeattle, WAA: Schacht Aslani ArchitectsD: Snyder Architectural SystemsPage 23Davie West BuildingFlorida Atlantic University/University of FloridaDavie, FLA: Schenkel ShultzC: Pirtle Construction CompanyD: Cladding SystemsPage 24Mazda DealershipElk Grove, CAA: Martin Consulting GroupC: Chatfield Construction Inc.D: Blackwood Associates, Inc.Page 25Lincoln ElementaryLouisville, KYA: Bravura ArchitectsD: D T & Associates, Inc.Page 26South Texas Research FacilitySan Antonio, TXA: Rafael Vinoly ArchitectsC: Vaughn ConstructionD: Wade Architectural SystemsPage 12Families, Inc.Jonesboro, ARA: CahoonSteiling Studio ArchitectureC: Tate General Contractors, Inc.D: Sold DirectPage 16Faribault Energy ParkFaribault, MNA: Nelson ArchitectsC: Dahlen Berg & Co.D: ArmetexPage 18Baylor Charles A. SammonsCancer CenterDallas, TXA: Perkins + WillC: MEDCO ConstructionD: National Panel Systems, Inc.Page 20Heart of the City Health SystemGrand Rapids, MIA: Design PlusC: Pioneer ConstructionD: Architectural Metals, Inc.Page 22Sherwood Middle SchoolShrewsbury, MAA: Lamoureaux Pagano ArchitectsC: Gilbane Building CompanyD: LYMO ConstructionPage 29Interurban Transit PartnershipWealthy Street Operations ExpansionGrand Rapids, MIA: Progressive AEC: Christman CompanyD: Architectural Metals Inc.Page 32Harrison County HospitalCorydon, INA: Laughlin Millea Hillman/Walker Architects, Inc.C: Whittenberg Construction Co.D: J.C. Industries Inc.Page 34Parkway Central High School Science LabChesterfield, MOA: Parsons BrinkerhoffC: ICS Construction ServicesD: Mays Maune McWard Inc.Page 34University of LouisvilleRalph Wright NatatoriumLouisville, KYA: Browning Day Mullins Dierdorf ArchitectsC: Wittenberg Construction CompanyD: J.C. Industries Inc.To view photos of these and many more<strong>CENTRIA</strong> projects, visit our portfolio.A: Architect; C: Contractor; D: Dealer39

<strong>CENTRIA</strong>Performance.com1.800.759.74741005 Beaver Grade RoadMoon TownshipPA 15108-2944Phone: 412.299.8000Fax: 412.299.8317Office of Business DevelopmentPhone: 860.490.2670NORTHEASTREGION1.800.586.1372Baltimore, MDP: 410.549.6018F: 410.795.5984Boston, MAP: 978.779.7929F: 978.779.7930Cincinnati, OHP: 513.793.9160F: 513.793.9161Hartford, CTP: 860.659.4045F: 860.659.4034Newark, NJP: 973.860.8804F: 973.744.2041New York, NYP: 914.834.7697F: 914.833.1843Philadelphia, PAP: 215.643.6040F: 215.643.0629Pittsburgh, PAP: 412.299.8175F: 412.299.8016Syracuse, NYP: 315.214.3753F: 315.214.3753Washington, DCP: 703.406.9588F: 703.406.9457SOUTH CENTRALREGION1.800.586.1372Atlanta, GAP: 770.778.7997F: 770.518.8693Charlotte, NCP: 704.341.0202F: 704.341.0204Chicago, ILP: 262.538.4415F: 262.538.4417Detroit, MIP: 734.516.6929 (cell)F: 734.529.7257Greenville, SCP&F: 803.569.1212Indianapolis, INP&F: 317.456.7920Memphis, TNP: 901.550.0355F: 901.861.8144Minneapolis, MNP&F: 763.577.1417Sarasota, FLP&F: 941.893.3411Western MichiganP&F: 248.486.8939WESTREGION1.888.745.8527Dallas, TXP: 972.422.5856F: 972.390.9103Denver, COP: 303.743.7430F: 303.743.7451Houston, TXP: 281.397.9900F: 281.397.6363Phoenix, AZP: 480.282.2799F: 602.997.7062Sacramento, CAP: 408.768.9595F: 408.243.6182San Francisco, CAP: 650.369.9400F: 650.369.9483St. Louis, MOP: 314.432.3434F: 314.432.6863Seattle, WAP: 253.460.3779F: 253.460.1664Southern California(Los Angeles)P: 949.589.0997F: 562.690.1610Due to <strong>CENTRIA</strong>’s policy of continuous improvement, we reserve the right tochange, discontinue or modify our products, specifications and designs withoutnotice and without incurring obligations.Reference CAS-2/13 20M PG/GCS Copyright © 2013 <strong>CENTRIA</strong> Printed in the U.S.A.