tp-seal® and bio-tpseal® rotomoulding technologies - ARMO 2012

tp-seal® and bio-tpseal® rotomoulding technologies - ARMO 2012

tp-seal® and bio-tpseal® rotomoulding technologies - ARMO 2012

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TP-SEAL® AND BIO-TPSEAL®<br />

ROTOMOULDING TECHNOLOGIES:<br />

BIO-‐CORP/PR.12.030<br />

THE “TOTAL CAR CONCEPT”.<br />

<strong>ARMO</strong> <strong>2012</strong><br />

Lyon October 1, <strong>2012</strong><br />

Eric Maziers.<br />

Total Research & Technology Feluy - Belgium.

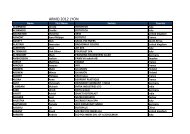

TOTAL STATISTICS<br />

(KEY FIGURES FOR 2011)<br />

Strong<br />

international presence<br />

over 130<br />

countries<br />

Over<br />

700<br />

industrial sites<br />

96,104<br />

employees<br />

Sales<br />

184.7<br />

billion euro<br />

Net income<br />

11.4<br />

billion euro<br />

+16%<br />

+11%<br />

<strong>2012</strong><br />

investment<br />

budget<br />

24<br />

billion dollars<br />

R&D<br />

investments<br />

7billion dollars<br />

between 2010 <strong>and</strong><br />

2015<br />

2<br />

5 th<br />

international<br />

oil <strong>and</strong> gas<br />

company

A MAJOR OIL COMPANY<br />

WITH AN INTEGRATED MODEL<br />

Oil <strong>and</strong> gas<br />

ou<strong>tp</strong>ut<br />

Oil<br />

Refining<br />

Gas<br />

Trading<br />

Making the link<br />

between our ou<strong>tp</strong>ut<br />

<strong>and</strong> our processing<br />

sites <strong>and</strong> providing a<br />

supply to our<br />

customers<br />

Petroleum products<br />

Petrochemicals<br />

Marketing<br />

3

4<br />

IAA FRANKFURT SEPTEMBER 2011.

- Reference, date, place<br />

5

� Car Manufacturers, like their clients, are under pressure. Reducing<br />

CO2 emissions is turning into a commercial argument, but despite<br />

efforts to promote public transport, sustainable urban mobility will<br />

not be able to disregard the car completely.<br />

7<br />

� Migration towards towns ans cities requires a greater ability to adapt<br />

to changing priorities wich goes beyond just shared transport.<br />

� Even, if it is just a start; some towns <strong>and</strong> cities are looking to<br />

develop electrical car hire services in addition to public transport.<br />

� The growth in the number of vehicules on the road is felt to be<br />

unavoidable, it is estimated to be more than 1.4 billion vehicles by<br />

2030.<br />

� This is an opportunity to turn this challenge into an advantage.

8<br />

� The electrical car demonstrates that the reduced weight of the city<br />

car will be the key to its success; lightweight construction materials<br />

will be vital to compensate for the weight of the batteries.<br />

� Lower consumption means less pollution.<br />

Ø� With BIO-TPSeal®, Total’s Refining <strong>and</strong> Chemicals Division has<br />

developed a lightweight robust structure for the car chassis<br />

production which is a contributing factor making the city car a<br />

sustainable part of mobility.<br />

Ø� It reduces dependence on fossil sources <strong>and</strong> non –renewable<br />

materials <strong>and</strong> the pollution encounterd in manufacturing.<br />

� It helps to manage the end of life a city cars.

9<br />

ENVIRONMENTAL IMPACT OF VEHICLES:<br />

• The environmental impact of classical vehicles is distributed equally<br />

between the manufacturing, use <strong>and</strong> end of life phases of their lifecycles (*)<br />

• The use of rotomolding process combined to BIO-TPSeal® technology<br />

allows to reduce the impact at each stage of vehicle life.<br />

Impact during<br />

production<br />

Much less number of elements<br />

No welding<br />

Lower weight<br />

(*) : JL Thuliez, Domteknika, Persico Nembro June 20th, <strong>2012</strong><br />

Impact of use<br />

Less CO 2 emissions<br />

Less maintance<br />

Impact of<br />

disposal<br />

More recycling possibilities

10<br />

TOTAL CONCEPT CAR: FULLY DESIGNED AND PRODUCED<br />

BY TOTAL R&D CENTERS.

11<br />

TOTAL CONCEPT CAR: FRONT PART TOOLING (PRODUCED BY PERSICO) FOR<br />

CONVENTIONAL ROTOMOULDING MACHINES.

12<br />

POLYOLEFIN PRODUCTS: INNOVATION.<br />

Technological Evolution<br />

REVOLUTION<br />

breakthrough<br />

innovation<br />

EVOLUTION<br />

incremental<br />

innovation<br />

LDPE<br />

Linear PE/PP<br />

Cr, Z-N<br />

Gas phase<br />

Metallocene<br />

Bimodal<br />

Materials Science<br />

1930 1940 1950 1960 1970 1980 1990 2000 2010 2020<br />

- Nano<br />

- Bio<br />

- Organic<br />

- Smart<br />

Futerro’s<br />

PLA<br />

Rotomolding resins:<br />

-M3581UV<br />

-M4041UV<br />

-M3671

TP-SEAL® AND BIOTPSEAL® ROTOMOULDING TECHNOLOGIES:<br />

BASED ON TOTAL METALLOCENE POLYOLEFINS (LUMICENE®<br />

PRODUCT RANGE).<br />

• skin/skin è� mPE / PA11<br />

• Low fuel permeation<br />

Fuel tanks<br />

(CARB/EPA – USA)<br />

(courtesy Elkamet Germany)<br />

TP-SEAL® BioTPSeal®<br />

• Skin/foam/skin è� mPE / mPE / mPE<br />

• Boats<br />

• Structural parts<br />

• Buoys<br />

(courtesy Sealver (France)<br />

• mPE-PLA alloys<br />

• Monolayers<br />

• Multilayers<br />

• Skin/foam/skin,<br />

• Skin/skin<br />

• Structural parts.<br />

• Low warpage parts.<br />

• Very high stiffness parts<br />

• Surface properties<br />

• Paintable parts<br />

• Design parts

14<br />

TP-SEAL® OR BIO-TPSEAL® FOR SKIN/FOAM/SKIN<br />

STRUCTURES.<br />

Conventional<br />

polyolefin structure<br />

TP-SEAL® or Bio-TPSeal®<br />

5 meters/ 330 kgs part<br />

(courtesy Dynamic rotomolding -France)

• For this car body the overall plastic weight is only 85 kg… <strong>and</strong> only two parts<br />

(w/o any welding) ready to be assembly just after rotomolding !<br />

BIO-TPSeal®<br />

Skin/foam/skin structures<br />

15<br />

TPSeal®

16<br />

� Skin/foam/skin structures allow:<br />

– very high impact / stiffness balance.<br />

q� See this test: a weight of 2000 kgs was applied five times to the Total Car<br />

Concept Front part:<br />

� No crack.<br />

� Limited deformation.<br />

q� Crash tests started by end 2011 <strong>and</strong> are still under progress:

17<br />

TP-SEAL® OR BIO-TPSEAL® ?<br />

Ø� TP-SEAL® è� Polyolefin structures.<br />

� Coloured compounds.<br />

Ø� BIO-TPSeal® è� Polyolefin & PLA structures, this will bring:<br />

Ø� Biosourced content in the structure è� sustainability.<br />

� Surface properties improvements: painting possibilities (PLA is a polar material)<br />

or coloured compounds.<br />

� Surface gloss improvement.<br />

� Stiffness improvement.<br />

� Shrinkage/warpage improvements.<br />

� New multilayer structures:<br />

� Skin/skin : PLA/mPE<br />

� mPE/ PLA filled PU Foam

BIO-TPSEAL® POSSIBILITIES:<br />

• Painted front parts (skin/skin): PLA /mPE BIO-TPSeal®<br />

18

19<br />

BIO-TPSEAL® POSSIBILITIES:

20<br />

WEATHERING: OUTDOOR APPLICATIONS.<br />

Ø� TP-SEAL® <strong>and</strong> BIO-TPSeal® resins are UV protected, with a target at : ><br />

UV10.<br />

� It is highly recommended to assess weathering properties on final parts:<br />

� To check the fit to the application (Weathering specifications).<br />

� To check the effect of pigments for coloured compounds.<br />

� To check the effect of paints.<br />

Ø� Total invested in a new « climate chamber » to make some testing on<br />

rotomoulded parts (under progress): TP-SEAL® <strong>and</strong> BIO-TPSeal®<br />

samples.<br />

Ø� + 10 to + 90 °C<br />

� 10 to 90 % HR<br />

� Total has started some outdoor Weathering in Florida & Arizona (USA) on<br />

rotomoulded parts: TP-SEAL® <strong>and</strong> BIO-TPSeal® samples.

21<br />

CONCLUSIONS:<br />

Ø� The Rotomolding process combined with TP-SEAL® or BIO-TPSeal ®<br />

<strong>technologies</strong> is now offering an amazing opportunity to develop city cars in<br />

a sustainable approach.<br />

� Total will act globally to suppport this business.<br />

� Of particular interest was the example of the VSV (Viability Service Vehicle)<br />

developed by Noremat. The VSV utility vehicle is used for mowing, pruning,<br />

collecting off-cuts, grinding up branches, gritting.<br />

� Other applications are under development : desing, boats , structural parts,<br />

….

Thank You !!<br />

TOTAL<br />

The statements, technical information <strong>and</strong> recommendations contained herein are believed to be<br />

accurate as of the date hereof. Since the conditions <strong>and</strong> methods of use of the product <strong>and</strong> of the<br />

information referred to herein are beyond our control, Total Research <strong>and</strong> Technology Feluy<br />

expressly disclaims any <strong>and</strong> all liability as to any results obtained or arising from any use of the<br />

product or reliance on such information; No warranty of fitness for any particular purpose,warranty<br />

or merchantability,or any other warranty,express or implied,is made concerning the goods described<br />

or the information provided herein. The information provided herein relates only to the specific<br />

product designated <strong>and</strong> may not be applicable when such product is used in combination with other<br />

materials or in any process. The user should thoroughly test any application before<br />

commercialization. Nothing contained herein constitutes a license to practice under any patent <strong>and</strong><br />

it should not be construed as an inducement to infringe any patent <strong>and</strong> the user is advised to take<br />

appropriate steps to be sure that any proposed use of the product will not result in patent<br />

infringement.<br />

22