G3 Series Modbus TCP Technical Manual - Numatics

G3 Series Modbus TCP Technical Manual - Numatics

G3 Series Modbus TCP Technical Manual - Numatics

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

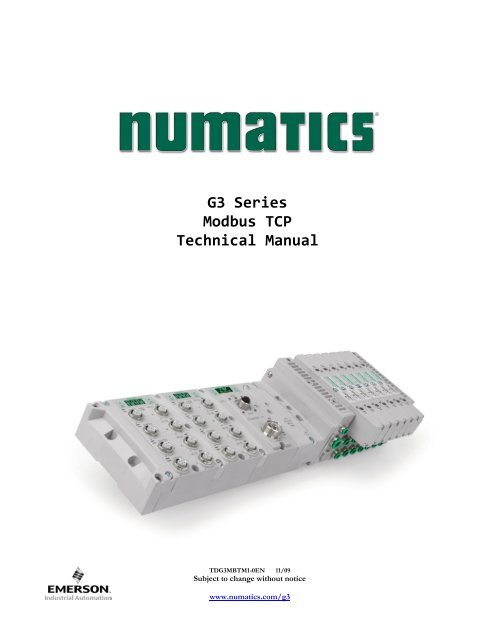

<strong>G3</strong> <strong>Series</strong><strong>Modbus</strong> <strong>TCP</strong><strong>Technical</strong> <strong>Manual</strong>TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3

<strong>G3</strong> Introduction<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>The <strong>G3</strong> <strong>Series</strong> is an electronic product platform that features an integrated graphic display for simplecommissioning and displaying of diagnostic information. In addition it has an innovative distributioncapability which allows the same I/O components that make up a centralized manifold configuration to beused as the distribution components as well, decreasing the need for duplicate components on centralized anddistributed applications. The <strong>G3</strong> platform interfaces to a variety of valve series and fieldbus interface protocolsand is capable of addressing a total of 1200 I/O points (150 bytes). With proper assembly and termination the<strong>G3</strong> modules will have an IP65 / IP67 rating.The manifold can be viewed as having two sections to it, the Valve Side and the Discrete I/O Side. The ValveSide supports a maximum of 32 solenoid coils and the Discrete I/O Side supports a maximum of 16 modulescapable of addressing up to 1200 outputs, 1200 inputs or various combinations.Various discrete modules with integrated graphic display are available. They include digital I/O, analog I/O,and specialty modules which cover various application needs. Pin-outs for all connectors are labeled on theside of the respective modules and are also detailed in the module section of this document.This manual details specific information for configuring and commissioning the <strong>Numatics</strong> <strong>G3</strong> <strong>Series</strong> productline. For more information relating to pneumatic valving and valve manifold assemblies, please refer to the<strong>Numatics</strong> In Control Catalog at www.numatics.com .ClipsAllows easy field changes of electronicmodules.Graphic DisplayAllows Easy Configuration& Diagnostic reportingARM(Auto Recovery Module)Automatically stores & reprogramsconfiguration informationSub-Bus OUTUsed to distributeadditional I/O andmanifoldsDiscrete I/O SideAccepts up to 16 modules incentralized or distributed configurationCommunication Module (Node)Available with variousIndustrial protocolsValve SideDrives up to 32 coilsTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 4

<strong>G3</strong> Electronics ModularityDiscrete I/O<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>The <strong>G3</strong> <strong>Series</strong> product line is a completely modular and scalable system. As shown below, all of the <strong>G3</strong>electronic modules plug together, via mechanical clips, allowing easy assembly and field changes.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 5

Pneumatic Valve Manifold<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>The pneumatic valve manifold with Internal Circuit Board Technology is also modular. The valve solenoidcoil connections are automatically made using Z-Board technology (plug together PC boards, which allowinternal connection from solenoid coils to output drivers without the use of wires). This allows easy assemblyand field changes.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 6

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Manifold ConnectorsSolenoid Coil Connections using Z-Board technologyZ-Board plug together technology connects all valve solenoids to the valve coil output driver board,located in the valve adapter. The 32 available coil outputs are divided into 2 separate connector groups.Output group No. 1 is comprised of the first output word, bits 0-15, and output group No. 2 is comprisedof the second output word, bits 16-31. Output group No. 1 connects directly to the Z-Boards . Outputgroup No. 2 is connected to the Z-Boards via an internal ribbon cable or valve side Sub-D. The firstoutput (bit 0) connects to the “14” (A) solenoid on the valve closest to the communication node. The 17 th– 32 nd solenoids interconnect via the Z-Boards to output group No. 2. For the maximum capability of 32solenoids on the same manifold, the 16 th and 17 th solenoid coils must NOT be on the same sub-base.Output GroupNo. 1Output GroupNo. 2Plug-in Manifold withIntergral "Z-Board"Eliminates WiringEarth Ground Pin No. 314(A) Solenoid Pin No. 1SINGLE"Z-BOARD"DOUBLE"Z-BOARD"SINGLE"Z-BOARD"DOUBLE"Z-BOARD"Common Pin No. 412(B) Solenoid Pin No. 2NOTE!A single solenoid valve’s coil is always on the “14” end.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 7

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Z-Board ConnectorsThe 2005/2012/2035 valve series utilize 2 different Z-Board designs to achieve the single and doublesolenoid output functions. This yields the possible 32 single, 16 double, or various combinations of valvecoil output capabilities.Single Z-Board Double Z-Board Ribbon ConnectionSingle Z-Board Ribbon ConnectionDouble Z-Board singledoubleNOTE!The 17 th solenoid (output group No. 2’s first bit) must be accessed via either thevalve side Sub-D output module or a ribbon connector type Z-board.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 8

Z-Board and Ribbon Cable Example<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>If fourteen (14) single solenoid and one (1) double solenoid valves are connected directly to thecommunication node via their Z-Boards , and one (1) single solenoid and four (4) double solenoid valvesare connected to the communication node via the ribbon cable, the following would be the valve side bitmap:Output Word 0 1Output Byte 0 1 2 3Output Bit No. 00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31Solenoid Coil1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32Output No.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 9

Z-Board with Valve Side Sub-D Example<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>If sixteen (16) single solenoid valves are connected directly to the communication node via their Z-Boards , and a valve side Sub-D connector is connected to the communication node via the output GroupNo. 2 connector then the following would be the valve side bit map:Output Word 0 1Output Byte 0 1 2 3Output Bit No. 00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31Solenoid Coil1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32Output No.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 10

Communication Module<strong>Modbus</strong> <strong>TCP</strong> Communication Module (Node)<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>This module is the communication interface to the manifold. It contains communication electronics andinternal short circuit protection for power. It can be configured via software, via the graphic display ormanually via DIP switches through the optional <strong>Manual</strong> Configuration Module (MCM).Communication Module Kit Part Number<strong>Modbus</strong> <strong>TCP</strong> Communication module 240-292TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 11

Communication Module Description<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Detail No.Description1 “Set” Button – used to navigate through user menus and to set parameters2 Activity/Link Status LED3 4 Pin M12 D-Coded Female Communication Connector4 Mounting Hole5 “Next” Button – used to navigate through user menus and to set parameters6 Graphic Display – used to display parameter information7 Network Status LED8 Slot for text ID tags9 Keying for preventing I/O module insertion10 4 Pin MINI Male Power Connector15627389104TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 12

Connector Pin-Outs<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Industry standard connectors are used for communication and auxiliary power.The Ethernet communication connector is a D-coded keyway 4 pin female M12 connector.The Power connector is a single keyway 4 pin male 7/8” MINI connector.<strong>Modbus</strong> <strong>TCP</strong> Communication Connector Pin-OutPin No. Function Description1 TX+ Positive Transmit Line2 RX+ Positive Receive Line3 TX- Negative Transmit Line4 RX- Negative Receive LinePower Connector with Cenelec Pin-OutCenelecPin No.1234Function+24 VDC(Valves and Outputs)+24 VDC(Node and Inputs)0 VDC(Node and Inputs)0 VDC(Valves and Outputs)DescriptionVoltage used to power outputs(valve coils and discrete outputs) SWVoltage used to power discrete inputs andnode electronics UNSW0 VDC Voltage used to power discrete inputs andnode electronics UNSW0 VDC Voltage used to power outputs(valve coils and discrete outputs) SW!Power common (0 VDC) pins 3 and 4 are isolated from each other to allowseparate (isolated) power supply connection if required. However, they canbe tied together if a single common, non-isolated, application is preferred.The combined draw of the +24VDC Valves and Outputs and +24VDCNode and Inputs pins cannot exceed 8 Amps, at any given moment in time.The Node and Inputs pin supplies power to the node electronics. This pinmust be powered at all times for communication node to be functional.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 13

Electrical ConnectionsPower Connector Wiring DiagramPower Supply Example (Non-isolated commons)<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Power Supply Example (Isolated commons)!Please see page 18 for external fuse sizing guide.When using molded connector power cables, Do Not rely on wire colors forPin-Out. Always use pin number references.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 14

Ethernet Straight-Through Cabling Diagrams<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Straight-Through Ethernet cable is used when connecting an Ethernet node to a basic media component(router, switch, hub, etc.). Here are some basic wiring examples of Straight-Through cabling.RJ45 to M12 D Coded Cable6RX- (GREEN)RX+ (WHITE/GREEN)RX+ (WHITE/GREEN)TX- (ORANGE)3MALE2STRAIGHT-THROUGHCABLEMALE324 11TX- (ORANGE)TX+ (WHITE/ORANGE)RX- (GREEN)TX+ (WHITE/ORANGE)M12 D Coded to M12 D Coded CableTX- (ORANGE)RX+ (WHITE/GREEN)RX+ (WHITE/GREEN)TX- (ORANGE)32MALE4 1TX+(WHITE/ORANGE)STRAIGHT-THROUGHCABLEMALERX- (GREEN)324 1RX- (GREEN)TX+ (WHITE/ORANGE)NOTE!These are examples only. For appropriate network cabling information,please see the ODVA document titled, “EtherNet/IP TM : MediaPlanning and Installation <strong>Manual</strong>”.RJ45 shown as T-568B standard.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 15

Ethernet Crossover Cabling Diagrams<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>A Crossover Ethernet cable is used when connecting two Ethernet nodes directly together. For example, whenyou connect a computer directly to a <strong>Numatics</strong>’ valve manifold, a Crossover cable would be used. Here aresome basic wiring examples of Crossover cabling.RJ45 to M12 D Coded Cable6TX- (ORANGE)TX+ (WHITE/ORANGE)RX+ (WHITE/GREEN)TX- (ORANGE)3MALE2CROSSOVER CABLEMALE324 11RX- (GREEN)RX+ (WHITE/GREEN)RX- (GREEN)TX+ (WHITE/ORANGE)M12 D Coded to M12 D Coded CableRX- (GREEN)TX+ (WHITE/ORANGE)RX+ (WHITE/GREEN)TX- (ORANGE)3232MALECROSSOVER CABLEMALE4 1RX+(WHITE/GREEN)RX- (GREEN)4 1TX- (ORANGE)TX+ (WHITE/ORANGE)NOTE!These are examples only. For appropriate network cabling information,please see the ODVA document titled, “EtherNet/IP TM : MediaPlanning and Installation <strong>Manual</strong>”.RJ45 shown as T-568B standard.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 16

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Power ConsumptionPower ConnectionCENELECPin No.1234FunctionDescription+24 VDC Voltage used to power outputs(Valves and Outputs) (valve coils and discrete outputs) SW+24 VDC Voltage used to power discrete inputs and(Node and Inputs) node electronics UNSW0 VDC Common 0 VDC (-V) Voltage used to power discrete inputs and(Node and Inputs) node electronics UNSW0 VDC Common 0 VDC (-V) Voltage used to power outputs(Valves and Outputs) (valve coils and discrete outputs) SWPower Rating For maximum supply current capability please refer to page 45. Loads should not draw more than 0.5 Amps of current from any one individual discrete output point(Contact factory for higher current capability requirements).Component Voltage Tolerance+24VDC(Valves and Outputs)Pins 1 & 4+24VDC(Node and Inputs)Pins 2 & 3Current Power Current PowerSolenoid Valve Coil 2002 (Each) 24 VDC +10%/-15% 0.021 A 0.5 W 0 A 0 WSolenoid Valve Coil 2005 (Each) 24 VDC +10%/-15% 0.056 A 1.35 W 0 A 0 WSolenoid Valve Coil 2012 (Each) 24 VDC +10%/-15% 0.105 A 2.5 W 0 A 0 WSolenoid Valve Coil 2035 (Each) 24 VDC +10%/-15% 0.105 A 2.5 W 0 A 0 WSolenoid Valve Coil ISO - SPA 24 VDC +10%/-15% 0.167 A 4.0 W 0 A 0 WValve Adapter (Driver) 24 VDC +/- 10% .134 A 3.22 W 0 A 0 WDiscrete Digital Input Module 24 VDC +/- 10% .012 A .29 W .085 A* 2.04 W*Discrete Digital Output Module 24 VDC +/- 10% .051 A 1.2 W .060 A* 1.44 W*Discrete Digital I/O Module 24 VDC +/- 10% .035 A 0.84 W .076 A* 1.82 W*Discrete Analog Input Module (V & C) 24 VDC +/- 10% .012 A 0.288 W .077 A* 1.85 W*Discrete Analog I/O Module (V & C) 24 VDC +/- 10% .018 A 0.432 W .087 A* 2.08 W*Communication Module (Node) 24 VDC +/- 10% .006 A 0.144 W .091 A* 1.7 W*Sub-Bus Valve Module 24 VDC +/- 10% .012 A 0.288 W .066 A* 1.58 W*Auto Recovery Module (ARM) 24 VDC +/- 10% 0A 0 W .022 A .53 W<strong>Manual</strong> Configuration Module (MCM) 24 VDC +/- 10% 0 A 0 W .022 A .53 W* Current depends on graphic display brightness setting. Max. value shown with high brightness.Values decrease by approx. 12% for Medium and 25% for Low brightness settings.NOTE!Total power consumption for each Discrete I/O point is dependent onthe specific current draw of input sensor devices and output loads.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 17

Recommended External Fuses<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>External fuses should be chosen based upon the physical manifold configuration. Please refer to thetable below for the fuse sizing chart.External Fuse Sizing ChartPower Consumption - Power Connector Pin for Valves and OutputsDescriptionCurrentNumber of Solenoid Valve Coils Energized Simultaneously___ X 0.167 A (ISO - SPA <strong>Series</strong>) = __________Amps___ X 0.105 A (2012 and 2035 <strong>Series</strong>) = __________Amps___ X 0.056 A (2005 <strong>Series</strong>) = __________Amps___ X 0.021 A (2002 <strong>Series</strong>) = __________Amps+Total load current drawn by simultaneously energized Discrete Outputs =__________Amps+Number of I/O modules installed ___ X 0.008 A =__________Amps+Valve Adapter =.134 Amps+Communication Node Power Consumption =.006 Amps+Total: __________AmpsSurge Compensation: X 1.25Suggested External +24 VDC (Valves and Outputs) Fuse Value: __________AmpsPower Consumption – Power Connector Pin for Node and InputsDescriptionCurrentCommunication Node Power Consumption = .091 Amps+Total load current drawn by Sensor Devices from Discrete Inputs source =__________Amps+Number of I/O modules installed ___ X 0.080 A = __________Amps+Total: __________AmpsSurge Compensation: X 1.25Suggested External Pin +24 VDC (Node and Inputs) Fuse Value: __________Amps*Factory Default SettingsNOTE!The Node and Inputs Aux Power pins supply power to the node electronics.These pins must be powered at all times for communication node and Inputs to be functional.The internal electronic fuses exist to protect against damage due to catastrophic failure ofinternal components. External fuses are always recommended for protection against powersupply failure, over-current conditions, etc…TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 18

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>DiagnosticsCommunication Module LED FunctionsUpon power up, the LEDs indicate the status of the unit. There are three LEDs on the <strong>G3</strong> Ethernet node.These LEDs are described below.LED Name Color Status DescriptionOff OFF No power applied to +24V NODE/ IN .ON Device operational. The module is operating correctly.GreenFLASHING Standby. The module has not been configured.MODULEON Major fault. A major internal error has been detected.STATUSRedMinor fault. A minor recoverable fault has been detected.FLASHINGSelf -Test Mode - An error has occurred in the initialization process.Green Red FLASHING Self -Test Mode.Off OFFIP address has not been assigned to node or no power applied to+24V NODE/ IN .ON Connected. The module has established an <strong>Modbus</strong> <strong>TCP</strong> connection.GreenNo connection. There are no <strong>Modbus</strong> <strong>TCP</strong> connections established to theNETWORKFLASHINGmodule.STATUSDuplicate IP address. The module has detected that its IP address is alreadyONbeing used elsewhere on the networkRed<strong>Modbus</strong> <strong>TCP</strong> connection has timed out. One or more of the connections forFLASHINGwhich this module is the target has timed out.OFF No Ethernet connection is detectedACTIVITY/LINK Green ON The module is connected to an Ethernet networkFLASHING The LED flashes each time a packet is received or transmitted.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 19

Output Short Circuit ProtectionStatus Bit Action During Fault Condition<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Output TypeValve Solenoid Coil DriverValve Solenoid Coil DriverDiscrete OutputsOutputStateONOFFONFault ConditionStatusBitNo Fault 0Fault - Short Circuit, Over Temp/Over Current 1No Fault 0Fault - Open Load 1No Fault 0Fault - Short Circuit, Over Temp/Over Current 1TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 20

<strong>G3</strong> Graphic Display<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>The <strong>G3</strong> Communication and I/O modules have an integrated graphic display that may be used to configurethe parameters of the modules as well as showing diagnostic information.The following graphic displays represent the main menu selections of the communication module (node). Usethe NEXT button to scroll through the Main menu headings shown below. At this level pressing the SETbutton allows access the Sub-Menus. Please see the appropriate pages referenced below for further details anddescriptions of the Sub-Menus. NOTE: WHEN A NETWORK I/O CONNECTION IS ESTABLISHEDMANUAL CHANGES TO NODE PARAMETERS ARE NOT ALLOWED!Home ScreenIP ADDRESSSUBNET MASKDHCP‐BOOTPMAC ADDRADVANCEDFACTORY192.168.1.10 0.15.24.00.06.69SETTINGSDEFAULTSDIAGNOSTICS255.255.255.0DISABLEDSee page 22for Sub‐MenuSee page 23for Sub‐MenuSee page 24for Sub‐MenuSee page 25for Sub‐MenuSee page 26for Sub‐MenuSee page 31for Sub‐MenuSee page 33for Sub‐MenuTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 21

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>IP Address Sub-MenuSteps to Set IP Address1. Press the SET button to enter the IP ADDRESS sub-menu.IP ADDRESS192.168.3.120IP ADDRESS192.168.3.1202. Press the NEXT button to select the octet that you would like to change.Press the SET button to change the value.IP ADDRESS192.168.3.120IP ADDRESS092.168.3.1203. Press the SET button to scroll through the hundred, tens and ones digits of theoctet.Press the NEXT button to scroll through the valid digits (0-9).Press the SET button to advance through the octet.Press the NEXT button to advance to the next octet, scroll pass the fourthoctect to accept the entire IP Adress4. Press the SET button to input the address shown on the display,ACCEPTIP ADDR Y NSAVE SETTINGSNOW LATER5. Press the NEXT button to select Yes or No to accept the IP Address shown onthe display..a. Selecting No will bring you back to the main Address menu.b. Selecting Yes will take you to the following SAVE SETTINGS menu6. Press the NEXT button to select either NOW or LATER.a. Selecting NOW will cause the node to reset and apply the newsetting.b. Selecting LATER will cause the new Address to be saved intemporary memory to allow you to make additional parameterchanges before the node is reset. However, you must ACCEPT thesaved changes before your next power cycle otherwise they will belost.Press the SET button to confirm your choice.NOTE! Factory default address is 192.168.3.120 0 and 255 are not valid for the fourth octetTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 22

Subnet Mask Sub-Menu<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>SUBNET MASK255.255.255.0Steps to Set Subnet Mask1. Press the SET button to enter the Subnet Mask sub-menu.SUBNET MASK255.255.255.02. Press the NEXT button to select the octet that you would like to change.Press the SET button to change the value.SUBNET MASK255.255.255.0SUBNET MASK255.255.255.03. Press the SET button to scroll through the hundred, tens and ones digits of theoctet.Press the NEXT button to scroll through the valid digits (0-9).Press the SET button to advance through the octet.Press the NEXT button to advance to the next octet, scroll pass the fourthoctect to accept the entire Subnet Mask4. Press the SET button to input the value shown on the display,ACCEPTMASK Y NSAVE SETTINGSNOW LATER5. Press the NEXT button to select Yes or No to accept the Subnet Mask shownon the display..c. Selecting No will bring you back to the main Subnet Mask menu.d. Selecting Yes will take you to the following SAVE SETTINGS menu6. Press the NEXT button to select either NOW or LATER.c. Selecting NOW will cause the node to reset and apply the newsetting.d. Selecting LATER will cause the new Address to be saved intemporary memory to allow you to make additional parameterchanges before the node is reset. However, you must ACCEPT thesaved changes before your next power cycle otherwise they will belost.Press the SET button to confirm your choice.NOTE! Factory default subnet mask is 255.255.255.0TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 23

DHCP-BOOTP Sub-Menu<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>This will allow the enabling / disabling of the DHCP (Dynamic Host Control Protocol) and / BOOTPparameters. Enabling this parameter will allow the IP Address to be set via a BOOTP/DHCP server.DHCP-BOOTP StepsDHCP-BOOTPDISABLED1. Press the SET button to enter the DHCP-BOOTP sub-menu.DHCP-BOOTPDISABLEDDHCP-BOOTPENABLED2. Press the NEXT button to scroll through the choices to enable or disable thefeature.a. ENABLED (Factory Default)b. DISABLEDc. RETURN (this will return you to the main menu)Press the SET button to confirm your choice.DHCP-BOOTPRETURNACCEPTENABLED Y N3. Press the NEXT button to select Yes or No to accept the selection.a. Selecting No will bring you back to the main menu.b. Selecting Yes will take you to the following apply changes menu.Press the SET button to confirm your choice.ACCEPTENABLED Y NSAVE SETTINGSNOW LATERApply Changes Steps4. Press the NEXT button to select either NOW or LATER.a. Selecting NOW will cause the node to reset and apply the newsetting.b. Selecting LATER will cause the new setting to be saved inmemory, you must accept the saved changes before your nextpower cycle otherwise they will be lost.Press the SET button to confirm your choice.NOTE!Factory default setting for DHCP-BOOTP is enabled.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 24

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>MAC ADDR MenuMAC (Machine Access Control) AddressMAC ADDR0.15.24.00.00.06.691. The MAC Address is a fixed unique value that can not be edited.The actual MAC ADDR has an extra leading zero. The actual number in theexample shown is 00-15-24-00-06-69NOTE!The MAC ADDR can not be editedPlease note that the leading 0 in this number has been left offTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 25

Advanced Settings - I/O Diag. Menu<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>This will allow the enabling / disabling of the IO Status bits. The IO status bits include valve coil, discreteoutput, short circuit and alarm status bits.ADVANCEDSETTINGSI/O Status Steps1. Press the SET button to enter the ADVANCED SETTINGS sub-menu.ADVANCEDMENUSET STATUS2. Press the SET button to enter the ADVANCED MENU / SET STATUS.SET STATUSI/O STATUS3. Press the SET button to enter the SET STATUS / I/O STATUS.I/O STATUSENABLED4. The current state of the parameter is shown.I/O STATUS.ENABLEDI/O STATUSDISABLED5. Press the SET button to change this parameterUse the NEXT button to scroll through the choices to enable/disable theDiagnostic status for I/O.a. ENABLED (Factory Default)b. DISABLEDc. RETURN (this will return you to the SET STATUS menu)Press the SET button to confirm your choice.I/O STATUSRETURN6. Press NEXT to confirm the warning message.INPUT MAPPINGWILL SHIFTACCEPTDISABLED Y NSAVE SETTINGSNOW LATER7. Press the NEXT button to select Yes or No to accept the selectiona. Selecting No will bring you back to the main SET STATUS menu.b. Selecting Yes will take you to the following saved settings menu.Press the SET button to confirm your choice.Save Settings Steps8. Press the NEXT button to select either NOW or LATER.a. Selecting NOW will cause the node to reset and apply the newsetting.b. Selecting LATER will cause the new I/O STATUS selection to besaved in memory, you must Accept the saved changes before yournext power cycle otherwise they will be lost.Press the SET button to confirm your choice.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 26

Advanced Settings - Diagnostic Word<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>This will allow the enabling / disabling of the Diagnostic Word Status bits. The Diagnostic word bits includepower status and sub-bus related status bits. Detailed information regarding these bits can be found on page93. The Diagnostic Word comes enabled from the factory.Diag. Word Status SettingsADVANCEDSETTINGS9. Press the SET button to enter the ADVANCED SETTINGS menu.ADVANCED MENUSET STATUS10. Press the SET button to enter the ADVANCED MENU /SET STATUS.SET STATUSIO STATUSSET STATUSDIAG WORD11. Press the NEXT button to scroll to the SET STATUS / DIAG WORDmenu.Press the SET button to enter the SET STATUS / DIAG WORD menu.DIAG WORD.ENABLED12. The current state of the parameter is shown.DIAG WORD.ENABLEDNODE DIAG.DISABLED13. Press the SET button to change this parameterUse the NEXT button to scroll through the choices to enable/disable theDiagnostic Word status for.a. ENABLED (Factory Default)b. DISABLEDc. RETURN (this will return you to the SET STATUS menu)Press the SET button to confirm your choice.NODE DIAG.RETURNINPUT MAPPINGWILL SHIFT!14. Press Next to confirm the warning message.ACCEPTDISABLED Y NSAVE SETTINGSNOW LATER15. Press the NEXT button to select Yes or No to accept the selectiona. Selecting No will bring you back to the main SET STATUS menu.b. Selecting Yes will take you to the following saved settings menu.Press the SET button to confirm your choice.Save Settings Steps16. Press the NEXT button to select either NOW or LATER.a. Selecting NOW will cause the node to reset and apply the newsetting.b. Selecting LATER will cause the new NODE DIAG selection to besaved in memory, you must Accept the saved changes before yournext power cycle otherwise they will be lost.Press the SET button to confirm your choice.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 27

Advanced Settings - Fault Action<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>ADVANCEDSETTINGSFault Action Settings1. Press the SET button to enter the ADVANCED SETTINGS menu.ADVANCED MENUSET STATUSADVANCED MENUSET FAULT IDLE2. Press the NEXT button to scroll to the ADVANCED MENU / SET FAULTIDLE.3. Press the SET button to enter the ADVANCED MENU / SET FAULT IDLE.SET FAULT IDLEFAULT ACTION4. Press the SET button to enter the SET FAULT IDLE / FAULT ACTIONmenu.5. The current state of the parameter is shownFAULT ACTIONOFFFAULT ACTIONOFFFAULT ACTIONHOLD LAST STATE6. Press the SET button to change this parameterPress the NEXT button to scroll the choices for the desired output action duringa fault state.a. OFF (Factory Default)b. HOLD LAST STATEc. RETURN (this will return you to the SET FAULT/IDLE menu)Press the SET button to confirm your choice.FAULT ACTIONRETURNACCEPTOFF H.L.S. Y NSAVE SETTINGSNOW LATER7. Press the NEXT button to select Yes or No to accept the selectionPress the SET button to confirm your choicea. Selecting No will bring you back to the main SET FAULT/IDLEmenu.b. Selecting Yes will take you to the following saved settings menu.Save Settings Steps8. Press the NEXT button to select either NOW or LATER.Press the SET button to confirm your choice.a. Selecting NOW will cause the node to reset and apply the new settingb. Selecting LATER will cause the new FAULT ACTION selection tobe saved in memory, you must Accept the saved changes before yournext power cycle otherwise they will be lost.Press the SET button to confirm your choice.NOTE!See page 78 for more details.Factory Default is “ALL OFF”TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 28

Advanced Settings - Idle ActionADVANCEDSETTINGS<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Idle Action Settings9. Press the SET button to enter the ADVANCED SETTINGS menu.ADVANCED MENUSET STATUSADVANCED MENUSET FAULT IDLE10. Press the NEXT button to scroll to the ADVANCED MENU / SET FAULTIDLE.11. Press the SET button to enter the ADVANCED MENU / SET FAULT IDLE.SET FAULT IDLEIDLE ACTION12. Press the NEXT button to scroll to the IDLE ACTION menu13. Press the SET button to enter the SET FAULT IDLE / IDLE menu.FAULT ACTIONOFFFAULT ACTIONOFFFAULT ACTIONHLD LAST STATE14. The current state of the parameter is shown15. Press the SET button to change this parameterPress the NEXT button to scroll the choices for the desired output action duringa fault state.d. OFF (Factory Default)e. HOLD LAST STATEf. RETURN (this will return you to the SET FAULT/IDLE menu)Press the SET button to confirm your choice.FAULT ACTIONRETURNACCEPTLAST STATE Y NSAVE SETTINGSNOW LATER16. Press the NEXT button to select Yes or No to accept the selectionPress the SET button to confirm your choicec. Selecting No will bring you back to the main SET FAULT/IDLEmenu.d. Selecting Yes will take you to the following saved settings menu.Save Settings Steps17. Press the NEXT button to select either NOW or LATER.Press the SET button to confirm your choice.c. Selecting NOW will cause the node to reset and apply the new settingd. Selecting LATER will cause the new FAULT ACTION selection tobe saved in memory, you must Accept the saved changes before yournext power cycle otherwise they will be lost.Press the SET button to confirm your choice.NOTE!See page 78 for more details.Factory Default is ALL OFFTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 29

Advanced Settings - Brightness<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Brightness SettingsADVANCEDSETTINGS1. Press the SET button to enter the ADVANCED SETTINGS menu.ADVANCEDMENUSET STATUSADVANCEDMENUSET BRIGHTNESSBRIGHTNESSHIGH2. Press the NEXT button to scroll to the CONFIG MENU / SETBRIGHTNESS.Press the SET button to enter the CONFIG MENU / SET BRIGHTNESS.3. The current state of the parameter is shownBRIGHTNESSLOWBRIGHTNESSMEDIUMBRIGHTNESSHIGH4. Press the SET button to change this parameterPress the NEXT button to scroll the choices for the desired brightness of thegraphic display for all modules on the <strong>G3</strong> system.a. LOWb. MEDIUMc. HIGH (Factory Default)Press the SET button to confirm your choice. The changes will take effectimmediately.NOTE!This a global setting that affects all modulesEach module, however, has its own setting if different settingsare required.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 30

Advanced Settings - Parameters<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>PARAMETER StepsPARAMETERSUNLOCKED1. Press the SET button to enter the Parameters sub-menu.PARAMETERSUNLOCKEDPARAMETERSLOCKEDPARAMETERSRETURNACCEPTLOCKED Y N2. Press the NEXT button to scroll through the choices to enable or disable thefeature.d. UNLOCKED (Factory Default)e. LOCKEDf. RETURN (this will return you to the main menu)Press the SET button to confirm your choice.By choosing LOCKED, all settable parameters will be read only via thegraphic display. UNLOCKED, the factory default, will allow all parametersto be settable through the graphic display.Please note that all parameters are read only, regardless of this setting, when an IOconnection between the communication module and the controller (PLC) is present3. Press the NEXT button to select Yes or No to accept the selection.c. Selecting No will bring you back to the main menu.d. Selecting Yes will take you to the following apply changes menu.Press the SET button to confirm your choice.ACCEPTLOCKED Y NSAVE SETTINGSNOW LATERApply Changes Steps4. Press the NEXT button to select either NOW or LATER.c. Selecting NOW will cause the node to reset and apply the newsetting.d. Selecting LATER will cause the new setting to be saved inmemory, you must accept the saved changes before your nextpower cycle otherwise they will be lost.Press the SET button to confirm your choice.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 31

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Factory DefaultsFactory Default Settings1. Press the SET button to enter the FACTORY DEFAULTS sub-menu.FACTORYDEFAULTS2. Press the SET button to change this parameterSET DEFAULTSNOSET DEFAULTSNO3. Press the NEXT button to select Yes or No.a. Selecting No will bring you back to the main FACTORYDEFAULTS menu.b. Selecting Yes will cause the node to reset and return allparameters to the factory default conditions.c. Selecting RETURN will bring you back to the main FACTORYDEFAULTS menuPress the SET button to confirm your choice.FACTORY DEFAULT SETTINGSDescriptionDefaultIP Address 193.168.3.120Sub Net Mask 255.255.255.0Diagnostic WordEnabledI/O Diagnostic StatusEnabledFault ActionReset to All OffIdle ActionReset to All OffBrightnessHighParametersUnlockedTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 32

Diagnostics - Self Test Mode<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>An internal diagnostic tool can be enabled on the communication module (node) using the graphic display.This tool allows the user to confirm that all of the inputs and outputs on the manifold and any of thedistributed modules are fully functional without needing a network connection or controller. There are two testmodes that the user can choose. The “CYCLE OUTPUTS” test mode tests all the outputs by sequentiallyturning them ON and OFF for approximately .5 seconds. The “INPUTS” test mode tests the inputs by causingall of the outputs to toggle between even and odd values when any input is made. The Self Test mode on thecommunication module (node) is a global setting and will test all devices connected on the main manifold aswell as any distributed modules and/or manifolds.Similar “local” self tests are available on all output modules types. This “local” self test function allows anyoutput module to be tested without affecting any other output module.NOTE: The number of Valve outputs that are tested are affected by the I/O size settings.To use the Self Test Mode, the user must first set some initial conditions. Follow these steps to initiate theself-test mode.1) Disconnect Air and Communication from the manifold!2) Select the desired test mode using the graphic display. (See example below)3) Starting at the Home Screen, navigate the menus by selecting the NEXT button until theDIAGNOSTICS menu is shown.4) Select the SET button to access the DIAGNOSTICS menu and then again to access theSELF-TEST menu5) Push NEXT to navigate to the desired test mode: CYCLE OUTPUTS or INPUTS6) Push SET to select the desired test mode.7) A message will appear: DISCONNECT AIR HOLD SET BUTTON8) Hold the SET button down for approximately 10 seconds to enable the test. The Display will flashthe above message while the button is pushed.9) When the display stops flashing, the self-test mode will run and the Module Status LED will flashRed/Green while the display shows SELF TEST RUNNING.10) The global self-test mode can only be disabled by disconnecting the power to the manifold.IP ADDRESS192.168.3.120DIAGNOSTICSDIAGNOSTICSSET SELF‐TESTSET SELF TESTCYCLE OUTPUTSSET SELF‐TESTINPUTSDISCONNECT AIRHOLD SET BUTTONHOLD FOR 10 SECONDS TOINITIATETD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 33

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Diagnostics Cont.DIAGNOSTICS1. All diagnostic information is read only2. Press the SET button to enter DIAGNOSTICS sub-menu.USNW POWER24.83 VNETWORKERRORSMAIN NETWORKMAIN NETWORKNO ERRORS3. Press the NEXT button to scroll through the main diagnostic menu choices.a. UNSW POWERi. - Displays voltage level of unswitched power (Node & Inputs)b. NETWORK ERRORS - ERROR CODEi. - Displays fieldbus network errorsc. MAIN NETWORKi. - Displaysd. SUB-NETWORKi. - Displays log of network errorse. FIRMWARE REV.i. - For service personnelf. FIRMWARE BUILDi. For service personnelSUB-NETWORKSUB-NETWORKNO ERRORSg. BOOTCODE REV.i. -For service personnelh. BOOTCODE BUILDi.j. PART NUMBERi. - Displays replacement part number of moduleFIRMWARE REV.1.1FIRMWARE BUILDXXXXXLOADFIRMWAREBOOTCODE REV.1.0BOOTCODE BUILDXXXXXPART NUMBER240-181NOTE!The UNSW POWER screen indicates the voltage level present on the UNSW(Node & Input) power pins (Pin No. 2 and 3) of the main power connector.A voltage level less than 19 volts will generate an error screen and anassociated diagnostic bit (see ‘Diagnostic’ section for more details).TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 34

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Error MessagesThe following are automatic error messages that are displayed when specific faults occur during operation:SUB-BUS SHORTDisplayed when a short circuit condition isdetected on the Sub-Bus power lines.SHORTED COILNO. XDisplayed when a short circuit condition isdetected on a valve coilMISSING MODULENUMBER XDisplayed when a Sub-Bus module that hadbeen previously installed becomes absent fromthe configurationVALVE/ OUTPUTPOWER OFFDisplayed when +24 VDC on Pin No. 1 andNo. 4 (Valves and Outputs) is not present orbelow 22 VDCUNSWITCHEDPOWER LOWDisplayed when +24 VDC on Pin No. 2 andNo. 3 (Node and Inputs) is below 19 VDCTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 35

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>MCM – <strong>Manual</strong> Configuration Module (Optional)The MCM is an optional module that is installed between the node and the valve adapter module and allowsthe user to manually set the last octet of the IP address without the need for software configuration or the useof the integrated graphic display in the node. If software configuration or configuration via the integratedgraphic display in the node is preferred, this module is not necessary.DescriptionReplacement Part NumberComplete Module 240-186TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 36

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>DIP Switch SettingsIP Address:The DIP switches provide a manual way to configure the node’s IP address. The values of the first, secondand third octets are factory set to 192.168.001, respectively. The switches set the binary value of the last octet inthe IP address. When all DIP switches are set to OFF, manual configuration is disabled and other means ofsetting the IP address must be used. DIP switch configuration settings require power to be cycled before anychanges will take effect.IP address:192.168.001.XXX (192.168.001.SW1)Subnet Mask 255.255.255.0Gateway address: 0.0.0.0 (no gateway set)XXX = DIP switch setting per the table belowON1 2 3 4 5 6 7 8All switches shown inthe "OFF" position.2 7 =128SW-82 6 =64SW-72 5 =32SW-62 4 =16SW-52 3 =8SW-42 2 =4SW-32 1 =2SW-22 0 =1SW-1OFF OFF OFF OFF OFF OFF OFF OFF 0*OFF OFF OFF OFF OFF OFF OFF ON 1OFF OFF OFF OFF OFF OFF ON OFF 2OFF OFF OFF OFF OFF OFF ON ON 3OFF OFF OFF OFF OFF ON OFF OFF 4Octet Value(Decimal)OFF ON ON ON ON OFF OFF OFF 120ON ON ON ON ON ON OFF ON 253ON ON ON ON ON ON ON OFF 254ON ON ON ON ON ON ON ON 255**Not valid for fourth octetTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 37

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>ARM – Auto Recovery Module (Optional)The Auto Recovery Module (ARM) is an optional memory module that is installed between the node andthe valve adapter module and is used to preserve the manifold configuration settings even duringcatastrophic failure. During the power-up process it reads the configuration of the manifold, includingany user settable parameters of I/O modules, and stores the information in its non volatile memory. Oncethe information is stored, it automatically disconnects itself from the power circuits while stillmechanically attached to the manifold. Upon power-up it reconnects itself and compares the storedconfiguration settings to the actual manifold configuration. If these settings are different it gives the userthe option of:1. Updating the manifold setting with the stored values2. Updating the ARM module with the current settings3. Continue operation with present configuration without updating ARMDescriptionReplacement Part NumberComplete ARM Module 240-182TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 38

Distribution<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Distribution of I/O capability can be easily achieved with the <strong>G3</strong> platform by means of Sub-Bus modules.I/O modules, valve manifolds and/or a combination of both can be simply separated from the main manifoldand distributed via a sub-bus communication cable. The <strong>G3</strong> platform uses the same I/O modules on the mainmanifold as on the distribution chain. The main communication module can control up to 16 I/O moduleseither on the main manifold or as part of the sub-bus connections. To utilize the sub-bus distributioncapabilities the Sub-Bus OUT module must be located on the end of the main communication manifold and aTerminator Module must be located at the last sub-bus component.Example 1Fieldbus network5712Main FieldbusValve Manifoldwith I/O5PowerSupply36DistributedSub-Bus ValveManifoldwith I/O5774874DistributedSub-BusI/OModulesDetail No.Description1 Main Communication Module (Node)2 Sub-Bus Power Cable (Can be connected to additional power supply)3 Distributed Sub-Bus Valve Module4 Sub-Bus IN module5 Sub-Bus OUT module6 Sub-Bus Communication Cable7 I/O Modules8 Terminator ModuleTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 39

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Sub-Bus Distribution ModulesSUB-BUS OUT Module Used only when distributing the Sub-Bus to another assembly is required.SUB-BUS OUT - 5 pin M12 female communication connector.o Used to distribute the Sub-Bus to the next Sub-Bus assembly.o Carries 24 VDC power for electronics of the next module.AUX. POWER OUT - 4 pin M12 female aux. power connector.o Optional connection.o Used as a convenience way to distribute the power connection to the nextSub-Bus assembly.DescriptionReplacement Part NumberSub-Bus OUT Module with Din Rail Mounting 240-244Sub-Bus OUT module without Din Rail Mounting 240-183TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 40

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>SUB-BUS IN Modules Used to distribute I/O assemblies that do not have valveso Must be installed to the right of the I/O modules.SUB-BUS IN - 5 pin M12 male communication connector.o Must be connected to the Sub-Bus Out connector of the previous assemblyo Carries 24 VDC power for electronics of moduleAUX. POWER IN - 4 pin M12 male connector.o Aux power is required for Output modules. This connection also allows Output power to beinterrupted to all Output modules connected to this module.o Aux. Power is optional for Inputs. Power from the SUN-BUS IN connection is used to powersensors but can be augmented, if necessary, by adding additional power to this connector.DescriptionPart NumberSub-Bus IN module with Din Rail Mounting 240-246Sub-Bus IN module without Din Rail Mounting 240-185TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 41

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Terminator ModuleUsed to terminate SUB-BUS connections.o Must be installed on the left side of the last Sub-Bus module.DescriptionPart NumberTerminator Module with Din Rail Mounting 240-245Terminator Module without Din Rail Mounting 240-184NOTE!The terminator module is required to be installed in the <strong>G3</strong> system for properoperationTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 42

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Sub-Bus Valve ModuleCOMM - 5 pin M12 male Sub-Bus input communication connector.o Must be connected to the SUB-BUS OUT connector of the previous assemblyo Carries 24 VDC power for electronics of modulePOWER - 4 pin MINI male power connector.o Power is required for OutputsUsed to distribute Valves on the Sub-Bus.o Can accepts discrete I/O module to allow a Sub-Bus Valve manifold with I/ODescriptionPart NumberSub-Bus Valve Module 240-241Digital I/O ModulesNOTE!There is a 0.8 VDC drop in power across this module.Please consider this when distributing the Aux. Power after this module.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 43

Digital I/O ModuleDigital I/O Module Rules<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>The maximum number of modules that can be used on the Discrete I/O side of the manifold is 16. Thesemodules can be centralized on the main fieldbus manifold, distributed or a combination of both. Modules canbe connected in any combination of inputs, outputs and specialty up to the physical limitation of 16 modules.Input Module TypesOutput Module TypesInput/Output Module TypesValve Side Output Module TypesTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 44

I/O Module <strong>Technical</strong> Data<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>ModuleNo.DescriptionConnector TypeCurrentLimitation forModuleCurrent Limitation forconnector240‐203 16 PNP Inputs Terminal Strip 1.2A.30A for each+24VDC terminal240‐204 16 NPN Inputs Terminal Strip 1.2A.30A for each+24VDC terminal240‐205 16 PNP Inputs M12 1.2A .15A (Pin 1 to Pin 3)240‐206 8 PNP Inputs M12 1.2A .15A (Pin 1 to Pin 3)240‐207 16 PNP Outputs M12 1.2A .50A (Pin 3 to Pin 2/4)240‐208 8 PNP Outputs M12 1.2A .50A (Pin 3 to Pin 2/4)240‐209 16 NPN Inputs M12 1.2A .15A (Pin 1 to Pin 3)240‐210 8 NPN Inputs M12 1.2A .15A (Pin 1 to Pin 3).50A / output connector240‐2118 PNP Input and(Pin 3 to Pin 2/4)M12 1.2A8 PNP Outputs.15A / input connector(Pin 1 to Pin 3)CurrentLimitation forphysicalmanifoldassembly4A for +24Valves andOutputs4A for +24 Nodeand InputsTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 45

I/O Module Descriptions and Menus<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Detail No.Description1 “Set” Button – used to navigate through user menus and set parameters2 Module Function (I/O Type)3 Alignment arrow for SPEEDCON connector4 Bit Designation for I/O5 “Next” Button – used to navigate through user menus and set parameters6 Graphic Display7 5 Pin M12 female I/O connector8 Connector designation9 Metal threads for SPEEDCON connector10 Slot for text ID tags11 Dust Cover12 Mounting hole123567841091112MenuIO MAPPINGDIAG BYTE XXIO MAPPINGOUPUT BYTE XXDESCRIPTIONPART NUMBER240‐XXXFIRMWAREV 2.XXXSETBRIGHTNESSTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 46

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Digital Input ModulesOne Digital Input per Connector – M12 Female ModulesModulePart No.I/O Type240-206 NPN (Sinking)240-210 PNP (Sourcing)Short Circuit ProtectionShort CircuitProtection Status BitsInput PointsYES – Visual YES – Optional 8Input MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Required)X+1(Optional)Input 7 Input 6 Input 5 Input 4 Input 3 Input 2 Input 1 Input 0Conn. HSCPStatusConn. GSCPStatusConn. FSCPStatusConn. ESCPStatusConn. DSCPStatusConn. CSCPStatusConn. BSCPStatusConn. ASCPStatusTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 47

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Two Digital Inputs per Connector – M12 Female ModulesModulePart No.I/O Type240-209 NPN (Sinking)240-205 PNP (Sourcing)Short Circuit ProtectionShort CircuitProtection Status BitsInput PointsYES – Visual YES – Optional 16Input MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Required)X+1(Required)X+2(Optional)Input 7 Input 6 Input 5 Input 4 Input 3 Input 2 Input 1 Input 0Input 15 Input 14 Input 13 Input 12 Input 11 Input 10 Input 9 Input 8Conn. HSCPStatusConn. GSCPStatusConn. FSCPStatusConn. ESCPStatusConn. DSCPStatusConn. CSCPStatusConn. BSCPStatusConn. ASCPStatusTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 48

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Sixteen Digital Inputs – Terminal Strip ModulesSpecifications- Wire Range: 12 to 24 AWG- Strip Length: 7mm- Tightening Torque: 0.5 NmModulePart No.I/O Type240-203 PNP (Sourcing)240-204 NPN (Sinking)Short Circuit ProtectionYESVisual andLogical Status BitsShort Circuit ProtectionStatus Bits4 user enabled bitsmonitor Short Circuits onthe four different +voltage connections ofterminal stripInput Points16Input MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Required)X+1(Required)X+2(Optional)Input 7 Input 6 Input 5 Input 4 Input 3 Input 2 Input 1 Input 0Input 15 Input 14 Input 13 Input 12 Input 11 Input 10 Input 9 Input 8AllocatedandReservedAllocatedandReservedAllocatedandReservedAllocatedandReservedSCP Status1 = Fault+DSCP Status1 = Fault+CSCP Status1 = Fault+BSCP Status1 = Fault+A“+C”“+A”“+D”“+B”TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 49

Digital Output Modules<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>One Digital Output per Connector - M12 Female ModulesModuleShort CircuitI/O TypeShort Circuit ProtectionOutput PointsPart No.Protection Status Bits240-208 PNP (Sourcing) YES – Visual YES (8) – Optional 8Output MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Required)Output 7 Output 6 Output 5 Output 4 Output 3 Output 2 Output 1 Output 0Input MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Optional)Output 7StatusOutput 6StatusOutput 5StatusOutput 4StatusOutput 3StatusOutput 2StatusOutput 1StatusOutput 0StatusTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 50

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Two Digital Outputs per Connector - M12 Female ModulesModuleShort CircuitI/O TypeShort Circuit ProtectionPart No.Protection Status BitsOutput Points240-207 PNP (Sourcing) YES – Visual YES (8) – Optional 16Output MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Required)X+1(Required)Output 7 Output 6 Output 5 Output 4 Output 3 Output 2 Output 1 Output 0Output 15 Output 14 Output 13 Output 12 Output 11 Output 10 Output 9 Output 8Input MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Optional)X+1(Optional)Output 7StatusOutput 15StatusOutput 6StatusOutput 14StatusOutput 5StatusOutput 13StatusOutput 4StatusOutput 12StatusOutput 3StatusOutput 11StatusOutput 2StatusOutput 10StatusOutput 1StatusOutput 9StatusOutput 0StatusOutput 8StatusTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 51

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Sub-Bus Valve ModuleUsed to control a distributed valve manifold through the Sub-Bus. See page 43 for more information.ModuleShort CircuitI/O TypeShort Circuit ProtectionOutput PointsPart No.Protection Status Bits240-241 NPN (Sinking) YES – Visual YES (32) – Optional 32Output MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Required)X+1(Optional)X+2(Optional)X+3(Optional)Valve CoilNo. 7Valve CoilNo. 15Valve CoilNo. 23Valve CoilNo. 31Valve CoilNo. 6Valve CoilNo. 14Valve CoilNo. 22Valve CoilNo. 30Valve CoilNo. 5Valve CoilNo. 13Valve CoilNo. 21Valve CoilNo. 29Valve CoilNo. 4Valve CoilNo. 12Valve CoilNo. 20Valve CoilNo. 28Input MappingValve CoilNo. 3Valve CoilNo. 11Valve CoilNo. 19Valve CoilNo. 27Valve CoilNo. 2Valve CoilNo. 10Valve CoilNo. 18Valve CoilNo. 26Valve CoilNo. 1Valve CoilNo. 9Valve CoilNo. 17Valve CoilNo. 25Valve CoilNo. 0Valve CoilNo. 8Valve CoilNo. 16Valve CoilNo. 24BYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Optional)X+1(Optional)X+2(Optional)X+3(Optional)Coil 7StatusCoil 15StatusCoil 23StatusCoil 31StatusCoil 6StatusCoil 14StatusCoil 22StatusCoil 30StatusCoil 5StatusCoil 13StatusCoil 21StatusCoil 29StatusCoil 4StatusCoil 12StatusCoil 20StatusCoil 28StatusCoil 3StatusCoil 11StatusCoil 19StatusCoil 27StatusCoil 2StatusCoil 10StatusCoil 18StatusCoil 26StatusCoil 1StatusCoil 9StatusCoil 17StatusCoil 25StatusCoil 0StatusCoil 8StatusCoil 16StatusCoil 24StatusTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 52

Digital Input/Output Modules<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Two Digital I/O per Connector - 12mm Female ModulesShort Circuit Short Circuit Output InputModule Part No.I/O TypeProtection Protection Status Bits Points Points240-211 PNP (Sourcing) YES – Visual YES (8) – Optional 8 8Output MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0…X(Required)Output 7 Output 6 Output 5 Output 4 Output 3 Output 2 Output 1 Output 0Input MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Required)X+1(Optional)X+2(Optional)Input 7 Input 6 Input 5 Input 4 Input 3 Input 2 Input 1 Input 0AllocatedandReservedOutput 7Status BitAllocatedandReservedOutput 6Status BitAllocatedandReservedOutput 5Status BitAllocatedandReservedOutput 4Status BitConn. DSCPStatusOutput 3Status BitConn. CSCPStatusOutput 2Status BitConn. BSCPStatusOutput 1Status BitConn. ASCPStatusOutput 0Status BitTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 53

Valve Side Digital Output Modules<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>The valve side output module is used to distribute available valve side output points (i.e. when valves arelocated away from the rest of the electronics). These modules go to the right of the <strong>G3</strong> valve adapter. The 16 bitoutput module utilizes the last 16 output bits on the valve side of the manifold (bits 16-31).Sixteen Outputs per Connector - Sub-D 25 Pin Female ModuleModuleShort Circuit Internal StatusI/O TypeOutput Points Module SizePart No.Protection Bits239-1713 NPN (Sinking) Yes 16 – Optional 16 NarrowTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 54

Analog I/O Modules<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Analog I/O Module RulesThe analog I/O modules follow the same rules as the digital I/O modules. The maximum total number ofmodules on the Sub-Bus is 16. The analog boards allow the user to control devices using an analog signal.The analog modules also allow the user to relay analog information from input devices. These modules areavailable in two analog signal types: 0-10 V and 4-20 mA. These two signal types are offered in two differentI/O configurations: 2 analog input channels/ 2 analog outputs channels and 4 analog input channels.Four I/O - 12mm Female ModulesSpecifications- Input Resolution: 16 bit (65,536 Counts),- Output Resolution: 16 bit (65,536 Counts)- Settling Time: 3 ms Max- Absolute Precision: ≤ 1.0% of Signal- Voltage Input Impedance: 0-10VDC – 40K Ohms- Current Input Impedance: 250 Ohms- Input Cutoff Frequency: 100 HzModulePart No.Signal Type Input Points Output Points Short Circuit Protection240-212 0 - 10V 4 0240-213 0 - 10V 2 2240-214 4 - 20mA 4 0Yes240-215 4 - 20mA 2 2TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 55

Analog Module Descriptions and Menus<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Detail No.Description1 “Set” Button – used to navigate through user menus and set parameters2 Module Function (I/O Type)3 Bit Designation for I/O4 Alignment arrow for SPEEDCON connector5 5 Pin M12 female I/O connector6 “Next” Button – used to navigate through user menus and set parameters7 Graphic Display8 Connector designation9 Metal threads for SPEEDCON connector10 Slot for text ID tags11 Mounting hole1267384591011TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 56

Analog Graphic Display Menu<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>AnalogBar Graph4. Analog Bar Grapha. 2 separate screens, each with 2 I/O pointsIO MAPPINGINPUT BYTE XX5. Input mapping designationsa. Byte allocations for inputs.IO MAPPINGOUTPUT BYTE XX6. Input mapping designationsa. Byte allocations for outputs (2I/2O modules only)MODULE NUMBERXX7. Module Numbera. Details the Sub-Bus module number (1-16)ALARM SETTINGS8. Alarm Settingsa. See page 58 for more informationDESCRIPTIONXAI/XAO9. Descriptiona. Describes the number and type of inputs and outputsPART NUMBER240-XXXX10. Part numbera. Displays replacement part number of moduleFIRMWARE REV.V2.XXX11. Firmware Rev.a. For service personnelSET BRIGHTNESSLOWSET SELF TEST12. Set Brightness Levela. Changes brightness level of display between low, medium andhigh.13. Self Test modea. Allows the ability to test the Analog output points on the module.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 57

Analog Alarm Settings Graphic Display Menu<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Alarm Setting StepsALARMSETTINGSSET ALARMCHANNEL AI05. Press the SET button to enter the Alarm Settings sub-menu.6. Press the NEXT button to scroll through the different analog channelsa. Press SET to confirm your choiceSET ALARMCHANNEL AI1SET ALARMCHANNEL AI2SET ALARMCHANNEL AI3SET ALARMLO = X.XX7. Press the NEXT button to choose between low and high alarmse. Pressing SET will allow you to change the value of the alarmf. Pressing NEXT will change the value of the digit highlitedg. Pressing SET will accept the value highlighted.SET ALARMHI = X.XXSET ALARMRETURN8. Press the NEXT button to select either Yes or No to accept the value.ACCEPTXX.XX Y NSET ALARMRETURNTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 58

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>One Analog Input per Connector – M12 Female ModulesModulePart No.Signal Type240-212 0-10 VDC240-214 4-20 mAShort CircuitProtectionShort CircuitProtection Status BitsInput PointsYES – Visual YES (4) – Optional 4Input MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Required)X+1(Required)X+2(Required)X+3(Required)X+4(Required)X+5(Required)X+6(Required)X+7(Required)X+8(Optional)X+9(Optional)Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1Input No. 1(MSB)Input No. 1(LSB)Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2Input No. 2(MSB)Input No. 2(LSB)Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2Input No. 3 Input No. 3 Input No. 3 Input No. 3 Input No. 3 Input No. 3 Input No. 3Input No. 3(MSB)Input No. 3(LSB)Input No. 3 Input No. 3 Input No. 3 Input No. 3 Input No. 3 Input No. 3 Input No. 3Input No. 4 Input No. 4 Input No. 4 Input No. 4 Input No. 4 Input No. 4 Input No. 4Input No. 4(MSB)AllocatedandReservedHigh Alarmfor Conn. DInput No. 4(LSB)Input No. 4 Input No. 4 Input No. 4 Input No. 4 Input No. 4 Input No. 4 Input No. 4AllocatedandReservedLow Alarmfor Conn. DAllocatedandReservedHigh Alarmfor Conn. CAllocatedandReservedLow Alarmfor Conn. CPower Statusfor Conn. DHigh Alarmfor Conn. BPower Statusfor Conn. CLow Alarmfor Conn. BPower Statusfor Conn. BHigh Alarmfor Conn. APower Statusfor Conn. ALow Alarmfor Conn. ATD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 59

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>One Analog I/O per Connector – M12 Female ModulesModulePart No.Signal Type240-213 0-10 VDC240-215 4-20 mAShort CircuitProtectionShort CircuitProtection Status BitsOutputPointsInputPointsYES – Visual YES (4) – Optional 2 2Output MappingBYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Required)X+1(Required)X+2(Required)X+3(Required)Output No.1Output No.1 (MSB)Output No.2Output No.2 (MSB)Output No.1Output No.1Output No.2Output No.2Output No.1Output No.1Output No.2Output No.2Output No.1Output No.1Output No.2Output No.2Input MappingOutput No.1Output No.1Output No.2Output No.2Output No.1Output No.1Output No.2Output No.2Output No.1Output No.1Output No.2Output No.2Output No.1 (LSB)Output No.1Output No.2 (LSB)Output No.2BYTE Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0X(Required)X+1(Required)X+2(Required)X+3(Required)X+8(Optional)X+9(Optional)Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1Input No. 1(MSB)Input No. 1(LSB)Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1 Input No. 1Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2Input No. 2(MSB)AllocatedandReservedHigh Alarmfor Conn. DInput No. 2(LSB)Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2 Input No. 2AllocatedandReservedLow Alarmfor Conn. DAllocatedandReservedHigh Alarmfor Conn. CAllocatedandReservedLow Alarmfor Conn. CPower Statusfor Conn. DHigh Alarmfor Conn. BPower Statusfor Conn. CLow Alarmfor Conn. BPower Statusfor Conn. BHigh Alarmfor Conn. APower Statusfor Conn. ALow Alarmfor Conn. ATD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 60

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>I/O Module(s) Wiring DiagramsNPN/PNP DefinitionsNPN Descriptions Sinking Switching Negative Positive CommonLOADPNP Descriptions Sourcing Switching Positive Negative CommonLOADNPN (Sinking) Input ConnectionElectric Sensor TypeMechanical Sensor Type23231414PNP (Sourcing) Input ConnectionElectric Sensor TypeMechanical Sensor Type23231414TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 61

I/O Module(s) Wiring Diagrams ContinuedNPN (Sinking) Output Connection<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>PNP (Sourcing) Output ConnectionTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 62

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong><strong>Modbus</strong> <strong>TCP</strong> Configuration and MappingConnecting to a <strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> NodeThis section will discuss how to connect a computer to a <strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> node. There are multipleways to complete this task, so only two will be discussed. All computer commands are shown in Windows XP.1. Connect a 24VDC power supply to the valve manifold. The power pin-out can be found on the side ofthe <strong>Modbus</strong> <strong>TCP</strong> node or on page 12 of this document. (Note: 24VDC only needs to be applied to the“+24VDC (NODE & INPUTS)” pin to power the node.)2. Connect a crossover cable directly from the manifold to the computer -OR- Connect a straightthroughcable from the manifold to a router, hub, or switch. Next, connect a straight-through cablefrom the computer to the router, hub, or switch. (Network lights should appear on the router, hub, orswitch if the correct cables are used).3. Turn on the computer. Also, make sure the manifold and the router, hub, or switch has power.4. To communicate with an <strong>Modbus</strong> <strong>TCP</strong> manifold the IP address of your computer must be known. Tostart this process, left click on the “Start” button.5. Right click on “My Network Places” and then scroll down to “Properties”. Left click on “Properties”.6. The “Network Connections” window will open. Right click on “Local Area Connection”.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 63

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>7. The “Local Area Connection Properties” window will now open. Scroll down in the box labeled, “Thisconnection uses the following items”. Locate the “Internet Protocol (<strong>TCP</strong>/IP)” option and highlightit.8. Left click on the “Properties” button. The “Internet Protocol (<strong>TCP</strong>/IP) Properties” window will open.Choose the option marked “Use the following IP address” and type in an IP address that has thesame first three octets as the address that you will set the manifold to. For the last octet you maychoose any number from 0-255, just make sure that it is not the same number as the IP address thatthe manifold will have. Make sure your subnet mask is set to “255.255.255.0” (this value can bechanged, but this value will be used for demonstration purposes).9. Left click “OK” in the “Internet Protocol (<strong>TCP</strong>/IP) Properties” and “Local Area Connection”windows for the changes to take effect on the computer. Close out of any open windows.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 64

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>10. Once the IP address for the computer is known, you can set the IP address of the <strong>Numatics</strong> manifoldusing one of the methods described on page 73 .11. Left click on “Run”. This will open up the “Run” window.12. Type “cmd” on the command line and left click “OK”. The command prompt will open.13. Type, “Ping, and then the IP address that the manifold is set to, you can view the address on thegraphical display. For example, if the IP address is 192.168.3.120, “ping 192.168.3.120” would be typed.You will get a message stating, “Reply from 192.168.3.120: bytes=32 time

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>14. Open a web browser on the computer and type in the IP address of the manifold.Ex. http://192.168.3.12015. You have successfully connected a computer to a <strong>Numatics</strong> <strong>Modbus</strong> <strong>TCP</strong> manifold.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 66

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Using the Functionality of the <strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> Web ServerThis section will discuss the functionality of the built in Ethernet server. Every <strong>Numatics</strong> <strong>Modbus</strong> <strong>TCP</strong> hasthis feature. Through this server you can configure the node, force I/O, check diagnostics, etc. Each<strong>Numatics</strong>’ web page will be explained.HomeTo get to the <strong>Numatics</strong> “Home” page, open a web browser. In the URL line, type in the IP address of themanifold and press “Enter”. The <strong>Numatics</strong> “Home” page will appear. This page shows a picture of the<strong>Numatics</strong> <strong>Modbus</strong> <strong>TCP</strong> manifold. From this page, the user can navigate the entire built-in web server.NOTE!The 1 st three octets of the IP address of the computer MUST match theIP address of the node.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 67

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>Node ConfigurationThe “Node Configuration” window can be used to control different parameters within the manifold. Theseparameters include, “IP Address”, “Subnet Mask”, “Gateway Address”, “SMTP Server”, “DHCP/BOOTPenabled”, “MAC Address”, and “COMM Fault/Idle Mode”. “DHCP/BOOTP enabled” is controlled by asingle check mark box. “COMM Fault/Idle Mode” has two options that can be chosen: “Hold last OutputState” and “Turn OFF All Outputs”.Once the changes have been made, left click on the “Update Configuration” button. The “ConfigurationSuccessfully Updated” window will appear. The <strong>Modbus</strong> <strong>TCP</strong> TM node will reset in a few seconds, or theuser may cycle power to enable the new configuration.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 68

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>PasswordThe “Password” window allows the user to set a password that will prevent unwanted access to the I/O Forceand Test functionality. The password comes disabled from the factory. To set the initial password, leave the“Enter Current Password” field blank and type in the new password in the “Enter New Password” field.Once a Password has been set, the security check screen will appear when accessing the I/O force and testpageNOTE!If the password has been lost or forgotten, go through the processof changing the password. Enter the last 6 digits of the MACAddress in the current password field and then enter the desiredpassword in the new password field.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 69

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>I/O Force and TestThe “I/O Force and Test” window allows the user to test the outputs and inputs of the manifold. A SafetyWarning will appear telling the user to shut off the air supply to the valve manifold. Once the air is shut off, leftclick on “Accept”.The “Force Outputs and View Inputs” window will open. This window lets the user turn on outputs andmonitor the status of inputs that are connected to the manifold. Use the drop box to choose which I/O word tocontrol/monitor. Output forces can be applied using either the check boxes or “Output Byte Decimal Value”.Left click on “Send I/O data” to force the outputs on/monitor the inputs.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 70

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong>DiagnosticsThe “Diagnostics” window allows the user to monitor different values. These values include, “MAC Address”,“Serial Number”, “Firmware Revision”, and “Valve Diagnostic Table”. The “Valve Diagnostic Table” enablesthe user to check the status of the valve side outputs.Software ExamplesThe “Software Examples” window provides examples of a <strong>Numatics</strong>’ <strong>Modbus</strong> <strong>TCP</strong> module withProWORX 32 and Unity PRO softwareTD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 71

<strong>G3</strong> <strong>Series</strong> <strong>Modbus</strong> <strong>TCP</strong> <strong>Technical</strong> <strong>Manual</strong><strong>Numatics</strong>.comThe “<strong>Numatics</strong>.com” tab is a quick link to <strong>Numatics</strong>’ website. The computer must have internet accessfor this tab to be functional.TD<strong>G3</strong>MBTM1-0EN 11/09Subject to change without noticewww.numatics.com/g3Page 72