ECOVENT Valves

ECOVENT Valves

ECOVENT Valves

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

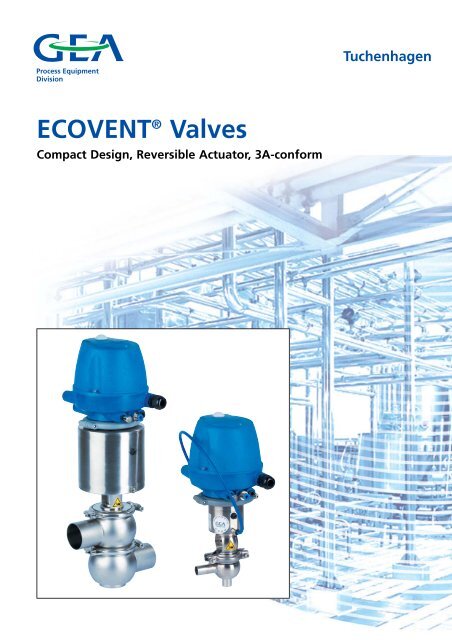

Process EquipmentDivisionTuchenhagen<strong>ECOVENT</strong> ® <strong>Valves</strong>Compact Design, Reversible Actuator, 3A-conform

<strong>ECOVENT</strong> ®Single Seat <strong>Valves</strong> . . .. . . represent a cost-effective alternative toour shut-off and shuttle valves for simplehygienic process applications. They form thenext innovative generation of the proven<strong>ECOVENT</strong> ® series.They stand out by reliable function, CIP/SIPabilityand low maintenance - thefundamental factors for achievingconsistent product quality, high outputrates and economical operating,maintenance and service costs.1Features of <strong>ECOVENT</strong> ® valves1. Electrical componentsin the control moduleare fully splash-waterprotected.2. Sturdy and reversibleactuator — spring-toclose/air-to-openorvice versa.Air backup of thespring is possible.3. <strong>ECOVENT</strong> ® actuatorswith direct internal airsupply from the controlmodule.4. Open lantern for visualinspection of the stemseal and the valve´sswitching position.5. The machine rolledvalve spindle finishprovides for excellentwiping action as itpasses through the seal,ensuring long life of thestem seal.6. The <strong>ECOVENT</strong> ® Systemhas optimal cleaningcharacteristics —without domes andpools.7. The valve disks are, asa matter of principle,manufactured in asingle piece.8. The metallic stop of thevalve disk provides adefined deformation ofthe seal, ensuring longseal life.346PressureNo deformation of the sealunder pressure – no productinclusions2578

Control and feedback systemsThe valves can be equipped with the well-establishedTuchenhagen control and feedback systems.Proximity switch holder withtwo proximity switchesT.VIS ® control systemActuatorThe spring-to-close / spring-to-open action is freelyselectable by reversing the actuator.Sight lanternAn open lantern as a separation between the actuatorand the product section permits visual inspection of thevalve stem seal and prevents temperature transfer fromthe pipe system to the actuator.<strong>ECOVENT</strong> ® single seat valves reduce your costs!The very favourably priced Tuchenhagen <strong>ECOVENT</strong> ®single seat valves enable you to considerably reduceyour plant investment costs!Housing connectionsClamp connections between the individual componentsfacilitate rapid installation. Housing body connectionswith detachable clamp ferrules allow for unrestrictedfreedom of choice of the socket position.- Optional: welded seat ring available without surchargeAs the <strong>ECOVENT</strong> ® series is based on the VARIVENT ®sealing philosophy, it also reduces your operating costs.The metallic stop of the valve disk ensures defineddeformation of the seal, which provides a long servicelife of the seals.The combination of low investment costs and thepotential to reduce operating costs in the long runclearly shows how <strong>ECOVENT</strong> ® valves can help you toreduce your costs!Constant compression sealDiffusion of stress in the sealWelded seat ringClamp connectionAdvantages of <strong>ECOVENT</strong> ® valves:• Cost-effective single seat valves• Reduces operating costs thanks to the long servicelife of the seals (metallic stop)• Compact design, low overall height• Flexible actuator design• Can be combined with all proven Tuchenhagenfeedback systems• No product can creep behind the special-contour seal

Housing combinations for <strong>ECOVENT</strong> ® <strong>Valves</strong>The housing configuration of the VARIVENT ® System is used and allows any conceivable housing combination.L* T* B* C* A* E* K** V** P**O** W** Y** X** Z** U** M** N** G*** for valve type N only; ** for valve type W onlyTechnical Data and MaterialsMaterialsProduct contacthousing1.4404 (AISI 316 L)interior parts1.4404 (AISI 316 L)No product contact1.4301 (AISI 304)Surface finishProduct contactinsideR a ≤ 0.8 µmother surface finisheson requestNo product contactoutsidematt finishoptionalhousing as rolledSealsStandardEPDM (FDA)Operating temperature135 °CSterile temperature150 °C (1 hour max.)OptionalFPM (FDA)HNBR (FDA)FFPM (on request)Operating pressureStandard 5 barhigher pressureson requestControl airStandard 6 barmin. 4.8, max. 8 bardue to process data<strong>ECOVENT</strong> ® valves are available in the followingpipe connection sizes and nominal widths:MetricOutside diameter acc. to DIN 11850, Row II,DIN 11866, Row AMetric: DN 10 to DN 100Inch ODOutside diameter following ASME-BPE-a-2004,DIN 11866, Row CInch OD: 1" to 4 "DIN ISO 9001 / EN 29001<strong>ECOVENT</strong> ® valves meet the regulationsaccording to 3A, FDA, LMBG 4/94 and EN 93Process EquipmentDivisionTuchenhagenA company of GEA GroupTuchenhagen GmbH . Am Industriepark 2-10 . 21514 Büchen, GermanyTel.: +49-41 55/49 24 02 . Fax: +49-41 55/49 24 28 . fc-sales@tuchenhagen.de . www.tuchenhagen.de619e-03/06