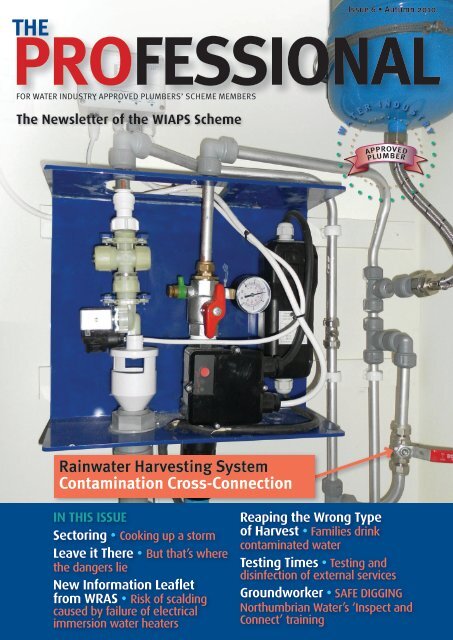

Rainwater Harvesting System Contamination Cross-Connection

Rainwater Harvesting System Contamination Cross-Connection

Rainwater Harvesting System Contamination Cross-Connection

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TheProfessionalFor Water Industry Approved Plumbers’ Scheme MembersThe Newsletter of the WIAPS SchemeIssue 6 • Autumn 2010<strong>Rainwater</strong> <strong>Harvesting</strong> <strong>System</strong><strong>Contamination</strong> <strong>Cross</strong>-<strong>Connection</strong>IN THIS ISSUESectoring • Cooking up a stormLeave it There • But that’s wherethe dangers lieNew Information Leafletfrom WRAS • Risk of scaldingcaused by failure of electricalimmersion water heatersReaping the Wrong Typeof Harvest • Families drinkcontaminated waterTesting Times • Testing anddisinfection of external servicesGroundworker • Safe DiggingNorthumbrian Water’s ‘Inspect andConnect’ training

Editorial DetailsContactAll correspondence should bedirected to:The Editor, Paul Hamley, South WestWater Ltd, Peninsula House, RydonLane, Exeter, EX2 7HR. E-mail:phamley@southwestwater.co.ukCopyrightNo article may be reproduced infull or in part without the expresswritten permission of the Editor.In some instances there may be areproduction fee. Right of translationand reproduction is reserved.AdvertisingAdvertisements must comply withthe ASA Code of Practice. Enquiriesconcerning advertising should bemade to the Editor at the aboveaddress.DisclaimerPublication of an article does notimply agreement by the Editoror the WIAPS scheme with theviews expressed, nor does it implyendorsement of the content of anyadvertisement. The Scheme doesnot accept any liability for errorsor omissions.PublicationThe Professional is intended to bean annual publication, and is madefreely available to members of theWIAPS scheme.A wordfrom theEditorHi allFirstly – the sharp witted amongst you will have notedour absence from the scene. As you know we do thisas an addition to our daytime jobs (and our daytimejobs seem to take up a lot of night-time as well!) and with the Water Industry going through it’snever ending cycles of Audits, Reviews, and other stuff we wouldn’t wish on anyone – time hassadly been short. In addition we’ve had a few editorial issues to sort out – but we’re back.We’ve got good news on the Sectoring front, with about 1,500 more people about to join our ranks,but sadly in the time we’ve been away another tragic death, this time a baby, has occurred as aresult of the same poor installer practice that was described in Issue 2. Guidance has been issued byWRAS on the risks from these types of arrangements, and that has been reproduced in this issue.Cut it out, photocopy it, post it on Notice Boards, do what ever you think might get the messageacross to as many people as possible. None of us want to read about another similar death.Enough doom and gloom – read on. If nothing else, we’re something you can enjoy that does notconsume diesel or petrol.P. Hamley • EditorThe Scheme Manager’s ContributionMuch has happened in the world of WIAPS sincethe last edition of the Professional, we at WRASalong with representatives of the Water Industryhave developed and introduced new sectors withregards to the knowledge of the Water Regulationsinto the scheme for the Catering and Chilled WaterIndustries and we’re working on one for the installersof rainwater harvesting systems (See, Reaping thewrong type of Harvest).The sector with regards to the Catering Industry wasdeveloped in conjunction with the trade associationsrepresenting the industry these being the CateringEquipment Suppliers’ Association (CESA) & theCatering Equipment Distributors Association (CEDA).The sector was officially launched to the Standards and Regulations Board representing thesetrade associations in August 2008 at their London office with a trial assessment in the knowledgeof the Water Regulations taking place in January 2009 at the Training Centre of Hobart, which isbased in Peterborough.With regards to the Chilled Water Industry the development of this sector was carried out by thesector working group with representation from the Water Industry and in close connection withthe trade association European Point of use Drinking Water Association (E.P.D.W.A.).The assessment content and training was carried out by WRc NSF Ltd with candidates travellingfrom as far afield as Northern Ireland and Scotland to sit the assessment; these assessments areongoing with some 300 engineers trained in the knowledge of the Water Regulations.Sources of Informationon the Net:For those websurfers amongstyou here are a few sites youcan visit to obtain informationrelating to the Regulations:WRAS –www.wras.co.ukDEFRA –www.environment.gov.ukJust a reminder to you the installer it is your responsibility to install fittings that meet therequirements of the Water Regulations. Using fittings that are listed in the Water Fittings andMaterials Directory (on-line www.wras.co.uk/directory & FREE) will give you confidence that yourresponsibility is met.Should you wish to contact me regarding any issues please don’t hesitate to telephone on01495 236274; or paul.phillips@wras.co.ukWIAPS membership at the end of September 2010APPROVED PLUMBERS 3631GROUNDWORKERS 4151CATERING 29P.O.U. WATER CHILLERS 532Paul Phillips • WIAPS Manager

SECTORING,Cooking up aStormYouIn conjunction with the good people at CEDA(Catering Equipment Distributors Association) andCESA (Catering Equipment Suppliers Association),we have launched a Sector for – you guessed it –catering equipment installers.About 1500 people are members of the installationcompanies represented by CEDA and CESA, andthey will undergo a similar training and assessmentas you guys all did, the first session took place atthe training centre of Hobart UK in Peterborough inJanuary 2009 where 24 engineers were assessedin the knowledge of the Water Regulations over aperiod of two days with a 100% pass rate.We’re very pleased with this achievement becauseit means we have been successful in highlightingto yet another group of people, the dangersassociated with plumbing systems and the need forinstallers to be qualified and understand the risksassociated with what they do.LEAVE IT THERE!But there’s where the dangers liemay recall from previous issues that the Industry,and in particular WIAPS, has been discussing thepossibility of setting up Sectors of membership forthose people who are not fully trained plumbers,but who still carry out restricted work on plumbingsystems. Its been a long, and very hard, road but weare pleased to announce the completion of this Sector.So the next time the fitters arrive with those weird bits of kit to fit out the kitchen inthe restaurant you have just plumbed out – cut them some slack – they may be fellowWIAPS members!However, prior to the launch of the catering sector, the newly developed sectorfor the point of use and chilled water installers has been launched with extensivetraining already being carried out and substantial membership enquiries andapplications taking place.Work is also being carried out on a new sector for the Automatic Vending Association(AVA), with a view of completion and launching in 2010.We’ve also been approached by Associations representing the Domestic Fire SprinklerInstallers, and Kitchen and Bathroom Installers. So watch this space for furtherdevelopments!How many times have you had a clientdecide to leave a bit of kit connected – justin case? How many times have you done ityourself? In truth we’ve all done it. It waseasier, quicker, and you never know whenyou might want to use it later – and thenpromptly forgot it existed!But did you really consider the legacy you had leftbehind? Here’s a little story to demonstrate whyyou should disconnect kit even if you don’t removeit physically.Some years ago I received a call from a medicalcentre that was complaining about poor qualitywater supply. Periodically it tasted and smeltterrible, and the attendant threats of pressinvolvement and lawsuits came along withthe complaint. Being Regulations people weimmediately asked our Quality staff to takesamples – sometimes difficult when the problemis intermittent – whilst we asked to inspectthe internal plumbing. Now when a customercomplains and you want to check their plumbingone of two things happens – either they welcomeyou in with open arms because anything you cando to sort the problem is welcome, or they gettwitchy and less cooperative because they’re notentirely sure you won’t find something wrong with their system.In this case we did get into the premise, albeit with a vociferous guide, who informedus that only the treatment room, the toilets and the kitchen, had water supplies.Having checked all of these supplies we had to agree that they were compliant, allbut a short dead-leg disappearing into the wall which we were assured used to feedan outside tap, and we got quality water from all of the taps when we ran them.Being skilled investigators we don’t take the assured statements of customers asour sole source of evidence, and we insisted in entering every room in the buildingincluding all broom cupboards, store-rooms, roof spaces, out-buildings … if you couldget into it or see into it, we were there! So in the furtherest corner of the building wecame across a store-room used for record storage for over ten years. We were assuredthat there wasn’t, and had never been, any plumbing at this end of the building.I guess by now not even the most reluctant gambler among you could resist bettingyour life savings on what’s coming next … would you? After climbing over the boxesand making sure we could see along all the wall surfaces we found ….. a wash-handbasin unused for over a decade.After opening the taps, and marvelling that water could actually get to be that blackand smell that exotic, we gave the pipework a good initial flush before returning totalk to our, now very embarrassed, guide to explain how this stagnant water hadbeen being drawn back into the rest of the surgery, and was causing the problems. Ittranspired that the pipe that used to feed the outside tap – never did feed an outsidetap – it ran the entire length of the building and into the room now used for filestorage. Needless to say the ‘T’ to this pipe-run was removed shortly after.This was just a taste and odour complaint. Maybe sometime we’ll be able to showyou some picture of what can happen if you don’t remove a back-boiler properly.3

Information for Water Suppliers,Plumbing Installers, Landlords and HouseholdersElectric Immersion Water Heaters and Plastic Water Storage CisternsADVICE REGARDING THERISK OF SCALDING CAUSEDBY FAILURE OF ELECTRICIMMERSION WATERHEATERSInformation for Water Suppliers,Plumbing Installers, Landlords andHouseholdersINTRODUCTIONHouseholders may have seen recent press reports of a risk ofscalding arising from the collapse of plastic water storage cisternscontaining very hot water due to electric immersion water heaterswhich fail to switch themselves off. The background to the incidentswhich have been reported is outlined below for information.Serious incidents of this type are very rare, but two fatalities in fouryears from the same cause make it prudent to carry out checks ofolder plumbing systems where this equipment may be installed.The following advice is to reassure householders and landlordsregarding the likely risks and to advise them about relevant checksof their plumbing systems and what to do if they are planning tochange their storage cisterns or immersion heaters.WHAT CAUSED THE FATAL SCALDING?The recently reported incident occurred in a house, where a faultyelectric immersion heater which heated the domestic hot waterfailed to switch off when the normal hot water temperature wasreached (electrical thermostat failure). This caused the water in thehot water storage cylinder to boil. To avoid over-pressurisation ofthe hot water cylinder, the plumbing system operated as designedby allowing the boiling water to discharge through a vent pipe intoa plastic storage cistern (tank) in the roof space.This continued for some hours until the plastic tank was full ofvery hot water, and partly because it wasn’t properly supportedunderneath, it distorted and split, spilling the very hot water ontothe bedroom ceiling above a child’s cot. The hot water cascadedonto the baby sleeping in the cot, who suffered severe scaldingfrom which she subsequently died.CURRENT REQUIREMENTSNot all water heating systems use immersion heaters. If youare replacing an existing immersion heater or storage cistern orhaving a new installation, insist on the equipment and installationmeeting the following requirements.Electric immersion heaters made in accordance with BritishStandard BS EN 60335-2-73:2003 1 include an independent non selfresettingover-temperature cut-out safety device to prevent waterin the hot water cylinder from overheating. This is in addition tothe normal switching mechanism of the immersion heater.Since April 2004 it has been recommended that any repair,replacement or installation work on domestic immersion heatersshould include the fitting of such a safety feature.Recently-built houses and flats may not have water storage cisternsat all, instead having all their water supplied directly from thewater main. Where water storage cisterns are used they are oftenlocated in the roof space above the upper rooms and are typicallyused to store cold water for use directly, for example at bathroomtaps, and to supply water to the vented hot water system.Modern plastic cisterns should be able to contain boiling waterwithout collapsing or splitting, provided they are adequatelysupported. Suitable plastic cisterns are those made since 1986which are:(a) WRAS Approved Products (from 1999 onwards). Plastic cisternswhich are currently WRAS Approved are listed in the WaterFittings and Materials Directory in Sections 0120, 0130, 0135and 0170. Details are given in the individual entries indicatingtheir suitability for storing water to be used for domesticpurposes. The Directory is available free of charge on theWRAS website at www.wras.co.uk/directoryor(b) approved by WRAS’ predecessors before 1999 and have aWater Byelaws Advisory Service Listed Certificate Awarded orare Water Byelaws Scheme Approved Products (see oppositefor markings)or(c) manufactured in accordance with the British StandardBS 4213: (1986 or later) 2 .CHECKS ON YOUR EXISTING SYSTEMParticular attention should be given to systems over ten years oldand those where householders or landlords may have other reasonto suspect the adequacy of the initial installation or anysubsequent work.1 British Standard BS EN 60335-2-73:2003 ‘Specification for safety of householdand similar electrical appliances. Particular requirements for fixed immersionheaters’2 BS4213: 2004 ‘Cisterns for domestic use – Cold water storage and combinedfeed and expansion (thermoplastic) cisterns up to 500 litres – Specification’4

SUPPORT FOR CISTERNSThe minimum support quoted in the British Standard for plasticstorage cisterns of capacity up to 500 litres is at least 15mm thickmarine plywood to provide a durable, rigid, flat and level platformbeneath the whole base of the cistern.If you are replacing an existing galvanised (metal) storage cisternby a plastic one, ensure the replacement complies with thestandard or is WRAS Approved and is properly supported.Timber bearingssupporting cisternExample of close boarded support to a plastic cistern7/R16.2CHECKS ON IMMERSION HEATERS18.01.2000 okay1. Look for marking on the immersion heater to show if it is maderevised 16.6.2000in accordance with British Standard BS EN 60335-2-73:2003. If not,consider having it changed for one which does meet this standard.The cost of a replacement immersion heater should be less than£10, but the cost of having it installed by a qualified person will beadditional.CHECKS ON CISTERNS2. Look for marking on the plastic cistern showing either:(a) the logo for WRAS Approved Products or the earlier approvalmarks, or:(b) marking showing that the cistern was manufactured inaccordance with BS 4213 (dating from 1986 or later).Close boardingCisterns with these marks should be capable of withstandingboiling water if correctly supported.3. It is not suitable to stand a plastic cistern directly on the joistsof the ceiling because the weight will not be uniformly distributed.Check that the cistern is standing on a support which is of asuitable thickness and type of material, and which extends beneaththe whole of the base of the cistern and does not allow any part ofit to overhang the support. Check also that the support is not rottenor distorted due to leakage or condensation.4. Check that the float valve and the overflow (warning) pipe aresecurely fastened through the cistern wall by the clamping nuts.Check the outside of the cistern to see that water isn’t leaking fromthe entry holes in the cistern wall where the pipes pass through it.5. Check that the water pipe leading to the float valve and alsothe overflow (warning) pipe, designed to take excess water safelyaway to waste, are properly supported so that their weight doesnot distort the cistern sides.6. Ensure that the cistern lid is correctly in position.SIGNS OF A PROBLEM WITH YOURIMMERSION HEATERThere are a number of warning signs if the immersion heater isoverheating the hot water:(a) Excessively hot water coming out of the hot taps;(b) Excessive noise or ‘bubbling’ from the hot water cylinder(c) Hot water coming out of certain cold water taps.(Some storage cisterns also feed cold water taps, forexample in the bathroom).(d) Steam or condensation in the roof space.(e) Unusual warmth between the insulating cover and cistern(tank) sides on the outside of the cold water storage cisternin the roof space (that is, more warmth than would be dueto the surrounding air temperature).If you suspect there is a problem with the immersion heater,arrange for a qualified person (plumber or electrician) to checkit urgently. If you are a tenant, depending on the terms of yourtenancy, arranging and paying for these checks may be theresponsibility of your landlord. If so, ask the landlord to arrange thechecks as a matter of urgency.FURTHER INFORMATIONRequirements for water storagecisterns:See the WRASWater Regulations GuideSection 7 pages 7.11 to 7.15.Order by telephone from WRAS on01495 248454. £16.30 plus £3.50post and packing (UK).Health and Safety Executive alert:The Health and Safety Executive issued a safety alert onthis subject: HSE Safety Alert: Scalding Risk from domestichot water systems, 19 July 2007. Available on thewebsite: www.hse.gov.uk/services/localgovernment/alert.htmAdvice should also be available from competentplumbers. Look for one who is a member of a professionalinstitute such as the Institute of Plumbing and HeatingEngineers or who is an Approved Contractor. See theWRAS website: www.wras.co.uk/WIAPS/Issued by the Water Regulations Advisory Scheme, which is fundedby the UK Water Suppliers to publicise the Water Fittings Regulationsand Scottish Water byelaws and operates a scheme to assess andapprove water fittings and plumbing materials which comply withthe requirements of the Regulations and Byelaws.WRAS, 30 Fern Close, Pen-y-Fan Industrial Estate, OAKDALE,Gwent, NP11 3EH Tel: 01945 248454e-mail: info@wras.co.uk and website: www.wras.co.ukJanuary 14th 2008The essential guide to the legislationaffecting water supply installations in the UKIncorporating DETR Guidance andWater Industry Recommendations togetherwith clear illustrations in colourWaterRegulationsGuideF I R S T E D I T I O N5

Reaping theWrong Typeof HarvestFamilies Drink Contaminated<strong>Rainwater</strong>Families living in an eco-home development in EasternEngland were drinking mains water contaminated withstored rainwater, because the rain-water harvestingsystems installed in their houses had direct crossconnectionsto the drinking water supply. Alerted bycomplaints of ‘sewage’ odour in the tap water, theWater Supplier investigated the housing developmentand found that 87 homes (61% of those in thedevelopment) had illegal inter-connections of drinkingwater and rainwater pipework. In three cases thesewere causing actual contamination of drinking waterand samples of water showed signs of faecal matter.What went wrong?The proprietary rainwater systems were properly designed andmanufactured, but problems occurred during installation. Allthe installations done by one firm of contractors had crossconnections – suggesting persistent and deliberate deviation fromthe manufacturer’s installation instructions. Installers had madeillegal modifications to the rain water systems by cross connectingmains and rainwater pipework, with only closed valves betweenthem. A closed valve is not a backflow prevention device and theinstallers committed criminal offences by putting in these crossconnections without proper backflow prevention. The Water FittingsRegulations require fluid category 5 backflow protection, usually byusing a Type AA or AB air gap (see the Backflow Protection box).Other breaches of the Water Fittings Regulations includedinadequate marking of the pipework to distinguish the rainwatersystem from the drinking water pipes – in 95% of installations –and one installation with an inadequateair gap in a cistern which had bothtypes of water entering it.Getting it RIGHT<strong>Rainwater</strong> harvesting systems should be installed in accordancewith the manufacturer’s installation manual and in no way shouldthe installation be adapted.There’s a recent British Standard Reference BS 8515:2009‘<strong>Rainwater</strong> harvesting systems – Code of practice’ which gives goodguidance on the design, installation, testing and maintenance ofrainwater harvesting systems supplying non-potable water in the UK.Do not install any direct cross-connections. No mechanical device iscapable of protecting against this level of risk.Pipework carrying reclaimed water or rainwater MUST be madeclearly identifiable throughout the property and it’s recommendedto use more than one method of marking. Pipes are availablewith continuous marking applied during manufacture. If not usingpre-marked pipe, labels should be attached at a maximum ofevery 0.5m and at key connection points. See the ‘Labelling’ boxfor more information. Insulated pipes should be marked on theoutside of the insulation regardless of marking on the pipe itself.At the points of use the appliances oroutlets should be labelled to indicate thatthe water is not for drinking.

Labelling of PipesPremarked pipe is available with green stripes and thewarning printed on it.Pipes should be marked at intervals of not morethan 0.5m with labels which are self adhesive ormechanically fixed. The information on the label is asshown.BACKFLOW PROTECTION AND CROSS CONNECTIONS<strong>Rainwater</strong> collections systems usually have a back-up water supply from the drinking water systemto provide water during dry weather. Where this connection is made to a storage tank or flushingcistern, it must have fluid category five backflow protection,provided by a suitable air gap.Directly connecting pipes carrying rain water and mainswater without a suitable airgap in between is illegal anddangerous. Relying on a shut valve between the pipes isn’tallowed, because a valve isn’t recognised as a backflowprevention device under the Water Fittings Regulations andvalves can leak or be left open by mistake.Water supplied byWater SupplierSgVType AA, AB or AD airgap to be providedWarning pipeSpillover level<strong>Rainwater</strong>Illegal <strong>Cross</strong><strong>Connection</strong>RAINWATER HARVESTING SYSTEMS<strong>Rainwater</strong> harvesting systems divert water collected on roofs or other surfaces of a property into a storage vessel, often underground.It can be used for toilet flushing, garden hose taps and in some cases, after additional treatment, in washing machines.Direct systems deliver the rainwater straight to the point ofuse, but they can’t work if the pump or controls fail or there’sa power cut.Indirect systems pump from the underground tank to a highlevel cistern, for example in the roof space, from where the watergravitates to the points of use. Mains water top-up can be madeinto the high level cistern via an air gap.

Testing Times!Testing and Disinfection ofExternal ServicesSo, you have just finished laying a new MDPEwater service. You have laid the pipe at thecorrect depth, cushioned it with selected pipesurround, and installed a duct through thepoint of entry into the building. You havethen pressure tested the pipework as requiredby the Regulations. And now you are aboutto sign off the work and send the WIAPScertificates to the customer and the local watercompany.That’s a job well done right? Not quite!The Regulations Guide says that pipes of 50mm ID or greatershould be disinfected. Disinfection is required for:lllllNew installations (except private dwellings occupiedby a single family)Major extensions or alterations (except privatedwellings occupied by a single family)Underground pipework (except localised repairs orinsertion of junctions)Where it is suspected that contamination may have occurred,e.g. fouling by sewage, drainage, animals or physical entry bysite personnel for interior inspection, painting or repairsWhere a system has not been in regular use and notregularly flushed.With a small installation such as a single house most watersuppliers consider it normally sufficient for the system to be fullyinspected and flushed out. Take extra care where there is anysuspicion of contamination of the pipework by sewage, groundwater or the entry into pipes by insects or vermin.This may require disinfection in any case. In addition,contaminated ground will also need extra care, and you mustwork to the requirements of the local water supplier.What this all means is that even if the ground and pipeworkis clean, most water suppliers require 63mm diameter servicepipes (50mm ID or greater) to be disinfected, and this is in linewith the Regulations guide. However, as we have said above, therequirements of the water supplier should be followed especiallyconcerning the diameter and length of the service pipe, so checkfirst before taking any action.How is the testing and chlorination carried out?Information can be found in the Regulations Guide Section 4. Thework must also be in accordance with BS6700. Disinfection shouldbe carried our by a competent person so, if in doubt, consult theservices of a company who specialises in such work.So finally, the pipe has been tested, disinfected where required andflushed. Now you can sign the work off with a WIAPS certificateright? No, not quite!llPipes of all sizes should be properly sealed at the boundarywith a purpose made watertight fitting. This is especiallyrelevant where the pipe has been disinfected so use a suitablefitting for this. Failure to do this could compromise the pipe, astrenches are often wet and muddy. In addition to this, smallstones and other debris could find their way into the pipe. Ifthe pipe is compromised then further flushing and disinfectionmay be required!Internally fit an approved stop valve at the point of entryand leave this closed after installation, flushing, testing andtreatment.Please remember that connections will not normally be authorisedby water suppliers without an inspection by a water companyinspector or certification by a WIAPS installer. Make sure youinclude all testing and treatment certificates including sampleresults if the water supplier requires these, with your WIAPS forms.As we have said, checking first with your local watersupplier will avoid any unnecessary delays with new serviceconnections, so please remember to do this first.So lets work together to get this right. After all, it is clean freshwater at the customers tap that is the objective here. That is in allour interests.ONE DOOR CLOSESANOTHER OPENSDiscussions have taken place over the past few monthsbetween Yorkshire Water and the Water Regulations AdvisoryScheme (WRAS) with a view of Yorkshire Water ceasing tooperate their Approved Contractor Scheme and transferringtheir members to WIAPS.Yorkshire Water have operated their Approved ContractorScheme for ten years and over the years have introducedsectors such as the Catering industry and P.O.U. Water Chillerinstallers into their scheme bringing it in line with otherApproved Schemes.A meeting held on the 16th March 2010 at the offices of YW inSheffield resulted in an agreement where by all YW ApprovedContractors would be notified by YW of their decision to ceaseoperating an Approved Contractors Scheme and also informingtheir members of the many benefits available by becomingWIAPS approved.Present at the meetingon 16th March 2010 leftto right:Mr. Paul Straw YW,Mr. Mike Sunderland YW,Mr. Mark Shearstone YWandMr. Paul Phillips WIAPS.

TheEXTERNAL SERVICESINSPECT ANDCONNECTNorthumbrian Water has trained around 45 of theiremployees up to the standard of a Water IndustryApproved Ground Worker. The water workers are nowin a position to use their newly accredited skills to thefull in a trial scheme the water company is calling‘Inspect and Connect’.Northumbrian Water, along with the national developer BellwayHousing, is trialling the ‘Inspect and Connect’ scheme in theNorth East of England.When the developer requires a connection for a domesticproperty, the inspection and connection are combined intoone visit, rather than carrying out an inspection visit and aconnection visit. Both tasks will now be undertaken at the sametime by the same team.The benefits for both parties include more efficient use of timeand speedier connection. In addition, as trenches are no longerleft open for up to 21 days after the inspection, the site is saferand risk of damage to exposed pipework is reduced.As with any proposed change to a procedure or policy,Northumbrian Water is keen to ensure that the benefits tothemselves and Bellway are not achieved at the expense of thequality of service.It was clear that training of those involved would be necessary,and it was believed that this would be achieved by using anexternal company. Furthermore, the training needed to berecognisable and certified. Northumbrian Water decided thatthe most appropriate scheme was the Water Industry ApprovedGround Worker Scheme.Northumbrian Water has now identified more employees whowill be trained and accredited in the Water Industry ApprovedGround Worker Scheme.Safe DiggingOr why things aren’t where they’resupposed to be!Now we all know Groundworkers work in, on, andaround the ground. And whilst some might say thatplumbers work is more complicated, some otherswould say that your job is far more dangerous, and insome respects, far more complicated.Plumbers can generally see the pipework they’re working on,and all of the other pipes and cables near it, but you dig intoground which might contain any number of known, and unknown,dangers which you can’t see until you uncover them. Often youwill have plans to show you where the pipes are, but have youever wondered why the sometimes the water main is yards fromwhere it was shown on the plan? Here’s a bit of history, based onthe water supplies in the City of Plymouth, but probably applicableto all but the more modern locations in the UK, and to all utilitiesincluding Gas and Electric to a lesser degree.Water supplies have been around for hundreds of years. Longerthan the other utilities, and mains used to have a typical design lifeof about 100 years, so as a starting point we have some very oldrecords lying around. We also had a less than popular event calledthe Second World War, during which bombs fell destroying not onlybuildings, but underground services as well, and when you needa supply to fight the ensuing fires, mains were hurriedly laid tomaintain the crucial supplies, with records being a nicety that werecompleted from memory, as and when time permitted, and if theguy who laid it was not killed in the meantime.To further complicate issues it wasn’t until well after the War thatthe City had a centralised Council Water Utility, before that therewere small local companies in Stonehouse, Devonport etc, all withdifferent recording methods and quality. When they were mergedthe plans were pulled together into best-fit, but things did notalways match up. I was actually a draughtsman when the councilwater utilities merged to form the ‘modern’ water Companies andI can recall having to work on maps supplied by councils withmains drawn free-hand using what appeared to be a black felttippedmarker pen!If all that doesn’t bring a tear to your eye, consider the additionalcomplications of road layouts and levels being changed, mainlayingcontractors avoiding unforeseen below ground obstructions,farmers removing hedge-lines, and people altering building lines,abandoned mains being left in the ground, and it’s a marvel thatwe actually know where anything is!

February 2010INFORMATION FOR WATER SUPPLIERS, PLUMBINGINSTALLERS, LANDLORDS AND HOUSEHOLDERSINTERLINKED COLD WATER STORAGE CISTERNSGUIDANCE REGARDING CONNECTING COLD WATER STORAGE STOARGE CISTERNSWhere interlinked storage cisterns are used to supply drinking water, stagnation of water in some parts of thecisterns may cause the quality of the water to deteriorate.The installation of inter-linked storage cisterns should be avoided wherever possible. Where it is unavoidable, thenumber of inter-linked cisterns should be minimised.To avoid stagnation connect the cisterns so that water flow throughout each cistern is encouraged. Ways to do thisare shown in the diagram below, which features:Cisterns storage volume kept to a minimum;Cisterns connected in parallelInlets and outlets at opposite ends of the cistern;Use of delayed action float valves may help minimise the risk of stagnation.Please note that this diagram illustrates how compliance with the requirements of the Water Supply (WaterFittings) Regulations 1999 might be achieved and is for guidance purposes only.

WHY USINGLEAD-FREE SOLDERMATTERSDon’t listen tothe plumbers’merchantA tale has reached our ears of the assistant inthe plumbers’ merchant who was asked for aroll of lead-free solder. He told his customerit was out of stock and he should just usesolder containing lead as it is cheaper andnobody ever gets fined for using it. If anyonesays this to you, you’ll know better and cantell him why it matters to use the right sort.‘Not getting fined’ is missing the point. Using lead solder ondrinking water systems is dangerous to health, as well as illegal.Using lead solder on domestic plumbing systems could causeserious injury to someone else. Poisoning from drinking watercontaminated by lead solder has happened.Lead poisoning from use of solderOver eighteen months a young boy and his father had both beenunwell but without any clear causes. They went to see their doctor,who recognised the signs of lead poisoning. Blood tests confirmedthe diagnosis and detective work showed it was due to drinkingwater with excessive amounts of lead in it. The lead came fromlead-based solder used in jointing the pipework.The child was in the habit of taking a glass of water for nighttimedrinking from a little-used tap in an upstairs bathroom. Thefather drank a lot of water at home and took hot and cold drinksto work with him. They didn’t live in an old house which mighthave been built with lead plumbing. Lead solder had been used intheir recently built home, despite the 1987 water supply byelawsoutlawing it for hot and cold domestic water systems. A follow-upsurvey in their area revealed over 15% of houses up to three yearsold had illegal use of lead solder. This was not limited to one estateor one plumbing firm.Ban on use of lead solderLeaded solders must ONLY be used where the water can’t be fordrinking, for example on central heating closed circuit systems.Domestic plumbing systems serving kitchen, bathroom and washbasin taps, showers and storage cisterns must be lead-free ifsoldered. These requirements have been incorporated into theWater Fittings Regulations (Water Byelaws 2004 in Scotland).Installers have the legal duty to follow these regulations. Wherethe illegal use of lead-based solder is found in drinking watersystems, the Water Supplier is likely to require all the joints tobe remade at the installer’s cost. The installer could also face acriminal charge and a fine.Alternatives to lead solderPush-fit and press-fit fittings are alternatives to soldered joints. Butwhere soldered joints are required or preferred, lead free soldersare available either in integral solder ring fittings or for end-feeduse. The use of a solder such as number 23 tin/copper alloy softsolder, made to EN 29453, will ensure that lead levels are not aproblem. Not only is it suitable for all soldering work, but becauseit is less dense than lead solder, there’s more on a 500g reel, givingmore joints per reel.

ALERT forGROUNDWORKERSON CARAVAN SITES‘Winterising’ Caravans UsingAnti-freeze is IllegalFilling the plumbing systems of caravan holiday homes or parklodges with antifreeze solution has been declared illegal under theWater Fittings Regulations and Scottish Byelaws by representativesof the UK Water Suppliers. Groundworkers on caravan and park homesites are warned that if they use this method of ‘winterising’ they are committing acriminal offence, but more importantly, they could be putting someone’s health at risk. Antifreeze liquids arenot intended to be consumed and anyone who accidentally took water for drinking or cooking from a tap on the dosed systemrisks serious harm to health. People who unknowingly swallowed antifreeze in other circumstances have suffered blindness,deafness and kidney damage requiring a kidney transplant.Through the British Holiday & Home Parks Associationowners and site managers of caravan holiday homes(static caravans) and park homes or lodges have beenwarned about this and now through the ‘Professional’we’re warning Groundworkers. If you carry out thiswork you could be prosecuted for a breach of theRegulations, getting a criminal record and riskinga fine. But worse than that, you might harmsomeone’s health.Water Suppliers who enforce the Regulations orByelaws know about this risk and may check onparks to see if they are breaking the lawby using this method.NOTE: Protection of central heating systemclosed circuits and waste water traps.Protecting the closed circuit heatingsystem of a caravan holiday home or parkhome by adding antifreeze through theconnection intended for topping-up wateris allowed, because the closed circuit isseparated from the rest of the plumbingsystem and water in the circuit is notintended for drinking. A temporary fillingloop used to top up the closed circuit isaccepted provided the filling loop has adouble check valve to prevent backflowwhilst it is connected and the filling loopis removed immediately after use. Useof antifreeze in water traps in sinks andWCs is not affected by the Water FittingsRegulations or Byelaws.‘Winterising’– Caravan holiday homes/park lodgesThe Water Regulations say that fittings must be protected against freezing.How can this be achieved?l Shut off the water supply at the main stop tap to the caravan/lodge.l Open all drain off taps, then open taps and other outlets to allow the system to draindown. Flush the WC. Leave the taps and drain-off points open.Some systems do not allow all of the water to be drained through the draintaps – what now?l <strong>System</strong>s that are partially holding water should not be affected by freezing becausethere would be room within the system for expansion if the remaining water freezes.l A low pressure air pump (hand operated stirrup pump) may be used to blow out anyholding water at taps, valves and drain points.l If the shower incorporates a thermostatic mixing valve (TMV) of the type which hasbuilt in non-return valves and blowing out water doesn’t empty it, it may be necessaryto remove and drain it manually, storing the TMV in a suitable place.Can compressed air be used to remove any standing water in the system?l An electric oil-free compressor may be used, but avoid using high pressure.l It should be equipped with a filter to remove dust etc.l If it is fitted with a pressurized air receiver, it should be ‘blown down’ regularly toclear moisture.Upon restoring the premises after ‘Winterising’l Check all outlets, drain taps are closed and restore the thermostatic mixing valve if removed.l Simply flushing the system at all points for a few minutes will be sufficient for thesystem to be rendered operable.