Download Brochure - Spartech Corporation

Download Brochure - Spartech Corporation

Download Brochure - Spartech Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

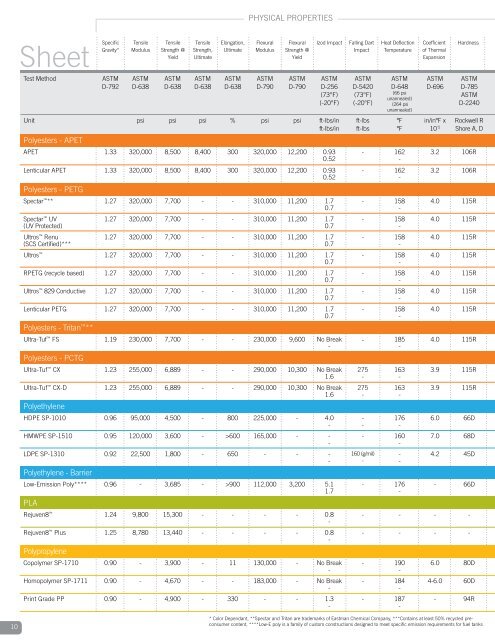

Physical Properties Performance Rating FlammabilitySheetTest MethodASTMD-792ASTMD-638ASTMD-638ASTMD-638ASTMD-638ASTMD-790ASTMD-790ASTMD-256(73°F)(-20°F)Unit psi psi psi % psi psi ft-lbs/inft-lbs/inPolyesters - APETAPET 1.33 320,000 8,500 8,400 300 320,000 12,200 0.930.52Lenticular APET 1.33 320,000 8,500 8,400 300 320,000 12,200 0.930.52Polyesters - PETGSpectar ** 1.27 320,000 7,700 - - 310,000 11,200 1.70.7Spectar UV(UV Protected)Ultros Renu(SCS Certified)***SpecificGravity*TensileModulusTensileStrength @YieldTensileStrength,UltimateElongation,UltimateFlexuralModulusFlexuralStrength @YieldIzod Impact1.27 320,000 7,700 - - 310,000 11,200 1.70.71.27 320,000 7,700 - - 310,000 11,200 1.70.7Ultros 1.27 320,000 7,700 - - 310,000 11,200 1.70.7RPETG (recycle based) 1.27 320,000 7,700 - - 310,000 11,200 1.70.7Ultros 829 Conductive 1.27 320,000 7,700 - - 310,000 11,200 1.70.7Lenticular PETG 1.27 320,000 7,700 - - 310,000 11,200 1.70.7Polyesters - Tritan **Ultra-Tuf FS 1.19 230,000 7,700 - - 230,000 9,600 No Break-Polyesters - PCTGUltra-Tuf CX 1.23 255,000 6,889 - - 290,000 10,300 No Break1.6Ultra-Tuf CX-D 1.23 255,000 6,889 - - 290,000 10,300 No Break1.6PolyethyleneHDPE SP-1010 0.96 95,000 4,500 - 800 225,000 - 4.0-HMWPE SP-1510 0.95 120,000 3,600 - >600 165,000 - --LDPE SP-1310 0.92 22,500 1,800 - 650 - - --Polyethylene - BarrierLow-Emission Poly**** 0.96 - 3,685 - >900 112,000 3,200 5.11.7PLARejuven8 1.24 9,800 15,300 - - - - 0.8-Rejuven8 Plus 1.25 8,780 13,440 - - - - 0.8-PolypropyleneCopolymer SP-1710 0.90 - 3,900 - 11 130,000 - No Break-Homopolymer SP-1711 0.90 - 4,670 - - 183,000 - No Break-Print Grade PP 0.90 - 4,900 - 330 - - 1.3-Falling DartImpactASTMD-5420(73°F)(-20°F)ft-lbsft-lbsASTMD-648(66 psiunannealed)(264 psiunannealed)ºFºF- 162-- 162-- 158-- 158-- 158-- 158-- 158-- 158-- 158-- 185-275-275---163-163-176-- 160-160 (g/mil)-Heat DeflectionTemperature--- 176-ASTMD-696ASTMD-785ASTMD-2240in/inºF x Rockwell R10 -5 Shore A, DASTMD-257ohm/SquareASTMD-52360º%3.2 106R - 90 Very High Average High High Average Very High High Low High Good - Passes3.2 106R - 90 Very High Average High High Average Very High High Low High Good - -4.0 115R - - Very High High High High Average Very High Excellent Average High Very Good V-2 at.118+Passes4.0 115R - - Very High High High High Average Very High Excellent High High Very Good V-2 at -.118+4.0 115R - - Very High High High High Average Very High Excellent Average High Very Good V-2 at -.118+4.0 115R - - Very High High High High Average Very High Excellent Average High Very Good V-2 at -.118+4.0 115R - - Very High High High High Average Very High Excellent Average High Very Good - -4.0 115R 10 5 - Very High High High High Average Very High Excellent Average High Very Good - -4.0 115R - - Very High High High High Average Very High Excellent Average High Very Good - -4.0 115R - - Very High High Average High Average Very High Very High Average High Very Good - Passes3.9 115R - - Very High High Average High Average Very High Very High Average High Very Good HB Passes3.9 115R - - Very High High Average High Average Very High Very High Average High Very Good HB -6.0 66D - - High High High Average Average Average Very High Average Low Good - Passes7.0 68D - - High High Average Average Average Average Very High Average Low Good - Passes4.2 45D - - Very High High Low High Low Average Very High Average Low Good - -- 66D - - High High High Average Average Average Very High Average Low Good - Passes- - - - - - Low Low Low Average Average Low Average Low Average Good - -- - - - - - Low Low Low Average Average Low Average Low Average Good - Passes- 190-- 184-- 187-Coefficientof ThermalExpansionHardnessSurfaceResistivityGardnerGlossImpactStrengthLow TemperatureImpactStrengthFlexuralModulus(Stiffness)TensileStrength6.0 80D - - High Average Average Average High Average Very High Average Average Average - Passes4-6.0 60D - - High Average Average Average High Average Very High Average Average Average - Passes- 94R - - High Average Average Average High Average Very High Average Average Average - PassesHeatDeflectionTemperatureGloss (AfterForming)ChemicalResistanceUVResistanceHardness Formability Rating ApprovalUL-94MVSS302* Color Dependant, **Spectar and Tritan are trademarks of Eastman Chemical Company, ***Contains at least 50% recycled preconsumerThe data herein is not meant to be product specifications. Customers are responsible for determining whether products and information are appropriate for their use.10 content, ****Low-E poly is a family of custom constructions designed to meet specific emission requirements for fuel tanksPolyOne <strong>Corporation</strong> and its subsidiaries assume no liability for the accuracy or completeness herein, and all information is subject to change without notice.888.721.4242 http://DSS.polyone.com 11