General Information Guide - ASSA ABLOY Door Security Solutions ...

General Information Guide - ASSA ABLOY Door Security Solutions ...

General Information Guide - ASSA ABLOY Door Security Solutions ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Door</strong> Closer <strong>General</strong> <strong>Information</strong><br />

Surface mounted <strong>Door</strong> Closers/Concealed <strong>Door</strong> Closers<br />

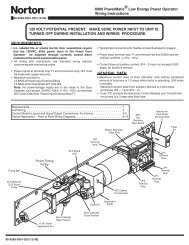

Norton ® closers can be surface-mounted or concealed in the frame. Each type has its advantages and disadvantages.<br />

6/10<br />

www.nortondoorcontrols.com<br />

DOOr<br />

CONTrOLS<br />

Surface-mounted Closers<br />

This type of door control is easiest to install, with four drilled and/or tapped holes for the body, and two, four or five holes for the arm<br />

bracket. They require a minimum amount of preparation of the door and frame. The surface-mounted closer is also more accessible<br />

to the occasional adjustment that may be necessary with changes in usage or environmental conditions. Although surface-mounted<br />

closers, by definition, are never truly concealed, most Norton closers can be ordered with covers in a variety of painted or plated<br />

finishes to soften the closer's effect on the building design.<br />

Concealed Closers<br />

On the occasions where the architect's design calls for a door closer that is not visually obvious, a concealed closer is recommended.<br />

This installation requires considerably more door and frame preparation than a similar surface-mounted closer.<br />

Overhead Concealed Closers<br />

This type of door control is normally mortised into the transom of the frame above the door. A slide track is mortised into the<br />

top rail of the door. All elements — closer, arm and slide track — are totally concealed when the door is closed. Norton overhead<br />

concealed closers provide sweep and latch speed adjustments, backcheck cushioning and shock absorption. The Series 7900 closers<br />

also provide a 50% power adjustment feature. They are available with or without the hold open feature.<br />

regular Arm, Top Jamb and Parallel Arm<br />

There are three basic methods of mounting surface door closers to the door and frame. The method the architect chooses is<br />

influenced by some combination of these five factors:<br />

• Closer position, relative to the locations of door, frame and hinges<br />

• Space limitations on the top rail of the door<br />

• Space limitations on the frame face above the door<br />

• Appearance<br />

• Accessibility of the closer arm (especially in schools)<br />

The three basic mounting methods which follow are illustrated with a double lever arm.<br />

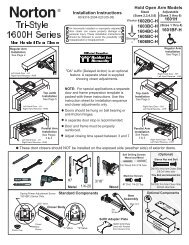

regular Arm<br />

The closer body is mounted on the top rail , hinge<br />

side of the door. The forearm is mounted to the frame<br />

face by means of a mounting shoe. The closer body<br />

requires less space on the door's top rail than a parallel<br />

arm installation. The arm projects from the door at<br />

approximately a right angle. Finally, the geometry of the<br />

assembly makes a regular arm closer somewhat more<br />

power-efficient than a parallel arm closer.<br />

11