Winter 2007 - Marshall Group

Winter 2007 - Marshall Group

Winter 2007 - Marshall Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

© 2004 Stretch, Inc. All rights reserved. The Stretch logo, Stretch, and Extendingthe Possibilities are trademarks of Stretch, Inc. All other trademarks andbrand names are the properties of their respective owners.This preliminary publication is provided “AS IS.” Stretch, Inc. (hereafter“Stretch”) DOES NOT MAKE ANY WARRANTY OF ANY KIND, EITHER EX-PRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THEIMPLIED WARRANTIES OF TITLE, NONINFRINGEMENT, MERCHANT-ABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Information inthis document is provided solely to enable system and software developers touse Stretch S5000 processors. Unless specifically set forth herein, there are noexpress or implied patent, copyright or any other intellectual property rights orlicenses granted hereunder. Stretch does not warrant that the contents of thispublication, whether individually or as one or more groups, meets your requirementsor that the publication is error-free. This publication could includetechnical inaccuracies or typographical errors. Changes may be made to the informationherein, and these changes may be incorporated in new editions ofthis publication.Part #: AN-0000-0001-04Stretch, Inc. — Confidential & Proprietary

Aerospace NewsCAV Aerospace sign up <strong>Marshall</strong> AerospaceManufacturing for a further 5 years<strong>Marshall</strong> Aerospace has signed a furtheragreement with CAV Aerospace which will seethe company’s Manufacturing division continueto prepare aircraft stringers for a further 5years at its Cambridge facility as part of acontract worth £9.8m.Alumax long bed gantry mill which enables thedivision to carry out preparation machiningoperations on stringers up to 22 metres inlength. The second twin spindle bridge on thismachine is now fully commissioned and will beused initially for machining stringers complete.compacter has also been procured, which willbe used in conjunction with the new machine.One of these compactors is already operatingin the stringer machining facility, which enablesa cleaner and more efficient method fordisposing of swarf.The stringers which are produced for CAVare ultimately for Airbus and are in supportof a range of aircraft types; A318, A319,A320, A321, A330, A340-500, A340-600and A380.Since the initial contract was signed in April2006 to set up a stringer preparationmachining facility at Cambridge, MA hasworked closely with CAV Aerospace to produceover 13,600 stringers to date, which hasdemonstrated to them how the company isable to provide an efficient and adaptablemachining service for CAV.Building on the success of the working contractand as a result of this further agreement, asecond phase of investment has now begun inthe Manufacturing facility which will reflect thisgrowth and partnering. The facility atCambridge currently houses a 40 metreFurther upgrades to the facilities include: anupgrading program of the machines in No 2Machine Shop. The first 2 machines (a Trace4 and 5) has been removed already, and thearea is being cleared and prepared inreadiness for a completely new retro-fittedmachine which is being specially built at themoment by established machine buildersElectron Engineering Services (EES). Thismachine will have four German high poweredcutting spindles mounted on it, capable ofproducing four finished stringerssimultaneously. The machine will have eightstringers on the machine table, being setupand run at one setting. The length of thismachine will also need to be quite long, as thestringers will be up to 11.40 metres in length.As the upgraded machines are installed, ageneral upgrade of the facilities is planned tohappen at the same time. A further swarfFurther upgrades of machines are alsoplanned, with the 17 metre machine to be thenext one to be fully upgraded (subject to furthercontract). This is planned to be removed oncethe new machine has been bought in, the newmachine is estimated to be installed by week 3in 2008.Update from the Netherlands Design Office“The Year <strong>2007</strong> has seen the official opening of the Netherlandsoffice in February; growth to a respectable 15 full time employeesand 2 student placements; and appointment as EASA approvedDesign Sub-contractor to <strong>Marshall</strong> Aerospace. This growth bringswith it a strong, young and dynamic engineering team with extensiveexperience in the areas of composites, design, stress analysis andprogram management. The engineering teams are led by MarcelRoggeveen (Lead Design Engineer) and Louis van Rijn (Lead StressEngineer), supported by various group leaders.The office supports the ADO with various design, stress and repairtasks. During 2008 the office will assist in giving composite trainingto ADO personnel and will shift towards an aggressive plan to expandthe <strong>Marshall</strong> Aerospace footprint in the Netherlands and surroundingareas. The office is fortunate to have appointed Arjan de Jong as theBusiness Development Manager. With Arjans’s extensive experienceat Stork Fokker Services and impressive contacts list across theaerospace community, the office plan to secure valuable externalwork in 2008. A focus area will be interior engineering work,however, any suitable engineering work will be tackled and workpackages may involve the ADO and hangers.The office is going from strength to strength but its success is largelybased on hard work, support and dedication from key personnel inCambridge. Alan Greenbank, Mark Johnston and Philip Andrewsprovides the main management and technical interface between theoffice and Cambridge with support from Sue Rolls and the rest of theHR team, Peter Thompson and Elaine Richardson from Accounts,Tony Neary from Offset, and Jonathan Conder from the MilitaryBusiness Unit.The office is steadily becoming a recognised entity in the Netherlandsand we are looking forward to a very productive 2008.”Andries Vermaak,General Manager,MA Netherlands B.V.From left to right;Louis van Rijn, MarcelRoggeveen, AndriesVermaak and Arjande Jong

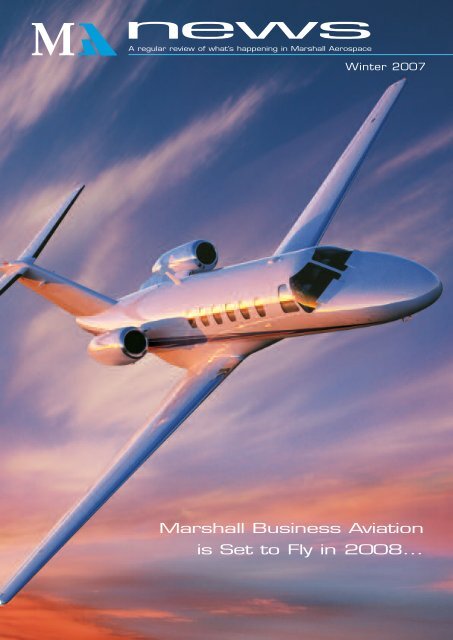

Aerospace News<strong>Marshall</strong> Executive Aviation is expanding its fleetBuilding on the success of its charter services with G-FIRM, <strong>Marshall</strong> Executive Aviation (MEA) is adding three more Citation XLS to its fleet.Established in 2003, MEA has seen its business grow as its reputation for first class service has spread throughout the market. The threeCitation XLS will continue the Company’s long association with Cessna Aircraft Company and will add an extra dimension to the company’scapability to enable it to satisfy customer demand for spacious and comfortable aircraft suited to the widest range of businessand private travel requirements.Operation of the first new aircraft will commence in January 2008 with phased introduction of the second and third overthe following 2 years<strong>Marshall</strong> Aviation ServicesSince the launch of MAS in 2003 it continues to grow with contract awards for theprovision of Air Traffic Services Management, Air Traffic Engineering and recently theProject Management Radar System, from remote feed to on site installation. This yearMAS has been awarded Airport Management Contracts for the first time.MAS has a particular expertise in the prevention of FOD on aerodromes and in June2005 MAS took over the UK and Ireland franchise to market the FOD Boss product.This has proved to be a very successful acquisition with a total of 47 units being sold todate. The ultimate FOD sweeper it collects simple debris such as nuts, bolts washersstones and gravel. A precision sweeper proven to be outstanding in its ability to preventFOD damage. This product has also been sold in its duplex and triplex configurations.Fire Behaviour UnitsA new feature to be found on the airfield is three fire behaviourtraining units, installed by Cambridge Fire and Rescue Service,adjacent to the Airport Fire Service training ground. These unitswill be used to train all firefighters within Cambridgeshire torecognise and deal with the phenomena, created by certain typesof fire, known as flashover and back draft. This has been a jointventure between CFRS and our own Airport Fire Service whichcontinues to demonstrate the excellent professional relationshipthat exists between the two services. There will also be the addedbenefit of adding our own firefighters, in due course, onto thetraining programme being run by CFRS.

Aerospace NewsVulcan Returns to the SkyThursday 18th October marked an important day for aviation heritage as Vulcan XH558 finally took to the air at Bruntingthorpe airfield on its longawaited test flight. The successful test flight lasted 30 minutes and returned with only very minor snags.It is 14 years since XH558, or G-VLCN as she is now known, flew into Bruntingthorpe and this test flight is the culmination of possibly the mostcomplicated restoration project yet undertaken. It began in earnest in April 2005 when, following a generous grant from the Heritage LotteryFund, <strong>Marshall</strong> Aerospace signed a contact with the Vucan to the Sky Trust.As the Engineering Authority for the aircraft, MA has been responsible for overseeing all aspects of the restoration. The most visible aspect hasbeen the team of MA technicians, led by John Boyle, who have been at Bruntingthorpe for the last two years. They have supervised a team ofVOC fitters and technicians. The onsite team have been supported by the rest of the Project team working at Cambridge, including Design, Quality,Production Support and Purchasing. Many of whom were at Bruntingthorpe to witness the first flight.Although the aircraft was flown by an experienced Vulcan crew, the test flying is being carried out under the control of our flight test department.Two or three further test flights will be required to clear the aircraft, including the new avionic equipment, fitted to meet current CAA requirements.The majority of the required paperwork has already been submitted to the CAA so when the flight test is complete, an application can be madeto the CAA for the Permit to Fly.The MA team have now returned to Cambridge but will return to complete the flight test programme. It is hoped that this work can be carriedout early next year so that G-VLCN can take its rightful place on the display circuit next year.The whole team can be rightly proud of the superb achievement in achieving the first test flight.

Aerospace NewsAerospace ExhibitionsIn September, MA and Cambridge City Airport hosted thebiennial Business & General Aviation Day (BGAD) inconjunction with EBAN magazine for the fourth time.Hangar 1 provided the perfect setting for the exhibition asover 35 companies participated, together with 7 aircraft onstatic display outside. The day was a great success (the sunshone the whole day!), and was attended by over 500 peopleincluding 30 aircraft that brought visitors in for the day. Itwas the result of team work from across a number ofdepartments within the company, in particular Security,Hangar 1, Operations & Handling, Air Traffic Control,Facilities, Catering, Health & Safety, AeroClub, <strong>Marshall</strong>Executive Aviation, Test Services, Manufacturing andCambridge City Airport and many more. A large number of<strong>Marshall</strong> employees also come down to the hangar tosupport the event too.Other conferences attended by the MA in October include theLAVEX Show in Libya, which was attended by Steve Amner ofthe Military Business Unit; and the Hercules OperatorsConference in Atlanta, at which the MA C-130 Avionics Rigcreated the centre piece of the stand.

Environmental /Health & SafetyNew Cycle Facilities on site at MAMA continues to provide bicycle specific facilities to encourage the uptake ofcommuter cycling as an alternative mode of transport to and from the site.In addition to the two new cycle shelters erected/installed behind ADO and inP-car park, the company has invested in 22 secure, weather-proof,‘BIKEAWAY’ cycle lockers complete with storage for wet weather gear.The lockers have been strategically located at high density employee areas ofwork; 11 are situated at the rear of ASC 1, 8 behind ADO, and a further 3at 8 Hangar. If you are interested in using a BIKEAWAY locker, keys areavailable through the Environmental Department (ext 3395) on a first comefirst serve basis.Health & Safety: IOSH PresentationsIn November, Martin Broadhurst presented another successful group with their IOSH Certificates after they had passed the NationalInstitute of Occupational Safety and Health “Managing Safely” Award. The certificates were presented to Barry Day, Stephen Crisp, MarkHemms, Daisy Cole, John Sneller, (Martin Broadhurst) Sean Brown, (Phil Sprinks) Antony Pannell, Irha Luijk, Gary Shadbolt, Gary Lindsay,Robert Butler, and Mark Jones (as shown in the photo).To achieve this award, the candidates had to pass a writtenexam and carry out project work exploring risk managementin the work place. The course is aimed at senior and middlemanagement depending on the level of hazard and risk intheir area of work. It is normally run twice a year however thisyear there have been four groups as there are many newsenior people. It is our top Health & Safety course in thecompany, and during the eight years it has been held over200 people have completed the course.Phil Sprinks, <strong>Group</strong> Health & Safety Advisor, said“Congratulations to another successful group on achievingthis award which keeps us on the straight and narrow, doinggood for the company and all of our employees”Core Health & Safety Values by Phil Sprinks MA H&S AdvisorWe are often asked what we believe in regarding our Health & Safety. We have a very useful reference manual that is our SAFETYMANAGEMENT SYSTEM but that is too detailed to follow easily, so what we have done is develop a series of central or core values thatwe believe in as the basis of our Health & safety at work.10 CORE HEALTH & SAFETY VALUES1. All injuries can be prevented2. Everyone is responsible for Safety3. Safety is a condition of employment4. It is no use wishing for the best5. Never stop checking what you are doing6. Everyone has the right to challenge anyone and expect a responsible action7. No injuries are minor8. Remember - Workplace safety is only half the story9. Everyone is valuable, we can all learn from each other10. Never think you can stop improving

MA PeopleThis article was run in the 20 – 26 November <strong>2007</strong> edition of Flight Global about MA’s very own Mark Johnston and his Working Week...Apprentice’s progress to the topMark Johnston, head of structures in the design office at <strong>Marshall</strong> Aerospace in Cambridge in theUK, began work with the company as a 16-year-old and tells Working Week that he never looked back.How did you get into theaviation business?I was a local lad. <strong>Marshall</strong> was oneof the biggest companies in thearea and I happened to be good atschool at what was then called"technical drawing". Like every kid Ihad an interest in aviation and Iguess it has grown from there. Icame for an interview and got a jobas a technician apprentice.What did yourtraining involve?I did a four-year apprenticeship thatinvolved basic training. I spentsome time going around thecompany and two years learningthe trade of a draughtsman. I'vebeen head of structures for thepast 10 months. Before that I washead of systems for five years, butduring that time I was also seniordesigner for the Airbus MilitaryA400M flight testbed programme[modifying a Lockheed Martin C-130 to carry the new EuropropTP400 engine for the militarytransporter].What does yourcurrent role entail?I'm responsible for around 120structural design engineers. Iensure the workforce has all thenecessary skills to carry out thevaried work that we undertake. Atthe moment probably about 75% ofmy time is dedicated to the C-130.[<strong>Marshall</strong> has a £1.5 billion ($3billion) contract to support the UKAround 75% of Johnston’s time is taken up by the UK RAF’s C-130sRoyal Air Force's C-130J/Ktransports for the rest of theirservice lives.] Other main areas aresupporting the RAF's LockheedTriStar fleet and looking at whatother work we can obtain in thefuture.What are the best andworst aspects of your job?The best is meeting a newchallenge every day. You have aplan and pretty much things goaccording to it, but you always getsomething that surprises you.That's good - that's the way youlearn. Worst aspect? Meetings.The demand for meetings hasgrown and it's something where weneed to find a way of working“We have a verygood apprenticescheme as well as agraduate trainingscheme that isaccredited with theRoyal AeronauticalSociety”smarter. We've tried videoconferencing, Web-X andteleconferencing and they can workvery well. We probably need to usethem more.What qualities wouldsomeone need to doyour job?You would need to be flexible andadaptable. You need to be able totake the rough with the smooth interms of the variety of work andthe people you deal with.Does the company stilloffer apprenticeships?Absolutely. We have a very goodapprentice scheme as well as agraduate training scheme that isaccredited with the RoyalAeronautical Society. We're puttingmany graduates through becominga chartered engineer and that is aroute also open to apprentices,who have the opportunity to go onand get a degree. We take about20 apprentices a year.Does <strong>Marshall</strong> suffer fromthe long-running problemin the UK of school-leaversand graduates not wantingto "get their hands dirty"in the manufacturingsector?Just the opposite. I have an awfullot of applications to look throughand the majority are graduates. Mybiggest difficulty is gettingexperienced people. We like ourgraduates to have had one year ofindustrial placement with us. Theyget a sponsorship when they havedone that and would come back tous after completion of their degree.We have a very successfulretention rate with thosegraduates. Primarily they areengineering graduates, but we alsotake people with degrees insubjects such as mathematics.

MA PeoplePete Brindley’s visit to Nicaragua in <strong>2007</strong>“This year saw my 4th trip to Nicaragua on ahumanitarian mission, and it was verychallenging and at the same time extremelyrewarding. I managed, with the help of my localprimary school, to bring a Nicaraguan ladycalled Aida Alverado over to the UK whichresulted in a visit to the Houses of Parliamentto meet Peter Kilfoyle MP and the OverseasDevelopment Minister Douglas Alexander MP.Aida stayed in Cambridgeshire for over 2weeks until returning with me to Nicaragua.Our team this year consisted of 5 teachers andPaul Bedford from ADO IT who went toNicaragua for 2 weeks. Everyone on thesetrips is self funded and gives of their own freetime. We visited some of the poorest areas inthe country called Bluefields and La Barra RioGrande. We found in Managua the capitol citythe computers that were shipped earlier in theyear which were bound for the island ofOmetepe. These were donated by AirportHouse IT department with thanks to IsobelAylott and Doug Want.Many <strong>Marshall</strong> Employees and their familiescontributed cuddly toys and stationery. I set agoal to provide for 200 young children, but thiswas very quickly superseded and I was able toprovide for 365 children. Dawn Frampton(ADO) along with Julie Harris (ADO) producedcolouring books that were delivered to thechildren of La Barra Rio Grande together withthe cuddly toys. It was amazing to see howhappy the children and adults looked when theyreceived these gifts provided by <strong>Marshall</strong>Employees. We visited all 5 schools on theisland of Ometepe which have now beentwinned with 5 schools in Cambridgeshire. It isfantastic to see how much their lives have beenimproved over the last 4 years with the little wecan do for them.In summary what we achieved this year was32 computers, 365 cuddly toys, 220colouring books, 1835 pencils, 820 pens, and120 reams of paper (in essence enoughstationery to support 4 schools forapproximately 1 year), and $920 which willprovide highly nutritious milk for 80malnourished children on the island ofOmetepe for 9 monthsI am already looking forward to next year’s tripwhich will take me via Guatemala, Honduras,Nicaragua and Costa Rica.”Pete Brindley - ADO ITCall to Duty...“I’ve been a member of 7010 (VR) Squadron,Royal Auxiliary Air Force for 18 years workingas an Intelligence Analyst so it was no surprisewhen in August <strong>2007</strong> I was called up tosupport operations in Afghanistan. Initially Ireported to RAF Waddington, Lincs, toprogress my admin and be officially acceptedback into formal RAF service. I then spent aweek with Waddington’s RAF Regiment Flightto complete the Individual ReinforcementTraining course, which provided me withessential ‘in theatre’ information covering arange of subjects from first aid, land mineclearance, rules of engagement and of coursethe live firing of my SA 80A2 rifle that wouldremain by my side during my deployment.I left RAF Brize Norton on a Tristar flight toKandahar, Afghanistan. After a 7 hour flight,the approach in to Kandahar was ‘interesting’as the aircraft was blacked out with everyonedonning body armour and helmets, essentialfor safety. After arrival I found myself airborneagain on a C-130J heading for my finaldestination, Camp Bastion in HelmandProvince. Within a few hours of my arrival Iwas on the firing range ensuring my rifleoperated as advertised, and I was briefed by aLt Col. on security, first aid, helicopteroperations and rules of engagement - the latterI will always remember. His final words of thebrief were the most sobering as he addressed100 personnel; ‘Be under no illusion, in thenext few weeks the majority of you in this roomwill be fighting for your lives’.At this point it Iwas left in no uncertain terms that I was inembedded in the middle of a War Zone.After the arrival briefings I met the team I hadgone out to support performing the Herti UAVtrials, unfortunately due to a technical problemthe trial was terminated early and so it wasdecided that the team would return to Blightywithout me! I stayed in theatre to act as liaisonwith the various parties to ensure the team’sequipment was returned to the UK. Once thistask had been completed, I moved into CampBastion’s J2 Intelligence Cell to support 40Commando, Royal Marines. I got in to a workroutine, the days came and went, and theweeks passed by supporting the Marines. Sowith a week to go I contacted the movementspersonnel in Kandahar and booked myself aseat on an outgoing flight. However, my initialflight to Kandahar would be via C-130. C-130splay a significant part of the military operationin Afghanistan. It’s easy to forget what a majorcontribution that we, at MA, make supportingthis important military capability. Serving atCamp Bastion, Afghanistan was one of themost sobering experiences of my life; I washappy to board the C-130J for Kandahar, butmy thoughts were with the many personnelthat had to remain there and in most casesfight the Taliban at the Forward OperatingBases. I departed a very dusty and coldAfghanistan on a C17 Globemaster and arrivedin ‘Blighty’ the following day. On the drive backto RAF Waddington, the contrast between theaustere and hostile environment of theHelmand Province to the beautiful and peacefulrolling hills of the Cotswolds was astounding.On a final note I would like to say thank you tomy friends and colleagues in the ADO at MA,particularly Val Cox, Helen Scarborough andRon Blakeman for their constant emails. AlsoI’d like to say thank you to Graeme Jones andthe Chief Designer, Ian Roberts.”Jon Land – ADO

MA People<strong>Marshall</strong> Aerospace Apprentice AwardsThe following Apprentices received awards at the <strong>Marshall</strong> Aerospace Apprentice Training Awards held on Thursday, 15th November at the Airport Works.FIRST YEAR APPRENTICES (2006 INTAKE)Name Specialism AwardMark Furbank Mechanical Manufacturing Apprentice Top Apprentice<strong>Marshall</strong> Teversham CupDominic Coverley Airframe Fitter Apprentice Best AchieverKyle Brennan Airframe Fitter Apprentice Best Cold ChiselJohn Huntridge CupSECOND YEAR APPRENTICES (2005 INTAKE)Name Specialism AwardMichael Shingfield Technician Apprentice Top Apprentice<strong>Marshall</strong> of Cambridge CupJames Dowell Airframe Fitter Apprentice Best AchieverTHIRD YEAR APPRENTICES (2004 INTAKE)Name Specialism AwardMark StainesTop ApprenticeMichael <strong>Marshall</strong> CupMarc Dewing Avionics/Electrical Apprentice Best AchieverFOURTH YEAR APPRENTICES (2003 INTAKE)Name Specialism AwardLee Woods Mechanical Manufacturing Top ApprenticeApprenticeSir Arthur <strong>Marshall</strong> CupSEMTA AWARD FOR BEST NVQ PORTFOLIOName Specialism AwardMark Staines Airframe Fitter Apprentice The SEMTA Challenge TrophyFIRST YEAR ADULT TRAINEE AWARDName Specialism AwardIan Lock Adult Trainee (Electrical) TrophyThe following Apprentice Completion Certificates werealso awarded: Matthew Bowyer; Cara Duncombe;Jonathan Roberts; Mark Staines; Paul Waller and LeeWoods. Donny Everett also received an Adult TraineeCompletion Certificate.SECOND YEAR ADULT TRAINEE AWARDName Specialism AwardDonny Everett Adult Trainee (Airframe) TrophyTop EEF Awards for MA Engineering ApprenticesIn the summer, the EEF (EngineeringEmployers’ Federation) held the final of theEngineering Apprentice of the Yearcompetition at Barleythorpe.There were four categories: 1st YearApprentices (large and small companies)and 3rd Year Apprentices (large and smallcompanies).MA had three finalists on the day who hadbeen chosen form a very large number ofentrants. In the 1st Year large companycategory, we had two of the four finalists,Matthew Pearson and Jamie Houghton.Jamie was the runner-up to the winner ofthe category. In the 3rd Year large companycategory, we had one finalist Ollie Raymondwho was runner-up to the overall winner.Once again MA has demonstrated that theability of our apprentices is as good as, if notbetter, than our competitors in theengineering sector.The photo shows Matthew Pearson, RogerTingey (<strong>Group</strong> Training Manager), JamieHoughton and Ollie Raymond with theircertificates.Competition“Last year, I started with <strong>Marshall</strong>s, entailing amove for the whole family from Scotland, withthe children having to move and adjust to a newschool in London where I offered the school mysupport with science activities which I had doneat their previous school.It would seem that a paper aeroplanecompetition is a simple thing to arrange: youjust turn up with paper, get the children to foldit up and have some fun throwing aeroplanesabout. However, I wanted to achieve somethingmore than this, by setting off a spark for thewonder of science and aviation.An airshow promotional gifts supplier kindlyoffered to supply 100+ free samples free ofcharge, but because they were liable to bebroken easily I spent a Sunday afternoon,slotting 80 balsa wings, tails and rudders intofuselages. With a little test flying help from myson, we discovered that to give a smootherglide, the nose weight supplied, was bestreplaced by a paper clip. I also adjusted my planfor the competition, which had now turned intoa flight workshop. On the day of the workshops,we started with a general description ofaircraft parts, using models of a 777 and 747.With gliders from the other group whizzingpast, the first competition was furtherest glideand the children each had two turns and learntthe basics of aircraft control surfaces. The nextcompetition was the longest glide, timed formaximum time in the air. There werecertificates for all, for completing the workshop,and competition winner certificates also.Many of the children, after the workshops,thanked me personally and asked me to do thecompetition again next term. I think there wereeven a few children whose imagination hadbeen “sparked” in the way that I had hoped for.All of this made for a very worthwhile day andan additional bonus was that I got a chance torelive my childhood.”Sohail Chughtai - ADO Stress Engineer

MA PeopleAll for Charity!During the second half of <strong>2007</strong>, MAemployees have taken part in all sorts offundraising events for a variety of charities.In September, the annual Charity DragonBoat Race took place on the River Cam insupport of the Cambridgeshire CommunityFoundation. Three teams from the <strong>Marshall</strong><strong>Group</strong> entered; an MA Commercial team, aHIOS team, and an MSV team. Either due tocoincidence or the organisers’ competitiveintentions, all three teams were entered inthe same heat. And who won this heat?! Itwas the MSV team… but the MACommercial team successfully managed tocome second overall in the competition andare very keen to race for the winning titlenext year!Several teams also took part in the annualChariots of Fire relay race from across the<strong>Marshall</strong> <strong>Group</strong> of Companies, however thefastest MA team once again were theTraining School team with a time of 1 hour,4 minutes and 46 seconds and who came15th overall – edging closer each year tothe winners’ spot. This year the charity theywere raising money for was the ArthurRank Hospice.At MA in October, all employees wereinvited to wear their jeans for the day in aidof Jeans for Genes Day; a wonderful sum of£520 was raised which will go towards aselection of children’s charities. Later inNovember, MA was visited by two Pudseybears for Children in Need. With greatsupport from Avenance in particular SueChapman and her daughter Louise, andPaul Hodgson and Kelly Green of HIOS TSG,a fantastic £1450 was raised through araffle and sponsorship money paid by thosewho wanted to see Avenance’s JaisonWaldoch and William Drewitt go throughthe pain of waxing.A fantastic effort has been made byeveryone who has taken part or contributedto charity events this year – keep up thegood work for 2008!

Aerospace News10 years12 years16 yearsHappy RetirementMr David H GilkesPRODUCTION SUPPORTRetirement: 21/12/<strong>2007</strong>Mr Trevor JonesPRDAMRetirement: 31/08/<strong>2007</strong>Mr Douglas John ReadmanHorseheath LodgeRetirement: 31/08/<strong>2007</strong>Competition TimeThe winner of the last edition’s competition is Peter Robinsonfrom PC Support. Congratulations and your vouchers are inthe post! To be in with a chance of winning £25 in vouchers,simply identify the story and the page number from whicheach photo clip below was taken from in this edition of MANews. Please return the completed form to Vicki Lea inMarketing by 15/01/08.Here are this edition’s five photographs...Good Luck!!!PICTURE 1:Page Number:Story Name:PICTURE 2:Page Number:Story Name:23 yearsMr Colin CutlerQualityRetirement: 30/11/<strong>2007</strong>PICTURE 3:Page Number:Story Name:25 yearsMr Michael DaviesPRDAMRetirement: 22/01/2008PICTURE 4:Page Number:Story Name:35 yearsMr William David DicksonPRDAMRetirement: 24/01/2008PICTURE 5:Page Number:Story Name:Bob Burton (Aircraft Mod & Maintenance) who retiredon (19th October) after 23 years (pictured bottom left)Name:Martyn Redmore (Airport Management) who retired on30th November after 10 years (pictured bottom right)Dept:Tel No: