CFI Wall Panel (Concrete Face Insulated Wall Panel) - Northland ...

CFI Wall Panel (Concrete Face Insulated Wall Panel) - Northland ...

CFI Wall Panel (Concrete Face Insulated Wall Panel) - Northland ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MATERIAL SAFETY DATA SHEETTech-Crete Processors LTDProduct Name: <strong>CFI</strong> <strong>Wall</strong> <strong>Panel</strong> (<strong>Concrete</strong> <strong>Face</strong> <strong>Insulated</strong> <strong>Wall</strong> <strong>Panel</strong>)Issue Date: 2009/08/17The <strong>Concrete</strong> <strong>Face</strong> <strong>Insulated</strong> (<strong>CFI</strong>) <strong>Wall</strong> <strong>Panel</strong> is a composite of Styrofoam® RM brand extrudedpolystyrene foam thermal insulation with an attached coating of latex modified concrete . We willtreat this MSDS as a two part document: (A) covering the extruded polystyrene foam thermalinsulation, and (B) the concrete topping.( A ) Extruded Polystyrene Thermal Foam Insulation1. PRODUCT AND COMPANY IDENTIFICATION Product Name:Roofmate Extruded Foam Roof Insulation CDN as base substrate for Tech-Crete <strong>CFI</strong> <strong>Wall</strong> <strong>Panel</strong>Manufacturer Identification:Dow Chemical Canada LLC A Subsidiary of The Dow Chemical Company 4445 Marie-Victorin BlvdVarennes, QC J3K 1T3 CanadaCompany Identification:Customer Information Number: 800-331-6451EMERGENCY TELEPHONE NUMBER24-Hour Emergency Contact:Local Emergency Number:989-636-4400989-636-44002. HAZARDS IDENTIFICATIONEmergency Overview:Color:BluePhysical State:BoardOdor: OdorlessHazards of product: Toxic fumes may be released in fire situations.Potential Health Effects:Eye Contact: Solid or dust may cause irritation due to mechanical factor. Fumes/vapor released duringthermal operations such as hot-wire cutting may cause eye irritation.Skin Contact: Essentially nonirritating to skin. Mechanical injury only.Page 1 of 10

Inhalation: Dust may cause irritation to upper respiratory tract (nose and throat). Fumes/vaporsreleased during thermal operations such as hot wire cutting may cause respiratory irritation.Concentrations of the blowing agents anticipated incidental to proper handling are expected to be wellbelow those which cause acute inhalation effects and below exposure guidelines.Ingestion: Swallowing is unlikely because of the physical state. Very low toxicity if swallowed.Harmful effects not anticipated from swallowing small amounts. May cause choking or blockage of thedigestive tract if swallowed.Birth Defects / Development Effects: Contains component(s) which did not cause birth defects inanimals; other fetal effects only occurred only at doses toxic to the mother. The component(s) is/are:1,1,1,2-Tetrafluoroethane. Testing has indicated that normal handling and cutting are unlikely to resultin exposure levels sufficient to cause the listed effects.3. COMPOSITION , INFORMATION ON INGREDIENTSComponent: CAS # Amount W/W2-Propenenitrile polymer with ethenylbenzene 9003-54-7 < 90.0%Styrene, polymers 9003-53-6 < 90.0%1,1,1,2-Tetrafluoroethane 811-97-2 >= 0.0 - < 10.0%1-Chlor-1, 1-difluoroethane 75-68-3 >= 0.0 - < 10.0%Copolymer mixture Trade secret < 5.0%Amounts are presented as percentage by weight.Extruded styrenic polymer foam containing a halogenated flame retardant system.4. FIRST-AID MEASURESEye Contact: May cause injury due to mechanical action. If irritation occurs, flush eyes thoroughlywithwater for several minutes. Remove contact lenses after the initial 1-2 minutes and continue flushingfor several additional minutes. It effects occur, consult a physician, preferably an ophthalmologist.Skin Contact: Wash skin with plenty of water.Inhalation: Move person to fresh air. If effects occur, consult a physician.Ingestion: If swallowed, seek medical attention. May cause gastrointestinal blockage. Do not givelaxatives. Do not induce vomiting unless directed to do so by medical personnel.Notes to Physician: No specific antidote. Treatment of exposure should be directed at the control ofsymptoms and the clinical condition of the patient.5. FIRE FIGHTING MEASURESExtinguishing Media: Water fog or fine spray. Dry chemical fire extinguishers. Carbon dioxide fireextinguishers. Foam.Fire Fighting Procedures: Keep people away. Isolate fire and deny unnecessary entry. Soak thoroughlywith water to cool and prevent re-ignition. If material is molten, do not apply direct water stream. Use finewater spray or foam. Cool surroundings with water to localize fire zone.Special Protective Equipment for Firefighters: Wear positive-pressure self-contained breathingapparatus (SCBA) and protective fire fighting clothing (includes fire fighting helmet, coat, trousers,boots, and gloves). If protective equipment is not available or not used, fight fire from a protectedlocation or safe distance.Unusual Fire and Explosion Hazards: Container may vent and/or rupture due to fire. When product isstored in closed containers, a flammable atmosphere can develop. Mechanical cutting, grinding, or sawingcan cause formation of dusts. To reduce the potential for dust explosion, do not permit dust to accumulate.This product contains a flame retardant to inhibit accidental ignition from small fire sources. This plasticfoam product is combustible and should be protected from flames and other high heat sources. For moreinformation, contact Dow. Dense smoke is produced when product burns.Page 2 of 10

Hand Protection: Use gloves to protect from mechanical injury. Selection of gloves will depend onthe task.Respiratory Protection: Respiratory protection should be worn when there is a potential to exceedthe exposure limit requirements or guidelines. If there are no applicable exposure limit requirementsor guidelines, wear respiratory protection when adverse effects, such as respiratory irritation ordiscomfort, have been experienced, or where indicated by your risk assessment process. Whenrespiratory protection is required for certain operations, including but not limited to saw, router or hotwirecutting, use an approved air-purifying respirator. In dusty or misty atmosphere, use an approvedparticulate respirator. The following should be effective types of air-purifying respirators: Organicvapor cartridge with a particulate pre-filter.Ingestion: No precautions necessary due to the physical properties of the material.Engineering Controls:Ventilation: Use local exhaust ventilation, or other engineering controls to maintain airborne levelsbelow exposure limit requirements or guidelines. If there are no applicable exposure limitrequirements or guidelines, general ventilation should be sufficient for most operations. Localexhaust ventilation may be necessary for some operations.9. PHYSICAL AND CHEMICAL PROPERTIESPhysical State BoardColor BlueOdor OdorlessFlash Point – Closed Cup Not ApplicableFlammable Limits in Air Lower: Not ApplicableUpper: Not ApplicableAutoignition Temperatures 354ºC ASTM D1929Vapor Pressure Not ApplicableBoiling Point (760 mmHg) Not ApplicableVapor Density (air = 1) 0.027 – 0.064 EstimatedLiquid Density Not ApplicableFreezing Point Not ApplicableMelting Point 90 - 130º C EstimatedSolubility in water (by weight) insoluble in waterpH Not ApplicableDecomposition Temperature No test data availableKinematic Viscosity Not Applicable10. STABILITY AND REACTIVITYStability/Instability: Thermally stable at typical use temperatures.Conditions to Avoid: Avoid temperatures above 300º C. Exposure to elevated temperatures can causeproduct to decompose. Avoid direct sunlight.Inhibitor: CristobaliteIncompatible Materials: Avoid contact with oxidizing materials. Avoid contact with: Aldehydes,Amines, Esters, Liquid fuels, Organic solvents.Hazardous Polymerization: Will not occur.Thermal Decomposition:Page 4 of 10

Does not normally decompose. Evolution of small amount of hydrogen halides occur when heatedover 250ºº C (482º F). Decomposition products depend upon temperature, air supply, and the presenceof other materials. Decomposition products can include and are not limited to: Aromatic compounds,Aldehydes, Hydrogen halides, Polymer fragments. Decomposition products can include trace amountsof: Acrylonitrite, Hydrogen cyanide, Styrene, Ethylbenzene. Toxic flammable gases can be releasedduring decomposition.11. TOXICOLOGICAL INFORMATIONRepeated Dose Toxicity: Additives are encapsulated in the product and are not expected to bereleased under normal processing conditions or foreseeable emergency.Chronic Toxicity and Carcinogenicity: Contains component(s) which did not cause cancer inlaboratory animals.Developmental Toxicity:Contains component(s) which did not cause birth defects in animals; otherfetal effects occurred only at doses toxic to the mother. The component(s) is/are: 1,1,1,2-Tetrafluoroethane. Testing has indicated that normal handling and cutting are unlikely to result inexposure levels sufficient to cause the listed effects. Contains component(s) which did not cause birthdefects or any other fetal effects in lab animals.Reproductive Toxicity: Contains component(s) which did not interfere with reproduction in animalstudies.Genetic Toxicology:Genetic toxicity studies on tested components were predominantly negative.Animal genetic toxicity studies were predominantly negative.Component Toxocology: 1,1,1,2-Tetrafluorothane12. ECOLOGICAL INFORMATIONENVIRONMENTAL FATEMovement & PartitioningNo bioconcentration is expected because of the relatively high molecular weight (MW greater than1000). In the terrestrial environment, material is expected to remain in the soil. In the aquaticenvironment, material is expected to float.Persistence and DegradabilitySurface photodegradation is expected with exposure to sunlight. No appreciable biodegradation isexpected. Based largely or completely on information for the blowing agent: 1,1,1,2-Tetrafluoroethane (HFC-134a)remains in the foam and diffuses out slowly, most of it degrading inthe troposphere to CO2 and HF. 1,1,1,2-Tetrafluoroethane (HFC-134a) has a stratospheric ozonedepletion potential (ODP) of zero, relative to CFC 12 (ODP=1). Chlorodifluoroethane (HCFC142b) has a stratospheric ozone depletion (ODP) of 0.065, relative to CFC 12 (ODP=1).ECOTOXICITYNot expected to be acutely toxic in aquatic organisms.13. DISPOSAL CONSIDERATIONSDO NOT DUMP INTO ANY SEWERS, ON THE GROUND, OR INTO ANY BODY OF WATER. All disposalpractices must be in compliance with all Federal, State/Provincial, and local laws and regulations.Regulations may vary in different locations. Waste characterizations and compliance with applicablelaws are the responsibility solely of the waste generator. AS YOUR SUPPLIER, WE HAVE NO CONTROLOVER THE MANAGEMENT PRACTICES OR MANUFACTURING PROCESSES OF PARTIES HANDLING ORUSING THIS MATERIAL. THE INFORMATION PRESENTED HERE PERTAINS ONLY TO THE PRODUCT ASSHIPPED IN ITS INTENDED CONDITION AS DESCRIBED IN MSDS SECTION: Composition Information.FOR UNUSED & UNCONTAMINATED PRODUCT, the preferred options include sending to a licensed,Page 5 of 10

permitted: Recycler, Reclaimer, Landfill, Incinerator or other thermal destruction device.14. TRANSPORT INFORMATIONTDG Small container NOT REGULATEDTDG Large Container NOT REGULATEDIMDG NOT REGULATEDICAO/IATA NOT REGULATED15. REGULATORY INFORMATIONUS Toxic Substance Control Act All components of thisproduct are on the TSCA Inventory or are exempt from TSCAInventory requirements under 40 CFR 720.30CEPA – Domestic Substances List (DSL)All substances contained in this product are listed on the Canadian Domestic Substances List(DSL) or are not required to be listed.Hazardous Products Act Information: CPR ComplianceThis product has been classified in accordance with the hazard criteria of the Canadian ControlledProducts Regulations (CPR) and the MSDS contains all the information required by the CPR.Hazardous Products Act Information: WHMIS ClassificationThis product is not a “Controlled Product” under WHMIS Classification16. OTHER INFORMATIONHazard Rating SystemNFPA Health Fire Reactivity0 1 0Recommended Uses andRestrictionsThermal insulation. We recommend that you use this product in a manner consistent with the listed use. Ifyour intended use is not consistent with the stated use, please contact your sales or technical servicerepresentative.RevisionDow Identification Number: 81896 / 1002 / Issue Date 2009.03.03 / Version 3.0Dow Chemical Canada ULC urges each customer or recipient of this (M)SDS to study it carefully and consult appropriateexpertise, as necessary or appropriate, to become aware of and understand the data contained in this (M)SDS and any hazardsassociated with the product. The information herein is provided in good faith and believed to be accurate as of the effectivedate shown above. However, no warranty, express or implied, is given. Regulatory requirements are subject to change and maydiffer between various locations. It is the buyer’s responsibility to ensure that his activities comply with all federal, state,provincial, or local laws. The information presented here pertains only to the product as shipped. Since conditions for use ofthe product are not under the control of the manufacturer, it is the buyer’s/user’s duty to determine the conditions necessaryfor the safe use of this product. Due to the proliferation of sources for information such as manufacturer-specific (M)SDS’, weare not and cannot be responsible for (M)SDS’s obtained from any source other than ourselves. If you have obtained an(M)SDS from another source or if you are not sure that the (M)SDS you have is current, please contact us for the most currentversion.Page 6 of 10

( B ) LATEX MODIFIED CONCRETE TOPPING1. PRODUCT AND COMPANY INFORMATIONProduct Name: <strong>Concrete</strong> Topping for Tech-Crete <strong>CFI</strong> <strong>Wall</strong> <strong>Panel</strong>The concrete topping on the Tech-Crete <strong>CFI</strong> <strong>Wall</strong> <strong>Panel</strong> is a latex modified concrete which isformed and extruded on the surface of the Styrofoam brand extruded polystyrene foam thermalinsulation. After the concrete is allowed to cure, there are no serious hazards when utilized exceptthose as noted below.Company Identification:Tech-Crete Processors Ltd.2930 13 th Avenue SWSalmon Arm, BC V1E 3K1Company Information:Tel: 250-832 9705Fax: 250-832 9707Email: info@tech-crete.comwww.tech-crete.com2. HAZARDS IDENTIFICATIONColor: GreyPhysical State: Cured concrete toppingOdor: Slight cement odorEmergency Overview: <strong>Concrete</strong> in its intact state will not release airborne dust, but dust can beproduced during cutting, grinding, drilling, and other machining of the product. A single, shorttermexposure to concrete dust presents little or no hazard.Potential Health Effects:Eye Contact (acute): <strong>Concrete</strong> dust may cause immediate or delayed irritation or inflammation.Eye exposures require immediate first aid and medical attention. Direct contact can cause irritationbefore mechanical abrasion.Skin contact: Cured concrete dust may cause dry skin, discomfort, irritation,severe burns,and dermatitis.Ingestion : Expected to be practically non-toxic. Ingestion of large amounts may causegastrointestinal irritation and blockage.Inhalation (general) :May result, depending on the degree of the exposure, from exposure to dustgenerated from cutting, grinding, crushing, or drilling hardened concrete.Inhalation (acute): Breathing dust may cause nose, throat lung or mucous membrane irritation,including choking. Inhalation of high levels of dust can cause chemical burns to the nose, throatand lungs.Inhalation (chronic): Risk of injury depends on duration and level of exposure.Silicosis: This product contains crystalline silica. Prolonged or repeated inhalation of respirablecrystalline silica from this product can cause silicosis, and other seriously disabling and fataldiseases.Carcinogenicity: <strong>Concrete</strong> is not listed as a carcinogen by IARC or NTP; however, concretePage 7 of 10

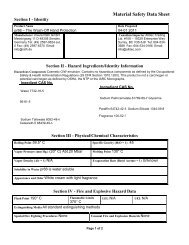

contains trace amounts of crystalline silica and hexavalent chromium which are classified byIARC and NTP as known human carcinogens.Autoimmune Disease: Some studies show that exposure to respirable crystalline silica (withoutsilicosis) or that the disease silicosis may be associated with the increased incidence of severeautoimmune disorders such as scleroderma (thickening of skin), systemic lupus erythematosus,rheumatoid arthritis and diseases affecting the kidneys.Medical Conditions Aggravated by Exposure: Individuals with lung disease (e. g. bronchitis,emphysema, COPD, pulmonary disease) can be aggravated by exposure to concrete dust.3. COMPOSITION, INFORMATION ON INGREDIENTSHazardous Components(Chemical Identity /Common Names)CAS No. OSHA PEL ACGIH TLV MSHA PEL %Cement65997-15-115mg/m3 (Total)5mg/m3 (Respirable)10mg/m3(Total)10mg/m3 (Total) 10-30%Limestone (CaCo3)(Calcium carbonate,present, if limestoneaggregates are used)Crystalline Silica (Quartz)(<strong>Concrete</strong> aggregates maycontain silica)1317-653 15 mg/m3 (Total)14808-60-7Aluminum Oxide (Al2O3) 1344-28-130 (%SiO2+2)mg/m3(Total Particulate)10/(%SiO2+2)mg/m3(RespirableParticulate)15mg/m3 (Total)5mg/m3 (Respirable)10 mg/m3(Total)0.1mg/m3(Total)(Respirablequartz)10 mg/m3 0-80%30 (%SiO2+2)mg/m3(Total)10/(%SiO2+2)mg/m3(Respirable)0.5-80%10mg/m3 10mg/m3 0.1-2%Amorphous Silica61790-53-280mg/m3 /(%SiO2)10mg/m3(Total)3mg/m3(Respirable)20mppcf 0.01-3%Calcium Oxide (CaO) 1305-78-8 5mg/m3 2mg/m3 5mg/m3 0-1%Iron Oxide (as Fe2O3) 1309-37-1 10mg/m3 10mg/m3 10mg/m3 0.1-2%Latex (Styrene ButadienePolymer)Proprietary N/A N/A N/A

6. ACCIDENTAL RELEASE MEASURESAvoid actions that cause the concrete dust to become airborne. Avoid inhalation of concrete dust.Wear protective equipment as described in Section 8.7. HANDLING AND STORAGEDry cutting or grinding concrete will release respirable crystalline silica. Use all appropriatemeasures of dust control or suppression, and use appropriate personal protective equipment.Where possible, wet cutting is recommended to minimize dust and airborne particles.8. EXPOSURE CONTROLS AND PERSONALPersonal Protection:Respiratory Protection NIOSH: Dust may cause irritation to the respiratory tract. Use approveddust masks.Protective Gloves: In damp conditions, abrasion and skin irritation due to the alkali in the cement.Eye Protection: Use ANSI approved safety glasses with shields while cutting.Other Protective Clothing/Equipment: Possible use of aprons.Engineering Controls: Ventilation, use general or local to control airborne levels of dust.9. PHYSICAL AND CHEMICAL PROPERTIESAppearance & Odor: a hard grey covering with a slight cement odorBoiling Point: N/ASpecific Gravity: N/AVapor Pressure: N/A% volatile: N/AVapor Density: N/AEvaporation rate: N/AFlash Point: N/AFlammable Limits of Air: N/AExtinguisher Type: water Unusual Fire & Explosion Hazard: none10. STABILITY AND REACTIVITYStability: StableIncompatibility: Strong AcidsMaterials to Avoid: Strong Acids Hazardous Decomposition Products: Gases from StrongAcid Degradation11. and 12. TOXICOLOGICAL and ECOLOGICAL INFORMATIONFor questions regarding toxicological and ecological information refer to contact information inSection 1.12. DISPOSAL CONSIDERATIONSDispose of waste and packaging in compliance with applicable Federal, Provincial, State andLocal regulations13. TRANSPORT INFORMATIONThis product is not classified as a Hazardous Material under U.S. DOT or Canadian TDGregulations.13. REGULATORY INFORMATIONOSHA/MSHA Hazard Communication: This product is considered by OSHA/MSHA to be aPage 9 of 10

hazardous chemical and should be included in the employer’s hazard communication program.CERCLA/SUPERFUND: This product is not listed as a CERCLA hazardous substance.EPCRA SARA Title III: This product has been reviewed according to the EPA Hazard Categoriespromulgated under Sections 311 and 312 of the Superfund Amendment and Reauthorizations Actof 1986 and is considered a hazardous chemical and a delayed health hazard.EPCRA SARA Section 313: This product contains none of the substances subject to the reportingrequirements of Section 313 of Title III of the Superfund Amendments and Reauthorization Act of1986 and 40 CFR part 372.WHMIS/ Canadian Domestic and Substances List (DSL): Products containing crystalline silica areclassified as D2A, E and are subject to WHMIS requirements.OTHER INFORMATIONThe information presented here is based on the information available to us at the time of publication and isbelieved to be accurate. Since this information may have been obtained in part from independentlaboratories or other sources not under our direct supervision, no representation is made that theinformation is accurate, reliable, complete or representative.Any party using this product should review for compliance, all laws, rules, or regulations prior to use,including but not limited to Canada and US Federal, Canada Provincial, US State and Local regulations.® Styrofoam is a registered trademark of Dow Chemical CompanyTM Tech-Crete is a trademark of Tech-Crete Processors Ltd.Page 10 of 10