Can We Bury Global Warming? - Carbon Mitigation Initiative ...

Can We Bury Global Warming? - Carbon Mitigation Initiative ...

Can We Bury Global Warming? - Carbon Mitigation Initiative ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

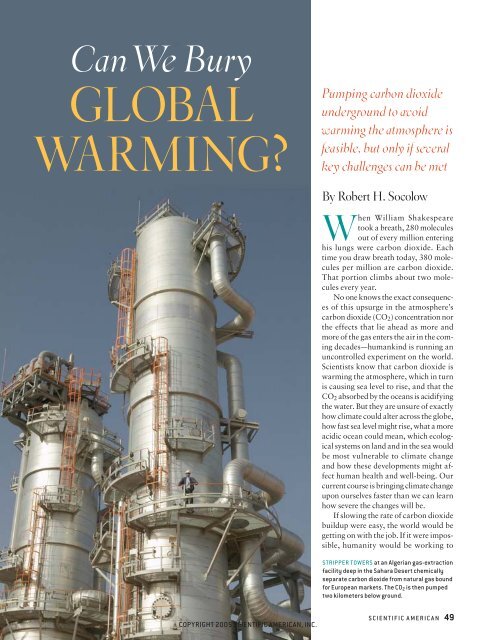

<strong>Can</strong> <strong>We</strong> <strong>Bury</strong>GLOBALWARMING?Pumping carbon dioxideunderground to avoidwarming the atmosphere isfeasible, but only if severalkey challenges can be metBy Robert H. SocolowWhen William Shakespearetook a breath, 280 moleculesout of every million enteringhis lungs were carbon dioxide. Eachtime you draw breath today, 380 moleculesper million are carbon dioxide.That portion climbs about two moleculesevery year.No one knows the exact consequencesof this upsurge in the atmosphere’scarbon dioxide (CO 2 ) concentration northe effects that lie ahead as more andmore of the gas enters the air in the comingdecades—humankind is running anuncontrolled experiment on the world.Scientists know that carbon dioxide iswarming the atmosphere, which in turnis causing sea level to rise, and that theCO 2 absorbed by the oceans is acidifyingthe water. But they are unsure of exactlyhow climate could alter across the globe,how fast sea level might rise, what a moreacidic ocean could mean, which ecologicalsystems on land and in the sea wouldbe most vulnerable to climate changeand how these developments might affecthuman health and well-being. Ourcurrent course is bringing climate changeupon ourselves faster than we can learnhow severe the changes will be.If slowing the rate of carbon dioxidebuildup were easy, the world would begetting on with the job. If it were impossible,humanity would be working toCREDITSTRIPPER TOWERS at an Algerian gas-extractionfacility deep in the Sahara Desert chemicallyseparate carbon dioxide from natural gas boundfor European markets. The CO 2 is then pumpedtwo kilometers below ground.www.sciam.com SCIENTIFIC AMERICAN 49COPYRIGHT 2005 SCIENTIFIC AMERICAN, INC.

adapt to the consequences. But realitylies in between. The task can be donewith tools already at hand, albeit notnecessarily easily, inexpensively or withoutcontroversy.<strong>We</strong>re society to make reducing carbondioxide emissions a priority—as Ithink it should to reduce the risks of environmentalhavoc in the future—wewould need to pursue several strategiesat once. <strong>We</strong> would concentrate on usingenergy more efficiently and on substitutingnoncarbon renewable or nuclear energysources for fossil fuel (coal, oil andnatural gas–the primary sources of manmadeatmospheric carbon dioxide). Andwe would employ a method that is receivingincreasing attention: capturingcarbon dioxide and storing, or sequestering,it underground rather than releasingit into the atmosphere. Nothingsays that CO 2 must be emitted into theair. The atmosphere has been our primewaste repository, because dischargingexhaust up through smokestacks, tailpipesand chimneys is the simplest andleast (immediately) costly thing to do.The good news is that the technology forcapture and storage already exists andthat the obstacles hindering implementationseem to be surmountable.<strong>Carbon</strong> Dioxide Capturethe combustion of fossil fuels produceshuge quantities of carbon dioxide.In principle, equipment could be installedto capture this gas wherever thesehydrocarbons are burned, but someOverview/Entombing CO2locations are better suited than others.If you drive a car that gets 30 milesto the gallon and go 10,000 miles nextyear, you will need to buy 330 gallons—about a ton—of gasoline. Burning thatmuch gasoline sends around three tonsof carbon dioxide out the tailpipe. AlthoughCO 2 could conceivably becaught before leaving the car and returnedto the refueling station, no practicalmethod seems likely to accomplishthis task. On the other hand, it is easierto envision trapping the CO 2 output ofa stationary coal-burning power plant.It is little wonder, then, that today’scapture-and-storage efforts focus onthose power plants, the source of onequarter of the world’s carbon dioxideemissions. A new, large (1,000-megawatt-generating)coal-fired power plantproduces six million tons of the gas annually(equivalent to the emissions oftwo million cars). The world’s total output(roughly equivalent to the productionof 1,000 large plants) could doubleduring the next few decades as the U.S.,China, India and many other countriesconstruct new power-generating stationsand replace old ones [see illustrationon page 52]. As new coal facilitiescome online in the coming quarter of acentury, they could be engineered to filterout the carbon dioxide that wouldotherwise fly up the smokestacks.Today a power company planning toinvest in a new coal plant can choosefrom two types of power systems, and athird is under development but not yet■ A strategy that combines the capture of carbon dioxide emissions from coalpower plants and their subsequent injection into geologic formations for longtermstorage could contribute significantly to slowing the rise of theatmospheric CO 2 concentration.■ Low-cost technologies for securing carbon dioxide at power plants and greaterexperience with CO 2 injection to avoid leakage to the surface are key to thesuccess of large-scale CO 2 capture and storage projects.■ Fortunately, opportunities for affordable storage and capture efforts areplentiful. <strong>Carbon</strong> dioxide has economic value when it is used to boost crude oilrecovery at mature fields. Natural gas purification and industrial hydrogenproduction yield CO 2 at low cost. Early projects that link these industries willenhance the practitioners’ technical capabilities and will stimulate thedevelopment of regulations to govern CO 2 storage procedures.available. All three can be modified forcarbon capture. Traditional coal-firedsteam power plants burn coal fully inone step in air: the heat that is releasedconverts water into high-pressure steam,which turns a steam turbine that generateselectricity. In an unmodified versionof this system—the workhorse ofthe coal power industry for the past century—amixture of exhaust (or flue)gases exits a tall stack at atmosphericpressure after having its sulfur removed.Only about 15 percent of the flue gas iscarbon dioxide; most of the remainderis nitrogen and water vapor. To adaptthis technology for CO 2 capture, engineerscould replace the smokestack withan absorption tower, in which the fluegases would come in contact with dropletsof chemicals called amines that selectivelyabsorb CO 2 . In a second reactioncolumn, known as a stripper tower,the amine liquid would be heated to releaseconcentrated CO 2 and to regeneratethe chemical absorber.The other available coal power system,known as a coal gasification combined-cycleunit, first burns coal partiallyin the presence of oxygen in a gasificationchamber to produce a “synthetic”gas, or syngas—primarily pressurizedhydrogen and carbon monoxide. Afterremoving sulfur compounds and otherimpurities, the plant combusts the syngasin air in a gas turbine—a modified jet engine—tomake electricity. The heat in theexhaust gases leaving the gas turbineturns water into steam, which is pipedinto a steam turbine to generate additionalpower, and then the gas turbine exhaustflows out the stack. To capture carbonfrom such a facility, technicians addsteam to the syngas to convert (or “shift”)most of the carbon monoxide into carbondioxide and hydrogen. The combinedcycle system next filters out the CO 2 beforeburning the remaining gas, nowmostly hydrogen, to generate electricityin a gas turbine and a steam turbine.The third coal power approach, calledoxyfuel combustion, would perform allthe burning in oxygen instead of air. Oneversion would modify single-step combustionby burning coal in oxygen, yieldinga fuel gas with no nitrogen, only CO 2COURTESY OF BP plc (preceding page)50 SCIENTIFIC AMERICAN JULY 2005COPYRIGHT 2005 SCIENTIFIC AMERICAN, INC.

TOTAL = 1,070 (billions of tons of carbon dioxide)386142542 501PAST: 1751–2002(252 years)and water vapor, which are easy to separate.A second version would modify thecoal gasification combined-cycle systemby using oxygen, rather than air, at thegas turbine to burn the carbon monoxideand hydrogen mixture that has exited thegasifier. This arrangement skips the shiftreaction and would again produce onlyCO 2 and water vapor. Structural materialsdo not yet exist, though, that canwithstand the higher temperatures thatare created by combustion in oxygenrather than in air. Engineers are exploringwhether reducing the process temperatureby recirculating the combustionexhaust will provide a way around thesematerials constraints.Tough Decisionsmodification for carbon dioxidecapture not only adds complexity andexpense directly but also cuts the efficiencyof extracting energy from the fuel. Inother words, safely securing the carbonby-products means mining and burningmore coal. These costs may be partiallyoffset if the plant can filter out gaseous8226TOTAL = 735FUTURE (projected): 2003–2030(28 years)LIFETIME FOSSIL-FUEL EMISSIONS from power plants projected to be built during the next quarterof a century will be comparable to all the emissions during the past 250 years. The left columnshows the cumulative carbon dioxide emissions produced by burning coal, oil and natural gas for alluses (including transportation and building heating) from 1751 to 2002, whereas that on the rightdepicts the lifetime CO 2 emissions from fossil-fuel power generation plants projected by theInternational Energy Agency to come online between 2003 and 2030. Coal-fired power plants areassumed to operate for 60 years and gas-fired power stations for 40 years.THE AUTHOROILGASCOALsulfur simultaneously and store it withthe CO 2 , thus avoiding some of the considerableexpense of sulfur treatment.Utility executives want to maximizeprofits over the entire life of the plant,probably 60 years or more, so they mustestimate the expense of complying notonly with today’s environmental rulesbut also with future regulations. Themanagers know that the extra costs forCO 2 capture are likely to be substantiallylower for coal gasification combined-cycleplants than for traditionalplants. Removing carbon dioxide athigh pressures, as occurs in a syngas operation,costs less because smaller equipmentcan be employed. But they alsoknow that only a few demonstrationgasification plants are running today, sothat opting for gasification will requirespending extra on backup equipment toensure reliability. Hence, if the managementbets on not having to pay for CO 2emissions until late in the life of its newplant, it will probably choose a traditionalcoal plant, although perhaps onewith the potential to be modified laterROBERT H. SOCOLOW is professor of mechanical and aerospace engineering at PrincetonUniversity. He teaches in both the School of Engineering and Applied Science and theWoodrow Wilson School of Public and International Affairs. A physicist by training, Socolowis currently co-principal investigator (with ecologist Stephen Pacala) of the university’s<strong>Carbon</strong> <strong>Mitigation</strong> <strong>Initiative</strong>, supported by BP and Ford, which focuses on globalcarbon management, the hydrogen economy and fossil-carbon sequestration. In 2003he was awarded the Leo Szilard Lectureship Award by the American Physical Society.for carbon capture. If, however, it believesthat government directives to captureCO 2 are on their way within a decadeor so, it may select a coal gasificationplant.To get a feel for the economic pressuresthe extra cost of carbon sequestrationwould place on the coal producer,the power plant operator and the homeowner who consumes the electricity, ithelps to choose a reasonable cost estimateand then gauge the effects. Expertscalculate that the total additional expenseof capturing and storing a ton ofcarbon dioxide at a coal gasificationcombined-cycle plant will be about $25.(In fact, it may be twice that much for atraditional steam plant using today’stechnology. In both cases, it will costless when new technology is available.)The coal producer, the power plantoperator and the home owner will perceivethat $25 cost increase quite differently.A coal producer would see a chargeof about $60 per ton of coal for capturingand storing the coal’s carbon, roughlytripling the cost of coal delivered to anelectric utility customer. The owner of anew coal power plant would face a 50percent rise in the cost of power the coalplant puts on the grid, about two centsper kilowatt-hour (kWh) on top of a basecost of around four cents per kWh. Thehome owner buying only coal-basedelectricity, who now pays an average ofabout 10 cents per kWh, would experienceone-fi fth higher electricity costs(provided that the extra two cents perkWh cost for capture and storage ispassed on without increases in the chargesfor transmission and distribution).First and Future Stepsrather than waiting for the constructionof new coal-fired power plantsto begin carbon dioxide capture andstorage, business leaders are starting theprocess at existing facilities that producehydrogen for industry or purify naturalgas (methane) for heating and powergeneration. These operations currentlygenerate concentrated streams of CO 2 .Industrial hydrogen production processes,located at oil refineries and ammoniaplants, remove carbon dioxide from aILLUSTRATION BY ALISON KENDALL; CONCEPT BY DAVID HAWKINS Natural Resources Defense Council; PAST DATA FROM GREGG MARLAND Oak Ridge National Laboratory52 SCIENTIFIC AMERICAN JULY 2005COPYRIGHT 2005 SCIENTIFIC AMERICAN, INC.

COURTESY OF BP plchigh-pressure mix of CO 2 and hydrogen,leaving behind carbon dioxide thatis released skyward. Natural gas purificationplants must remove CO 2 becausethe methane is heading for a liquefiednatural gas tanker and must be kept freeof cold, solid carbon dioxide (dry ice)that could clog the system or because theCO 2 concentration is too high (above 3percent) to be allowed on the natural gasdistribution grid.Many carbon dioxide capture projectsusing these sources are now underconsideration throughout the oil andgas industry. Hydrogen production andnatural gas purification are the initialstepping-stones to full-scale carbon captureat power plants; worldwide about5 percent as much carbon dioxide is producedin these two industries as in electricpower generation.In response to the growing demandfor imported oil to fuel vehicles, some nations,such as China, are turning to coalto serve as a feedstock for synthetic fuelsthat substitute for gasoline and dieselfuel. From a climate change perspective,this is a step backward. Burning a coalbasedsynthetic fuel rather than gasolineto drive a set distance releases approximatelydouble the carbon dioxide, whenone takes into account both tailpipe andsynfuels plant emissions. In synthetic fuelsproduction from coal, only about halfthe carbon in the coal ends up in the fuel,and the other half is emitted at the plant.Engineers could modify the design of acoal synfuels plant to capture the plant’sCO 2 emissions. At some point in the future,cars could run on electricity or carbon-freehydrogen extracted fromcoal at facilities where CO 2 is captured.Electricity can also be made fromPOROSITY OF A GEOLOGIC FORMATION near a carbon dioxide injection well (thin tubing) at theKrechba field in the Algerian desert was revealed by two sets of measurements. (Red and yellowrepresent high porosity regions of the 20-meter-thick reservoir; blue indicates low porosityareas.) BP engineers used the coarse mapping of the geologic layers, which was derived fromseismic echolocation soundings, to determine where best to place the well. A down-hole electricsensor probe, which gave a finer depiction of porosity (looking like colored beads), revealedporosity within a few centimeters of the well. Engineers employed these more accurate readingsto hunt for and steer the drilling apparatus toward regions of high porosity.biomass fuels, a term for commercialfuels derived from plant-based materials:agricultural crops and residues, timberand paper industry waste, and landfillgas. If the fossil fuels used in harvestingand processing are ignored, theexchanges between the atmosphere andthe land balance because the quantity ofcarbon dioxide released by a traditionalbiomass power plant nearly equals thatremoved from the atmosphere by photosynthesiswhen the plants grew. But biomasspower can do better: if carboncapture equipment were added to thesefacilities and the harvested biomass vegetationwere replanted, the net resultwould be to scrub the air of CO 2 . Unfortunately,the low efficiency of photosynthesislimits the opportunity for atmosphericscrubbing because of theneed for large land areas to grow thetrees or crops. Future technologies maychange that, however. More efficientcarbon dioxide removal by green plantsand direct capture of CO 2 from the air(accomplished, for example, by flowingair over a chemical absorber) may becomefeasible at some point.<strong>Carbon</strong> Dioxide Storagecarbon capture is just half the job,of course. When an electric utility buildsa 1,000-megawatt coal plant designed totrap CO 2 , it needs to have somewhere tostash securely the six million tons of thegas the facility will generate every yearfor its entire life. Researchers believe thatthe best destinations in most cases will beunderground formations of sedimentaryrock loaded with pores now filled withbrine (salty water). To be suitable, thesites typically would lie far below anysource of drinking water, at least 800meters under the surface. At 800 meters,the ambient pressure is 80 times that ofthe atmosphere, high enough that thepressurized injected CO 2 is in a “supercritical”phase—one that is nearly asdense as the brine it replaces in geologicformations. Sometimes crude oil or naturalgas will also be found in the brine formations,having invaded the brine millionsof years ago.The quantities of carbon dioxidesent belowground can be expressed in“barrels,” the standard 42-gallon unitof volume employed by the petroleumindustry. Each year at a 1,000-megawattcoal plant modified for carbon capture,about 50 million barrels of supercriticalcarbon dioxide would be secured—about100,000 barrels a day.After 60 years of operation, about threebillion barrels (half a cubic kilometer)would be sequestered below the surface.An oil field with a capacity to producethree billion barrels is six times the sizeof the smallest of what the industry calls“giant” fields, of which some 500 exist.This means that each large modifiedcoal plant would need to be associatedwith a “giant” CO 2 storage reservoir.www.sciam.com SCIENTIFIC AMERICAN 53COPYRIGHT 2005 SCIENTIFIC AMERICAN, INC.

Alternative CO 2 Storage SchemesCaptured carbon dioxide might be stored not only in depleted oil and gasreservoirs and subterranean brine formations but also in minerals that formcarbonate compounds, in coal seams and in the deep ocean.Minerals that can become carbonates could potentially sequester evenmore carbon dioxide on the earth’s surface than brine formations could storeunderground. The magnesium oxide in two abundant iron-magnesium minerals,serpentine and olivine, combines with CO 2 to produce highly stable magnesiumcarbonate. The big challenge is to get CO 2 to react quickly with bulk quantities ofthese rocks, perhaps by grinding them into fine powders to increase the surfacearea at which the chemical reactions occur.The pore surfaces within coal formations adsorb methane. During mining,some of this methane can be released, too often causing underground explosionsand, consequently, the deaths of miners. Pressurized carbon dioxide could beintroduced into unexploited coal seams where it would replace the adsorbedmethane, which could then be recovered and sold as fuel.Ocean injection of carbon dioxide is controversial. Advocates of storage in thedeep ocean point out that atmospheric CO 2 passes continuously into the oceansurface, as the air and ocean system seeks chemical equilibrium. Slowing theincrease of CO 2 levels in the air will reduce the amount dissolving into the surfacewater. Thus, deep-ocean injection would shift some CO 2 from the surface waters tothe lowest layers, reducing environmental impacts near the surface, where mostmarine life is found. Opponents of ocean storage cite international law that protectsthe oceans from certain kinds of industrial uses and the difficulties of monitoringcarbon dioxide transport after injection. In many parts of the world, opponents tapinto a strong cultural preference for leaving the oceans alone.—R.H.S.About two thirds of the 1,000 billionbarrels of oil the world has produced todate has come from these giant oil fields,so the industry already has a good dealof experience with the scale of the operationsneeded for carbon storage.Many of the first sequestration siteswill be those that are established becausethey can turn a profit. Amongthese are old oil fields into which carbondioxide can be injected to boost the productionof crude. This so-called enhancedoil recovery process takes advantageof the fact that pressurized CO 2is chemically and physically suited todisplacing hard-to-get oil left behind inthe pores of the geologic strata after thefirst stages of production. In this process,compressors drive CO 2 into the oilremaining in the deposits, where chemicalreactions result in modified crude oilthat moves more easily through the porousrock toward production wells. Inparticular, CO 2 lowers crude oil’s interfacialtension—a form of surface tensionthat determines the amount of frictionbetween the oil and rock. Thus, carbondioxide injects new life into old fields.In response to British government encouragementof carbon dioxide captureand storage efforts, oil companies areproposing novel capture projects at naturalgas power plants that are coupledwith enhanced oil recovery ventures atfields underneath the North Sea. In theU.S., operators of these kinds of fieldscan make money today while payingabout $10 to $20 per ton for carbon dioxidedelivered to the well. If oil pricescontinue to rise, however, the value of injectedCO 2 will probably go up becauseits use enables the production of a morevaluable commodity. This market developmentcould lead to a dramatic expansionof carbon dioxide capture projects.<strong>Carbon</strong> sequestration in oil and gasfields will most likely proceed side byside with storage in ordinary brine formations,because the latter structuresare far more common. Geologists expectto find enough natural storage capacityto accommodate much of the carbondioxide that could be captured fromfossil fuels burned in the 21st century.Storage Riskstwo classes of risk must be addressedfor every candidate storage reservoir:gradual and sudden leakage.Gradual release of carbon dioxide merelyreturns some of the greenhouse gas tothe air. Rapid escape of large amounts,in contrast, could have worse consequencesthan not storing it at all. For astorage operation to earn a license, regulatorswill have to be satisfied that gradualleakage can occur only at a very slowrate and that sudden leakage is extremelyunlikely.Although carbon dioxide is usuallyharmless, a large, rapid release of thegas is worrisome because high concentrationscan kill. Planners are well awareof the terrible natural disaster that occurredin 1986 at Lake Nyos in Cameroon:carbon dioxide of volcanic originslowly seeped into the bottom of thelake, which sits in a crater. One night anabrupt overturning of the lake bed letloose between 100,000 and 300,000tons of CO 2 in a few hours. The gas,which is heavier than air, flowed downthrough two valleys, asphyxiating 1,700nearby villagers and thousands of cattle.Scientists are studying this tragedy toensure that no similar man-made eventwill ever take place. Regulators of storagepermits will want assurance thatleaks cannot migrate to belowgroundconfined spaces that are vulnerable tosudden release.Gradual leaks may pose little dangerto life, but they could still defeat the climategoals of sequestration. Therefore,researchers are examining the conditionslikely to result in slow seepage.<strong>Carbon</strong> dioxide, which is buoyant inbrine, will rise until it hits an impermeablegeologic layer (caprock) and canascend no farther.<strong>Carbon</strong> dioxide in a porous formationis like hundreds of helium balloons,and the solid caprock above is like a circustent. A balloon may escape if the tenthas a tear in it or if its surface is tilted toallow a path for the balloon to movesideways and up. Geologists will have tosearch for faults in the caprock thatcould allow escape as well as determinethe amount of injection pressure that54 SCIENTIFIC AMERICAN JULY 2005COPYRIGHT 2005 SCIENTIFIC AMERICAN, INC.

COURTESY OF BP plccould fracture it. They will also evaluatethe very slow horizontal flow of the carbondioxide outward from the injectionlocations. Often the sedimentary formationsare huge, thin pancakes. If carbondioxide is injected near the middle of apancake with a slight tilt, it may notreach the edge for tens of thousands ofyears. By then, researchers believe, mostof the gas will have dissolved in the brineor have been trapped in the pores.Even if the geology is favorable, usingstorage formations where there areold wells may be problematic. Morethan a million wells have been drilled inTexas, for example, and many of themwere filled with cement and abandoned.Engineers are worried that CO 2 -ladenbrine, which is acidic, could find its wayfrom an injection well to an abandonedwell and thereupon corrode the cementplug and leak to the surface. To find out,some researchers are now exposing cementto brine in the laboratory and samplingold cements from wells. This kindof failure is less likely in carbonate formationsthan in sandstone ones; the formerreduce the destructive potency ofthe brine.The world’s governments must soondecide how long storage should be maintained.Environmental ethics and traditionaleconomics give different answers.Following a strict environmental ethicUNDERGROUND STORAGE of carbon dioxide is being performed today at the In Salah gas project inthe Algerian desert. The raw natural gas produced at this site by BP, Statoil and Sonatrachcontains too much CO 2 for commercial use, so the excess is removed by chemical absorbers (twopairs of stripper towers at center of plant), compressed and then injected under pressure intoa brine formation two kilometers below the surface. Subterranean injection proceeds ata rate that is only about six times less than what would be required at a 1,000-megawatt coalgasification plant fitted for CO 2 capture and storage.that seeks to minimize the impact of today’sactivities on future generations,authorities might, for instance, refuse tocertify a storage project estimated to retaincarbon dioxide for only 200 years.Guided instead by traditional economics,they might approve the same projecton the grounds that two centuries fromnow a smarter world will have inventedsuperior carbon disposal technology.The next few years will be criticalMORE TO EXPLOREfor the development of carbon dioxidecapture-and-storage methods, as policiesevolve that help to make CO 2 -emissionreduction profitable and as licensingof storage sites gets under way. Inconjunction with significant investmentsin improved energy efficiency, renewableenergy sources and, possibly,nuclear energy, commitments to captureand storage can reduce the risks of globalwarming.Capturing Greenhouse Gases. Howard Herzog, Baldur Eliasson and Olav Kaarstad in ScientificAmerican, Vol. 282, No. 2, pages 72–79; February 2000.Prospects for CO 2 Capture and Storage. International Energy Agency, OECD/IEA, 2004.Stabilization <strong>We</strong>dges: Solving the Climate Problem for the Next 50 Years with CurrentTechnologies. S. Pacala and R. Socolow in Science, Vol. 305, pages 968–972; August 13, 2004.Prospects for <strong>Carbon</strong> Capture and Storage Technologies. Soren Anderson and Richard Newell inAnnual Review of Environment and Resources, Vol. 29, pages 109–142; 2004.<strong>Carbon</strong> Dioxide Capture for Storage in Deep Geological Formations—Results from the CO 2Capture Project. Two volumes. Edited by David C. Thomas (Vol. 1) and Sally M. Benson (Vol. 2).Elsevier, 2005.Princeton University <strong>Carbon</strong> <strong>Mitigation</strong> <strong>Initiative</strong>: www.princeton.edu/˜cmiIntergovernmental Panel on Climate Change (IPCC): www.ipcc.ch/index.html (Look for the“Special Report on <strong>Carbon</strong> Dioxide Capture and Storage” expected in late 2005.)International Energy Agency (IEA) Greenhouse Gas R&D Program: www.ieagreen.org.uk/index.htmlOffice of Fossil Energy, U.S. Department of Energy: www.fe.doe.gov/programs/sequestration/CO 2 Capture Project: www.co2captureproject.orgwww.sciam.com SCIENTIFIC AMERICAN 55COPYRIGHT 2005 SCIENTIFIC AMERICAN, INC.