S-7001 ADVANTAGES - Eurosupport.nl

S-7001 ADVANTAGES - Eurosupport.nl

S-7001 ADVANTAGES - Eurosupport.nl

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

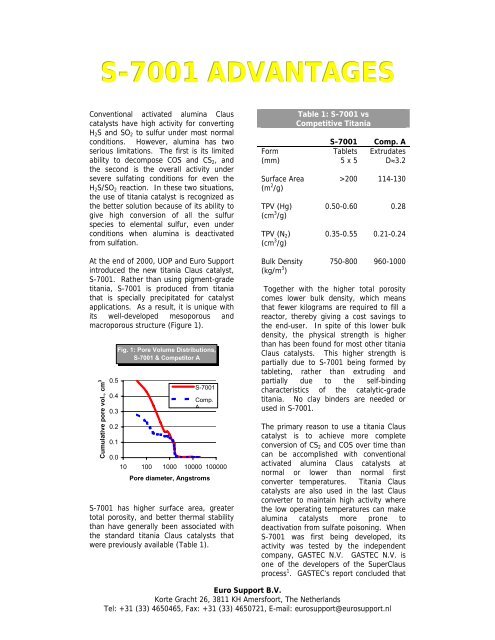

S-<strong>7001</strong> <strong>ADVANTAGES</strong>Conventional activated alumina Clauscatalysts have high activity for convertingH 2 S and SO 2 to sulfur under most normalconditions. However, alumina has twoserious limitations. The first is its limitedability to decompose COS and CS 2 , andthe second is the overall activity undersevere sulfating conditions for even theH 2 S/SO 2 reaction. In these two situations,the use of titania catalyst is recognized asthe better solution because of its ability togive high conversion of all the sulfurspecies to elemental sulfur, even underconditions when alumina is deactivatedfrom sulfation.At the end of 2000, UOP and Euro Supportintroduced the new titania Claus catalyst,S-<strong>7001</strong>. Rather than using pigment-gradetitania, S-<strong>7001</strong> is produced from titaniathat is specially precipitated for catalystapplications. As a result, it is unique withits well-developed mesoporous andmacroporous structure (Figure 1).Cumulative pore vol., cm 30.50.40.30.20.10.0Fig. 1: Pore Volume Distributions,S-<strong>7001</strong> & Competitor AS-<strong>7001</strong>Comp.A10 100 1000 10000 100000Pore diameter, AngstromsS-<strong>7001</strong> has higher surface area, greatertotal porosity, and better thermal stabilitythan have generally been associated withthe standard titania Claus catalysts thatwere previously available (Table 1).Form(mm)Surface Area(m 2 /g)TPV (Hg)(cm 3 /g)TPV (N 2 )(cm 3 /g)Bulk Density(kg/m 3 )Table 1: S-<strong>7001</strong> vsCompetitive TitaniaS-<strong>7001</strong> Comp. ATablets Extrudates5 x 5 D≈3.2>200 114-1300.50-0.60 0.280.35-0.55 0.21-0.24750-800 960-1000Together with the higher total porositycomes lower bulk density, which meansthat fewer kilograms are required to fill areactor, thereby giving a cost savings tothe end-user. In spite of this lower bulkdensity, the physical strength is higherthan has been found for most other titaniaClaus catalysts. This higher strength ispartially due to S-<strong>7001</strong> being formed bytableting, rather than extruding andpartially due to the self-bindingcharacteristics of the catalytic-gradetitania. No clay binders are needed orused in S-<strong>7001</strong>.The primary reason to use a titania Clauscatalyst is to achieve more completeconversion of CS 2 and COS over time thancan be accomplished with conventionalactivated alumina Claus catalysts atnormal or lower than normal firstconverter temperatures. Titania Clauscatalysts are also used in the last Clausconverter to maintain high activity wherethe low operating temperatures can makealumina catalysts more prone todeactivation from sulfate poisoning. WhenS-<strong>7001</strong> was first being developed, itsactivity was tested by the independentcompany, GASTEC N.V. GASTEC N.V. isone of the developers of the SuperClausprocess 1 . GASTEC’s report concluded thatEuro Support B.V.Korte Gracht 26, 3811 KH Amersfoort, The NetherlandsTel: +31 (33) 4650465, Fax: +31 (33) 4650721, E-mail: eurosupport@eurosupport.<strong>nl</strong>

CS 2 was 100% converted at temperaturesover 300°C, and COS hydrolysis was100% at temperatures over 300°C. A plotof the CS 2 conversion results from GASTECfor S-<strong>7001</strong> compared to CS 2 conversionresults from the pilot plant ofKaiser/LaRoche at the same conditions forthe old titania Claus catalyst S-701 isshown in Figure 2.CS 2 conversion, %Fig. 2: S-<strong>7001</strong> vs S-701(GHSV=1200 hr -1 )100908070S-<strong>7001</strong>60S-7015040200 250 300 350Temperature, °CWhat is most apparent from thiscomparison is the much superior activityat lower temperatures of S-<strong>7001</strong> versusthe S-701. As development of the S-<strong>7001</strong>continued, Euro Support built their ownClaus pilot plant. In this pilot plant,S-<strong>7001</strong> was compared to competitivetitania Claus catalysts, and again thisdifference at lower temperatures was seen(Figure 3).CS 2 conversion, %Fig. 3: S-<strong>7001</strong> vs CompetitiveTitanias10090807060(GHSV=2400 hr -1 )50280 290 300 310 320Temperature, °CS-<strong>7001</strong> Comp. AComp. B Comp. CNot o<strong>nl</strong>y is initial activity important, butlong-term catalyst life is important also.Two of the major modes of deactivation oftitania Claus catalyst are surface area andpore volume loss from thermal andhydrothermal aging and fouling fromhydrocarbons, especially BTX. As a severetest of thermal stability, the surface areaand total pore volume of a sample ofS-<strong>7001</strong> and samples of competitive titaniacatalysts were measured before and aftertreatment at 700°C for one hour. As canbe seen from the bar charts in Figure 4,the S-<strong>7001</strong> started with higher surfacearea and pore volume, and it retainedhigher levels of each after this thermaltreatment.Fig. 4: Comparison of Thermal Stability betweenS-<strong>7001</strong> and Competitive ProductSurface Area, m 2 /gTotal Pore Volume, cc/g3000.62000.41000S-<strong>7001</strong> Comp. 1 Comp. 2Initial700 C0.20S-<strong>7001</strong> Comp. 1 Comp. 2Initial700 CEuro Support B.V.Korte Gracht 26, 3811 KH Amersfoort, The NetherlandsTel: +31 (33) 4650465, Fax: +31 (33) 4650721, E-mail: eurosupport@eurosupport.<strong>nl</strong>

Titania catalyst can be more reactive withhydrocarbons than alumina catalyst.Figure 5 shows a comparison of heptenereactivity between an early developmentaltitania catalyst, MK-715, and S-<strong>7001</strong> and astandard alumina catalyst. S-<strong>7001</strong> hasbeen modified so that its reactivity withheptene is at the same level as that of thestandard alumina catalyst.Heptene conversion, %4.54.03.53.02.52.01.51.00.50.0Fig. 5: Heptene reactivity at 425°CS-<strong>7001</strong>MK-715Alumina0 200 400 600 800 1000Flow rate, cm 3 /min.In the paper, “Quantifying the Effect ofIndividual Aromatic Contaminants on ClausCatalyst”, by Pierre Crevier, et al 2 , xyleneswere identified as the worst aromaticcompounds to have in the process gas.For that reason, xylene was used in thefeed gas to Euro Support’s pilot plant tocompare the effect of xylene on the CS 2conversion activity of different titaniaClaus catalysts over time (Figure 6).CS 2 converson, %1009080706050403020100Fig. 6: Effect of xylene on CS 2conversionS-<strong>7001</strong>MK-715Comp. A0 500 1000 1500 2000 2500 3000 3500Time, mins.Again, comparative results are shown forMK-715, S-<strong>7001</strong>, and a competitive titaniacatalyst. Among these titania Clauscatalysts, the S-<strong>7001</strong> showed the lowestrate of deactivation from xylene.The use of S-<strong>7001</strong> has allowed anengineering company to guarantee a Clausperformance level that would not havebeen guaranteed otherwise. There havebeen no complaints from any customer,and customers have commented that theywant to install S-<strong>7001</strong> in their other unitswhen catalyst replacement is nextrequired.1. J.A. Lagas, J. Borsboom, P.H.Berben, and J.W. Geus, EuropeanPatent Application no. 0242006.2. P.P. Crevier, N.I. Dowling, P.D.Clark, M. Huang, “Quantifying theEffect of Individual AromaticContaminants on Claus Catalysts”,51 st Laurance Reid GasConditioning Conference, Norman,Oklahoma,Feb. 25-28, 2001.Euro Support B.V.Korte Gracht 26, 3811 KH Amersfoort, The NetherlandsTel: +31 (33) 4650465, Fax: +31 (33) 4650721, E-mail: eurosupport@eurosupport.<strong>nl</strong>