Download Document

Download Document

Download Document

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

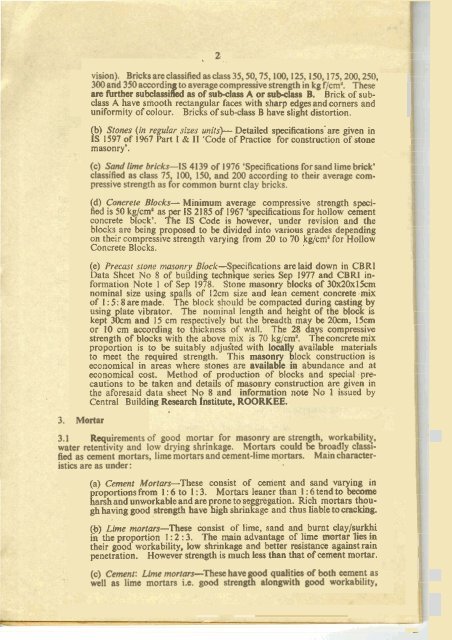

5. Mortar, 2, ..vision), Brk ks are classified as class 35,50,75,100,125,150,175,200,250,3O and 350 accordin to average compressive strength in kg f]cm9, Theseare further suklassi i! ed as of sub-class A or sub-class B. Brick of subclassA have srhooth rectangular faces with sharp edges and corners anduniformity of wlour. Bricks of sub-class B have slight distortion.(b) SIones (in reguIar sizes unifs)-- Detailed specifications' are given inIS 1 597 of 1967 Part I & I1 'Code of Practice for construction of stonemasonry*.(c) Sand lime bricks-IS 4139 of 1976 'Specifications for sandlime brick'classified as class 75, 100, 150, and 200 according to their average compressivestrength as for common burnt clay bricks.d) Concrete Blocks- Minimum average compressive strength speciked is 50 kdcmf as per IS 2185 of 1967 'specifications fbr hollow wmentconcrete block'. The IS Code is however, under revision and theblocks are being proposed to be divided into various grades dependingon their compresswe strength varying from 20 to 70 kg/cmS for HollowConcrete Blocks.(e) Precast slone masonry Block-Spi fications are laid down in CB RlData Sheet No 8 of building kchnlque series Sep 1977 and CBRI informationNote 1 of Sep 1978. Stone masonry blocks of 30x20x15cmnominal size using spalls of 12cm size and lean cement concrete ,mixof I : 5: 8 are made. The block should be compacted during casting byusing piate vibrator. The nominal length and height of the block iskept 30cm and 15 cm respectively but the breadth may be 2 h , t5cmor I0 cm according to thickness of wall. The 28 days compressivestrength of blocks with the above mix is 70 kg/cma. Theconcretemixproportion is to k suitably adjusted with available materialsto meet the required strength. This lock constructioniseconomical in areas where stones areabundance and ateconomical cost. Method of production of blocks and spwial precautionsto be taken and details of masonry construction are given inthe aforesaid data sheet No 8 and information note Na 1 issued byCentral Buildi3.1 Requirements of good mortar for masonry are strength, workability,water retentivity and low drying shrinkage, Mortars wu1d Be broadly dassifiedas cement mortars, lime mortars and cement-Iime rqortars. Main characteristicsare as under :(a) Cement Mortars-These consist of cement and sand varying inproportionsfrom 1:6 to 1:3. Mortars leaner than 1:btendto becomeharsh and unworkable and are prone to seggregation. Rich mortars thoughhaving good strength have high shrinkage and thus liable to cracking.Cb) Lime mortars-These consist of lime, sand and burnt clay/surkhiin the proportion 1 : 2 : 3. The main advantage of lime miortat lies intheir good workability, low shrinkage and better resistance againstrainpenetration. However strength is much less than that of cement mortar.(c) Cement: Lime mortars-These have good qualities of both &ment aswe11 as lime mortars i.e. good strength aIongwith good workability,-