Pipe End Preparation Technology

Pipe End Preparation Technology

Pipe End Preparation Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

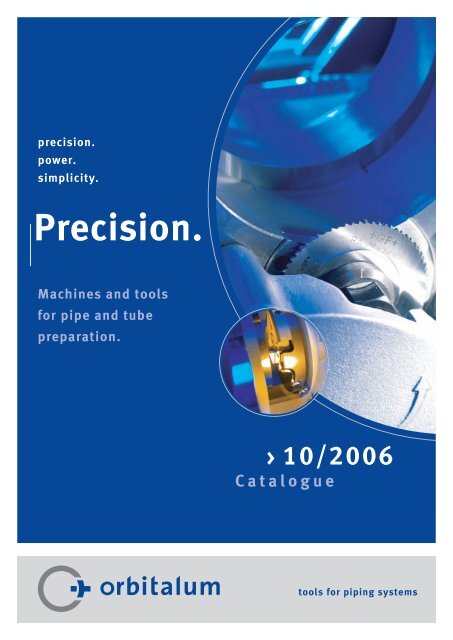

precision.power.simplicity.Precision.Machines and toolsfor pipe and tubepreparation.> 10/2006C a t a l o g u eorbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

New productsTube Squaring MachinesRPG 1.0 CordlessBurr-free and square preparationof thin-walled stainlesssteel tubes up to 1 inch.The cost-effective tube endpreparation for welds conformingto industry standards.Your benefits:∤ High-quality machining results∤ Burr-free and square∤ High-perfomance coated tool bit withtwo cutting edges∤ Quick clamping system for tubes,tools and clamping shells∤ No additional tools required foroperation∤ Space saving, light-weight and portablemachine∤ Built-in electronic speed regulation∤ Micrometer feed for optimum results∤ Feed unit adjustable for crampedworking areasOrbital Cutting MachineOTM 2.0Chipless cutting of thin-walledstainless steel tubes up to 2 inch.Optimal tube end preparationfor welding joints conforming toindustry standards.Your benefits:∤ The ideal tube cutting machine forhigh-purity applications∤ Deformation-free stainless steelclamping system∤ Burr-free, square and deformation-freecut∤ Portable machine for a mobile andsecure application∤ Orbital and automated process foraccuracy, time after time after time∤ 1 tool for different wall thicknesses(0.8 - 3 mm/.032 - .118 inch) anddifferent tube materials∤ Quick clamping system for tubes andtools and adjusting facility to compensatefor pipe irregularities<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong>MachineREB 20The most powerful, square andburr-free solution for pipe endpreparation.Your benefits:∤ Wide application range fromOD 290 – 508 mm (11.42 - 20 inch)∤ Quick-Tool-Change QTC ®∤ High-performance tool bit withBalinit ® Futura protective coatingagainst tool wear∤ Quick clamping system for tools∤ Sturdy construction...more from page 43...more from page 26...more from page 19Subject to alteration. Please consult our General Conditions of Supply.orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Table of contentsPage<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong> 5<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong> 25Tungsten Grinding <strong>Technology</strong> 53Threading, Jointing and Sealing <strong>Technology</strong> 57Copper <strong>Pipe</strong> Installation <strong>Technology</strong> 65Accessories for Workshop and Site 69Table of contents3orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

According to our mission statement„Precision. Power. Simplicity.“the products produced in Singen, Germany combine high precision, due tosuperior drive and tooling concepts with secure and mobile handling.Look and see!Precision.Power.A square, deformation- and burr-freecut or a reproducible pipe endpreparation is a must for a optimisedsubsequent treatment.The Orbitalum Tools GmbH develops,produces and markets these highlyprecise machines and tools as well asthe corresponding consumables forthe industrial and plumbing pipingindustries.Durable, robust and powerfulmachines and tools enable a continuousand effective usage for your individualapplication.Either for a professional weld preparationor for preparing pipe ends and fittings formechanical joints, the Orbitalum ToolsGmbH is your highly efficient partnerwith a worldwide presence andlogistics network.Simplicity.As complexity and demand arecontinuously increasing in oursurroundings, Orbitalum Tools GmbH isfocusing on machines and tools that areergonomic and user friendly and speciallymade for pipeline constructors.The Orbitalum Tools GmbH stands fora quick, precise and easy preparationof any kind of pipe.4orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Page<strong>Pipe</strong> Cutting and Beveling MachinesRA 2, RA 4, RA 6, RA 8, RA 12 (AVM/MVM) 6<strong>Pipe</strong> Cutting and Beveling MachinesRA 21 S 8<strong>Pipe</strong> Cutting and Beveling MachinesRA 41 Plus 9Accessories for RA machines 10Saw blades and bevel cutters for RA machines 14Portable Tube Saws PS 4.5 and PS 6.6 17Accessories for PS machines 18Orbital Cutting Machine OTM 2.0 19Accessories for OTM 2.0 20Universal <strong>Pipe</strong> CutterSCORP 220 Plus, SCORP 360 21Saw blades for SCORP machines 22Metal Tube Cutter MRA 23Accessories for MRA 24<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>5orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

RA <strong>Pipe</strong> Cutting and Beveling Machines• Square, burr-free and cold machining process• Deformation-free clamping system for tubes and pipes• Optimum preparation for the automated welding process• Sturdy design with powerful drive• Unique and automated orbital cutting processRA 2, RA 4, RA 6, RA 8 and RA 12RA 4Cutting and beveling high-alloy steel (stainless steel), low-alloy and carbon steel,casting materials, non-ferrous metal and plastic pipes in just seconds, using the superior«Planetary Cutting <strong>Technology</strong>».The above-mentioned RA machines are also available in the following versions:RA H<strong>Pipe</strong> Cutting and Beveling Machines with additional intermediate gear for lower cuttingspeed and more torque for high-performance pipes e.g. Hastelloy, Inconel, Duplex, highalloysteel (stainless steel) and titanium alloys.RA INOX<strong>Pipe</strong> Cutting and Beveling Machines with special stainless steel clamping jaws or stainlesssteel attachment. RA 6, RA 8 and RA 12 have as a standard, stainless steel clamping jaws.Feed versions:RA 6 AVM, RA 8 AVM and RA 12 AVM<strong>Pipe</strong> Cutting and Beveling Machines with integrated crown wheel and automatic feedmodule AVM. By means of the intelligent AVM the feed is controlled and the cuttingprocess is automated. The AVM will be separately delivered with the RA machine and iseasy and fast to mount to the pipe cutter.RA 6 MVM, RA 8 MVM and RA 12 MVM<strong>Pipe</strong> Cutting and Beveling Machines with manual feed module MVM. With the help of ahand wheel, the machine head rotates around the pipe with constant feed easily.RA 8 AVMScope of delivery:• 1 <strong>Pipe</strong> Cutting and Beveling Machine RA• 1 Wooden shipping case• 1 Saw blade• 1 Quick mounting plate• 1 Tool set• 1 Tube of saw blade lubricating compound GF TOP (Code 790 060 228)• 1 Tube of special gear oil (Code 790 041 030)• 1 Operating instructions and spare parts listAll RA‘s are equipped with the swivel cable (Code 790 041 076).Electric drive with single-phase AC motor:Power: 1.6 kW (2.18 HP)Protection class II (double insulated)Built-in electronic speed regulation:RA: 150 - 270 rpmRA H: 40 - 70 rpmPneumatic drive (only on request):Saw blade speed range:approx. 120 rpmAir supply requirement:1.5 m³/min at 6 bar(53 cfm at 90 PSI)RA 6 MVM6<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Application range RA 2 RA 4 RA 6 RA 8 RA 12<strong>Pipe</strong> OD [mm] 12 - 63 13 - 120 44 - 182 124 - 230 180 - 325[inch] 0.472 - 2.480 0.518 - 4.724 1.732 - 7.165 4.882 - 9.055 7.087 - 12.795Wall thickness(depends on material)*<strong>Pipe</strong> ID min.Saw blade-Ø 63 mm / 2.480 inch<strong>Pipe</strong> ID min.Saw blade Ø 68 mm / 2.677 inch<strong>Pipe</strong> ID min.Saw blade Ø 80 mm / 3.150 inch<strong>Pipe</strong> ID min.Saw blade Ø 100 mm / 3.937 inch[mm] 2 - 5.5 2 - 7 2 - 10 2 - 10 2 - 10[inch] 0.079 - 0.217 0.079 - 0.276 0.079 - 0.394 0.079 - 0.394 0.079 - 0.394[mm] 7 21 76 137 190[inch] 0.276 0.827 2.992 5.394 7.480[mm] 2 16 71 132 185[inch] 0.079 0.630 2.795 5.197 7.283[mm] - 4 59 120 173[inch] - 0.157 2.329 4.724 6.811[mm] - - 39 - -[inch] - - 1.535 - -* when processing thin-walled tubes there are special clamping shells to eliminate distortion, see page 10.Article Version Code kgRA 2 200 - 240 V, 50/60 Hz EU 790 041 095 45.000RA 2 100 - 120 V, 50/60 Hz EU 790 041 092 45.000RA 2 INOX 200 - 240 V, 50/60 Hz EU 790 041 057 49.000RA 2 H 200 - 240 V, 50/60 Hz EU 790 041 097 47.000RA 2 H 100 - 120 V, 50/60 Hz EU 790 041 401 47.000RA 2 H INOX 200 - 240 V, 50/60 Hz EU 790 041 402 49.000RA 4 200 - 240 V, 50/60 Hz EU 790 042 095 76.000RA 4 100 - 120 V, 50/60 Hz EU 790 042 092 76.000RA 4 INOX 200 - 240 V, 50/60 Hz EU 790 042 057 78.000RA 4 H 200 - 240 V, 50/60 Hz EU 790 042 097 80.000RA 4 H 100 - 120 V, 50/60 Hz EU 790 042 401 80.000RA 4 H INOX 200 - 240 V, 50/60 Hz EU 790 042 402 80.000RA 6 200 - 240 V, 50/60 Hz EU 790 043 095 98.000RA 6 100 - 120 V, 50/60 Hz EU 790 043 092 98.000RA 6 H 200 - 240 V, 50/60 Hz EU 790 043 097 102.000RA 6 H 100 - 120 V, 50/60 Hz EU 790 043 401 102.000RA 6 AVM 200 - 240 V, 50/60 Hz EU 790 043 001 108.000RA 6 AVM 100 - 120 V, 50/60 Hz EU 790 043 005 108.000RA 6 H AVM 200 - 240 V, 50/60 Hz EU 790 043 003 112.000RA 6 H AVM 100 - 120 V, 50/60 Hz EU 790 043 006 112.000RA 6 MVM 200 - 240 V, 50/60 Hz EU 790 043 069 101.000RA 6 MVM 100 - 120 V, 50/60 Hz EU 790 043 078 101.000RA 6 H MVM 200 - 240 V, 50/60 Hz EU 790 043 071 105.000RA 6 H MVM 100 - 120 V, 50/60 Hz EU 790 043 079 105.000RA 8 200 - 240 V, 50/60 Hz EU 790 045 095 112.000RA 8 100 - 120 V, 50/60 Hz EU 790 045 092 112.000RA 8 H 200 - 240 V, 50/60 Hz EU 790 045 097 116.000RA 8 H 100 - 120 V, 50/60 Hz EU 790 045 401 116.000RA 8 AVM 200 - 240 V, 50/60 Hz EU 790 045 001 122.000RA 8 AVM 100 - 120 V, 50/60 Hz EU 790 045 005 122.000RA 8 H AVM 200 - 240 V, 50/60 Hz EU 790 045 003 126.000RA 8 H AVM 100 - 120 V, 50/60 Hz EU 790 045 006 126.000RA 8 MVM 200 - 240 V, 50/60 Hz EU 790 045 069 115.000RA 8 MVM 100 - 120 V, 50/60 Hz EU 790 045 078 115.000RA 8 H MVM 200 - 240 V, 50/60 Hz EU 790 045 071 118.000RA 8 H MVM 100 - 120 V, 50/60 Hz EU 790 045 079 118.000RA 12 200 - 240 V, 50/60 Hz EU 790 047 095 141.000RA 12 100 - 120 V, 50/60 Hz EU 790 047 092 141.000RA 12 H 200 - 240 V, 50/60 Hz EU 790 047 097 143.000RA 12 H 100 - 120 V, 50/60 Hz EU 790 047 401 143.000RA 12 AVM 200 - 240 V, 50/60 Hz EU 790 047 001 144.000RA 12 AVM 100 - 120 V, 50/60 Hz EU 790 047 005 144.000RA 12 H AVM 200 - 240 V, 50/60 Hz EU 790 047 003 147.000RA 12 H AVM 100 - 120 V, 50/60 Hz EU 790 047 006 147.000RA 12 MVM 200 - 240 V, 50/60 Hz EU 790 047 069 137.000RA 12 MVM 100 - 120 V, 50/60 Hz EU 790 047 078 137.000RA 12 H MVM 200 - 240 V, 50/60 Hz EU 790 047 071 140.000RA 12 H MVM 100 - 120 V, 50/60 Hz EU 790 047 079 140.000RA 4 H<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>7orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

RA <strong>Pipe</strong> Cutting and Beveling Machines• Square, burr-free and cold machining process• Deformation-free clamping system, especially applicable for thin-walled tubes• Ideal for simultaneous cutting and beveling• Fast dimension adjustment• Lightweight machine specially to use on site• Sturdy design with powerful driveRA 21 SCutting and beveling high-alloy steel (stainless steel), low- and unalloyed steel, castingmaterials, non-ferrous metal and plastic pipes in just seconds, using the superior «PlanetaryCutting <strong>Technology</strong>». Ideal for thin-walled and press fitting applications.The above-mentioned RA machine is also available in the following version:RA 21 S INOX<strong>Pipe</strong> Cutting and Beveling Machine with special stainless steel clamping jaws and/orstainless steel attachment.Scope of delivery:• 1 <strong>Pipe</strong> Cutting and Beveling Machine RA 21 S• 1 Durable storage and shipping case• 1 Saw blade (Code 790 041 035)• 1 Quick mounting plate• 1 Tool set• 1 Tube of saw blade lubricating compound GF TOP (Code 790 060 228)• 1 Tube of special gear oil (Code 790 041 030)• 1 Operating instructions and spare parts listElectric drive with single-phase AC motor:Power: 550 W (0.75 HP)Protection class II (double insulated)Saw blade speed: 180 rpmApplication range [mm] [inch]<strong>Pipe</strong> OD 5 - 63 0.197 - 2.481Wall thickness, depends on material 0.5 - 4.5 0.019 - 0.177<strong>Pipe</strong> ID min. (saw blade-Ø 63 mm/2.480 inch) 7 0.276<strong>Pipe</strong> ID min. (saw blade-Ø 68 mm/2.677 inch) 2 0.079<strong>Pipe</strong> OD for bars (saw blade-Ø 63 mm/2.480 inch) 6 - 16 0.236 - 0.630Article Version Code kgRA 21 S 230 - 240 V, 50/60 Hz EU 790 044 008 34.200RA 21 S 115 V, 50/60 Hz EU 790 044 015 34.200RA 21 S INOX 230 - 240 V, 50/60 Hz EU 790 044 060 34.2008<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

RA <strong>Pipe</strong> Cutting and Beveling Machines• Square, burr-free and cold machining process• Deformation-free clamping system, especially applicable for thin-walled tubes• Ideal for simultaneous cutting and beveling• Fast dimension adjustment• Sturdy design with powerful drive• Optimum preparation for automated welding processes• Clamping jaws made of aluminumRA 41 PlusCutting and beveling tubes and cutting elbows made of high-alloy steel (stainless steel),low- and unalloyed steel, casting materials and non-ferrous metal in just seconds, usingthe superior «Planetary Cutting <strong>Technology</strong>».The above-mentioned RA machine is also available in the following version:RA 41 Plus H<strong>Pipe</strong> Cutting and Beveling Machine with additional intermediate gear for lower cuttingspeed and more torque for high-performance pipes e.g. Hastelloy, Inconel, Duplex, highalloysteel (stainless steel) and titanium alloys.Scope of delivery:• 1 <strong>Pipe</strong> Cutting and Beveling Machine RA 41 Plus (H)• 1 Transportation box• 1 Saw blade (Code 790 042 064)• 1 Quick mounting plate• 1 Tool set• 1 Tube of saw blade lubricating compound GF TOP (Code 790 060 228)• 1 Tube of special gear oil (Code 790 041 030)• 1 Operating instructions with spare parts listElectric drive with single-phase AC motor:Power: 1.6 kW (2.18 HP)Protection class II (double insulated)Built-in electronic speed regulation: 150 - 270 rpmApplication range [mm] [inch]Tube OD (tubes) 10 - 120 0.394 - 4.724Tube OD (elbows) 30 - 120 1.181 - 4.724Wall thickness (depends on material) 0.6 - 7 0.024 - 0.276Tube ID min. (saw blade-Ø 68 mm/2.677 inch) 16 0.630Tube ID min. (saw blade-Ø 80 mm/3.150 inch) 4 0.157Article Version Code kgRA 41 Plus 200 - 240 V, 50/60 Hz EU 790 046 011 77.000RA 41 Plus 100 - 120 V, 50/60 Hz EU 790 046 014 77.000RA 41 Plus H 200 - 240 V, 50/60 Hz EU 790 046 017 79.000RA 41 Plus H 100 - 120 V, 50/60 Hz EU 790 046 030 79.000<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>9orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Accessories for RA machinesAluminum clamping shellsFor RA 6, RA 8 and RA 12.Customised aluminum clamping shells for deformation-free clamping of thin-walledtubes. When ordering, please indicate the outside diameter and/or inside diameter andthe wall thickness of the tube to be worked on.Scope of delivery:• 4 Cylinder head screws• 1 Set of clamping shellsWhen ordering clamping shells for RA 8 you will also receive:• 1 Drilling jig for the assembly of the clamping shells• 2 Cylinder head screws for the drilling jigOther dimensions are available.ArticleTube OD[mm]Tube OD[inch]for RA 6 76.1 3.000 790 043 216 4.500for RA 8 129.0 5.079 790 045 216 4.300for RA 8 167.0 6.575 790 045 218 4.000for RA 8 210.0 8.268 790 045 217 2.900for RA 12 209.0 8.230 790 047 221 11.500for RA 12 219.0 8.620 790 047 220 11.200for RA 12 254.0 10.000 790 047 216 9.200for RA 12 273.0 10.750 790 047 219 8.400for RA 12 324.0 12.760 790 047 218 6.100for RA 12 325.0 12.790 790 047 215 6.100CodekgAluminum clamping shells for RA 41 PlusFor deformation-free clamping of thin-walled tubes.Other dimensions are available.Tube OD[mm]Tube ODCodekg[inch]25.40 1.000 790 046 316 3.02538.10 1.500 790 046 331 2.95050.80 2.000 790 046 345 2.85076.10 2.996 790 046 358 2.80088.90 3.500 790 046 363 2.500108.00 4.252 790 046 367 1.640114.30 4.500 790 046 368 1.640Special stainless steel clamping jaws for RA 2, RA 21 S and RA 4In pairs.Article Code kgSpecial stainless steel clamping jaws for RA 2, RA 21 S 790 041 323 1.035Special stainless steel clamping jaws for RA 4 790 042 201 2.35010<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Aluminum clamping jawsFor RA 4 and RA 41 Plus.Standard part of the RA 41 Plus.1 pair.Article Code kgAluminum clamping jaws 790 046 250 2.600Saw blade lubricating compound GF TOPSynthetic high-performance lubricant for pipe cutting and beveling.Increases the life of the saw blades. Complies with USDA H2 registration.Easy and constant lubrication of the saw blade, supplied with a special brush.Article Version Code kgSaw blade lubricating compound GF TOP Tube, 180 g 790 060 228 0.205Saw blade lubricating compound ROCOLHigh-performance lubricant for pipe cutting and beveling.Increases the life of the saw blades.Article Version Code kgSaw blade lubricating compound ROCOL Tube, 150 ml 790 041 016 0.195Saw blade lubricating compound ROCOL Can, 0.5 kg 790 041 013 0.605Saw blade lubricating compound ROCOL Can, 5.0 kg 790 041 019 5.520Special gear oilFor all RA machines.Article Version Code kgSpecial gear oil Bottle, 250 ml 790 041 030 0.235<strong>Pipe</strong> length gauge barFor all RA 2, RA 4, RA 6 and RA 8 machines.Measuring range up to 680 mm (26.77 inch).Article Code kg<strong>Pipe</strong> length gauge bar 790 041 011 1.568<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>11orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Length gaugeCombined metric and inch scale.Measuring range up to 250 mm (9.84 inch).Article Code kgLenght gauge for RA 21 S 790 044 020 0.815Lenght gauge for RA 41 790 046 020 1.000Intermediate retrofit gear kit for RA machinesTo convert the RA machines to RA H machines.Reducing the cutting speed of the RA machine to 40 - 70 rpm and more torque.For cutting of high-performance materials e.g. Hastelloy and Inconel.Fits for all RA 2, RA 4, RA 41, RA 41 Plus, RA 6, RA 8 and RA 12 machines. The kit includesall parts necessary for retrofitting as well as special gear oil (Code 790 041 030).Article Code kgIntermediate gear retrofit kit 790 041 063 2.000Swivel cableTo prevent twisting of the cable.For all RA and PS machines with protection class II (double insulated).Cable length: 4 m (15.75 inch).Article Code kgSwivel cable 790 041 076 0.550Quick-mounting base plateWith integrated screw clamps for easy and fast mounting of the machine to the bench.Ideal for frequent location change.Article Code kgQuick-mounting base plate for RA 2 (H), RA 21 S 790 041 027 4.230Quick-mounting base plate for RA 4 (H), RA 6 (H), RA 8 (H), RA 41 (Plus) 790 042 027 6.165RA carrierFor easy transportation of RA machines.For all RA 4, RA 41, RA 41 Plus and RA 6 machines.On request, the RA carrier can be pre-mounted on new purchases of one of the aboveRA machines.Article Code kgRA carrier 790 042 035 5.00012<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

<strong>Pipe</strong> feeder base unitThe pipe feeder accurately feeds long and heavy pipes into RA machines. Very sturdy andstable design with powder-coated frames and stainless steel rollers.This feature helps the squarness of the cut and is suitable for all +GF+ pipe cutting andbeveling RA machines made by Orbitalum Tools (not for RA 2 and RA 21). The RA machinescan be directly mounted onto the base plate of the pipe feeder base unit, without furtherparts. The RA machines can be easily adjusted to the required cutting dimension. Themachine is resilient supported on the base plate.Application range<strong>Pipe</strong> feeder base unit<strong>Pipe</strong> OD [mm] 16 - 325<strong>Pipe</strong> OD [inch] 0.630 - 12.795Dimensions [cm] approx. 185 x 105 x 50Dimensions [inch] approx. 72.8 x 41.3 x 19.7Load max. [kg] 400Article Code kg<strong>Pipe</strong> feeder base unit 790 068 051 116.000<strong>Pipe</strong> feeder extension unitTo extend the the base unit, can be used singularly or in multiples, easily bolted together.Application range<strong>Pipe</strong> feeder extension unit<strong>Pipe</strong> OD [mm] 16 - 325<strong>Pipe</strong> OD [inch] 0.630 - 12.795Dimensions [cm] approx. 160 x 105 x 50Dimensions [inch] approx. 62.9 x 41.3 x 19.7Load max. [kg] 400Article Code kg<strong>Pipe</strong> feeder extension unit 790 068 061 72.000Floor bracket accessoryTo fasten the base unit or the extension unit to the floor.The assembly consists of:• 4 Brackets• 8 Bolts with washersArticle Code kgFloor bracket accessory 790 068 053 1.900<strong>Pipe</strong> supportWith rotating support roller. Adjustable from 85 up to 110 cm (33.47 - 43.31 inch).Load: max. 300 kgArticle Code kg<strong>Pipe</strong> support 790 052 301 7.000<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>13orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Saw blades and bevel cutters for RA machinesThese saw blades and bevel cutters are especially designed for our pipe cutters forhighest requirements and longest service life.4 different high-quality tool ranges are available for different applications:• Economy Rangefor low and unalloyed steel and cast iron pipes• Performance Rangefor high-alloy steel (stainless steel)• High-Performance Rangefor high-performance materials and high-alloy steel (stainless steel)• Premium Rangeespecially made for stainless steel applications with extra long durabilityWorkable pipematerialsAlMild steel, Cu, CuNi,CuZn, CuSnINOX, V2A, V4A,304, 316 (L)Ti, Duplex, InconelEconomy * *Performance * *High-Performance * * *Premium *Saw bladesMinimum order quantity: 5 bladesArticle <strong>Pipe</strong> wall thickness Saw blade Ø Code kg[mm] [inch] [mm] [inch]Economy 1.2 - 2.0 .047 - .079 63 2.480 790 041 040 0.031Economy* 1.5 - 6.0 .059 - .236 68 2.677 790 042 063 0.036Economy* 5.0 - 12.0 .197 - .472 75 2.953 790 043 030 0.053Economy 2.0 - 5.5 .079 - .217 63 2.480 790 041 020 0.032Economy 2.5 - 7.0 .098 - .276 68 2.677 790 042 020 0.045Performance 0.6 - 1.2 .024 - .047 63 2.480 790 041 036 0.027Performance 1.0 - 1.6 .039 - .063 68 2.677 790 042 049 0.040Performance 1.0 - 2.5 .039 - .098 63 2.480 790 041 041 0.042Performance 1.0 - 3.0 .039 - .118 63 2.480 790 048 072 0.025Performance 1.2 - 2.5 .047 - .098 63 2.480 790 041 035 0.045Performance 1.2 - 2.5 .047 - .098 68 2.677 790 042 064 0.050Performance** 1.2 - 2.5 .047 - .098 100 3.937 790 043 036 0.104Performance 1.5 - 2.5 .059 - .098 80 3.150 790 046 022 0.085Performance 2.5 - 5.5 .098 - .217 63 2.480 790 041 048 0.035Performance** 2.5 - 5.5 .098 - .217 100 3.937 790 043 038 0.104Performance 2.5 - 7.0 .098 - .276 68 2.677 790 042 048 0.045Performance 2.5 - 7.0 .098 - .276 77 3.031 790 043 018 0.060Performance 6.0 - 10.0 .236 - .394 75 2.953 790 043 022 0.055Performance 6.0 - 10.0 .236 - .394 100 3.937 790 047 026 0.105Performancefor bar stock up to82 3.228 790 046 023 0.070Ø 30 mm / 1.181"High-Performance 1.0 - 2.5 .039 - .098 68 2.677 790 042 159 0.040High-Performance 1.2 - 2.5 .047 - .098 80 3.150 790 046 021 0.064High-Performance 1.2 - 2.5 .047 - .098 63 2.480 790 041 034 0.031High-Performance 2.5 - 7.0 .098 - .267 68 2.677 790 042 058 0.045Premium 1.2 - 2.5 .047 - .098 63 2.480 790 041 049 0.033* applicable only for aluminum pipes** only for RA 6, RA 8 and RA 1214<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Saw blade/bevel cutter combinationsSimultaneous cutting and beveling of pipes in just seconds.Weld-prep saw blade/bevel cutter combination (V-seam)*Article <strong>Pipe</strong> wall thickness BevelingangleHeight ofbevel max.Sawblade-Ø[mm] [inch] [°] [mm] [inch] [mm] [inch]Performance 2.5 - 5.0 .098 - .197 30 5 .197 68 2.677 790 042 155 0.095Performance 2.5 - 5.0 .098 - .197 35 5 .197 68 2.677 790 042 157 0.103Performance 2.5 - 7.0 .098 - .276 30 7 .276 68 2.677 790 042 161 0.108High-Performance 2.5 - 5.0 .098 - .197 30 5 .197 68 2.677 790 042 018 0.095High-Performance 2.5 - 5.0 .098 - .197 35 5 .197 68 2.677 790 042 015 0.120High-Performance 2.5 - 6.0 .098 - .236 45 4 .157 68 2.677 790 042 023 0.135High-Performance 2.5 - 7.0 .098 - .276 30 7 .276 68 2.677 790 042 013 0.108CodekgReplacement parts for weld prep saw blade/bevel cutter combination (V-seam)Article Version Code kgSaw blade for 790 042 155, 790 042 157 and Performance 790 042 153 0.040790 042 161Bevel cutter 30° for 790 042 155 Performance 790 042 154 0.045Bevel cutter 30° for 790 042 161 Performance 790 042 160 0.060Bevel cutter 35° for 790 042 157 Performance 790 042 156 0.060Saw blade for 790 042 018, 790 042 015,High-Performance 790 042 016 0.040790 042 023, 790 042 013Bevel cutter 30° for 790 042 018 High-Performance 790 042 017 0.045Bevel cutter 35° for 790 042 015 High-Performance 790 042 014 0.060Bevel cutter 30° for 790 042 013 High-Performance 790 042 021 0.077Bevel cutter 45° for 790 042 023 High-Performance 790 042 022 0.077Press fitting saw blade/bevel cutter combination**Article<strong>Pipe</strong> wallthicknessBevelingangleHeight of bevelmax.Sawblade-Ø[mm] [inch] [°] [mm] [inch] [mm] [inch]Performance 1.0 - 2.0 .039 - .079 45 / 70 0.4/1.0 .016/.039 63 2.480 790 044 046 0.090High-Performance 1.0 - 2.0 .039 - .079 45 / 70 0.4/1.0 .016/.039 63 2.480 790 044 047 0.090CodekgReplacement parts for press fitting saw blade/bevel cutter combinationArticle Version Code kgSaw blade for 790 044 046 Performance 790 044 040 0.027Bevel cutter for 790 044 046 Performance 790 044 042 0.064Saw blade for 790 044 047 High-Performance 790 044 041 0.030Bevel cutter for 790 044 047 High-Performance 790 044 043 0.065Support disc for saw blade/bevel cutter combinationWe recommend to use 1 support disc when using saw blade/bevel cutter combination.Article Code kgSupport disc 790 046 188 0.068* Consisting of one saw blade and one bevel cutter with high-performance coating. It is possible to order the individual parts.** Consisting of one saw blade and one bevel cutter (uncoated). Especially for stainless steel press fitting systems. It is possibleto order the individual parts.<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>15orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Bevel cuttersFor V-seam profiles on pipe ends.The bevel cutter is mounted on the RA pipe cutter instead of a saw blade.Reproducible weld seam preparation in just seconds.Bevel cutters V-seamArticleBevelingangleHeight of bevelmax.Bevel cutter-Ø Code kg[°] [mm] [inch] [mm] [inch]Economy 30.0 9.5 .374 72 2.835 790 042 045 0.135Economy 35.0 8.9 .350 70 2.756 790 042 037 0.170Economy 37.5 8.4 .331 70 2.756 790 042 036 0.162Economy 45.0 7.5 .295 70 2.756 790 042 038 0.162Economy 60.0 4.7 .185 70 2.756 790 042 046 0.175Performance 30.0 9.5 .374 72 2.835 790 042 071 0.153Performance 30.0 13.0 .512 76 2.992 790 043 023 0.187Performance 37.5 8.4 .331 70 2.756 790 042 070 0.163Performance 50.0 5.8 .228 70 2.756 790 042 050 0.168High-Performance 30.0 9.5 .374 72 2.835 790 042 073 0.157High-Performance 37.5 8.4 .331 70 2.756 790 042 072 0.163Saw blade lubricating compound GF TOPSynthetic high-performance lubricant for pipe cutting and beveling.Increases the life of the saw blades. Complies with USDA H2 registration.Easy and constant lubrication of the saw blade, supplied with a special brush.Article Version Code kgSaw blade lubricating compound GF TOP Tube, 180 g 790 060 228 0.205Saw blade lubricating compound ROCOLHigh-performance lubricant for pipe cutting and beveling.Increases the life of the saw blades.Article Version Code kgSaw blade lubricating compound ROCOL Tube, 150 ml 790 041 016 0.195Saw blade lubricating compound ROCOL Can, 0.5 kg 790 041 013 0.605Saw blade lubricating compound ROCOL Can, 5.0 kg 790 041 019 5.52016<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Portable Tube Saws• Lightweight and easily transportable machine (only 19 kg / 22 kg) to provide flexibilityfor on-site applications• Deformation-free clamping of thin-walled tubes• For cutting of thin-walled tubes and elbows• No rework necessary because of a burr-free and square cut• Cold cutting process prevents corrosion• Orbital cutting process saves time• Multipoint clamping system of tubes• Fast adjustment of tube dimensions• Long saw blade service lifePS 4.5, PS 6.6Tube cutting made easy!Cutting thin-walled stainless-steel tubes and elbows using the superior «PlanetaryCutting <strong>Technology</strong>».Deformation-free clamping systems by integrated clamping jaws made from coated castaluminum for different tube diameters.Scope of delivery:• 1 Portable Tube Saw PS 4.5 or PS 6.6• 1 Set of aluminum clamping jaws• 1 Durable storage and shipping case• 1 Saw blade, already mounted to the PS-machine (Code 790 048 072)• 1 Tool bag equipped with tools• 1 Tube of saw blade lubricating compound GF TOP (Code 790 060 228)• 1 Operating instructions with spare parts listPS 6.6 PS 4.5Electric drive with a single phase AC motor:Power: 1010 W (1.35 HP)Protection class II (double insulated)Built-in electronic variable cutting speed: 30 - 160 rpmApplication range Material SawTube ODWall thicknessposition [mm] [inch] [mm] [inch]Tube 1 6 – 120 0.236 - 4.724PS 4.5Elbow 2 30 – 120 1.181 - 4.724< 3 < 0.118Tube 1 50* – 170 1.969* - 6.693PS 6.6Elbow 2 50* – 170 1.969* - 6.693* It is possible to cut tubes with a outer diameter min. 30 mm (1.181 inch) by using additional clamping jaws (accessory,Code 790 048 380). These clamping jaws are delivered as a standard with the PS 4.5.Article Version Code kgPS 4.5 230 V, 50/60 Hz EU 790 048 001 34.000PS 4.5 110 V, 50/60 Hz EU 790 048 002 34.000PS 6.6 230 V, 50/60 Hz EU 790 049 001 41.000PS 6.6 110 V, 50/60 Hz EU 790 049 002 41.000<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>17orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Accessories for PS machinesQuick mounting plate with screw clampsWith integrated screw clamps for easy and fast mounting of the machine to the bench.Ideal for frequent location change.Article Code kgQuick mounting plate with screw clamps 790 048 334 2.600Saw BladesPerformance range for high-alloyed steel (stainless steel).Recommended saw blades for the Portable Tube Saws PS 4.5 and PS 6.6.ArticleTube wallthickness[mm]Tube wallthickness[inch]Saw blade-Ø[mm]Saw blade-Ø[inch]Performance 1.0 - 3.0 0.039 - 0.118 63 2.480 790 048 072 0.035Performance 1.2 - 2.5 0.047 - 0.098 63 2.480 790 041 035 0.045Performance 0.6 - 1.2 0.024 - 0.047 63 2.480 790 041 036 0.027CodekgTripodMade of stainless steel. Ideal for on-site work with PS machines.• Space saving• Fast application• Easy handlingArticle Code kgTripod 790 048 335 10.600Clamping jaws replacement set for PS 4.5 and PS 6.6Made from coated cast aluminum.Extends the dimension range of the PS 6.6 from 1.181 inch min.Article Code kgClamping jaws replacement set for PS 4.5 and extension jaws for PS 6.6 790 048 380 2.030Saw blade lubricating compound GF TOPSynthetic high-performance lubricant for pipe cutting and beveling.Increases the life of the saw blades. Complies with USDA H2 registration.Easy and constant lubrication of the saw blade, supplied with a special brush.Article Version Code kgSaw blade lubricating compound GF TOP Tube, 180 g 790 060 228 0.20518<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Orbital Cutting Machine• The ideal tube cutting machine for high-purity applications• Deformation-free stainless steel clamping system• Burr-free, square and deformation-free cut• Portable machine for a mobile and secure application• Orbital and automated cutting process• 1 tool for different wall thicknesses and different tube materials• Quick clamping system for tubes and tools and adjusting facility to compensate fortube irregularitiesOTM 2.0Cutting of thin-walled stainless steel tubes up to 2".The optimal tube end preparation for welding joints conforming to industry standards.Scope of delivery:• 1 Orbital Cutting Machine OTM 2.0• 1 Durable storage and shipping case• 1 Tool holder WH (Code 790 022 736) with high-performance coated tool bit(Code 790 022 737)• 1 Tool set• 1 Operating instructions with spare parts listElectric drive with single-phase AC motor:Power: 1010 W (1.35 HP)Protection class II (double insulated)Built-in electronic variable cutting speed: 24 - 42 rpmApplication range [mm] [inch]Tube OD 6.35 - 50.8 ¼ - 2Wall thickness (depends on material) 0.8 - 3 0.032 - 0.118Article Version Code kgOTM 2.0 200 - 240 V, 50/60 Hz EU 790 022 701 8.000OTM 2.0 100 - 120 V, 50/60 Hz EU 790 022 703 8.000<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>19orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Accessories for OTM 2.0Tool bitTwo-sided tool bit with high-performance protective coating against tool wear (TiN).1 tool for different wall thicknesses (0.8 -3 mm/.032 -.118 inch) and different tubematerials.Article Code kgTool bit for OTM 2.0 790 022 737 0.003Tool holder WHIncluding Torx-screw.Article Code kgToold holder for OTM 2.0 790 022 736 0.066Clamping shellsThe two-piece-design of the stainless steel clamping shells with click mechanism areextremely durable.• Ensures accurate and deformation-free centering of the tube• Quick clamping shell change, no tools requiredFurther dimensions are available.ArticleTube OD[mm]Tube OD[inch]Clamping shells for OTM 2.0 6.35 0.250 790 022 781 0.915Clamping shells for OTM 2.0 9.53 0.375 790 022 787 0.905Clamping shells for OTM 2.0 12.70 0.500 790 022 782 0.857Clamping shells for OTM 2.0 19.05 0.750 790 022 783 0.860Clamping shells for OTM 2.0 24.40 1.000 790 022 784 0.754Clamping shells for OTM 2.0 38.10 1.500 790 022 785 0.580Clamping shells for OTM 2.0 50.80 2.000 790 022 786 0.342Codekg20<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Universal <strong>Pipe</strong> Cutter• Wide range of applications and dimensions• No rework necessary• Suitable for clamping joints• Reduction of tool costs and cutting time• Flexible application rangeSCORP 220 Plus, SCORP 360The ultimate and fast solution for cutting of cast iron, stainless steel, steel, copper,aluminum and plastic pipes.Ideal for pipe fitters to use on construction sites and in industrial pipe installations.Scope of delivery:• 1 <strong>Pipe</strong> Cutter SCORP 220 Plus or SCORP 360• 1 Bag for easy transportation• 4 Small pipe roller (SCORP 220 Plus) or 2 small and 1 large pipe roller (SCORP 360)• 1 Saw blade TCT (Code 790 014 055)• 1 Operating instructions with spare parts listElectric drive with single-phase AC motor:Power:SCORP 220 Plus: 1.1 kW (1.5 HP)SCORP 360: 1.4 kW (1.9 HP)Max. saw blade speed range: 4.000 rpmSCORP 220 PlusApplication range SCORP 220 Plus SCORP 360<strong>Pipe</strong> OD [mm] 20 - 220 75 - 360<strong>Pipe</strong> OD [inch] 0.800 - 8.660 2.950 - 14.170Wall thickness (steel) max. [mm] 8 8Wall thickness (steel) max. [inch] 0.315 0.315Wall thickness (plastic) max. [mm] 10 27.9Wall thickness (plastic) max. [inch] 0.394 1.098Article Version Code kgSCORP 220 Plus 200 - 240 V, 50/60 Hz EU 790 014 007 9.500SCORP 220 Plus 100 - 120 V, 50/60 Hz EU 790 014 008 9.500SCORP 360 200 - 240 V, 50/60 Hz EU 790 015 001 14.300SCORP 360 100 - 120 V, 50/60 Hz EU 790 015 002 14.300<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>21orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Saw blades for SCORP machinesSaw blade TCTArticle For pipe material Sawblade-Ø[mm]Saw blade TCT Steel, copper, aluminum, all kindsof plasticrpmmax.Code140 4.200 790 014 055 0.154Saw blade TCT* All kinds of plastic 155 4.200 790 014 058 0.195* only for SCORP 360kgApplication range SCORP 360 with TCT saw bladesPlastic pipe OD[mm]Saw blade Ø 140 mmmax. wall thickness [mm]Saw blade Ø 155 mmmax. wall thickness [mm]75 15.1 22.690 11.4 18.9100 10.1 17.6110 9.3 16.8115 9.1 16.6140 8.7 16.2160 9.1 16.6165 9.3 16.8190 10.4 17.9215 11.8 19.3240 13.4 20.9270 15.4 22.9320 18.6 26.1355 20.4 27.9Cutting blade DiamondArticle For pipe material Sawblade-Ø[mm]rpmmax.Cutting blade Diamond Cast iron 140 4.200 790 014 057 0.173CodekgSaw blade CermetArticle For pipe material Sawblade-Ø[mm]rpmmax.Saw blade Cermet Stainless steel 140 4.200 790 014 056 0.153Codekg22<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Metal Tube CutterThe clever solution for cutting metal tubes manually. This Metal Tube Cutter is especiallydesigned for cramped working places and for chipless cutting processes.• Deformation-free and square cut• No electricity required• Chipless cutting procedure• Requires little space, for use in limited access areasMRAFor manual cutting of metal tubes.Easy to use – first-rate cutting technology.For tube materials:• Stainless steel (special steel material no. 1.40... – 1.45... as per DIN 17 455 and DIN 17 456)• Low alloy and unalloyed steel• Aluminum• Cast materials• Non-ferrous metals• PVDF plasticVersions:MRA HPMetal Tube Cutter for high-purity applications. Only applicable with the HP multi-rollercutting chain (Code 790 008 014).Scope of delivery:• 1 Metal Tube Cutter MRA*• 1 Plastic carrying case (ABS)• 1 Socket head key• 1 Connection clamp• 1 Tube of lubricating compound GF TOP (Code 790 060 228)**• 1 Pair of working gloves• 1 Operating instructions with spare parts list* without multi-roller cutting chains and without clamping shells (see accessories)** not with MRA HPApplication range [mm] [inch]Tube OD 33.7 - 254.0 1.327 - 10.000Wall thickness (depends on material) 0.8 - 3.0 0.031 - 0.118Article Version Code kgMetal Tube Cutter MRA Standard 790 008 001 8.000Metal Tube Cutter MRA HP 790 008 002 8.000<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>23orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Accessories for MRAMulti-roller cutting chainCutting wheels made from hardened steel.ArticleTube OD[mm]Tube OD[inch]Numberof cuttingwheels[pieces]Multi-roller cutting chain 33.7 - 114.3 1.330 - 4.500 15 790 008 018 0.500Multi-roller cutting chain HP* 33.7 - 114.3 1.330 - 4.500 15 790 008 014 0.510Multi-roller cutting chain 114.3 - 154.0 4.500 - 6.060 10 790 008 013 0.610Multi-roller cutting chain 114.3 - 254.0 4.500 - 10.000 16 790 008 041 0.900* Multi-roller cutting chain for high-purity applications. Only applicable with the HP Metal Tube Cutter (Code 790 008 002).CodekgClamping shells MRASet of two pieces, made from hardened steel.Further dimensions of clamping shells are available.Tube OD [mm] Tube OD [inch] Code kg33.7 1.330 790 008 105 0.88538.1 1.500 790 008 130 0.95540.0 1.575 790 008 135 0.95542.4 1.670 790 008 140 1.00548.3 1.900 790 008 155 1.10050.0 1.970 790 008 160 1.13050.8 2.000 790 008 165 1.14052.0 2.050 790 008 175 1.19054.0 2.125 790 008 185 1.10060.3 2.375 790 008 195 1.31563.5 2.500 790 008 200 1.37570.0 2.755 790 008 215 1.44575.0 2.950 790 008 225 1.60076.1 2.996 790 008 230 1.56084.0 3.300 790 008 240 1.69085.0 3.350 790 008 245 1.75088.9 3.500 790 008 250 1.780101.6 4.000 790 008 260 2.025104.0 4.095 790 008 270 1.925110.0 4.330 790 008 285 2.150114.3 4.500 790 008 290 2.295129.0 5.080 790 008 315 3.000139.7 5.500 790 008 325 3.365154.0 6.060 790 008 340 3.365160.0 6.300 790 008 355 3.520168.3 6.625 790 008 365 3.600204.0 8.030 790 008 380 4.375219.1 8.625 790 008 385 4.680<strong>Pipe</strong> vice for MRAFor pipes up to OD 300 mm (11.81 inch), with a plastic clamping strap, reversible. Can be easilycombined with the Manual Tube Cutter MRA due to an integrated clamping shell bearing.Article Code kg<strong>Pipe</strong> vice for MRA 790 008 008 17.00024<strong>Pipe</strong> Cutting and Beveling <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

PageTube Squaring Machines RPG 1.0 Cordless,RPG 1.0 Cordless with right-angled drive 26Accessories for RPG 1.0 27Tube Squaring MachinesRPG 1.5, RPG 1.5 Cordless 28Accessories for RPG 1.5 29Tube Squaring Machines RPG 4.5 31Accessories for RPG 4.5 32Tube Squaring Machines RPG 8.6 34Accessories for RPG 8.6 35Boiler <strong>Pipe</strong> <strong>Preparation</strong> Machines BRB 2 36Boiler <strong>Pipe</strong> <strong>Preparation</strong> Machines BRB 4 38Accessories for BRB machines 40<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> MachinesREB 6, REB 14, REB 20 43Accessories for REB machines 44Accessories for BRB and REB machines 47Description of the different weld prep profilesand the tools made by Orbitalum Tools 48Combination possibilities of tool holder andmultifunctional tools for REB and BRB machines 49Application range of tool holder 50Length of land with the use of thetool holder for facing 52<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>25orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Tube Squaring Machines• Squaring tube ends with a high-quality finish• Burr-free and square• Quick clamping system for tools, clamping shells and tubes• <strong>Preparation</strong> of thin-walled stainless steel tubes (V4A) and micro fittings• High-performance coated tool bit with two cutting edges• Built-in electronic speed regulation• Micrometer feed for optimum results• No additional tools required for operation• Space saving, light weight and portable machine for a mobile and secure applicationRPG 1.0 Cordless, RPG 1.0 Cordless right-angled driveDesigned for burr-free squaring of thin-walled stainless steel tubes and micro fittingsup to OD 25.4 mm (1 inch). The clean and cost-effective solution for precise weldsconforming to industry standards.RPG 1.0 Cordlessright-angled driveRPG 1.0 CordlessScope of delivery:• 1 Tube Squaring Machine RPG 1.0 Cordless / Cordless right-angled drive• 1 Durable storage and shipping case• 2 Rechargeable batteries• 1 Battery charger (110 - 120 V, 50/60 Hz or 240 V, 50/60 Hz)• 1 Multifunctional tool (Code 790 038 314)• 1 Torx T-spanner for securing the multifunctional tools (T15)• 1 Operating instructions with spare parts list• Operating instructions and safety notes for the battery chargerDrive with rechargeable batteryVoltage of rechargeable battery: 12 VSpeed RPG 1.0 Cordless: 0 - 400 rpmSpeed RPG 1.0 Cordless right-angled drive: 0 - 350 rpmApplication range RPG 1.0 Cordless RPG 1.0 Cordlessright-angled driveTube OD [mm] 3.18 - 25.40 3.18 - 25.40Tube OD [inch] 0.125 - 1.000 0.125 - 1.000Wall thickness max. [mm] 2 2Wall thickness max. [inch] 0.079 0.079Dimensions approx. [mm] 235 x 380 x 75 145 x 380 x 75Dimensions approx. [inch] 9.25 x 15 x 3 5.7 x 15 x 3Article Version (battery charger) Code kgRPG 1.0 Cordless EU 220 - 240 V, 50/60 Hz 790 036 001 2.100RPG 1.0 Cordless EU 110 - 120 V, 50/60 Hz 790 036 003 2.100RPG 1.0 Cordless right-angled drive EU 220 - 240 V, 50/60 Hz 790 036 011 2.900RPG 1.0 Cordless right-angled drive EU 110 - 120 V, 50/60 Hz 790 036 013 2.90026<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Accessories for RPG 1.0One-piece stainless steel clamping shellsExtremely durable. Ensures accurate centring and quick clamping shell change without anytools. For use on all materials with a OD of 3.18 mm up to 25.40 mm (0.125 - 1.000 inch).Further clamping shell dimensions are available.Tube OD[mm]Tube ODCodekg[inch]3.18 0.125 790 036 201 0.1196.35 0.250 790 036 202 0.1189.53 0.375 790 036 203 0.11510.00 0.375 790 036 204 0.11512.00 0.472 790 036 205 0.11212.70 0.500 790 036 206 0.11117.20 0.677 790 036 207 0.10419.05 0.750 790 036 208 0.10021.30 0.839 790 036 209 0.09425.40 1.000 790 036 210 0.083Multifunctional tool MFWTwo-sided tool bit with high-performance Balinit ® Futura protective coating against toolwear. Usable for all machines of the RPG series.Article Quantity Code kgMultifunctional tool MFW-P-2 1 790 038 314 0.003Multifunctional tool MFW-P-2 10 790 038 315 0.045Durable storage and shipping caseHigh-quality blue transportation case with insert. Very sturdy design.Already included in the standard scope of delivery of the RPG 1.0 Cordless right-angled drive.Article Code kgDurable storage and shipping case 790 036 080 5.400<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>27orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Tube Squaring Machines• Squaring tube ends with high-quality surface• Burr-free and square• Quick clamping system for tools, clamping shells and tubes• <strong>Preparation</strong> of thin-walled stainless steel tubes (V4A) and micro fittings• High-performance coated tool bit with two cutting edges• Built-in electronic speed regulation• Micrometer feed for optimum results• No additional tools required for operation• Space saving, light weight and portable machine for a mobile and secure applicationRPG 1.5, RPG 1.5 CordlessRPG 1.5Designed for burr-free squaring of thin-walled stainless steel tubes and micro fittingsup to OD 38.1 mm (1.5 inch). The cost-effective solution for precise welds conforming toindustry standards. Clean and secure working area with clear view cutting head.RPG 1.5:• Removable bench standRPG 1.5 Cordless:• Light-weight and portable machine• Right-angled machine with carrying handle and rechargeable battery• Short machine lengthRPG 1.5 CordlessScope of delivery:• 1 Tube Squaring Machine RPG 1.5 or RPG 1.5 Cordless• 1 Durable storage and shipping case• 2 Rechargeable batteries*• 1 Battery charger*• 1 Tool holder (Code 790 037 152) with multifunctional tool (Code 790 038 314)• 1 Tool set• 1 Operating instructions with spare parts list• Operating instructions and safety notes for the battery charger** only with RPG 1.5 CordlessRPG 1.5 with single-phase AC motor:Power: 1010 W (1.35 HP)Protection class II (double insulated)Built-in electronic variable cutting speed: 20 - 160 rpmSpeed stabilisationRPG 1.5 Cordless with rechargeable battery12 v rechargeable battery1. speed: 0 - 350 rpm2. speed: 0 - 1300 rpmApplication range [mm] [inch]Tube OD 3.0 - 38.1 0.118 - 1.500Wall thickness max. 3.0 0.118Article Version Code kgRPG 1.5 200 - 240 V, 50/60 Hz EU 790 037 001 9.500RPG 1.5 100 - 120 V, 50/60 Hz EU 790 037 003 9.500RPG 1.5 Cordless 200 - 240 V, 50/60 Hz EU 790 037 011 10.100RPG 1.5 Cordless 100 - 120 V, 50/60 Hz EU 790 037 013 10.10028<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Accessories for RPG 1.5 (Cordless)One-piece stainless steel clamping shellsExtremely durable. Ensures accurate centring and quick clamping shell change withoutany tools. For use on all materials with a OD of 3.0 mm up to 38.1 mm (0.118 - 1.500 inch).Further clamping shell dimensions are available.Tube OD[mm]Tube ODCodekg[inch]3.00 0.118 790 037 220 0.3003.18 0.125 790 037 221 0.3084.00 0.157 790 037 222 0.3084.78 0.188 790 037 223 0.3085.00 0.197 790 037 224 0.2906.00 0.236 790 037 225 0.3106.35 0.250 790 037 226 0.3068.00 0.314 790 037 227 0.2999.53 0.375 790 037 228 0.29710.00 0.394 790 037 229 0.29812.00 0.472 790 037 230 0.29312.70 0.500 790 037 231 0.29213.00 0.512 790 037 232 0.29113.50 0.531 790 037 233 0.29014.00 0.551 790 037 234 0.28815.00 0.591 790 037 235 0.28615.88 0.625 790 037 236 0.28516.00 0.630 790 037 237 0.28217.20 0.677 790 037 238 0.30018.00 0.709 790 037 239 0.28019.00 0.748 790 037 240 0.27719.05 0.750 790 037 241 0.27420.00 0.787 790 037 242 0.27221.30 0.839 790 037 243 0.27022.00 0.866 790 037 244 0.26423.00 0.906 790 037 245 0.26124.00 0.945 790 037 246 0.25625.00 0.984 790 037 247 0.25225.40 1.000 790 037 248 0.24026.90 1.059 790 037 249 0.26028.00 1.102 790 037 250 0.23829.00 1.142 790 037 251 0.23530.00 1.181 790 037 252 0.23231.80 1.250 790 037 280 0.23033.40 1.315 790 037 281 0.22033.70 1.327 790 037 282 0.21834.00 1.339 790 037 283 0.21035.00 1.377 790 037 284 0.21036.00 1.417 790 037 285 0.20438.00 1.496 790 037 286 0.19938.10 1.500 790 037 287 0.194<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>29orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

One-piece stainless steel clamping shells for micro fittingsExtremely durable. Ensures accurate centring and quick clamping shell change withoutany tools. For use on all materials with a OD of 3.0 mm up to 21.2 mm (0.118 - 0.835 inch).Further clamping shell dimensions are available.Tube OD [mm] Tube OD [inch] Code kg3.00 0.118 790 037 300 0.2413.18 0.125 790 037 301 0.2274.00 0.157 790 037 302 0.2374.78 0.188 790 037 303 0.2345.00 0.197 790 037 304 0.2286.00 0.236 790 037 305 0.2206.35 0.250 790 037 306 0.4608.00 0.314 790 037 307 0.2239.53 0.375 790 037 308 0.30010.00 0.394 790 037 309 0.22212.00 0.472 790 037 310 0.22012.70 0.500 790 037 311 0.22017.20 0.678 790 037 312 0.22021.20 0.835 790 037 313 0.213Tool holder WHFor multifunctional tool 790 038 314. Adjustable tool holder with Torx screw.Application range Standard Tool holder Optional Tool holder<strong>Pipe</strong> OD [mm] 3.0 - 38.1 15.0 - 38.1<strong>Pipe</strong> OD [inch] 0.118 - 1.500 0.590 - 1.500Best machining results with tube OD [mm] 15.0 –Best machining results with tube OD [inch] 0.590 –Article Code kgStandard Tool holder WH12-I 790 037 152 0.040Optional Tool holder WH12-I 790 037 154 0.050Optional Tool holder WH for micro fittingsFor multifunctional tool 790 038 314. With Torx screw.Application rangeOptional Tool holderMicro fittings OD [mm] 3.0 -21.2Micro fittings OD [inch] 0.118 - 0.835Article Code kgOptional Tool holder for micro fittings WH12-I 790 037 156 0.100Multifunctional tool MFWTwo-sided tool bit with high-performance Balinit ® Futura protective coating against toolwear. Usable for all machines of the RPG series.Article Quantity Code kgMultifunctional tool MFW-P-2 1 790 038 314 0.003Multifunctional tool MFW-P-2 10 790 038 315 0.04530<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Tube Squaring Machines• Squaring tube ends with high-quality surface• Burr-free and square• Quick clamping system for tools, clamping shells and tubes• <strong>Preparation</strong> of stainless steel tubes• High-performance coated tool bit with two cutting edges• Built-in electronic speed regulation• Micrometer feed for optimum results• No additional tools required for operation• Portable and light weight machine for a mobile and secure applicationRPG 4.5Designed for burr-free squaring of thin-walled stainless steel tubes up to OD 114.3 mm(4.5 inch). The cost-effective solution for precise welds conforming to industry standards.Clean and secure working area with clear view cutting head. Machine with removablebench stand.Scope of delivery:• 1 Tube Squaring Machine RPG 4.5• 1 Durable storage and shipping case• 1 Tool holder (Code 790 038 320) with multifunctional tool (Code 790 038 314)• 1 Tool set• 1 Operating instructions with spare parts listElectric drive with single-phase AC motor:Power: 1010 W (1.35 HP)Protection class II (double insulated)Built-in electronic variable cutting speed: 8 - 52 rpmSpeed stabilisationApplication range [mm] [inch]Tube OD 12.7 – 114.3 0.500 - 4.500Wall thickness max. 3.0 0.118Article Version Code kgRPG 4.5 200 - 240 V, 50/60 Hz EU 790 038 001 19.400RPG 4.5 100 - 120 V, 50/60 Hz EU 790 038 003 19.400<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>31orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Accessories for RPG 4.5Stainless steel clamping shellsExtremely durable. The two-piece-design with click mechanism ensures accurate centringand quick clamping shell change without any tools. For use on all materials with a ODof 12.0 mm up to 114.3 mm (0.500 - 4.500 inch). Further clamping shell dimensions areavailable.Tube OD[mm]Tube ODCodekg[inch]12.00 0.472 790 038 454 2.17012.70 0.500 790 038 438 2.17713.00 0.512 790 038 439 2.17613.50 0.531 790 038 440 2.17514.00 0.551 790 038 441 2.17416.00 0.630 790 038 442 2.16817.20 0.677 790 038 443 2.16418.00 0.709 790 038 444 2.16119.00 0.748 790 038 445 2.15019.05 0.750 790 038 446 2.15720.00 0.787 790 038 447 2.15321.30 0.839 790 038 448 2.10022.00 0.866 790 038 449 2.14423.00 0.906 790 038 450 2.14024.00 0.945 790 038 451 2.13325.00 0.984 790 038 452 2.12725.40 1.000 790 038 051 2.10026.90 1.059 790 038 400 2.09028.00 1.102 790 038 401 2.11029.00 1.142 790 038 402 2.10530.00 1.181 790 038 403 2.09531.75 1.250 790 038 052 2.09031.80 1.252 790 038 404 2.08033.40 1.315 790 038 405 2.04033.70 1.327 790 038 406 2.06034.00 1.339 790 038 407 2.04035.00 1.378 790 038 408 2.05036.00 1.417 790 038 409 2.04438.00 1.496 790 038 410 2.02538.10 1.500 790 038 053 2.02040.00 1.575 790 038 411 2.00041.00 1.614 790 038 412 1.99042.00 1.654 790 038 413 1.97642.16 1.660 790 038 414 1.95042.40 1.669 790 038 415 1.96542.70 1.681 790 038 416 1.95044.45 1.750 790 038 417 1.95544.50 1.752 790 038 418 1.95545.00 1.772 790 038 419 1.94848.26 1.900 790 038 420 1.88048.30 1.902 790 038 421 1.90548.60 1.913 790 038 422 1.87550.00 1.969 790 038 456 1.88050.80 2.000 790 038 054 1.89551.00 2.008 790 038 423 1.87052.00 2.047 790 038 424 1.85053.00 2.087 790 038 425 1.83554.00 2.126 790 038 426 1.82757.00 2.244 790 038 457 1.78060.30 2.375 790 038 427 1.70060.45 2.380 790 038 428 1.72660.50 2.382 790 038 429 1.69563.00 2.480 790 038 461 1.68863.50 2.500 790 038 055 1.67032<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Tube OD[mm]Tube OD[inch]Code70.00 2.756 790 038 430 1.54573.03 2.875 790 038 453 1.48573.15 2.880 790 038 431 1.48275.00 2.953 790 038 462 1.44376.10 2.996 790 038 432 1.42076.20 3.000 790 038 056 1.39076.30 3.004 790 038 433 1.39085.00 3.346 790 038 434 1.22085.90 3.382 790 038 435 1.20088.90 3.500 790 038 057 1.13089.10 3.508 790 038 436 1.100101.60 4.000 790 038 058 0.800104.00 4.094 790 038 437 0.740108.00 4.252 790 038 458 0.620114.30 4.500 790 038 059 0.435kgTool holder WHFor multifunctional tool 790 038 314.With Torx screw.Article Code kgTool holder WH 790 038 320 0.025Multifunctional tool MFWTwo-sided tool bit with high-performance Balinit ® Futura protective coating against toolwear. Usable for all machines of the RPG series.Article Quantity Code kgMultifunctional tool MFW-P-2 1 790 038 314 0.003Multifunctional tool MFW-P-2 10 790 038 315 0.045<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>33orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Tube Squaring Machines• Squaring tube ends with high-quality surface• Burr-free and square• Quick clamping system for tools, clamping shells and tubes• <strong>Preparation</strong> of thin-walled stainless steel tubes (V4A)• High-performance coated tool bit with two cutting edges• Built-in electronic speed regulation• Micrometer feed for optimum results• No additional tools required for operation• Portable machine for a mobile and secure applicationRPG 8.6Designed for burr-free squaring of thin-walled stainless steel tubes up to OD 219.1 mm(8.6 inch). The cost-effective solution for precise welds conforming to industry standards.Clean and secure working area with clear view cutting head. Machine with removablebench stand.Scope of delivery:• 1 Tube Squaring Machine RPG 8.6• 1 Durable storage and shipping case• 1 Tool holder (Code 790 038 320) with multifunctional tool (Code 790 038 314)• 1 Tool set• 1 Operating instructions with spare parts listElectric drive with single-phase AC motor:Power: 1010 W (1.35 HP)Protection class II (double insulated)Built-in electronic variable cutting speed: 7 - 18 rpmSpeed stabilisationApplication range [mm] [inch]Tube OD 50.8 – 219.1 2 – 8.6Wall thickness max. 3.6 0.142Article Version Code kgRPG 8.6 200 - 240 V, 50/60 Hz EU 790 039 001 20.500RPG 8.6 100 - 120 V, 50/60 Hz EU 790 039 003 20.50034<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Accessories for RPG 8.6Clamping shellsMade from aluminum or stainless steel. Extremely durable. The two-piece-design withclick mechanism ensures accurate centring and quick clamping shell change without anytools. For use on all materials with a OD of 50.8 - 219.5 mm (2.000 - 8.625 inch).Further clamping shell dimensions are available.VersionTube OD[mm]Tube OD[inch]Aluminum 101.6 4.000 790 039 252 3.800Aluminum 114.3 4.500 790 039 256 3.500Aluminum 141.3 5.563 790 039 257 2.900Aluminum 152.4 6.000 790 039 253 2.700Aluminum 168.3 6.625 790 039 254 2.300Aluminum 219.1 8.625 790 039 255 0.600Stainless steel 114.3 4.500 790 039 280 4.700Stainless steel 141.3 5.563 790 039 281 4.500Stainless steel 152.4 6.000 790 039 283 4.400Stainless steel 168.3 6.625 790 039 284 4.000Stainless steel 219.1 8.625 790 039 285 1.500CodekgTool holder WHFor multifunctional tool 790 038 314.With Torx screw.Article Code kgTool holder WH 790 038 320 0.025Multifunctional tool MFWTwo-sided tool bit with high-performance Balinit ® Futura protective coating against toolwear. Usable for all machines of the RPG series.Article Quantity Code kgMultifunctional tool MFW-P-2 1 790 038 314 0.003Multifunctional tool MFW-P-2 10 790 038 315 0.045<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>35orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Boiler <strong>Pipe</strong> <strong>Preparation</strong> Machines• Compact design for precise and reproducable weld prep profiles• Maximum performance and lightweight• High-performance coated tool bit with two cutting edges• Quick clamping system for tools with easy adjustment• Adjustable air outlet• Ergonomic handling• Tools adaptable on all BRB machines• Low noise level• Application optimised housing designBRB 2Lightweigth and robust Boiler Prep Machine. For high-precision and reproducible weldprepprofiles. Simultaneous facing, beveling, counterboring and axial turning of pipesmade from high-alloy steel (stainless steel), low-alloy and carbon steel with the uniquetool system QTC ® .Designed for pipe end preparations and boiler pipe applications.Up to 3 tools can be used at the same time.Scope of delivery:• 1 Boiler <strong>Pipe</strong> <strong>Preparation</strong> Machine BRB 2• 1 Durable storage and shipping case• 1 Mandrel• 3 Clamping sets (Kit 1) or 8 clamping sets (Kit 2)• 1 Tool retainer• 1 Cooling and cutting lubrication KSS-TOP (Code 790 060 226)• 1 Tool set• 1 Operating instructions with spare parts listPneumatic power drive:Power: 0.38 kW (0.52 HP)Air supply requirement: 0.7 m 3 /min at 6 bar (35.3 cfm at 90 PSI)Manufacturer’s warranty can only be given when using the original mobile air unit fromOrbitalum Tools, Code 790 093 060.Application range /CharacteristicsBRB 2 Kit 1 BRB 2 Kit 2[mm] [inch] [mm] [inch]<strong>Pipe</strong> ID 12.75 - 24.00 0.502 - 0.945 19.05 - 46.00 0.750 - 1.811Wall thickness with steel 1 - 8 0.039 - 0.315 1 - 8 0.039 - 0.315Wall thickness with stainless steel(max. OD approx. 40 mm/1.57 inch)1 - 6 0.039 - 0.236 1 - 6 0.039 - 0.236Mandrel Ø 12.75 0.502 19.05 0.750Tool retainer Ø 50 / 19.05 1.97 / 0.75 50 / 19.05 1.97 / 0.75Article Version Code kgBRB 2, Kit 1 Pneumatic drive EU 790 085 001 7.700BRB 2, Kit 2 Pneumatic drive EU 790 085 002 8.40036<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Retrofit kits for BRB 2Retrofit kits are available for both basic machines.Retrofit kit to basic machine 1 consists of:• 7 Clamping sets• 1 Mandrel complete with spindleRetrofit kit to basic machine 2 consists of:• 2 Clamping sets• 1 Mandrel complete with spindleApplication range /CharacteristicsRetrofit kit for BRB 2basic machine 1Retrofit kit for BRB 2basic machine 2[mm] [inch] [mm] [inch]<strong>Pipe</strong> ID 22.10 - 46.00 0.870 - 1.810 12.75 - 21.50 0.500 - 0.850Mandrel Ø 19.05 0.750 12.75 0.500Clamping sets [pieces] 7 2Article Code kgRetrofit kit for BRB 2, basic machine 1 790 085 006 0.835Retrofit kit for BRB 2, basic machine 2 790 085 005 0.371<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>37orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Boiler <strong>Pipe</strong> <strong>Preparation</strong> Machines• Compact design for precise and reproducable weld prep profiles• Maximum performance and lightweight• High-performance coated tool bit with two cutting edges• Quick clamping system for tools with easy adjustment• Adjustable air outlet• Ergonomic handling• Tools adaptable on all BRB machines• Low noise level• Application optimised housing designBRB 4The powerful and durable Boiler <strong>Pipe</strong> Prep Machine. For high-precision and reproducibleweld-prep profiles. Simultaneous facing, beveling, counterboring and axial-turning ofpipes made from high-alloy steel (stainless steel), low-alloy and carbon steel with theunique tool system QTC ® . Designed for pipe end preparations and boiler pipe applications.Up to 3 tools can be used at the same time. Pneumatic or electric drive available.Scope of delivery:• 1 Boiler <strong>Pipe</strong> <strong>Preparation</strong> Machine BRB 4• 1 Durable storage and shipping case• 1 Cooling and cutting lubrication KSS-TOP (Code 790 060 226)• 1 Tool set• 1 Operating instructions with spare parts listBRB 4ElectricdriveBRB 4PneumaticdriveAdditionalScope of deliveryClamping setsClamping range[pieces][mm][inch]BRB 4Kit 14--19.1 - 33.8--0.752 - 1.330--BRB 4Kit 2-3--32.0 - 61.7--1.260 - 2.429-BRB 4Kit 3-33-32.0 - 61.759.4 - 110.8-1.260 - 2.4292.339 - 4.362BRB 4Kit 443-19.1 - 33.832.0 - 61.7-0.752 - 1.3301.260 - 2.429-BRB 4Kit 543319.1 - 33.832.0 - 61.759-4 - 110.80.752 - 1.3301.260 - 2.4292.339 - 4.362Threaded spindle M8 M8 M8 M8 M8Clamping disc ØMandrel ØTool support Ø[mm][inch][mm][inch][mm][inch]18.8-0.740-19.05-0.750-68 / 19--2.677 / 0.748---30.0-1.181-31.50-1.240-68 / 27--2.677 / 1.063--30.0-1.181-31.50-1.240--120 / 27--4.724 / 1.06318.830.00.7401.18119.0531.500.7501.24068 / 1968 / 27-2.677 / 0.7482.677 / 1.063-18.830.00.7401.18119.0531.500.7501.24068 / 1968 / 27120 / 272.677 / 0.7482.677 / 1.0634.724 / 1.063Electric drive with single-phase AC motor:Power: 1.2 kW (1.63 HP)Protection class II (double insulated)Built-in electronic variable cutting speed: 35 - 120 rpm38<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Pneumatic power drive:Power: 1 kW (1.36 HP)Air supply requirement: 1 m 3 /min at 6 bar (35.3 cfm at 90 PSI)Speed: 50 - 110 rpmManufacturer’s warranty can only be given when using the original mobile air unit fromOrbitalum Tools, Code 790 093 060.Application range BRB 4, Kit 1 BRB 4, Kit 2 BRB 4, Kit 3 BRB 4, Kit 4 BRB 4, Kit 5<strong>Pipe</strong> ID[mm] 19.1 - 33.8 32.0 - 61.7 32.0 - 110.8 19.1 - 61.7 19.1 - 110.8[inch] 0.752 - 1.330 1.260 - 2.429 1.260 - 4.370 0.752 - 2.429 0.752 - 4.362<strong>Pipe</strong> OD[mm] 64.0 73.0 114.3 73.0 114.3[inch] 2.51 2.87 4.50 2.87 4.50Wall thickness [mm] 2.0 - 15.0 2.0 - 15.0 2.0 - 15.0 2.0 - 15.0 2.0 - 15.0min - max. [inch] 0.079 - 0.590 0.079 - 0.590 0.079 - 0.590 0.079 - 0.590 0.079 - 0.590Article Version Code kgBRB 4, Kit 1 230 V, 50 Hz EU 790 086 011 15.000BRB 4, Kit 1 110 V, 50 Hz EU 790 086 021 15.000BRB 4, Kit 2 230 V, 50 Hz EU 790 086 012 16.000BRB 4, Kit 2 110 V, 50 Hz EU 790 086 022 16.000BRB 4, Kit 3 230 V, 50 Hz EU 790 086 013 17.000BRB 4, Kit 3 110 V, 50 Hz EU 790 086 023 17.000BRB 4, Kit 4 230 V, 50 Hz EU 790 086 014 18.000BRB 4, Kit 4 110 V, 50 Hz EU 790 086 024 18.000BRB 4, Kit 5 230 V, 50 Hz EU 790 086 015 19.000BRB 4, Kit 5 110 V, 50 Hz EU 790 086 025 19.000BRB 4, Kit 1 Pneumatic drive EU 790 086 001 14.000BRB 4, Kit 2 Pneumatic drive EU 790 086 002 15.000BRB 4, Kit 3 Pneumatic drive EU 790 086 003 17.000BRB 4, Kit 4 Pneumatic drive EU 790 086 004 16.600BRB 4, Kit 5 Pneumatic drive EU 790 086 005 18.600Retrofit kits for BRB 4Retrofit kits for pneumatic and electric drive consisting of:Scope of delivery /Application rangeKit 1 to Kit 4Kit 1 to Kit 3Kit 2 to Kit 1 / Kit 3 to Kit 1Kit 2 to Kit 3 / Kit 4 to Kit 5Kit 1 to Kit 5Kit 3 to Kit 2Mandrel Ø Tool support Ø Extension of dimensionto pipe IDExtension of dimensionto pipe OD max.[mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch]-31.50-31.5019.05----31.50---1.240-1.2400.750----1.240--68.0--110.868.0--110.868.0110.868.0-2.677--4.3622.677--4.3622.6774.3622.677-19.1 - 61.7 0.752 - 2.429 70.0 2.75619.1 - 110.8 0.752 - 4.362 114.3 4.50019.1 - 61.7 0.752 - 2.429 70.0 2.75632.0 - 120.0 1.260 - 4.724 114.3 4.50019.1 - 120.0 0.752 - 4.724 114.3 4.50032.0 - 110.8 1.260 - 4.362 114.3 4.500Article Code kgKit 1 to Kit 4 790 086 051 2.600Kit 1 to Kit 3 790 086 052 3.700Kit 2 to Kit 1 / Kit 3 to Kit 1 790 086 053 1.900Kit 2 to Kit 3 / Kit 4 to Kit 5 790 086 054 1.900Kit 1 to Kit 5 790 086 055 4.200Kit 3 to Kit 2 790 086 056 0.700<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>39orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Accessories for BRB machinesTool support Ø 90 mm (3.543 inch)For Mandrel Ø 31.5 mm (1.240 inch)Article Code kgTool support Ø 90 mm (3.543 inch) 790 086 207 1.100Tool holder WH for I-prepWith torx screw.Combination possibilities of tool holder and multifunctional tools, see page 49.ArticleApplicable withBRB typeHeight[mm]Height[inch]WH5-I BRB 2 10 0.394 790 085 230 0.005WH4-I* BRB 2 10 0.394 790 085 234 0.033WH12-I BRB 4 20 0.787 790 086 210 0.035WH15-I BRB 4 20 0.787 790 092 202 0.100WH15-I BRB 4 27 1.063 790 092 204 0.100* Special tool holder for facing pipes in pipe plates.CodekgAdjustable tool holder WH for I-prepCombination possibilities of tool holder and multifunctional tools, see page 49.Scope of delivery:• Adjustable tool holder• Multifunctional tool MFW 15-V / I-4 (Code 790 093 037)• Torx screws• Adjusting platesArticleApplicable withBRB typeHeight[mm]Height[inch]WH15-I BRB 4 16.5 - 23 0.650 - 0.906 790 093 410 0.247CodekgTool holder WH for V- and Y-prepWith Torx screw.Combination possibilities of tool holder and multifunctional tools, see page 49.Article Applicable with BRB type Code kgWH5-V-30° BRB 2 790 085 236 0.015WH12-V-30° BRB 4 790 086 214 0.040WH12-V-37.5° BRB 4 790 086 216 0.115WH12-V-80° BRB 4 790 093 462 0.048WH12-V-35° BRB 4 790 086 272 0.100WH15-V-30° BRB 4 790 092 210 0.100WH15-V-37.5° BRB 4 790 092 216 0.100WH15-V-60° BRB 4 790 092 212 0.10040<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Tool holder WH for U-prepWith Torx screw. Combination possibilities of tool holder and multifunctional tools, see page 49.Article Applicable with BRB type Code kgWH5-U-20° BRB 2 790 085 228 0.014WH12-U-10° BRB 4 790 086 208 0.044WH12-U-20° BRB 4 790 086 224 0.047WH12-U-25° BRB 4 790 086 212 0.051WH30-U-7° BRB 4 790 093 408 0.206WH30-U-10° BRB 4 790 093 220 0.174WH30-U-20° BRB 4 790 093 218 0.184Tool holder WH for counterboringWith Torx screw. Combination possibilities of tool holder and multifunctional tools, see page 49.Article Applicable with BRB type Code kgWH5-ID-14°, 10 mm (0.394") deep BRB 2 790 085 232 0.017WH5-ID-14° BRB 4 790 093 406 0.139WH5-ID-45° BRB 4 790 086 218 0.160WH10-ID-14° BRB 4 790 093 402 0.170WH10-ID-14°, 30 mm (1.181") deep BRB 4 790 093 466 0.155WH12-ID-10° BRB 4 790 086 274 0.042Tool holder WH for cutting tubes from tube sheetsWith Torx screw. Combination possibilities of tool holder and multifunctional tools, see page 49.Article Applicable with BRB type Code kgWH10-ID-80° BRB 2 / BRB 4 790 086 275 0.075Tool holder WH for cutting tubes from tube sheetsWith Torx screw. Combination possibilities of tool holder and multifunctional tools, see page 49.Article Applicable with BRB type Code kgWH5-ID-45° BRB 2 / BRB 4 790 086 218 0.155Multifunctional tool MFWFor pipe wall thickness up to 6 mm (0.236 inch)Two-sided tool bit with high-performance Balinit ® Futura protective coating against toolwear. For high-alloy steel (stainless steel) low-alloy steel, carbon steel and cast iron pipes.Article Applicable with WH Applicable with BRB type Code kgMFW5-V / I-2 WH5-I and WH5-U-20° BRB 2 790 085 030 0.155<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>41orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Multifunctional tool MFWFor pipe wall thickness up to 3 mm (0.118 inch)Two-sided tool bit with high-performance Balinit ® Futura protective coating against toolwear. For high-alloy steel (stainless steel) low-alloy steel, carbon steel and cast iron pipes.Article Applicable with WH Applicable with BRB type Code kgMFW4-I-2 WH4-I-2 (special tool holder) BRB 2 790 085 031 0.002Multifunctional tool MFWFor pipe wall thickness 2 up to 15 mm (0.079 - 0.591 inch)Four-sided tool bit with high-performance Balinit ® Futura protective coating against toolwear. For high-alloy steel (stainless steel) low-alloy steel, carbon steel and cast iron pipes.Article For weld prep profiles Applicable with BRB type Code kgMFW15-V / I-4 V-, Y-, I-preps BRB 4 790 093 037 0.055Multifunctional tool MFWFor pipe wall thickness 2 up to 10 mm (0.079 - 0.394 inch)Two-sided tool bit with high-performance Balinit ® Futura protective coating against toolwear. For high-alloy steel (stainless steel) low-alloy steel, carbon steel and cast iron pipes.Article For weld prep profiles Applicable with CodekgBRB typeMFW12-V / I-2 V-, Y-, I- and U-preps with a prepradius 1.2 mm (0.047 inch)BRB 4 790 086 060 0.025Multifunctional tools MFWFor counterboring IDTwo-sided tool bit with high-performance Balinit ® Futura protective coating against toolwear. For high-alloy steel (stainless steel) low-alloy steel, carbon steel and cast iron pipes.Article Applicable with WH Applicable with CodekgBRB typeMFW5-ID-2-R0.4 (14°) WH5-ID-14° with a prep BRB 4 790 093 039 0.003radius 0.4 mm (0.016 inch)MFW5-ID-2-R0.4 (45°) WH5-ID-45° BRB 4 790 086 061 0.002MFW10-ID-2-R0.4 (80°) WH10-ID-80° BRB 4 790 086 062 0.00242<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> Machines• Compact design for precise and reproducable weld prep profiles• Quick-Tool-Change QTC ®• Square and burr-free• High-performance coated tool bit with two or four cutting edges• Sturdy construction• Tools adaptable on all REB machines• Optimised performance and ergonomic drive system• Portable with an integral carrying handleREB 6, REB 14, REB 20The powerful pipe end preparation solution. For high-precision and reproducible weldprepprofiles on high-alloy steel (stainless steel), low-alloy and carbon steel pipes with theunique tool system QTC ® . Up to 4 tools can be used at the same time.Scope of delivery:• 1 <strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> Machine REB 6, REB 14 or REB 20• 1 Transportation box• 1 Clamping chuck (REB 6 and REB 14) or 2 clamping chucks (REB 20)• 5 Clamping sets, each with 3 clamping wedges (REB 6) or6 Clamping sets, each with 3 clamping wedges (REB 14 and REB 20)• 1 Tool set• 1 Cooling and cutting lubrication KSS-TOP (Code 790 060 226)• 1 Operating instructions with spare parts listREB 6 ElectricPneumatic power drive:Power: 1.8 kW (2.45 HP)Air supply requirement: 2 m 3 /min at 6 bar (70.6 cfm at 90 PSI)Nominal speed range: REB 6: 0 - 26 rpm, REB 14: 0 - 13 rpm, REB 20: 0 - 13 rpmREB 14 PneumaticManufacturer’s warranty can only be given when using the original mobile air unit fromOrbitalum Tools, Code 790 093 060.Electric drive with single-phase AC motor (only REB 6 and REB 14):Power: 1.2 kW (1.63 HP)Built-in electronic variable cutting speed: REB 6: 10 - 32 rpm, REB 14: 5 - 16 rpmApplication range* <strong>Pipe</strong> ID Wall thickness s <strong>Pipe</strong> OD[mm] [inch] [mm] [inch] [mm] [inch]REB 6 min. 49 1.93 3 0.12 56 2.20max. 159 6.26 22 0.87 168 6.61REB 14 min. 92 3.62 4 0.16 100 3.94max. 320 12.60 30 1.18 355.6 14.00REB 20 min. 282 11.10 4 0.16 290 11.42max. 500 19.69 10 0.39 508 20REB 20 Pneumatic* It is possible to extend the dimensions by using the optional clamping wedges (accessories).Article Version Code kgREB 6 Pneumatic drive EU 790 093 001 32.000REB 6 230 V, 50/60 Hz EU 790 093 002 35.000REB 14 Pneumatic drive EU 790 094 001 61.000REB 14 230 V, 50/60 Hz EU 790 094 002 64.000REB 20 Pneumatic drive EU 790 094 010 70.000<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>43orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com

Accessories for REB machinesTool holder WH for I-prepWith Torx screw. Combination possibilities of tool holder and multifunctional tools, see page 49.ArticleHeight[mm]Height[inch]WH15-I 20 0.787 790 092 202 0.100WH15-I 27 1.063 790 092 204 0.100WH30-I 20 0.787 790 093 202 0.166WH30-I 27 1.063 790 093 204 0.235CodekgAdjustable tool holder WH for I-prepCombination possibilities of tool holder and multifunctional tools, see page 49.Scope of delivery:• Adjustable tool holder• Multifunctional tool MFW 15-V / I-4 (Code 790 093 037)• Torx screws• Adjusting platesArticleHeight[mm]Height[inch]WH15-I 16.5 - 23 0.650 - 0.906 790 093 410 0.247CodekgTool holder WH for V- and Y-prepWith Torx screw. Combination possibilities of tool holder and multifunctional tools, see page 49.Article Code kgWH12-V-80° 790 093 462 0.115WH15-V-30° 790 092 210 0.100WH15-V-37.5° 790 092 216 0.100WH15-V-60° 790 092 212 0.100WH30-V-15° 790 093 468 0.200WH30-V-30° 790 093 210 0.192WH30-V-32.5° 790 093 424 0.234WH30-V-37.5° 790 093 216 0.199WH30-V-45° 790 093 404 0.204WH30-V-25° 790 093 476 0.206Tool holder WH for U-prepWith Torx screw. Combination possibilities of tool holder and multifunctional tools, see page 49.Article Code kgWH30-U-7° 790 093 408 0.206WH30-U-10° 790 093 220 0.174WH30-U-20° 790 093 218 0.184WH30-U-14° 790 093 474 0.174WH30-U-25° 790 093 478 0.16544<strong>Pipe</strong> <strong>End</strong> <strong>Preparation</strong> <strong>Technology</strong>orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com