High-strength Low-alloy Heat-treatable Steels with Good Enamel ...

High-strength Low-alloy Heat-treatable Steels with Good Enamel ...

High-strength Low-alloy Heat-treatable Steels with Good Enamel ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

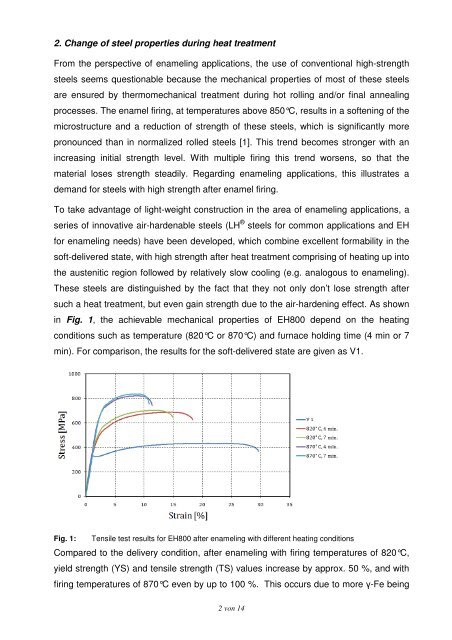

2. Change of steel properties during heat treatmentFrom the perspective of enameling applications, the use of conventional high-<strong>strength</strong>steels seems questionable because the mechanical properties of most of these steelsare ensured by thermomechanical treatment during hot rolling and/or final annealingprocesses. The enamel firing, at temperatures above 850°C, results in a softening of themicrostructure and a reduction of <strong>strength</strong> of these steels, which is significantly morepronounced than in normalized rolled steels [1]. This trend becomes stronger <strong>with</strong> anincreasing initial <strong>strength</strong> level. With multiple firing this trend worsens, so that thematerial loses <strong>strength</strong> steadily. Regarding enameling applications, this illustrates ademand for steels <strong>with</strong> high <strong>strength</strong> after enamel firing.To take advantage of light-weight construction in the area of enameling applications, aseries of innovative air-hardenable steels (LH ® steels for common applications and EHfor enameling needs) have been developed, which combine excellent formability in thesoft-delivered state, <strong>with</strong> high <strong>strength</strong> after heat treatment comprising of heating up intothe austenitic region followed by relatively slow cooling (e.g. analogous to enameling).These steels are distinguished by the fact that they not only don’t lose <strong>strength</strong> aftersuch a heat treatment, but even gain <strong>strength</strong> due to the air-hardening effect. As shownin Fig. 1, the achievable mechanical properties of EH800 depend on the heatingconditions such as temperature (820°C or 870°C) and furnace holding time (4 min or 7min). For comparison, the results for the soft-delivered state are given as V1.Fig. 1: Tensile test results for EH800 after enameling <strong>with</strong> different heating conditionsCompared to the delivery condition, after enameling <strong>with</strong> firing temperatures of 820°C,yield <strong>strength</strong> (YS) and tensile <strong>strength</strong> (TS) values increase by approx. 50 %, and <strong>with</strong>firing temperatures of 870°C even by up to 100 %. This occurs due to more γ-Fe being2 von 14