Surtronic 3+

Surtronic 3+

Surtronic 3+

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

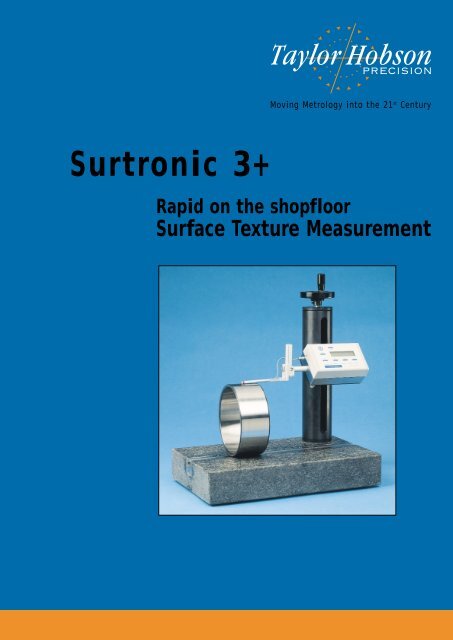

Moving Metrology into the 21 stCentury<strong>Surtronic</strong> <strong>3+</strong>Rapid on the shopfloorSurface Texture Measurement

SURTRONIC <strong>3+</strong>S I M P L E , A C C U R A T E A N D V E R S A T I L ETotal portability for workshopor laboratoryFast, simple operationAccurate and versatileSelectable range ofparameters, cut-off lengthsand filtering(see specifcation for fulldetails)Software analysis optionsData processing optionsMulti-language selectionBattery powered andcompletely self-contained<strong>Surtronic</strong> <strong>3+</strong> combines advanced technologywith high precision and value to giveeffective measurement of surface finish inthe workshop, inspection room or laboratory.With <strong>Surtronic</strong> <strong>3+</strong>, users across a wide rangeof skills can become proficient withinminutes. Operating functions are minimal,measurement cycles are short and output isavailable from a built-in LCD display orvarious printer options.The measurement process and operation issimplicity itself, the entire cycle beingcontrolled from a wipe-clean membranetouch key panel, via ‘walk through’ menuselections.The instrument is usable on horizontal,vertical or inclined surfaces, or with selectedaccessories as a bench mounted system forlaboratory or batch measurementapplications. The pick-up holder is mountedon a slide for vertical adjustment and can berotated to different measuring positions,including right-angled measurement.<strong>Surtronic</strong> <strong>3+</strong> is powered by NiCAD batteriesor through an optional mains adaptor.The portable format of the <strong>Surtronic</strong> <strong>3+</strong>renders it particularly useful for measuringsurface texture on bores and inaccessibleparts which are unsuitable for conventionalmeasuring instruments.

ENHANCED MEASUREMENT AND ANALY S IS OPTIO N SData Processing ModuleFor Enhanced Measurement with <strong>Surtronic</strong> <strong>3+</strong>Comprehensive Analysis FunctionsWide Range of ParametersAllows Customised System ConfigurationAlphanumeric and Graphical OutputIntegral PrinterThe Data Processing Module converts <strong>Surtronic</strong> <strong>3+</strong> into acomprehensive measurement and analysis unit with a widerange of capabilities.T he Data Pro c e s s i ng Mo dule is de s ig ned specifically fo roperation in production environments. It is battery or mainsoperated, totally portable and connects directly to the<strong>Surtronic</strong> <strong>3+</strong> via the RS232 port.The Data Processing Module has an integral thermal printerfor hard copy output of measured profiles and results lists.Results can be saved onto a Memory Card for further analysison either the Data Processing Module or Talyprofile software.Analysis options are displayed in theform of ic o ns on screen. Me nu optio ns,system opera t ion and print are selectedu s i ng the me m b ra ne key pads. In add i t io nto a wide ra nge of int e r na t io na lroughness parameters, bearing ratio,t he Rk family and amplitude distributio ncurves can be printed when includedby the use of Macro Maker Software.• Simple, easy programming routine• Increases Flexibility of Data ProcessingModule• Allows Single Button OperationOptional Macro-Maker software for programming theData Processing Module allows single button sequentialmeasurement, significantly saving inspection time andreducing the skill required for component inspection onthe shop floor.A number of “Macros” can be configured to control individualmeasurement and analysis cycles, using a PC loaded with theMacro-Maker software.Macro Maker SoftwareA number of ma c ros can then be stored on a me mory card (via a Fre eStanding PC MCIA Memory Card Drive) and simply uploaded into the DataProcessing Module. This allows the <strong>Surtronic</strong> <strong>3+</strong> to be used as a totallyflexible measuring station tailored to suit operator, shift or customerrequirements.A complete analysis cantherefore be carried out withthe touch of a single key,with no settings required,and is of particular benefitfor on-the-spot qualitychecks on machine tools.

SURTRONIC ACCESSORIESAccessoriesReplica Kit (Code 112/727)Contains prepared quantities of materialsfor pro duc i ng re p l icas of surfaces ina c c e s s i b l efor direct measurement.UKAS CertificationThe calibration standards can be suppliedwith a United Kingdom Ac c re d i t a t io nService (UKAS) certificate, which gives atraceable guarantee of its accuracy.Detachable Skid ( C o de 112/1191)Clamped to the pick-up body, this accessoryenables the Datum Support Stand to beused with standard, recess, right angleand chisel edge pick-ups.Datum Support Stand(Code 112/865)Provides an independent straight datumwhere the surface is too short toa c c o m mo date the stylus and skid of thes mall bore pick-up. May also be used witho t her pick-ups fitted with the detachable skid.B a l lJo i ntV ic e( C o de 112/2695-01)Comprising a surface mounted swivel baseand a wide jaw vice. Suitable for holdingirregular shaped components.Vice Dimensions: Overall length 280mmJaw Width 54mmJaw Opening 160mmRoll and Bore Fixture(Code 112/1509)This fixture allows the <strong>Surtronic</strong> <strong>3+</strong> to bemounted onto cylindrical components.Impact Printer(Code B112/2390-01)Output includes all measuring conditionssuch as cut-off selected, traverse length,filter and selected parameter results. Theprinter also outputs a range of horizontaland vertical magnification settings forscaling of the graphical outputs.Precision Vice (Code 112/2694-01)H igh quality pre c i s ion vice ideal for ho l d i ngfinished components.Dimensions: Jaw WidthJaw Opening70mm80mmPick-up Lift (Code 112/1525)Used to lift the stylus clear of the workpie c eafter me a s u re me nt and to retain the pic k - u parm in a raised position, preventing thearm fa l l i ng onto the workpiece and da ma g i ngthe surface or stylus tip.Extension Rod( C o de 112/1533 100mm leng t h ,112/1510 200mm length)Provides 100mm (3.9in) or 200mm (7.8in)extension to pick-up penetration formeasurement in deep hole.Portable Base (Code 137/1734)Provides a support when used on machinetool applications and away from theme a s u r i ng ro o m .Mains AdaptorCodeB112/1594 US-110V112/1551 UK112/1595 Euro-230V 2 pinEnables instrument to be powered fromthe mains supply.

Support Stand (Code 112/1517)Converts <strong>Surtronic</strong> <strong>3+</strong> into a bench mounted instrument, particularlyuseful w hen che c k i ng small bores and for re p e t i t i v emeasurement.A swivel platform can be rotated and angled to keep the pick-uptraverse parallel to the measured surface.Column and Stand (see cover pho t o )( C o de 112/2693)Comprising a granite base and manually operated column withadjustment height of 260mm.<strong>Surtronic</strong> <strong>3+</strong> Additional Feature OptionsThe <strong>Surtronic</strong> <strong>3+</strong> also offers additional f e a t u res to further enhance thep e r fo r ma nc eof the instrument (please note that these features mustbe requested at the time of your <strong>Surtronic</strong> <strong>3+</strong> order):Parameter OptionsO ne of the fo l l o w i ng add i t io nal para meters can be purchased separa t e l y :• Pc (this parameter is provided in place of the Sm parameter)• tp% (this parameter is provided in place of the Rq parameter)Lock-out OptionThis feature gives the operator or supervisor t he capability to “lock-out”t he ins t r u me nt o p t io ns such as para meter selectio ns and c u t - of f sw h ich are not re q u i re d, thu s a l l o w i ng simple push-buttono p e ra t io n with no set up required.Parameter and Lock-out Combination OptionsThe above options can also be ordered in combination, allowings i ngle push-button opera t ion with pre v iously unavailable para me t e r s.Pick-Ups for <strong>Surtronic</strong> 360.860.860.860.2S t a n d a rd Pick-up (Code 112/1502)For ge ne ral surface ro u g h ne s sme a s u re me t. n Tip radius 5µm (200µin).Alternative Standard Pick-up(Code 112/1503)Has a 10µm (400µin) tip ra d i u s.C o n fo r ms to US specific a t ion ANSI.Small Bore Pick-up (Code 112/1504)For general use in small bores,grooves and on narrow surfaces.2µm tip radius version is alsoavailable (code 112/2673).62.960.660.7Right Angle Pick-up(Code 112/1505)For measurement at right angles tothe direction of traverse.Recess Pick-up (Code 112/1506)For measuring at the bottom of arecess or between shoulders andf l a nges up to 5.7mm (0.23in) deep.A 2µm tip radius version is available( c o de 112/2672). A 25mm (1in) de e precess pick-up is also available.Chisel Edge Pick-up(Code 112/1524)For me a s u r i ng along sharp edges orw i re. Not for use on flat surfa c e s.1.0Narrow Gauge Stylus(Code S11610)For me a s u r i ng in ‘O’ rings and na r ro wgrooves up to a depth of 5.5mm(0.22in).PLEASE NOTE: All Pick-ups have a 5µm(200µin) tip radius unlessotherwise specified.66.1Side Skid Pick-up (Code 112/1531)For use on curved surfaces such asgear teeth.Shoe Pick-up (Code 112/1599)For measuring rougher surfaces,particularly with the 2.5mm (0.1in)cut-off.

TALYPROFILE SOFTWARE FOR WINDOWSData Processing Module, and<strong>Surtronic</strong> <strong>3+</strong> CompatibilityExtended Analyses fromGraphical DisplaysReport ConfigurationFunctionsProfile ManipulationFacilities2CR ISO, 2CR Phase correctedand Gaussian Filter SelectionTalyprofile for WindowsTalyprofile for windows is a dedicatedsoftware package designed to be simple touse - whether in a workshop or laboratoryenvironment.The software has many advanced featureswhich make it the ideal package for themeasurement of profiles.User friendly interfaceThe software is visually advanced andprovides clear on screen profile images.It works using three concepts; the bank ofprofiles, the operators and the studies.The bank of profilesThe bank allows users to store any profile inthe computer’s memory, regardless of whetherit has been measured, loaded from disc orgenerated from an operator. The bank alsoallows the user to return to the profile at anylater time and make further analyses.The operatorsThese start from a measured profile and thenallow the user to modify it. For example, thezoom function will take a piece of the profileand study it separately. The form removal willflatten out a profile measured on a curvedpiece.The studiesThese analyse and visualise the profile. Eachstudy can easily be tailored using thebuttons panel on the menu bar.With these 3 concepts understood, thesoftware is straightforward and intuitiveto use.Desk top publishing facilityTalyprofile for Windows offers an additionaldesk top publishing function which allowclear presentation of measurements.Results of any analysis are automatically setinto pages and every set of numerical results,curves and profiles is saved inside a framewhich can be easily moved around the screenusing the mouse.The final document created can have textadded to incorporate comments, arrows andrings to link and emphasise details. It is alsopossible to add other images or spreadsheetsusing the copy and paste function.A nalysis Ac c e s s o r ie sFree Standing Memory Card Drive, Code B112/2580Required to load Macro Maker programmes into the Data Processing Module and to further analyseresults using Talyprofile software.Memory Card (256Kb), Code B112/2581Memory Card for use in the Data Processing Module.

S p e c i f i c a t i o nThe <strong>Surtronic</strong> <strong>3+</strong> System Includes:• Display and Traverse Unit• P ick-up and Dia mo nd Stylus• Calibration Standard• Carrying Case• Battery• HandbookT e c h n i c a l D a t aGauge Range ±150µm (0.006in) Resolution 0.01µm (0.4µin)Traverse Length (Max) 25.4mm (1.0in) Tra ve rse Length (min) 0.25mm (0.01in)Pick up typeVariable reluctanceStylus 112/1502: Diamond tip radius 5µm (200µin) Traverse Speed 1mm/sec (0.04in/sec)112/1503: Diamond tip radius 10µm (400µin)Cut Off Values 0.25, 0.8, 2.5, 8mm (0.01, 0.03, 0.1, 0.3in) Accuracy of 2% of reading + LSD µm(8mm Cut off only available when usingTalyprofile or Macro-Maker Software)ParametersParameters Ra, Rq, Rz (DIN), Ry, Sm, Rt Power Battery or Mains (optional)Optional additional Pc (in place of Sm), tp% (in place of Rq) Graphical studies Waviness + Roughness curves, withparameters - with optional EPROM available on request interactive selection of type offilter and cut-off, GraphicalParameters supplied with RA, RV, Rp, Rt. Rq, Ry, Rpm, Rz (DIN), RzJIS, studies of R&WData Processing Module Ir, Sm, Rsk, Rku, S, Pc, HSC, Rk, Rpk, Rvk, Mr1, Mr2, (ISO 12085): roughness andA1, A2, Rpk, Rvk, R, Rmax, Ar, Pt, Kr, tp%, Htp, Vo. waviness motifs, upper envelopeGraphical study of Rk (DIN 4776and ISO 13565-2 standards)Display of intermediate profilesParameters suplied with Roughness parameters obtained by filtering: Ra, Rq, used to compute Rk,Talyprofile Windows Rt, Rp, Rv, Rku, Rsk, RSm, Rz, R∆q, RTp, RHTp, Rlo, Interactive Abbott Curve,Rλq, RPC, RzJIS, R3z.Bearing Ratio Curve of ISOWaviness parameters obtained by filtering: Wa, Wq,13565 standard (Rk), ComputationWt,Wp, Wv, Wku, Wsk, WSm, Wz, WzJIS, Wλq, W∆q, WTp,profiles of ISO 13565 standardWHTp, WLo, WPC, W3z.(Rk), Volume of a hole andParameters on the raw profile (unfiltered): Pa, Pq,the associated rejected materialPt, Pp, Pv, Pku, Psk, PSm, Pz, P∆q, Pλq, PTp, PHTp,Distance, difference in height,PLo, PPc.slope between two points,Parameters obtained by double filtering (DIN 4776):Spectral analysis using FourierRk, Rpk, Rvk, MR1, MR2, A1, A2, Rpk, Rvktransform, Averaged SpectralParameters obtained by the motifs method ("R&W"):Density.R, AR, Pt, Rx, SR, SAR, Nr, Kr, W, AW, Wte, Wx, SW,SAW, Nw, Kw, Rke, Rpke, Rvke, Trc, HTrc.Overall Dimensions 130 x 80 x 65mm (5.1 x 3.3 x 2.5in) Weight 450g (1lb)Data Processing Module185 x 140 x 50mm (7.5 x 5.5 x 2in)

© DiskArt 1988Internet: www.taylor-hobson.comthe measuringsolutionAt Taylor Hobson we don’t sell products - we providesolutions. Whatever our customers’ measuring needs,we will find a solution to meet them.Our reputation for excellence is based on more than 100years of metrology design and manufacturing experience.Add to this our worldwide coverage, our after salessupport and our commitment to customer care and youhave a company which provides its customers with totalpeace of mind.The Taylor Hobson service:Special applicationsWe have a team of engineers who provide a design servicefor dedicated metrology solutions. This can involvecustomising standard Taylor Hobson instruments to meetspecific requirements or designing unique products.For details of your local support centre phone+44 116 246 3186 or e-mail sales@taylor-hobson.comCentre of excellenceOur Centre of Excellence, based at our headquarters inLeicester, offers:• product and theory training either at our Leicestertraining centre or at our customers’ premises• instrument and metrology advice• a trial measurement service to help you decide whichproduct to buy• lectures and presentationsContact the Centre on+44 116 276 3779 or e-mail cofe@taylor-hobson.comAfter sales supportTo ensure that all our products are maintained to thestandards you require, we offer a range of after salesservice packages. They include an on-site calibrationservice, field service and a refit and upgrade service.We also offer an instrument calibration service at ourUKAS laboratory in Leicester.For details of your local support centre phone+44 116 246 3135 or e-mail service@taylor-hobson.comTaylor Hobson LimitedPO Box 36, 2 New Star Road, Leicester, LE4 9JQ, England.Tel: +44 116 276 3771 • Fax: +44 116 274 1350e-mail: sales@taylor-hobson.comInternet: http://www.taylor-hobson.comTaylor Hobson SA6 avenue de Norvege, Hightec 4,91953 Courtaboeuf Cedex, FranceTel: +33 169 28 53 90 Fax: +33 169 28 33 37e-mail: contact@taylor-hobson.frTaylor Hobson GmbHPostfach 4827, Kreuzberger Ring 665038 Wiesbaden, GermanyTel: +49 611 973040 Fax: +49 611 97304600e-mail: info@taylor-hobson.deTaylor Hobson S.p.A.Via Vigentina 6-820090 Opera, Milan, ItalyTel: +39 0257 606424 Fax: +39 0257 606740e-mail: TaylorITA@compuserve.comTaylor Hobson Liaison OfficeAustria and Eastern EuropeAmalienstrasse 68, A-1130 Vienna, AustriaTel: +43 1877 557112 Fax: +43 1877 860516e-mail: thp@vienna.atTaylor Hobson KKNo 31 Kowa Building 19-1, 3-Chome, ShiroganedaiMinato-Ku, Tokyo 108, JapanTel: +81 33473 7001 Fax: +81 33473 7002e-mail: mail-box@taylor-hobson.co.jpTaylor Hobson K INC402, Hayan Bldg, Samsung Dong,Kangnam-Ku, Seoul 135-091, KoreaTel: +82 2564 0851 Fax: +82 2539 1708e-mail: thkorea@kornet.netTaylor Hobson China Office7/F, Corporation Square, 8 Lam Lok StreetKowloon Bay, Hong KongTel: +85 22757 3033 Fax: +85 22757 1767e-mail: talhobhk@netvigator.comTaylor Hobson IncSuite 350, 2100 Golf Road, Rolling Meadows,Illinois 60008, USA.Tel: +1 847 290 8090 Fax: +1 847 290 1430e-mail: 102167.236@compuserve.comMicrosoft Windows and Windows NT are registered Trademarks of the Microsoft Corporation. Sur 7E 3k CP1099TAYLOR HOBSONA8248 ISO9001