Yale Cable King Wire Electric Hoists - A-Lined Handling Systems

Yale Cable King Wire Electric Hoists - A-Lined Handling Systems

Yale Cable King Wire Electric Hoists - A-Lined Handling Systems

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

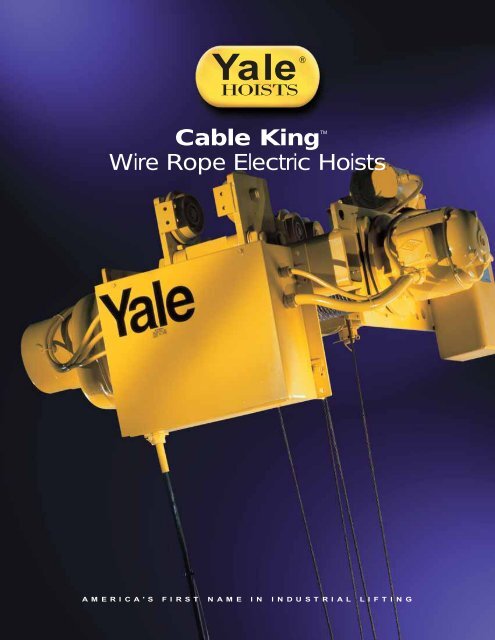

<strong>Yale</strong>®HOISTSTM<strong>Cable</strong> <strong>King</strong><strong>Wire</strong> Rope <strong>Electric</strong> <strong>Hoists</strong>AMERICA'S FIRST NAME IN INDUSTRIAL LIFTING

TM<strong>Cable</strong> <strong>King</strong><strong>Electric</strong> <strong>Wire</strong> Rope <strong>Hoists</strong>Built to last.<strong>Yale</strong> <strong>Cable</strong> <strong>King</strong> hoists have a well-deserved reputation forsuperior performance, low maintenance, and longevity in heavy-dutyapplications. The <strong>Cable</strong> <strong>King</strong> hoist is the result of years ofengineering that builds on time tested designelements that have proven so successful in the past. And inkeeping with our innovative tradition, we incorporatedsome new ones. The result is a hoist line that lives upto our own tough standards of dependabilityand durability. And with the capability oflonger lifts and greater capacities, you’ll finda <strong>Yale</strong> hoist to fit your needs and receivemore value for your investment. When youbuy a <strong>Cable</strong> <strong>King</strong> hoist, you buy it withconfidence that it will be on the job for along time to come.Built to perform.As standard, <strong>Cable</strong> <strong>King</strong> hoists are rated for Class H-4duty and can be configured for Class H-5 duty for moresevere applications. <strong>Cable</strong> <strong>King</strong> hoists are also loaded withstandard features that enhance performance, reducemaintenance costs and increase longevity. Features such as:2One-Piece Welded Steel FramePrecision Spur GearingMachined Steel Rope DrumEnclosed Bottom Blocks with 360° Hook RotationHigh Starting Torque Motor Designed Especially forHoisting ServiceAutomotive-Type Drive Shaft for a smooth running,long-lasting driveWeston Screw-Type Load Brake and Disk-Type ACMotor BrakesWide Variety of ControlsUpper and Lower Adjustable and Upper Block-Operated Control Circuit Limit Switches

With <strong>Yale</strong> hoists,quality is not an option,it is standard.125763Inside the <strong>Cable</strong> <strong>King</strong>Some of the standard features of the <strong>Cable</strong> <strong>King</strong> are:89123456789FrameOne-piece welded steel made from heavy structural shapes provides a rugged, anddurable foundation for precise mounting and alignment of the hoisting machinery.GearingPrecision spur gearing machined from high-alloy steel or drop forgings is casehardened for quiet operation and long life. Gearing operates in a precision machinedductile iron or steel gearcase and is oil bath lubricated.Rope DrumFabricated steel drum machined with grooving cuts up to 50% of the rope’s diameterto guard against the rope jumping out of the groove, which can damage and weakenthe rope.Bottom BlocksEnclosed blocks with 360 degree hook rotation. All hooks provided with a springloaded hook latch as standard.MotorsHigh starting torque made especially for hoisting service.The motors are TENV,30-minute rated with class F insulation and thermostats as standard.Automotive-type drive shaftBorrowing from the automotive industry, <strong>Cable</strong> <strong>King</strong> hoists incorporated a smoothrunning, long-lasting drive shaft for effective power transmission from the motor tothe drive gearing.BrakesWeston screw-type load control brake and disk-type AC motor brake rated at aminimum 125% of the motor’s torque.ControlsOne and two speed and variable frequency housed in a NEMA 12 enclosure asstandard. The 115-volt control circuit is fused.Limit SwitchAs standard an upper and lower adjustable geared control circuit limit switch isprovided along with an upper block-plugging limit switch.3• 1/2 to 35-ton capacity• Designed and built to meet thestandards of HMI, ASME and NEC• Available in monorail, base, and deckmounted and top-running versions• Available for air operation• Available in spark resistant andexplosion proof versionsOptional Features• Non-cataloged lifts and speeds• Hot metal applications• Car shaker applications• Bucket hoists• Marine duty offshore applications• Special paint finishes• Winch applications4

<strong>Cable</strong> <strong>King</strong> Standard and Optional FeaturesGearingPrecision spur machined fromhigh-alloy steel or drop forgingsand case hardened for long life andquiet operation. Gearing operatesin a precision machined ductile ironor steel gearcase and is continuousoil bath lubricated to reducemaintenance and increase life.Mechanical Load BrakeFully automatic in operation andadjustment. Weston design loadcontrol brake operates with orwithout power.<strong>Wire</strong> Rope DrumDrums are fabricated from steeltubing and grooved to a depth ofup to 50% of the rope’s diameterto guard against the rope jumpingout of the groove, which candamage and weaken the rope.Motors<strong>Cable</strong> <strong>King</strong> motors are highstarting torque built especially forhoisting applications. These highquality motors come standard as30-minute rated with Class Finsulation and thermal overloadsbuilt into the windings.AC Motor BrakeThe <strong>Cable</strong> <strong>King</strong> uses an AC-typegearcase mounted disc brake. Itsfeatures include precise loadspotting capabilities and moreefficient power consumption thanother types of hoisting brakes.<strong>Electric</strong>ally released and spring set,the brake operates automaticallyupon loss of power.Upper Block-Operated LimitSwitch (Except Winches)In addition to the geared limit switch,an upper block-operated controlcircuit limit switch is provided asstandard. The limit switch isactivated by the lower block andcontains a reverse plugging featurethat will momentarily reverse thedirection of the hoist if the blockcontinues to travel too high.Geared Limit SwitchHeavy-duty, adjustable gearedupper and lower control circuitlimit switch is standard on all<strong>Cable</strong> <strong>King</strong> hoists.Trolleys<strong>Yale</strong> <strong>Cable</strong> <strong>King</strong> hoists are availablewith hand-push, hand-geared ormotor-driven trolleys for use onwide-flange, I-beam or patentedtrack.4SpaceVector VariableFrequency DrivesOptional variable frequency drivesare available for hoisting andtraverse motions. Variablefrequency drives provide smootheracceleration and deceleration, lessload swing and impact on the drivetrain and allow the motors to runcooler improving load handling andextending equipment life.

A story of innovationIn 1875 Linus <strong>Yale</strong> invented the “Differential Hoist” which started the modernhoisting industry in the United States and the company known today as <strong>Yale</strong> <strong>Hoists</strong>.Since the beginning, <strong>Yale</strong> has been synonymous with quality, durability andinnovation. In 1879, a <strong>Yale</strong> engineer, Thomas Weston, invented the Weston ScrewLoad Brake, a mechanical load control brake, of which modern versions are still theindustry standard today. Since the late 19th Century, scarcely a year has gone bywithout new, better hoists and improved features being introduced. In 1938, FrankLocke, an engineer recruited from the Krupp Works in Germany, developed the<strong>Cable</strong> <strong>King</strong> hoist. The <strong>Cable</strong> <strong>King</strong> was the first large capacity electric wire ropemonorail hoist and is the predecessor of the modern <strong>Cable</strong> <strong>King</strong> line sold today.The momentumthat started over acentury ago continuestoday at the <strong>Yale</strong> facilityin Forrest City, Arkansas. <strong>Yale</strong><strong>Yale</strong> Works, 1920Stamford, Connecticuthoists are used in every country of the world in every kind of application imaginable.Quality, time-tested hoists for standard and special applications are the hallmarks of<strong>Yale</strong>. <strong>Yale</strong> hoists are sold through a worldwide organization of dealers. Parts and<strong>Yale</strong>service depots are found in all major metropolitan areas around the globe. Well intoits second century of existence, <strong>Yale</strong> is committed to maintaining the role as industryinnovator and leader.5

<strong>Yale</strong>®HOISTS!To Avoid Injury:• Do not exceed workingload limit, load rating,or capacity.• Do not use to lift peopleor loads over people.• Read and follow allinstructions.For additional information contact your <strong>Yale</strong> representative or <strong>Yale</strong> headquarters direct.3105 N. Washington • P.O. Box 1000 • Forrest City, Arkansas 72335-1000PH 800-999-6318 or 870-633-2250 • FX 800-766-0223PRINTED IN U.S.A. / COPYRIGHT 1999, YALE ® HOISTS , DIVISION OF COLUMBUS MCKINNON CORPORATION / BULLETIN NO Y/L-1001-1099<strong>Yale</strong> ®HOISTSLFT-347 10-99