OVERHEAD LINE SPLICES

OVERHEAD LINE SPLICES

OVERHEAD LINE SPLICES

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

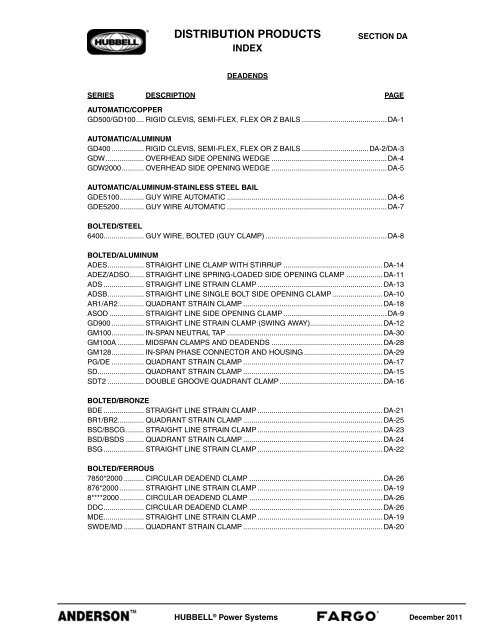

DISTRIBUTION PRODUCTSINDEXSection DAdeadendsSERIES DESCRIPTION PAGEautomatic/copperGD500/GD100.... RIGID CLEVIS, SEMI-FLEX, FLEX OR Z BAILS...........................................DA-1automatic/aluminumGD400................. RIGID CLEVIS, SEMI-FLEX, FLEX OR Z BAILS..................................DA-2/DA-3GDW................... <strong>OVERHEAD</strong> SIDE OPENING WEDGE..........................................................DA-4GDW2000........... <strong>OVERHEAD</strong> SIDE OPENING WEDGE..........................................................DA-5automatic/aluminum-stainless steel bailGDE5100............ GUY WIRE AUTOMATIC................................................................................DA-6GDE5200............ GUY WIRE AUTOMATIC................................................................................DA-7bolted/steel6400.................... GUY WIRE, BOLTED (GUY CLAMP).............................................................DA-8bolted/aluminumADES.................. STRAIGHT <strong>LINE</strong> CLAMP WITH STIRRUP..................................................DA-14ADEZ/ADSO....... STRAIGHT <strong>LINE</strong> SPRING-LOADED SIDE OPENING CLAMP...................DA-11ADS..................... STRAIGHT <strong>LINE</strong> STRAIN CLAMP...............................................................DA-13ADSB.................. STRAIGHT <strong>LINE</strong> SINGLE BOLT SIDE OPENING CLAMP..........................DA-10AR1/AR2............. QUADRANT STRAIN CLAMP......................................................................DA-18ASOD.................. STRAIGHT <strong>LINE</strong> SIDE OPENING CLAMP....................................................DA-9GD900................. STRAIGHT <strong>LINE</strong> STRAIN CLAMP (SWING AWAY)....................................DA-12GM100................ IN-SPAN NEUTRAL TAP..............................................................................DA-30GM100A.............. MIDSPAN CLAMPS AND DEADENDS........................................................DA-28GM128................ IN-SPAN PHASE CONNECTOR AND HOUSING........................................DA-29PG/DE................. QUADRANT STRAIN CLAMP......................................................................DA-17SD....................... QUADRANT STRAIN CLAMP......................................................................DA-15SDT2................... DOUBLE GROOVE QUADRANT CLAMP....................................................DA-16bolted/bronzeBDE..................... STRAIGHT <strong>LINE</strong> STRAIN CLAMP...............................................................DA-21BR1/BR2............. QUADRANT STRAIN CLAMP......................................................................DA-25BSC/BSCG.......... STRAIGHT <strong>LINE</strong> STRAIN CLAMP...............................................................DA-23BSD/BSDS.......... QUADRANT STRAIN CLAMP......................................................................DA-24BSG..................... STRAIGHT <strong>LINE</strong> STRAIN CLAMP...............................................................DA-22bolted/ferrous7850*2000........... CIRCULAR DEADEND CLAMP...................................................................DA-26876*2000............. STRAIGHT <strong>LINE</strong> STRAIN CLAMP...............................................................DA-198****2000............. CIRCULAR DEADEND CLAMP...................................................................DA-26DDC.................... CIRCULAR DEADEND CLAMP...................................................................DA-26MDE.................... STRAIGHT <strong>LINE</strong> STRAIN CLAMP...............................................................DA-19SWDE/MD........... QUADRANT STRAIN CLAMP......................................................................DA-20HUBBELL ® Power Systems December 2011

DISTRIBUTION PRODUCTSINDEXSection DADEADENDScontinuedSERIES DESCRIPTION PAGETHIMBLE/ALUMINUMADET................... ALUMINUM DEADEND THIMBLE...............................................................DA-27THIMBLE/DUCTILE-IRONDDT..................... DUCTILE DEADEND THIMBLE...................................................................DA-27ALUMINUMMSE.................... ALUMINUM MID-SPAN CONNECTOR........................................................DA-32MSN.................... ALUMINUM MID-SPAN CONNECTOR........................................................DA-31MSNT.................. ALUMINUM MID-SPAN CONNECTOR........................................................DA-31TTSB................... ALUMINUM SUPPORT BRACKET..............................................................DA-32December 2011HUBBELL ® Power Systems

• Fastest method of deadending Copper and Copperweld ®conductor.• Flared mouth of gripping unit permits easy conductorinstallation.• Four segment jaw is precision machined andautomatically adjusts to the contour of the wire.• High strength alloy copper tube for gripping Copperweld ®conductors• Available with galvanized steel stirrup clevis or stainlesssteel Z bail for primary applications.Material: Shell – High strength Copper AlloyJaws – Copper AlloyClevis Bail – Galvanized steelZ Bail – Stainless Steel, formed wireFlex Bail – Braided stainless steelSemi-flex Bail – Stainless Steel, formed wireDISTRIBUTION CONNECTORSDEADENDSAUTOMATICCOPPERSECTION DACOPPERGD500/GD100DA1CLEVISBAILCATALOG NUMBERZBAILFLEXBAILSEMI-FLEXBAILSOLIDASTM-B258CONDUCTOR RANGECOPPERSTRANDASTM-B8COPPERWELDSTRANDAPPROXIMATECONDUCTOR O.D.INCHES (MM)- - GD110 GD110R 8 - - .12-.13 (3.1-3.3)GD511 GD111Z GD111 GD111R 6 - - .16-.17 (4.0-4.4)GD512 GD112Z GD112 GD112R 4 - 8A .19-.20 (4.9-5.2)GD513 GD113Z GD113 GD113R 3 4 6A .22-.23 (5.7-5.9)GD514 GD114Z GD114 GD114R 2 3 5A .25-.26 (6.3-6.6)GD515 GD115Z GD115 GD115R 1 2 4A .28-.29 (7.2-7.4)GD516 GD116Z GD116 GD116R 1/0 1 3A .32-.33 (8.1-8.3)GD517 GD117Z GD117 GD117R 2/0 1/0 2A .36-.37 (9.1-9.3)GD518 GD118Z GD118 GD118R 3/0 2/0 - .40-.41 (10.2-10.5)GD519 GD119Z GD119 GD119R 4/0 3/0 - .45-.46 (11.5-11.8)GD520 GD120Z GD120 GD120R - 4/0 - .52-.53 (13.2-13.4)GD521 GD121Z GD121 GD121R - 250 KCMIL - .57-.58 (14.4-14.7)GD523 - - - - 300 KCMIL - .62-.63 (15.8-16.1)HUBBELL ® Power SystemsDA-1December 2011

DA2SECTION DAALUMINUMGD400Z BailGrippingUnit Retaining WasherBBYokeFlex BailAAClevis PinBailCotter PinGrippingUnitDISTRIBUTION CONNECTORSRetainingWasherClevis Washer(GD447 only)BBDEADENDSAUTOMATICALUMINUMClevis BailAClevis PinClevis WasherClevisCotter PinSemi-flex BailAC• Fastest method of deadending ACSR, AAAC, andAAC conductor.• Color coded funnel guide for easy identification.Flared conductor funnel guides ease installation.• Aluminum alloy shell and inhibitor protectedaluminum jaws assure corrosion resistance.• Available with galvanized steel stirrup clevis orstainless steel Z bail for primary applications.Flexible or semiflexible stainless steel bails canbe used on secondary applications.• See GDW Series for range-taking automaticdeadends.Note:For neoprene covered Flex or Semi-flex bailadd suffix “N”. Example GD402ANAdd suffix “TA” for pulling eye.Example GD4442ATA (Fig #1)Material: Shell – High Strength Aluminum AlloyJaws – Aluminum AlloyClevis Bail – Aluminum Alloy orGalvanized SteelZ Bail – Stainless Steel, formed wireFlex Bail – Braided stainless steelSemi-flex Bail – Stainless Steel,formed wirePulling Eye – Aluminum AlloyClevis WasherRetaining WasherGripping UnitCotter PinClevisCCPulling EyeFig#1CATALOGNUMBERBAIL TYPESTD. COND.SIZESDIMENSIONS OTHER INFORMATION APPROX.WT. EACHA B CDIA. RANGE IN. COLOR(MM) CODE LBS. (KG)GD442A CLEVIS11.0 5.0 -0.56 (.25)GD402AZ SS Z #4 ACSR (6/1) 10.4 5.0 -#4 AAAC.225-.2500.43 (.19)#4 AAC(5.59-6.35)ORANGEGD402A SS FLEX 12.8 5.0 2.0 0.20 (.09)GD462A SEMI-FLEX 12.0 5.0 2.2 0.24 (.10)GD4442A CLEVIS12.9 7.0 -0.63 (.29)GD4042AZ SS Z #2 & #4 ACSR 12.0 7.0 -#2 & #4 AAAC.220-.320 RED- 1.00 (.45)GD4042A SS FLEX #2 & #4 AAC 13.7 7.0 2.0 (5.59-8.13) ORANGE 0.34 (.15)GD4642A SEMI-FLEX 14.4 7.0 2.2 0.38 (.17)DA-2December 2011HUBBELL ® Power Systems

DISTRIBUTION CONNECTORSDEADENDSAUTOMATICALUMINUM(CONTINUED)SECTION DAALUMINUMGD400DA3CATALOGNUMBERBAIL TYPESTD. COND.SIZES*Maximum design rating 10,000 Lb./4535 kg.(1) Includes compact conductor of each size(2) For neoprene covered bail add suffix “N” Ex. GD406AN.DIMENSIONS OTHER INFORMATION APPROX.WT. EACHA B CDIA. RANGE IN. COLOR(MM) CODE LBS. (KG)GD446A CLEVIS12.3 6.4 -1.02 (.46)GD406AZ SS Z 1/0 ACSR14.2 6.4 -1/0 AAAC.355-.4000.20 (.09)1/0 AAC(9.02-10.16)YELLOWGD406A SS FLEX 15.3 6.4 2.0 0.40 (.18)GD466A SEMI-FLEX 15.8 6.4 2.2 0.30 (.14)GD447 CLEVIS17.8 9.3 -2.50 (1.13)GD407Z SS Z 2/0 ACSR17.6 9.3 -2/0 AAAC.400-.4701.40 (.64)2/0 AAC(10.15-11.94)GRAYGD407 SS FLEX 15.5 9.3 2.0 0.76 (.35)GD467 SEMI-FLEX 18.4 9.3 2.2 1.10 (.49)GD448 CLEVIS18.9 10.0 -2.40 (1.09)GD408Z SS Z 3/0 ACSR18.0 10.0 -3/0 AAAC.450-.5301.40 (.63)3/0 AAC(11.43-13.46)BLACKGD408 SS FLEX 17.6 10.0 2.0 1.16 (.53)GD468 SEMI-FLEX 19.0 10.0 2.2 1.10 (.50)GD449A CLEVIS17.5 9.0 -2.43 (1.10)GD409AZ SS Z 4/0 ACSR17.2 9.0 -4/0 AAC.505-.5951.40 (.63)4/0 AAAC(12.83-15.11)PINKGD409A SS FLEX 17.6 9.0 2.0 1.00 (.45)GD469A SEMI-FLEX 18.0 9.0 2.2 1.00 (.45)GD5205A CLEVIS11.6 4.6 -1.32 (.59)GD1205AZ SS Z 12.8 4.6 -266.8 AAC.518-.5951.00 (.45)(13.16-15.11)-GD1205A SS FLEX 13.6 4.6 2.0 0.64 (.29)GD1205AR SEMI-FLEX 14.4 4.6 2.2 0.66 (.29)GD450* CLEVIS18.5 9.6 -2.70 (1.22)GD410Z* SS Z 266.8 (18/1) ACSR 20.4 9.6 -312.8 AAAC.603-.6661.80 (.82)336.4 AAC(1)(15.32-16.92)BROWNGD410* SS FLEX 16.9 9.6 2.0 1.20 (.54)GD470* SEMI-FLEX 17.8 9.6 1.9 1.40 (.64)GD451* CLEVIS18.9 10.5 -2.0 (.90)GD411Z* SS Z 336.4 (18/1) ACSR 20.8 10.5 -394.5 AAAC.659-.7242.10 (.95)397.5 AAC(1)(16.74-18.39)GREENGD411* SS FLEX 17.7 10.5 2.0 1.80 (.82)GD471* SEMI-FLEX 18.6 10.5 1.9 1.70 (.77)- CLEVIS- - --GD412Z* SS Z 397.5 (18/1) ACSR 19.6 11.3 -465.4 AAAC.722-.7952.40 (1.08)477 AAC (1)(18.34-20.19)BLUEGD412* SS FLEX 19.0 11.3 2.0 2.00 (.91)GD472* SEMI-FLEX 19.3 11.3 1.9 2.00 (9.1)- CLEVIS- - --477 (18/1) ACSRGD413Z* SS Z 559.5 AAAC20.3 12.0 - .780-.8582.60 (1.18)500 AAC(19.81-21.79)WHITEGD413* SS FLEX 20.0 12.0 2.0 2.20 (.99)556 AAC(1)- SEMI-FLEX - - - -HUBBELL ® Power SystemsDA-3December 2011

DA4SECTION DAALUMINUMGDWDISTRIBUTION CONNECTORSDEADENDSAUTOMATIC<strong>OVERHEAD</strong> SIDE-OPENING WEDGEALUMINUM• Fastest method of deadending ACSR, AAAC,and AAC conductor.• Accepts wide range of conductor sizes. HighStrength Aluminum Alloy body and jaws.• Requires no wrenches or special tools.• Can be repositioned on conductor duringinstallation.• Rotated clevis eases placement of conductor.• Plated jaws available to accommodate copperconductors.Note: For plated jaws remove “A” suffix.Example: GDW440Material: Body and Jaws – High StrengthAluminum AlloyClevis Pin – Galvanized SteelCotter Pin – Stainless SteelCATALOGNUMBERGDW420A*GDW420GDW440A*GDW440GDW556A***GDW556**GDW795ADECIMAL RANGEINCHES (MM)ULTIMATE STRENGTH(LBS)CONDUCTOR RANGEDIMENSIONS INCHES (MM)MINIMUM MAXIMUM MINIMUM MAXIMUM BODY SAG EYE A B C D#4 str AAC#4 AAAC#4 ACSR#4 str CU#4 str AAC#4 AAAC#4 ACSR#4 str CU4/0 AAC4/0 AAAC4/0 ACSR4/0 str CU4/0 AAC4/0 AAAC4/0 ACSR2/0 str AAC2/0 AAAC2/0 ACSR2/0 str CU4/0 str AAC4/0 AAAC4/0 ACSR3/0 str CU600 AAC559.5 AAAC556.5 ACSR600 str CU900 AAC927.2 AAAC795 ACSR.23(5.8).23(5.8).52(13.2).52(13.2).45(11.4).57(14.5).90(22.8)1.11(28.1)6,000(2,727)9,000(4,090)10,000(4,545)15,000(6,818)4,000(1,818)6,000(2,727)6,000(2,727)6,000(2,727)9.45(240.1)9.84(249.8)16.2(335.3)20.2(513)296(75.1)3.31(84)5.67(144)5.90(150)3.97(100.8)4.08(103.6)5.25(133.4)5.78(146.8)0.75(19.2)0.76(19.2)0.81(20.6)0.71(18)* Plated aluminum jaws provided to accommodate copper conductors.** RUS ListedDA-4December 2011HUBBELL ® Power Systems

• Redesigned GDW2000 Series• Fastest method of deadending ACSR, AAAC,and AAC conductor.• Accepts wide range of conductor sizes. Highstrength Aluminum alloy body and jaws.• Requires no wrenches or special tools.• Can be repositioned on conductor duringinstallation.• Plated jaws available to accomodate copperconductors.Note: For plated jaws remove “A” suffix.Example: GDW2010DISTRIBUTION CONNECTORSDEADENDSAUTOMATIC<strong>OVERHEAD</strong> SIDE-OPENING WEDGEALUMINUMGDW2000 SERIESSECTION DAALUMINUMGDW2000DA5Material:Body and Jaws – High strengthAluminum AlloyClevis Pin – Galvanized SteelCotter Pin – Stainless Steel• To remove space bar, add Suffix “NSB”GDW2000 DEADENDDESIGN IMPROVEMENTS• Permanent Mold Body Casting: Higherstrength with tighter tolerance control.• Staked Jaw Keepers: Hold jaws in place.Permanently captivates jaw set. Jawsaccept a wide conductor range soinventory is minimized.• Parallel Legs: This improvement allowsfor easy conductor passage andinstallation of larger conductors.Conductor is quickly cradled withinthe deadend.• Pulling Eye: Moved on the body side foreasier access and sagging of conductor.• Interlocking Die Cast Jaws: Redesignedfor improved positive locking action andmovement. Helps eliminate tigheningerrors. Aluminum or plated jaws accomodatealuminum and copper conductors.CATALOGNUMBERGDW2010A***GDW2010**GDW2040A***GDW2040**CONDUCTOR RANGEDECIMAL RANGEINCHES (MM)* Plated aluminum jaws provided to accommodate copper conductors.** RUS ListedULTIMATE STRENGTH(LBS)DIMENSIONSINCHES (MM)MINIMUM MAXIMUM MINIMUM MAXIMUM BODY SAG EYE A B C#4 str AAC#4 AAAC#4 ACSR#4 str CU#4 str AAC#4 AAAC#4 ACSR#4 str CU2/0 str AAC2/0 AAAC2/0 ACSR2/0 str CU4/0 str AAC4/0 AAAC4/0 ACSR3/0 str CU.23(5.8).23(5.8).45(11.4).57(14.5)6,000 4,0008,000 6,0007.5(190.5)8.0(203.2)2.0(50.8)2.0(50.8)4.5(114.3)4.9(124.5)APPROX.WEIGHTEA LBS(KG)1.5(.07)2.0(0.9)DA-5HUBBELL ® Power SystemsDecember 2011

SECTION DADISTRIBUTION CONNECTORSDEADENDSAUTOMATICGUY WIREDA6ALUMINUMGDE5100Fargo GDE5100 Series Automatic deadends are designedfor use on High Strength, Common, Siemens-Martin, Utilities and Bell System Strand.Note: Consult factory for information on other applications.Material:Gripping Unit —Stainless SteelYoke —Aluminum AlloyBail— Stainless Steel<strong>LINE</strong> ART TO COMECATALOG PRIMARY STRANDDIMENSIONSNUMBERAPPLICATION RANGE (IN.) RANGE (MM)A B CGDE5100 1/4” 0.240-0.253 6.11-6.44 9.2 5.7 1.4GDE5101 5/16” 0.310-0.335 7.89-8.53 9.25 5.6 1.5GDE5101L 5/16” 0.310-0.335 7.89-8.53 13.1 9.5 1.5GDE5102 3/8” 0.360-0.405 9.16-10.31 11.9 7.1 1.7GDE5102L 3/8" 0.360-0.405 9.16-10.31 17.0 12.5 1.7NOTE: Suffix “L” Denoted Extended Bail.DA-6December 2011HUBBELL ® Power Systems

DISTRIBUTION CONNECTORSSECTION DADEADENDSAUTOMATICGUY WIREFargo GDE5200 Series Automatic deadends are designedfor use on all grades of galvanized steel wirestrand . . . High Strength, Extra High Strength, AlumoWeld,Alumonized, Common, Siemens-Martin,Utilities and Bell System Strand.Innovative yoke design allows for installation withoutuse of a gripping hook.Note: Consult factory for information on other applications.ALUMINUMGDE5200DA7Material:Gripping Unit —Stainless SteelCATALOGNUMBERPRIMARY STRANDAPPLICATION RANGE (IN.) RANGE (MM)GDE52001/4" EHS7#12 (6M) AWGDE5200L1/4" EHS7#12 (6M) AWGDE52015/16" EHS7#10 (10M), 7#11 (8M) AWGDE5201L5/16" EHS7#10 (10M), 7#11 (8M) AW3/8” EHSGDE5202 3#5, 7#8, 7#9 , 12.5M, 14M, 16M AW#4-2/5, #2-3/4, #1-5/2 AWAC3/8" EHSGDE5202L 3#5, 7#8, 7#9 , 12.5M, 14M, 16M AW#4-2/5, #2-3/4, #1-5/2 AWAC7/16" EHSGDE52037#7 (20M), 18M AW#2-2/5, #1-3/4, #1/0-5/2 AWAC7/16" EHSGDE5203L7#7 (20M), 18M AW#2-2/5, #1-3/4, #1/0-5/2 AWACNote: Suffix “L” denotes extended bail.DIMENSIONSA B C0.215-0.270 5.46-6.86 10.0 5.4 1.60.215-0.270 5.46-6.86 13.7 9.1 1.60.270-0.315 6.86-8.00 10.0 5.3 1.80.270-0.315 6.86-8.00 15.3 10.5 1.80.325-0.392 8.26-9.96 11.8 5.7 2.20.325-0.392 8.26-9.96 17.2 11.2 2.20.392-0.458 9.96-11.63 14.6 8.5 2.40.392-0.458 9.96-11.63 18.4 12.4 2.4INSTALLATIONBAILBail for GDE5200 /GDE5200LBail for GDE5201 /GDE5201LBail for GDE5202 /GDE5202LBail for GDE5203 /GDE5203LPART NO.PS3005200PS300552130051523005527Typical Installation with 2nd BailDA-7HUBBELL ® Power SystemsDecember 2011

SECTION DADISTRIBUTION CONNECTORSDASTEEL6400DEADENDSBOLTEDGUY WIREGUY CLAMPParallel grooves trap guy strand tightly without marring.Plate halves align evenly for easy application.Each has a shoulder to prevent turning while tightening.Hot dip galvanized8December 2011Material:Body–Hot Dip Galvanized SteelHardware– Galvanized SteelNo. 6461CATALOGNUMBER5/8" Clamp BoltsDIMENSIONS INCHESNO. OFBOLTS LENGTH WIDTH1/2" Clamp BoltsACCEPTSSTRAND SIZESHIP WTLBS PER 100 PCS6460 362 1/83/8 thru 5/8390*6461** 361 21/325/16 thru 1/22526462 241 21/325/16 thru 1/2178CATALOGNUMBERDIMENSIONS INCHESNO. OFBOLTS LENGTH WIDTHACCEPTSSTRAND SIZESHIP WTLBS PER 100 PCS6448 23 3/81 9/161/4 thru 7/161326449 341 9/161/4 thru 7/16162*6450** 361 9/161/4 thru 7/16228No. 6409GUY OFFSET CLAMP:This two-bolt guy clamp with curved clamping member provides a more positive hold on the guy strand. Available with 1/2"or 5/8" bolts. Hot dip galvanized.Material:Body– Hot dipped galvanized steelHardware– Galvanized steelCATALOGNUMBER**RUS ListedDIMENSIONS INCHESBOLT SIZE LENGTH WIDTHACCEPTSSTRAND SIZESHIP WTLBS PER 100 PCS6409** 1/23 1/41 1/23/16 thru 5/161356410** 5/841 5/85/16 thru 1/2172DA-8HUBBELL ® Power Systems

For distribution and light transmission construction withAAC, AAAC and ACSR conductors. The vertical springloadedkeeper provides the easiest installation of any currentbolted strain clamp.DISTRIBUTION CONNECTORSDEADENDSBOLTEDSTRAIGHT-<strong>LINE</strong> SPRING-LOADED—SIDE OPENINGALUMINUMSECTION DAALUMINUMASODDA9Material:Body and Keeper — 356-T6 aluminum alloyHardware — galvanized steelSockets and Clevises — ductile iron, galvanizedSpring and Cotter Pin — stainless steelFig. 1 Fig. 2U-BOLTS CLAMPING RANGE ULT. STR. (LBS) DIMENSIONS IN INCHESACSR ALUMINUM INCHESSAGCAT. NO. NO. SIZE MIN. MAX. MIN. MAX. MIN. MAX. BODY EYE A B CASOD3981N 1 3/8 #6 (6/1) 2/0 (6/1) #4 (7) 2/0 (19) 0.19 0.48 6000 6000 8.00 1.00 3.62ASOD5701N 1 1/2 #6 (6/1) 4/0 (6/1) #4 (7) 4/0 (19) 0.19 0.57 8000 8000 8.62 1.00 3.75ASOD6841N 1 1/2 #4 (6/1) 336.4 (18/1) #3 (7) 350 (37) 0.25 0.69 8000 8000 9.00 1.00 4.50ASOD8581N 1 1/2 #4 (6/1) 556.5 (18/1) #2 (7) 556.5 (37) 0.25 0.89 8000 6000 9.75 1.00 4.75ASOD8582N 2 1/2 3/0 (6/1) 556.5 (18/1) 4/0 (7) 556.5 (37) 0.50 0.89 12000 9000 13.50 1.00 6.00ASOD11602N 2 1/2 336.4 (18/1) 900 (54/7) 350 (37) 954 (61) 0.69 1.16 12000 9000 16.75 1.50 7.75NOTE: (1) Recommended torque on U-bolts: 3/8”–25 lb.-ft., 1/2”–45 lb.-ft.(2) Add Suffix “C” for Clevis Fitting (Type CA)(3) Add Suffix “S” for Socket Eye Fitting (Type SA)DA-9HUBBELL ® Power SystemsDecember 2011

DA10SECTION DAALUMINUMADSBDISTRIBUTION CONNECTORSDEADENDSSINGLE BOLTSTRAIGHT-<strong>LINE</strong> SPRING-LOADED – SIDE-OPENINGALUMINUMFor distribution construction using AAC, AAAC andACSR conductors. The spring-loaded design holds thekeeper out of the way for easier conductor installation. Theheavy-duty single 1 / 2 " bolt allows installation by hand orhydraulic.Material:Body and Keeper – 356 T6 AluminumHardware – Galvanized SteelSpring and Cotter – Stainless SteelCAT NO.NOBOLT CLAMPING RANGE ULT STR (LBS) DIMENSIONS IN INCHESSIZEACSR ALUMINUM INCHESMIN. MAX. MIN. MAX. MIN. MAX.BODYSAGEYE A B CADSB48N 1 1/2 #6 (6/1) 2/0 (6/1) #4 (7 STR) 2/0 (19 STR) 0.19 0.48 6,000 6,000 9.6 1.13 4.63NOTE:(1) Recommended Torque on Bolt: 45 lb-ft (540 lb-in)(2) For optional stainless steel lifting eye, add “E” to catalog numberExample: ADSB48ENDA-10December 2011HUBBELL ® Power Systems

DISTRIBUTION CONNECTORSDEADENDSBOLTEDSTRAIGHT <strong>LINE</strong> SPRING-LOADED—SIDE-OPENINGALUMINUMFor distribution and light transmission constructionwith all aluminum, ACSR or aluminum alloy conductor.The spring loaded keeper permits easy conductorinsertion and lower installation cost.Captive nuts prevent disassembly and loss of hardwareduring installation on energized or de-energizedlines.SECTION DAALUMINUMADEZ / ADSODA11The pivotal keeper design avoids friction betweenbody and keeper during installation.Material:Body and Keeper—356-T6 aluminum alloyHardware—galvanized steelSockets and Clevises—ductile iron, galvanizedSpring & Cotter Pin—#302 stainless steelADSOADEZONE “U” BOLTADSOTWO “U” BOLTSADEZCATALOGNUMBERADSO46NADSO46SADSO46CADEZ47NADEZ47SADEZ47CADEZ57NADEZ57SADEZ57CADEZ88NADEZ88SADEZ88CADEZ116NADEZ116SADEZ116CFITTINGCLAMPING RANGETYPE CAT. NO. ACSR ALUMINUMNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevis-SA04CA04-SA04CA04-SA04CA04-SA06CA06-SA06CA06#6 (6/1)To2/0 (6/1)#6 (6/1)To2/0 (6/1)#4 (6/1)To4/0 (6/1)2/0 (6/1)To556 (18/1)336.4 (18/1)To954 (36/1)#4To3/0#4 (7)To3/0 (9)#4 (7)To4/0 (19)3/0 (7)To556 (37 )350 (37)To1000 (61)INCHES(MM).18-.46(4.57-11.68).18-.47(4.57-11.98).23-.57(5.84-14.48).44-.88(11.18-22.25).68-1.16(17.27-29.46)ULTIMATEBODYSTRENGTHLBS. (KG)6,000(2,722)7,000(3,175)8,000(3,629)10,000(4,536)12,000(5,443)NO.12222U-BOLTSDIMENSIONSINCHES (MM)SIZEINCHES(MM) L B W D E3/8(9.53)3/8(9.53)3/8(9.53)1/2(12.70)1/2(12.70)6-5/8(168.4)6-5/8(168.4)7-7/8(123.8)9-5/16(236.54)10-13/16(274.63)3-5/8(92.2)3-5/8(92.2)4-1/8(104.8)4-23/32(119.83)5-5/8(142.90)3/4(19.05)3/4(19.05)3/4(19.05)15/16(23.81)1(25.40)125.4125.4125.41-1/825.581-5/841.281 -1/238.11 -1/238.11 -1/238.11-5/841.281-5/841.28APPROX.WT. EACHLBS. (KG)1.2 (.54)2.4 (1.09)2.8 (1.27)1.3 (.59)2.5 (1.13)2.9 (1.31)1.5 (.68)1.7 (.77)2.1 (.95)3.0 (1.36)4.3 (1.95)4.7 (2.13)3.7 (1.66)5.0 (2.27)5.4 (2.45)NOTES: (1) Recommended torque on bolts; 3/8”—240 in. lbs., 1/2”—480 in. lbs.(2) For optional stainless steel lifting eye add “E” to catalog number.Example: ADSO46ENHUBBELL ® Power SystemsDA-11December 2011

DA12SECTION DAALUMINUMGD900DISTRIBUTION CONNECTORSDEADENDSBOLTEDSTRAIGHT <strong>LINE</strong> DEADEND STRAIN CLAMPSWING AWAYALUMINUMFor distribution and light transmission construction.The angle beam pressure pad effectively convertstorque to maximum pressure and spreads this forceover the total contact area.The compressive forces are combined with the modifiedparabolic “V” groove of the body to provide maximumconductor encirclement and increased holdingability.The large pulling eye makes it convenient to connectand disconnect the “come-along” hook.SWING AWAY DESIGNThe pressure pad is easily lifted and swung clear of thecable groove permitting convenient top loading of theconductor without disassembly.Material:Body and Keeper—356-T6 aluminum alloyHardware—galvanized steelCotter Pin—#302 stainless steelCATALOGNUMBERTYPEFITTING CLAMPING RANGE ULTIMATEBODYCAT.NO.ACSRALUMINUMINCHES(MM)STRENGTHLBS. (KN)BOLTSIZEINCHES(MM)DIMENSIONSAPPROXIMATE INCHES(MM)L B W D EAPPROX.WT.EACHLBS.(KG)GD961A**NoneSocketClevis—SA04CA04#6 (6/1)to2/0 (6/1)#6 (7)to3/0 (7).18-.47(4.57-11.94)7,000(31.1)3/8(9.53)6 5/8 3 3/4 7/8 —1.1(0.5)GD963ANoneSocketClevis—SA04CA04#4 (6/1)to397.5 (30/7)#4 (7)to477 (37).25-.81(6.35-20.57)10,000(44.5)1/2(12.70)10 5 3/4 1 7/82.0(0.9)GD965ANoneSocketClevis—SA04CA043/0 (6/1)to556.5 (18/1)4/0 (7)to556.5 (37).50-.88(12.7-22.35)10,000(44.5)1/2(12.70)10 1/8 5 1/4 3/4 1 7/83.3(1.5)GD967ANoneSocketClevis—SA10CA101300 (26/7)to954 (36/1)336.4 (19)to954 (61).68-1.15(17.27-29.21)10,000(44.5)1/2(12.70)16 1/2 10 1 1/4 1 1/8 7/83.8(1.7)NOTES:(1) Recommended torque on bolts; 3/8”—240 in.-lbs., 1/2”—480 in.-lbs.(2) To obtain spring loaded pressure pad, add “S” to catalog numberExample GD961AS** RUS ListedDA-12December 2011HUBBELL ® Power Systems

DISTRIBUTION CONNECTORSDEADENDSBOLTEDSTRAIGHT <strong>LINE</strong> STRAIN CLAMPALUMINUMFor distribution and light transmission construction withall aluminum, ACSR or aluminum alloy conductor.These clamps have high holding power and large rangetaking ability. (Straight Contoured Groove)Material:Body and Keeper—356-T6 aluminum alloyHardware—galvanized steelSockets and Clevises—ductile iron, galvanizedCotter Pin—#302 stainless steelSECTION DAALUMINUMADSDA13CATALOGNUMBERTYPEFITTINGCLAMPING RANGECAT.INCHESNO. ACSR ALUMINUM (MM)ULTIMATEBODYSTRENGTHLBS. (KG)NO.U-BOLTSDIMENSIONSINCHES (MM)SIZEINCHES(MM) L B WAPPROX.WT.EACHLBS.(KG)ADS47NADS47SADS47C*ADS47LN*ADS47LS*ADS47LCADS48N**ADS48SADS48CADS60N**ADS60SADS60C*ADS60LN*ADS60LS*ADS60LCADS88NADS88SADS88C*ADS88LN*ADS88LS*ADS88LCADS116NADS116SADS116CADS130NADS130SADS130CADS155NADS155SADS155CNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevis-SA04CA04-SA04CA04-SA04CA04-SA04CA04-SA04CA04-SA06CA06-SA06CA06-SA07CA06-SA07CA06-SA07CA06#6 (6/1)To2/0 (6/1)#6 (6/1)To2/0 (6/1)#6 (6/1)To3/0 (6/1)#6 (6/1)To266.8 (18/1)#6 (6/1)To266.8 (18/1)#2 (6/1)To556.5 (18/1)#2 (6/1)To556.5 (18/1)#2 (6/1)To954 (36/1)266.8 (26/7)To1192.5 (45/7)336.4 (26/7)To1590.5 (54/19)#6-7 Str.To3/0-19 Str.#6-7 Str.To3/0-19 Str.#6-7 Str.To3/0-19 Str.#4-7 Str.To266.8-19 Str.#4-7 Str.To266.8-19 Str.#1-7 Str.To556.5-37 Str.#1-7 Str.To556.5-37 Str.#1-7 Str.To1000-61 Str.336.4 19 Str.To1272 61 Str.397.5 19 Str.To1800 127 Str..18-.47(4.57-11.94).18-.47(4.57-11.94).18-.502(4.57-12.75).19-.60(4.83-15.24).19-.60(4.83-15.24).31-.88(7.87-22.35).31-.88(7.87-22.35).31-1.16(7.87-29.46).64-1.30(16.26-33.02).72-1.55(18.3-39.9)7,000(3,175)7,000(3,175)7,000(3,175)8,000(3,629)8,000(3,629)10,000(4,536)10,000(4,536)15,000(6,804)15,000(6,804)15,000(6,804)11222222221/2(12.70)1/2(12.70)3/8(9.53)1/2(12.70)1/2(12.70)1/2(12.70)1/2(12.70)1/2(12.70)1/2(12.70)5/8(15.9)5-3/8(136.52)6-3/4(171.45)7-5/8190.50)8-1/4(209.55)10-5/8(269.88)9(228.60)12(304.80)10-1/2(266.70)10-1/2(266.70)11-3/4(298.5)2-1/8(53.98)3-1/2(88.90)3-7/8(98.43)4(101.60)6(152.40)4-1/2(114.30)7-1/2(190.50)5-1/2(139.70)5-1/2(139.70)6(152.4)11/16(17.46)11/16(17.46)11/16(17.46)3/4(19.05)3/4(19.05)15/16(23.81)15/16(23.81)1(25.40)1(25.40)1(25.4)1.1 (.50)2.4 (1.09)2.7 (1.22)1.3 (.59)2.6 (1.15)2.9 (1.32)1.6 (.73)2.9 (1.32)3.2 (1.46)2.0 (.91)3.2 (1.45)3.6 (1.63)2.2 (1.00)3.4 (1.54)3.8 (1.72)2.2 (1.00)3.5 (1.59)3.9 (1.77)2.4 (1.09)3.7 (1.68)4.1 (1.86)2.9 (1.32)4.2 (1.91)4.6 (2.09)3.0 (1.36)4.3 (1.95)4.7 (2.13)4.4 (2.0)5.8 (2.6)6.1 (2.8)NOTES:(1) Recommended torque on U-bolts; 3/8”—240 in.-lbs., 1/2”—480 in.-lbs., 5/8”—720 in.-lbs.(2) Lifting eye is standard on keeper for hot line work.*Extra length clamps for greater insulator clearance.** RUS ListedDA-13HUBBELL ® Power SystemsDecember 2011

DA14SECTION DAALUMINUMADESDISTRIBUTION CONNECTORSDEADENDSBOLTEDSTRAIGHT <strong>LINE</strong> STIRRUP CLAMPALUMINUMFor distribution construction with all aluminum, ACSRor aluminum alloy conductor. This clamp is a combinationdeadend and stirrup or tap clamp. The stirrup permitstapping energized conductors without arching damage tothe conductorMaterial and installation costs are less with the ADEScombination clamp than with other equivalent methods ofdeadending and tapping a conductor.Material:Body and Keeper—356-T6 aluminum alloyHardware—galvanized steelSockets and Clevises—ductile iron, galvanizedCotter Pin—#302 stainless steelStirrup—copperCATALOGNUMBERADES46NADES46SADES46CADES60NADES60SADES60CADES70NADES70SADES70CTYPENoneSocketClevisNoneSocketClevisNoneSocketClevisFITTINGCLAMPING RANGECAT.NO. ACSR ALUMINUM-SA04CA04-SA04CA04-SA04CA04#6(6/1)To2/0(6/1)1/0(6/1)To159(12/7)3/0(6/1)To336.4(18/1)#6-7 Str.To2/0-19 Str.1/0-7 Str.To266.8-19 Str.3/0-7 Str.To350-37 Str.INCHES(MM).18-.46(4.57-11.68).36-.60(9.14-15.24).46-.70(11.68-17.78)ULTIMATEBODYSTRENGTHLBS. (KG)6,000(2,722)8,000(3,629)8,000(3,629)NO.222U-BOLTSLOOPDIA.DIMENSIONSINCHES (MM)SIZEINCHES(MM) E L B W D3/8(9.53)1/2(12.70)1/2(12.70).289(7.3)#1.325(8.3)1/0.325(8.3)1/07-1/2(190.50)9-5/8(244.48)10-3/4(273.05)4(101.60)4(101.60)4-31/32(126.21)3/4(19.05)3/4(19.05)3/4(19.05)2(50.80)3-1/16(77.79)2-1/853.98)APPROX.WT. EA.LBS. (KG)1.8 (0.82)3.0 (1.36)3.4 (1.54)2.8 (1.3)]4.0 (1.81)4.4 (2.00)3.0 (1.40)4.2 (1.91)4.7 (2.13)NOTES:(1) Recommended torque on U-bolts 3/8”—240 in. lbs. 1/2”—480 in. lbs.(2) Lifting eye is standard on keeper for hot line work.DA-14December 2011HUBBELL ® Power Systems

For high tension transmission line construction withall aluminum, ACSR or aluminum alloy conductor.Material:Body and Keeper—356-T6 aluminum alloyHardware—galvanized steelSockets and Clevises—ductile iron, galvanizedCotter Pin—#302 stainless steelDISTRIBUTION CONNECTORSDEADENDSBOLTEDQUADRANT STRAIN CLAMPALUMINUMSECTION DAALUMINUMSDDA15CATALOGNUMBERDIMENSIONS INCHES (MM)L W H C K PDSD57SD70SD86SD112SD130SD155SD1859-1/16(230.19)10-1/4(260.35)11-1/4(285.75)13-1/8(333.38)14(355.6)15-1/2(393.70)17(431.80)3/4(19.05)15/16(23.81)1-1/16(26.99)1-3/8(34.93)1-7/16(36.51)2(50.8)1-7/8(47.63)6-3/4(171.45)8-3/8(212.73)9-5/8(244.48)11-1/2(292.1)13-1/8(333.38)15-3/4(400.05)18(457.20)5-1/8(130.18)6-1/2(165.10)7-3/8(187.33)8-1/4(209.6)9-1/2(241.3)12-3/8(314.32)12-3/8(314.32)1-1/4(31.75)1-1/4(31.75)1-1/4(31.75)1-3/8(34.33)1-1/2(38.10)1-1/2(38.10)1-1/2(38.10)5/8(15.88)5/8(15.88)5/8(15.88)3/4(19.05)3/4(19.05)3/4(19.05)1(25.40)CATALOGNUMBERFITTINGCLAMPING RANGETYPE CAT. NO. ACSR ALUMINUMINCHES(MM)ULTIMATEBODYSTRENGTHLBS. (KG)NO.U-BOLTSSIZEINCHES(MM)APPROX.WT. EACHLBS. (KG)SD57NSD57SSD57CSD70NSD70SSD70CSD86NSD86SSD86CSD112NSD112SSD112CSD130NSD130SSD130CSD155NSD155SSD155CSD185NSD185SSD185CNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevis--SA04CA04--SA06CA06--SA07CA06--SA1013CA1013--SA1013CA1013--SA1613CA1613--SA1417CA1517033#4-6/1To266.8-26/7#2-7/1To397.5-18/1#3/0-6/1To556-26/7#3/0-6/1To954-54/7336.4-26/7To1272-54/191,033.5 (36/1)To1510.5 (54/19)1,192.5 (45/7)To2,156 (84/19)#4-7 Str.To300-37 Str.#1-7 Str.To397.5-37 Str.3/0-19 Str.To650-61 Str.40-19 Str.To1033.5-61 Str.397.5-19 Str.To1431-61 Str.1,100-91 Str.To1,700-127 Str.1,272-61 Str.To2,500-127 Str..20-.64(5.08-16.26).30-.75(7.62-19.05).46-.94(10.16-23.88).50-1.20(12.80-30.48).70-1.39(17.78-35.30)1.18-1.52(29.97-38.61)1.30-1.85(33.02-46.99)15,000 (6,804) 320,000 (9,072) 425,000 (11,340) 430,000 (13,608)30,000 (13,608)25,000 (11,340)35,000 (15,876)30,000 (13,608)25,000 (11,340)35,000 (15,876)30,000 (13,608)25,000 (11,340)50,000 (22,680)30,000 (13,608)30,000 (13,608)55551/2(12.70)1/2(12.70)1/2(12.70)1/2(12.70)5/8(15.88)5/8(15.88)5/8(15.88)3.2 (1.45)4.4 (2.00)4.8 (2.63)4.7 (2.14)6.0 (2.72)6.4 (2.90)5.4 (2.45)6.8 (3.09)7.1 (3.22)8.4 (3.81)9.9 (4.5)10.4 (4.73)13.2 (6.00)15.3 (6.95)15.5 (7.04)15.5 (7.00)17.3 (7.85)17.3 (7.85)21.0 (9.53)22.7 (10.30)22.3 (10.11)NOTES: (1) Recommended torque on U-bolts; 1/2”—480 in.-lbs., 5/8”—720 in.-lbs.(2) For corona free application, add suffix “CRF.” Example, SD57NCRF.(This includes spherical or acorn type nuts or a combination of both.)(3) Clamp may be furnished with bolt, nut and cotter pin by adding “BNK” suffix to catalog number.DA-15HUBBELL ® Power SystemsDecember 2011

DA16SECTION DAALUMINUMSDT2DISTRIBUTION CONNECTORSDEADENDSBOLTEDDOUBLE GROOVEALUMINUMMade with double groove keeper to accommodate twinconductor. For high tension transmission line constructionwith all aluminum, ACSR or aluminum alloy conductor.Material:Body and Keeper—356-T6 aluminum alloy.Hardware—galvanized steelSockets and clevises—ductile iron, galvanizedCotter Pin—stainless steelCATALOGNUMBERSDT286NSDT286SSDT286CSDT2112NSDT2112SSDT2112CSDT2185NSDT2185SSDT2185CCLAMP RANGEULT.BODYSTR.LBS.U-BOLTS DIMENSIONS APPROX.WT.EACHLBS.ACSR ALUMINUM INCHES NO. SIZE L H C K PD R X1/0-6/1To2/0-6/13/0-6/1To4/0-6/1226.8-26/7To556.5-18/12/0-7 STR.To2/0-19 STR4/0-7 STRTo4/0-19 STR336.4-19 STRTo556.5-37 STR.398To.447.502To.562.642To.87925,00025,00025,00030,00030,00025,00050,00030,00030,0004 1/2 11 1/4 9 5/8 7 3/8 1 1/4 5/8 5 1 1/165 1/2 13 1/8 11 1/2 8 1/4 1 3/8 3/4 6 1/2 1 3/85 5/8 17 18 12 3/8 1 1/2 1 12 1 7/8Notes: (1) Catalog number suffixes indicate N=no fitting; s=socket; and c=clevis.(2) Clamp may be furnished with bolt, nut and cotter pin by adding “BNK” suffix to catalog number.5.46.06.48.49.910.021.022.722.3DA-16December 2011HUBBELL ® Power Systems

DISTRIBUTION CONNECTORSDEADENDSBOLTEDQUADRANT STRAIN CLAMPALUMINUMFor distribution and light transmission construction with allaluminum, ACSR or aluminum alloy conductor.Material:Body and Keeper—356-T6 aluminum alloyHardware—galvanized steelSockets and Clevises—ductile iron, galvanizedCotter Pin—#302 stainless steelSECTION DAALUMINUMPG/DEDA17CATALOGNUMBERDE46PG46PG57PG70PG86PG86LPG100LDIMENSIONS INCHES (MM)L W H K3-7/8(98.30)4-1/16(103.18)5-1/2(139.7)6-7/16(163.51)12-5/16(312.74)6-9/16(166.69)9-7/8(250.83)11/16(17.46)11/16(17.46)11/16(17.46)25/32(19.84)1-1/16(26.99)1-1/16(26.99)1-3/16(30.16)3-13/16(96.84)4-3/4(120.65)5-5/16(134.87)7(177.80)11(279.40)7-7/16(188.91)9-5/16(236.54)7/8(22.10)1(25.40)1(25.40)1-1/8(28.58)1-1/4(31.75)1(25.40)1-1/4(31.75)CATALOGNUMBERDE46NDE46SDE46CPG46N**PG46SPG46CPG57N**PG57SPG57CPG70NPG70SPG70CPG86LNPG86LSPG86LCPG100LNPG100LSPG100LCTYPENoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisFITTINGCLAMPING RANGECAT.NO. ACSR ALUMINUM--SA04CA04--SA04CA04--SA04CA04--SA04CA04--SA07CA06--SA10CA101#6 (6/1)To3/0 (6/1)#6 (6/1)To3/0 (6/1)#4 (6/1)To4/0 (6/1)101.8 (12/7)To336.4 (26/7)134.6 (12/7)To556.5 (18/1)3/0 (6/1)To666.6 (24/7)#6 -7 Str.To3/0-19 Str.#6 -7 Str.To3/0-19 Str.#3-7 Str.To4/0-19 Str.3/0-7 Str.To400-37 Str.4/0-7 Str.To556.5-37 Str.4/0-7 Str.To750-61 Str.INCHES(MM).18-.52(4.57-13.21).18-.52(4.57-13.21).25-.57(6.35-14.48).46-.73(11.68-18.54).52-.88(13.21-22.35).50-1.00(12.70-25.40)ULTIMATEBODYSTRENGTHLBS. (KG)8,000(3,629)8,000(3,629)10,000(4,536)15,000(6,804)15,000(6,804)18,000(8,165)NO.122222U-BOLTSSIZEINCHES(MM)1/2(12.70)3/8(9.53)1/2(12.70)1/2(12.70)1/2(12.70)1/2(12.70)GROOVEANGLE85°90°90°85°70°60°APPROX.WT. EACHLBS. (KG)1.2 (.54 ))2.2 (1.00)2.2 (1.00)1.1 (.50)2.4 (1.08)2.7 (1.22)2.0 (.91)3.2 (1.45)3.6 (1.63)2.5 (1.13)3.8 (1.72)4.1 (1.86)2.9 (1.32)4.2 (1.91)4.6 (2.09)4.5 (2.04)5.9 (2.68)6.2 (2.81)NOTE: Recommended torque on U-bolts; 3/8"—240 in. lbs., 1/2"—480 in. lbs.**RUS ListedDA-17HUBBELL ® Power SystemsDecember 2011

DA18SECTION DAALUMINUMAR1/AR2DISTRIBUTION CONNECTORSDEADENDSBOLTEDQUADRANT DEADEND STRAIN CLAMPALUMINUMThese clamps are used primarily for deadending aluminumsubstation cable bus.During installation the cable will slide free under the U-bolts,or if preferred, U-bolts may be removed and cable laid inclamp grooves from the side.These clamps are compact for greatest phase clearance.Material:Body and Keeper—356-T6 aluminum alloyHardware—galvanized steelSockets and Clevises—ductile iron, galvanizedCotter Pin—#302 stainless steelCATALOGNUMBERAR1100NAR1100SAR1100CAR1150NAR1150SAR1150CAR1200NAR1200SAR1200CAR2025NAR2025SAR2025CAR2050NAR2050SAR2050CAR2100NAR2100SAR2100CAR2150NAR2150SAR2150CAR2200NAR2200SAR2200CTYPENoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisFITTINGCLAMPING RANGECAT.NO ACSR ALUMINUM--SA06CA06--SA06CA06--SA06CA06--SA06CA06--SA06CA06--SA06CA06--SA06CA06--SA06CA06477 (18/1)To874.5 (54/7)900 (54/7)To1351.5 (45/7)1351.5 (45/7)To1780 (84/19)1/0 (6/1)To4/0 (6/1)159 (12/7)To477 (36/1)477 (18/1)To874.5 (54/7)900 (54/7)To1351.5 (45/7)1351.5 (54/19)To1780 (84/19)500To1000 MCM1000To1500 MCM1500To2000 MCM1/0To250-19 Str.250To500 MCM500To1000 MCM1000To1500 MCM1500To2000 MCMINCHES(MM).811-1.152(20.60-29.26)1.150-1.412(29.21-35.86)1.411-1.632(35.84-41.45).365-.574(9.27-14.58).574-.813(14.58-20.65).811-1.152(20.60-29.26)1.150-1.412(29.21-35.86)1.411-1.630(35.84-41.40)ULTIMATEBODYSTRENGTHLBS. (KG)15,000(6,804)15,000(6,804)15,000(6,804)8,000(3,629)10,000(4,536)15,000(6,804)15,000(6,804)15,000(6,804)NO.33333333U-BOLTSDIMENSIONSINCHES (MM)SIZEINCHES(MM) L W H1/2(12.70)5/8(15.88)5/8(15.88)3/8(9.53)1/2(12.70)1/2(12.70)5/8(15.88)5/8(15.88)9-1/8(231.78)10-1/2(266.70)12-3/4(323.85)8-1/16(204.7)8-3/4(222.25)9-1/8(231.78)10-1/2(266.70)12-3/4(323.85)------21/32(16.67)7/8(22.23)1-3/16(30.16)1-21/32(42.06)2-3/32(53.18)3-7/8(98.43)4-3/8(111.13)5(127)3-5/32(80.17)3-1/4(82.55)3-7/8(98.43)4-3/8(111.13)5(127)APPROX.WT. EACHLBS. (KG)3.5 (1.59)4.8 (2.18)5.2 (2.36)5.2 (2.36)6.5 (2.95)6.9 (3.13)6.0 (2.72)7.3 (3.31)7.7 (3.49)2.7 (1.22)4.0 (1.81)4.4 (2.00)3.5 (1.59)4.8 (2.18)5.2 (2.36)4.2 (1.91)5.5 (2.49)5.9 (2.68)7.5 (3.40)8.8 (3.99)9.2 (4.17)8.5 (3.86)9.8 (4.45)10.2 (4.63)NOTE: Recommended torque on U-bolts; 3/8”—240 in. lbs., 1/2”—480 in. lbs., 5/8”—720 in. lbs.DA-18December 2011HUBBELL ® Power Systems

For deadending static wires.May be used to deadend copper or Copperweld ® phase conductors.Magnetic induction heating will occur.Material:Body and Keeper—galvanized ductile ironHardware—galvanized steelSockets and Clevises—ductile iron, galvanizedCotter Pin—#302 stainless steelDISTRIBUTION CONNECTORSDEADENDSBOLTEDSTRAIGHT <strong>LINE</strong> STRAIN CLAMPFERROUSSECTION DADUCTILE IRONMDEDA19CATALOGNUMBERMDE40NMDE40SMDE40CMDE46NMDE46SMDE46CMDE60NMDE60SMDE60CTYPENoneSocketClevisNoneSocketClevisNoneSocketClevisFITTINGCAT. NO.—SA04CA04—SA04CA04—SA04CA04876722000 None —876822000 None —876922000 None —CLAMPINGRANGEINCHES(MM).16-.40(4.06-10.16).18-.46(4.57-11.68).36-.60(9.14-15.24).46-.86(11.68-21.84).65-1.25(16.51-31.75).86-1.55(21.84-39.37)ULTIMATEBODYSTRENGTHLBS. (KG)5,000(2,268)6,000(2,722)8,000(3,629)10,000(4,536)10,000(4,536)10,000(4,536)NO.122222U-BOLTSDIMENSIONSINCHES (MM)SIZEINCHES(MM) L W A X B1/2(12.70)3/8(9.53)1/2(12.70)1/2(12.70)1/2(12.70)3/8(9.53)6-3/16(157.16)7-1/2(190.5)8-15/16(227.01)9-1/4(234.95)11(279.40)12.5(317.50)13/16(20.6)3/4(19.05)3/4(19.05)3/4(19.05)3/4(19.05)3/4(19.05)7/8 x 1-1/4(22.2 x 31.8)7/8 x 1-1/4(22.2 x 31.8)7/8 x 1-1/4(22.2 x 31.8)1 x 1-7/16(25.4 x 36.5)1 x 1-13/16(25.4 x 36.5)1-1/18 x - 1/8(27.0 x 54.0)APPROX.WT. EACHLBS. (KG)2.1 (.95)3.4 (1.54)3.7 (1.68)2.5 (1.13)3.8 (1.72)4.1 (1.86)3.8 (1.72)5.0 (2.27)5.4 (2.45)3.8 (1.72)5.5 (2.49)7.9 (3.58)NOTES: (1) Recommended torque on U-bolts; 3/8”—240 ins. lbs., 1/2”—480 in. lbs., 5/8”—720 in. lbs.(2) Lifting eye is standard on MDE type clamps.(3) 87600 series without lifting eye.DA-19HUBBELL ® Power SystemsDecember 2011

DA20SECTION DADUCTILE IRONSWDE/MDDISTRIBUTION CONNECTORSDEADENDSBOLTEDQUADRANT STRAIN CLAMPFERROUSFor deadending static wires.May be used to deadend copper or Copperweld ® phaseconductors. Magnetic induction heating will occur.Material:Body and Keeper—galvanized ductile ironSockets and Clevises—ductile iron, galvanizedCotter Pin—#302 stainless steelCATALOGNUMBERMD52NMD52SMD52CSWDE46NSWDE46SSWDE46CSWDE55NSWDE55SSWDE55CSWDE84NSWDE84SSWDE84CDIMENSIONSINCHES (MM)L H C W2-25/32(70.61)6(152.40)8(203.20)10-3/4(273.05)4-3/32(103.89)5-1/2(139.70)8-5/8(219.08)10-5/8(270.00)2-1/8(54.10)4-3/8(111.12)7-3/8(187.33)8-7/16(214.38)5/8(15.88)5/8(15.88)11/16(17.46)15/16(23.88)CATALOGNUMBERMD52NMD52SMD52CSWDE46NSWDE46SSWDE46CSWDE55NSWDE55SSWDE55CSWDE84NSWDE84SSWDE84CFITTINGTYPENoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisCAT.NO.—SA04CA04—SA04CA04—SA04CA04—SA07CA06FIGURENUMBER4123CLAMPING RANGEGALV. STEELDIA. NO. STR. GRADEACSR#6 (6/1)4/0 (6/1)3/8 (9.53)7/16 (11.11)3/16 (4.76)1/4 (6.35)9/32 (7.14)5/16 (7.94)3/8 (9.53)7/16 (11.11)1/2 (12.70)3/8 (9.53)thru3/4 (19.05)— —777777777UtilitiesHigh Str.UtilitiesAllGradesWithinClampingAnd StrengthRatingCOPPER#6 Sol.To4/0 Str.#6 Str.To4/0 Sol.#4 (7)To4/0 (19)2/0 Sol.To500 Str.INCHES(MM).160-.563(4.06-14.30).18-.46(4.57-11.68).22-.55(5.59-13.97).36-.84(8.89-21.34)ULTIMATEBODYSTRENGTHLBS. (KG)12,000(5,443)15,000 (6,804)15,000 (6,804)15,000 (6,804)19,000 (8,618)18,000 (8,165)18,000 (8,165)30,000 (13,608)30,000 (13,608)25,000 (11,340)NO.1234U-BOLTSSIZEINCHES(MM)1/2(12.70)1/2(12.70)1/2(12.70)1/2(12.70)APPROX.WT. EACHLBS. (KG)1.9 (.86)3.2 (1.45)3.5 (1.59)4.1 (1.86)5.4 (2.45)5.7 (2.49)6.0 (3.08)8.0 (3.63)8.4 (3.81)11.0 (4.99)12.35 (5.60)12.7 (5.76)NOTE: Recommended torque on U-bolts; 1/2”—480 in. lbs.DA-20December 2011HUBBELL ® Power Systems

For distribution and light transmission construction withcopper or Copperweld ® conductor. Power loss, corrosionand heat rise are all reduced to a minimum due to the nonferrousconstructionMaterial:Body—high strength aluminum bronze alloyor red brassKeeper—electrical bronzeHardware—galvanized steelSockets and Clevises—ductile iron, galvanizedCotter Pin—#302 Stainless steelDISTRIBUTION CONNECTORSDEADENDSBOLTEDSTRAIGHT <strong>LINE</strong> STRAIN CLAMPBRONZESECTION DABRONZEBDEDA21CATALOGNUMBERBDE46NBDE46SBDE46CBDE60NBDE60SBDE60CBDE70NBDE70SBDE70CBDE86NBDE86SBDE86CBDE98NBDE98SBDE98CFITTINGTYPE CAT. NO. COPPERNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevis--SA04CA04--SA04CA04--SA04CA04--SA06CA06--SA06CA06CLAMPING RANGE#6 Sol.To4/0 Sol.2/0 Sol.To250 MCM4/0 Sol.To350 MCM4/0-7 Str.To550 MCM350-37 Str.To700 MCMINCHES(MM).16-.46(4.06-11.68).36-.60(9.14-15.24).46-.70(11.68-17.78).52-.86(13.21-21.84).68-.98(17.27-24.89)ULTIMATEBODYSTRENGTHLBS. (KG)6,000(2,722)8,000(3,629)8,000(3,629)8,000(3,629)9,000(4,082)NO.22222U-BOLTSDIMENSIONS(INCHES (MM)SIZEINCHES(MM) L W K3/8(9.53)1/2(12.70)1/2(12.70)1/2(12.70)1/2(12.70)7-1/4(184.15)8-3/4(222.25)10-3/4(273.05)11(279.40)11-5/8(295.28)3/4(19.05)3/4(19.05)3/4(19.05)15/16(23.81)1-1/16(26.99)7/8(22.23)7/8(22.23)15/16(23.81)15/16(23.81)15/16(23.81)APPROX.WT. EACHLBS. (KG)3.2 (1.45)4.4 (2.00)4.8 (2.18)5.6 (2.54)6.9 (3.13)7.2 (3.27)6.5 (2.95)7.8 (3.54)8.1 (3.67)7.0 (3.18)8.3 (3.76)8.7 (3.95)7.4 (3.36)8.7 (3.95)9.1 (4.13)NOTE:(1) Recommended torque on U-bolts; 3/8”—240 in. lbs., 1/2”—480 in. lbs.(2) Lifting eye is standard on keeper for hot line work.DA-21HUBBELL ® Power SystemsDecember 2011

DA22SECTION DABRONZEBSGDISTRIBUTION CONNECTORSDEADENDSBOLTEDSTRAIGHT <strong>LINE</strong> STRAIN CLAMPBRONZEThese compact strain clamps are ideal for pole type substationsand other short span deadending requirements with copper orcopperweld conductor.Because of non-ferrous construction, corrosion and heat rise onheavy current secondary circuits are reduced to a minimum.The threads do not protrude and all surfaces are rounded forquick, efficient taping.Material: Body and Keeper—high strength aluminum bronzealloyHex Head Bolts and Lock Washers—silicon bronzeSockets and Clevises—ductile iron, galvanizedClevis Pin—galvanized steelCotter Pin—#302 stainless steelCATALOGNUMBERBSG050NBSG050SBSG050CBSG100NBSG100SBSG100CFITTINGTYPE CAT. NO. COPPERNoneSocketClevisNoneSocketClevis--SA04CA04--SA04CA04CLAMPING RANGE2/0 Sol.To550 MCM500To1000 MCMINCHES(MM).36-.875(9.14-22.23).81-1.25(20.57-31.75)ULTIMATEBODYSTRENGTHLBS. (KG)5,500(2,495)7,500(3,402)NO.44HEX-HEADBOLTSDIMENSIONS(INCHES (MM)SIZEINCHES(MM) L W R1/2(12.70)1/2(12.70)6-1/2(165.1)7-1/2(190.5)11/16(17.46)11/16(17.46)4(101.60)6(152.40)APPROX.WT. EACHLBS. (KG)3.5 (1.59)4.8 (2.18)4.8 (2.18)4.7 (2.13)6.0 (2.72)6.3 (2.86)NOTE: Recommended torque on bolts; 1/2”—480 in. lbs.DA-22December 2011HUBBELL ® Power Systems

These clamps are recommended for copper or Copperweld® conductor. Type BSCG is supplied with a standoffguide to assure clearance between conductor and insulatordisc when clamps are used as a through type deadend orstrain.Material:Body—high strength aluminum bronze alloyKeeper and Guide—electrical bronzeHardware—galvanized steelSockets and Clevises—ductile iron, galvanizedCotter Pin—#302 stainless steelDISTRIBUTION CONNECTORSDEADENDSBOLTEDSTRAIGHT <strong>LINE</strong> STRAIN CLAMPBRONZESECTION DABRONZEBSC/BSCGDA23CATALOGNUMBERBSC024NBSC024SBSC024CBSC050NBSC050SBSC050CBSC100NBSC100SBSC100CBSCG024SBSCG024CBSCG050SBSCG050CBSCG100SBSCG100CFITTINGTYPE CAT.NO. COPPERNoneSocketClevisNoneSocketClevisNoneSocketClevisSocketClevisSocketClevisSocketClevis--SA04CA04--SA04CA04--SA04CA04SA04CA04SA04CA04SA04CA04CLAMPING RANGE#2 Sol.To4/0 Str.4/0 Str.To550 MCM500To1000 MCM#2 Sol.To4/0 Str.4/0 Str.To550 MCM500To1000 MCMINCHES(MM).258-.528(6.55-13.41).52-.875(13.21-22.23).81-1.25(20.57-31.75).258-.528(6.55-13.41).52-.875(13.21-22.23).81-1.25(20.57-31.75)ULTIMATEBODYSTRENGTHLBS. (KG)8,000(3,629)8,000(3,629)10,000(4,536)8,000(3,629)8,000(3,629)10,000(4,536)NO.223212131U-BOLTSDIMENSIONSINCHES (MM)SIZEINHCES(MM) L W1/2(12.70)1/2(12.70)1/2(12.70)1/2 (12.70)3/8 (9.53)1/2 (12.70)3/8 (9.53)1/2 (12.70)1/2 (12.70)9-1/8(231.78)9-5/8(244.48)13-1/8(333.38)9-1/8(231.78)9-5/8(244.48)13-1/8(333.38)11/16(17.46)11/16(17.46)13/16(20.64)11/16(17.46)11/16(17.46)13/16(20.64)APPROX.WT. EACHLBS. (KG)3.1 (1.41)4.4 (2.00)4.4 (2.00)3.8 (1.72)5.1 (2.31)5.1 (2.31)6.9 (3.13)8.2 (3.72)8.2 (3.72)5.2 (2.36)5.2 (2.36)6.8 (3.08)6.8 (3.08)11.0 (4.99)11.0 (4.99)NOTES: (1) Socket or clevis is necessary for Type BSCG to provide clearance for cable guide.(2) Recommended torque on U-bolts; 3/8”—240 in. lbs., 1/2”—480 in. lbs.(3) To obtain silicon bronze hardware add suffix—“ED”. Example, BSC024NED.DA-23HUBBELL ® Power SystemsDecember 2011

DA24SECTION DABRONZEBSD/BSDSDISTRIBUTION CONNECTORSDEADENDSBOLTEDQUADRANT STRAIN CLAMPBRONZEFor heavy duty application using copper or Copperweld ®conductor.Material:Body—high strength aluminum bronze alloyKeeper—electrical bronzeHardware—galvanized steelSockets and Clevises—ductile iron, galvanizedCotter Pin—#302 stainless steelCATALOGNUMBERBSD55BSD68BSD84BSD112BSD130BSD163DIMENSION INCHES (MM)L W C K PD10(254)11(279.40)12(304.80)13-1/8(333.38)14(355.60)14(355.60)11/16(17.46)3/4(19.05)1(25.40)1-3/8(34.93)1-7/16(36.51)1-23/32(43.66)7-1/2(190.50)9-1/2(241.30)12(304.80)8-1/4(209.60)9-1/2(241.30)5-3/4(146.05)1-1/4(31.75)1-5/16(33.34)1-1/4(31.75)1-1/2(38.10)1-23/32(43.7)1-1/2(38.10)5/8(15.88)5/8(15.88)5/8(15.88)3/4(19.05)3/4(19.05)5/8(15.88)CATALOGNUMBERBSD55NBSD55SBSD55CBSD68NBSD68SBSD68CBSD84NBSD84SBSD84CBSD112NBSD112SBSD112CBSD130NBSD130SBSD130CBSDS163NBSDS163SBSDS163CFITTINGTYPE CAT. NO. COPPERNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevis--SA04CA04--SA04CA04--SA06CA06--SA1013CA1013--SA1113CA1013--SA13CA13#4 Sol.-4/0 Str.1/0 Sol.-350-19 Str.4/0 Str.-500 MCM400-1000 MCM400-1500 MCM1250-2000 MCMCLAMPING RANGEINCHES(MM).200-.500(5.08-13.97).300-.680(7.62-17.27).475-.840(12.07-21.34).710-1.15(18.03-29.21).710-1.42(18.03-36.07)1.18-1.63(29.97-41.40)Notes: (1) Recommended torque on U-bolts; 1/2”—480 in. lbs., 5/8”—720 in. lbs.(2) To obtain silicon bronze hardware, add suffix “ED”.Example: BSD55NED.ULTIMATEBODYSTRENGTHLBS. (KG)NO.18,000 (8,165) 325,000 (11,340)20,000 (9,072)18,000 (8,165)25,000 (11,340)25,000 (11,340)25,000 (11,340)35,000 (15,876)30,000 (13,608)25,000 (11,340)35,000 (15,876)30,000 (13,608)25,000 (11,340)27,000 (12,247)27,000 (12,247)25,000 (11,340)44553U-BOLTSSIZEINCHES(MM)1/2(12.70)1/2(12.70)1/2(12.70)1/2(12.70)5/8(15.88)5/8(15.88)APPROX.WT. EACHLBS (KG)6.4 (2.90)7.7 (3.49)7.2 (3.27)8.7 (3.95)10.0 (4.54)10.0 (4.54)12.7 (5.76)14.0 (6.35)14.4 (6.53)14.8 (6.71)16.3 (7.39)16.8 (7.62)24.5 (11.11)26.0 (11.79)26.5 (12.02)18.4 (8.35)20.1 (9.12)20.2 (9.16)DA-24December 2011HUBBELL ® Power Systems

These clamps are used primarily for deadending coppersubstation cable bus.When installing, cable will slide freely under the U-bolts.If preferred, U-bolts may be removed and cable laid inclamp grooves from the side.These clamps are compact for greatest phase clearance.Material:Body and Keeper—high strength bronzeHardware—galvanized steelSockets and Clevises—ductile iron, galvanizedCotter Pin—#302 stainless steelDISTRIBUTION CONNECTORSDEADENDSBOLTEDQUADRANT STRAIN CLAMPBRONZESECTION DABRONZEBR1/BR2DA25CATALOGNUMBERBR1025NBR1025SBR1025CBR1050NBR1050SBR1050CBR1100NBR1100SBR1100CBR1150NBR1150SBR1150CBR1200NBR1200SBR1200CBR2025NBR2025SBR2025CBR2050NBR2050SBR2050CBR2100NBR2100SBR2100CFITTINGTYPE CAT. NO. COPPERNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevisNoneSocketClevis--SA06CA06--SA06CA06--SA06CA06--SA06CA06--SA06CA06--SA06CA06--SA06CA06--SA06CA06CLAMPING RANGE2/0 Sol.To250-19 Str.250-19 Str.To500 MCM500To1000 MCM1000To1500 MCM1500 MCMTo2000-Str.2/0 Sol.To250-19 Str.250-19 Str.To500 MCM500To1000 MCMINCHES(MM).365-.574(9.27-14.58).574-.813(14.58-20.65).811-1.152(20.60-29.26)1.150-1.412(29.21-35.86)1.411-1.632(35.84-41.40).365-.574(9.27-14.58).574-.813(14.58-20.65).811-1.152(20.60-29.26)ULTIMATEBODYSTRENGTHLBS. (KG)8,000(3,629)10,000(4,536)15,000(6,804)15,000(6,804)15,000(6,804)8,000(3,629)10,000(4,536)15,000(6,804)NO.33333333U-BOLTSDIMENSIONSINCHES (MM)SIZEINCHES(MM) L W H3/8(9.53)1/2(12.70)1/2(12.70)5/8(15.88)5/8(15.88)3/8(9.53)1/2(12.70)1/2(12.70)8-1/16(204.79)8-7/8(225.43)9-1/8(231.78)10-1/2(266.70)12-3/4(323.85)8-1/16(204.79)8-3/4(222.25)9-1/8(231.78)---------------21/32(16.67)7/8(22.23)1-3/16(30.16)3-5/32(80.17)33/8(85.73)3-7/8(98.43)4-3/8(111.13)5(127)3-5/32(80.17)3-1/4(82.55)3-7/8(98.43)APPROX.WT. EACHLBS. (MM)5.4 (2.45)6.7 (3.04)7.1 (3.22)7.0 (3.18)8.3 (3.76)8.7 (3.95)9.2 (4.17)10.5 (4.76)10.9 (4.95)13.4 (6.08)14.7 (3.67)16.1 (7.30)15.0 (6.80)16.3 (7.39)16.7 (7.58)5.7 (2.59)7.0 (3.18)7.4 (3.36)10.0 (4.54)11.3 (5.13)11.7 (5.31)14.0 (6.35)15.3 (6.95)15.7 (7.12)NOTE: Recommended torque on U-bolts; 3/8”—240 in.-lbs., 1/2”—480 in.-lbs., 5/8”—720 in.-lbs.DA-25HUBBELL ® Power SystemsDecember 2011

DA26SECTION DADUCTILE IRONDDCDISTRIBUTION CONNECTORSDEADENDSBOLTEDCIRCULAR DEADEND CLAMPFERROUSFor deadending static wires.May be used to deadend copper or Copperweld ® phase conductors.Magnetic induction heating will occur.TYPE DDCMaterial:Body and Keeper—ductile iron, galvanizedBolts and Washers—galvanized steel (lubricated)Grommet—neopreneClevis Pin—galvanized steelSockets and Clevises--ductile iron, hot dip galvanizedCotter Pin—#302 stainless steelSpring Clip—zinc plated steelCATALOG NUMBER80500CATALOG NUMBER85351CATALOG NUMBER88500CATALOG NUMBER78500CATALOGNUMBERDDC55NDDC55SDDC55CTYPEFITTINGCAT. NO.CLAMPINGRANGEINCHES (MM)ULTIMATEBODYSTENGTHLBS. (KG)WDIMENSIONSINCHES (MM)HNoneSocketClevis—SA05CA05.16-.55(4.06-13.97)16,000(7,258)13/16(20.64)5-3/16(131.76)APPROX.WT. EACHLBS. (KG)3.5 (1.59)4.8 (2.18)5.1 (3.09)FITTINGCATALOGNUMBER TYPE CAT. NO.805002000 None —853512000 Socket—SA04885002000 None —785002000785012000NoneSocket—SA04CLAMPING RANGEINCHES (MM)SMALLLARGEGROOVE.12-.19(3.05-4.83).16-.25(4.06-6.35).16-.33(4.06-8.38).20-.50(5.08-12.70)NOTE: Recommended torque on bolts; 1/2"—480 in.-lbs.ULTIMATEBODYSTENGTHLBS. (KG)8,000(3,628)10,000(4,536)10,000(4,536)14,000(6,350)DIMENSIONSINCHES(MM)GROOVE W H.19-.38(4.83-9.65).25-.44(6.35-11.18).33-.55(8.38-13.97)11/16(17.46)11/16(17.46)11/16(17.46)3/4(19.05)2-7/16(61.91)4-3/4(120.65)4-5/16(109.54)4-1/4(107.95)APPROX.WT. EACHLBS. (KG)1.5 (.68)2.3 (1.04)3.8 (1.72)2.4 (1.09)3.9 (1.77)5.4 (2.45)DA-26December 2011HUBBELL ® Power Systems

DISTRIBUTION CONNECTORSSECTION DADUCTILE DEADEND THIMBLETYPE DDTProvides a convenient and efficient means for loopdeadending of steel static wire and bare or insulatedaluminum or copper phase wires. Magnetic inductionheating will occur.Material: Body – ductile iron, galvanizedClevis Pin – galvanized steelCotter Pin - #302 stainless steelDUCTILE IRONDDTDA27CATALOGNUMBERDDT07CONDUCTORRANGE INCHES(MM)0-.875(0.22.23)ULTIMATEBODYSTRENGTHLBS. (KG)40,000 (18,144)0-1.0DDT12* (0-25.40)60,000 (27.216)*Bolt, Nut & Cotter Pin are standard.DIMENSIONS INCHES (MM)L B W H PD5 3/8(136.53)7 13/16(45.97)2 5/16(58.74)3 3/4(95.25)7/8(22.23)1 5/16(33.27)APPROX.WT. EACHLBS. (KG)3 1/4 (82.55) 3/4 (19) 2.5 (1.13)3 3/4 (95.25) 1 (25)* 5.7 (2.5)DEADENDSALUMINUM DEADEND THIMBLETYPE ADETALUMINUMADETProvides a convenient and efficient means for loop deadendingof steel static wire and bare or insulated aluminumphase wires. Generous pulling eye for easyinstallation.Material: Body – high strength aluminum alloyClevis Pin – galvanized steelCotter Pin - #302 stainless steelCATALOGNUMBERADET75ADET88CONDUCTOR RANGEINCHES (MM) RATED STRENGTH LBS. DIMENSIONS INCHES (MM)GUYACSR WIRE THIMBLE EYE A B C D E F#6 – 336.4 3/16 – 5/16 10,000 6,000 0.75 (19) 1.5 (38.1) 2.12 (53.8) 0.63 (16) 3 (76.2)#6 – 477 3/16 – 3/8 12,000 7,000 0.88 (22.4) 1.5 (38.1) 2.12 (53.8) 0.63 (16) 3 (76.2)4.81(122.2)4.81(122.2)DA-27HUBBELL ® Power SystemsDecember 2011

DA28SECTION DAALUMINUMGM100AGM125AGM104AGM124ADISTRIBUTION CONNECTORSDEADENDSBOLTEDMIDSPAN CLAMPS AND DEADENDSALUMINUMFargo Mid Span Clamps and Deadends may be used onopen wire or triplex secondaries for single or multiple serviceconnectors away from the pole. Cast, high strengthaluminum provides corrosion resistance and conductorcompatibility.The Fargo GM104A is designed for neutral deadend connections.Service deadends may be attached through theside loops permitting installation at any angle. The longcontact surfaces protect the neutral against corrosion anddamage from the pull of the service. Fitted grooves areprovided to protect covered phase wire when installed ontriplex secondaries.The Fargo GM1091A is easily installed by swiveling thekeepers over the run conductor. Double clamping of therun provides parallel current paths. Side opening keeperspermit easy insertion and quick connections. Either tap canbe installed or removed without unclamping the run conductorand installation is made without disassembly.The Fargo GM124A combination connector and deadendprovides both electrical and mechanical neutral connectionsfor secondary service drops. Service deadends of eitherrigid or flexible bail types may be easily installed onthe projecting hooks of the body of the clamp. The designof the hook retains the bail in position during vibration orshock loading of either the secondary neutral or the service.The aluminum 4 tap connector block provides a compactterminal for electrically joining the neutrals of one throughfour services. Each service is an individual connection permittingconvenient installation or removal of service.The Fargo GM125A utilizes the aluminum 4 tap connectorblock and an aluminum base or body with side loops for attachmentof service deadends.The use of high strength aluminumwasher head bolts permits ease of installation oneither open wire or triplex secondary neutrals away fromthe poles.Material: Casting–High strength alluminum alloyHardware – Stainless steel (GM1091A)High Strength AL Alloy (GM104, GM124,GM125)Note: Add suffix “L” to catalog number forinhibitor protection and individual packagingCONDUCTOR RANGE, ACSRAPPROX. DIMENSIONS INCHESCATALOGNUMBERRUNTAPA B C D E FMAX. MIN. MAX. MIN.GM104A 336.4 4 - - 4 1/8 2 2 1/8 - 3/8 5/8GM1091A 4/0 2 1/0 6 3 3/8 1 7/8 2 1/16 - 3/8 5/8GM124A 4/0 4 2/0 6 7 2 5/8 2 7/8 1/2 3/8 -GM125A 4/0 4 2/0 6 4 1/8 2 1/4 2 7/8 1/2 3/8 5/8DA-28December 2011HUBBELL ® Power Systems

DISTRIBUTION CONNECTORSSECTION DAIN-SPAN PHASE CONNECTOR AND HOUSINGThis in-span phase connector is designed for use onopen wire or multiple cable secondaries to permitaesthetic readily accessible service connections.The connector body is constructed of high strengthaluminum for optimum corrosion resistance andlight weight. The Fargo housing or case providesprotective insulation from adjacent conductors and isformed for accessibility and ease of application. Secondaryrun and service tap openings are pre-cut foralignment and tap conductor insertion or removal.The connector locks in position inside the case providingone piece for assembly.For best performance, the connectors are suppliedwith Fargolene ® inhibitor protected grooves and areindividually packaged in plastic bags.The Fargo GM128AKL makes an insulated phaseconnector system for up to four service taps and maybe used with the Fargo neutral span clamps.ALUMINUMGM128DA29CATALOGNUMBERGM128AL(Connector Only)GM128AKL(Connector and Housing)RANGE APPROX. OVERALL DIMENSIONS INCHES WEIGHTLBSRUN TAP LENGTH (MM) WIDTH (MM) HEIGHT (MM) (KG)2 Str. – 350 kcmil 4 Sol. – 3/0 Str.2 Str. – 350 kcmil 4 Sol. – 3/0 Str.3 5/16(84.03)3 13/16(97.03)2 5/8(66.81)3 1/4(82.71)2(50.90)3(76.35)1.04(.47)1.20(.54)HUBBELL ® Power SystemsDA-29December 2011

DA30SECTION DAALUMINUMGM100DISTRIBUTION CONNECTORSDEADENDSBOLTEDIN-SPAN NEUTRAL TAPSALUMINUMFargo in-span taps offer a wide range of neutral connectionson open wire or multiple cable secondaries.• A wide angle bell mouth opening permits tap offs up to45˚ in either direction from the center line of the clamp.• Constructed of high strength aluminum alloy theseclamps provide a minimum holding power of 1250pounds.• Long contoured contact surfaces protect the neutralfromthe pull of the service.• Using less parts than conventional units, these taps areavailable for one, two or four service dead endconnections.Material:Body Casing – Aluminum AlloyHardware – Stainless SteelNote: Add suffix “L” to catalog number for inhibitorprotection and individual packs. Ex. – GM102ALCATALOGRUNTAPAPPROX. OVERALL DIMENSIONS INCHESNUMBER MAX. MIN. MAX. MIN. NO. OF TAPS LENGTH WIDTH HEIGHTGM102A 4/0 ACSR 1/0 ACSR 2 ACSR 6 ACSR 1 3 3/8 1 1/2 2 3/4GM1024A 4/0 ACSR 1/0 ACSR 2 ACSR 6 ACSR 4 5 3/4 5 2 3/4DA-30December 2011HUBBELL ® Power Systems

For aluminum or ACSR triplex conductor.Eyebolt provides positive bonding of neutrals.Material:Body—Aluminum alloyEyebolt—Aluminum bronzeHardware—Galvanized steelDISTRIBUTION CONNECTORSALUMINUM MID-SPAN CONNECTORTYPE MSNSECTION DAALUMINUMMSNDA31CATALOGNUMBERCONDUCTOR RANGE (AWG) DIMENSIONS—INCHES (MM) APPROX.WT. EACHAAC ACSR L H W HLBS. (KG)MSN1 #2-2/0 #4-2/0MSN2 #2-2/0 #4-2/04-5/32(105.57)6-11/32(161.13)2-5/16(58.74)2-5/16(58.74)ALUMINUM MID-SPAN CONNECTORTYPE MSNT1-5/8(41.28)1-5/8(41.28)3/8(9.52)3/8(9.52).46(.21).64(.29)ALUMINUMMSNTFor aluminum or ACSR triplex conductor.Has a double take-off loop.Bolts are peened to make nut captive.Material:Body—Top Member-Aluminum alloyBottom Member—Bronze alloy-tin platedHardware—Galvanized steelCATALOGNUMBERCONDUCTOR RANGE (AWG) DIMENSIONS—INCHES (MM) APPROX.WT. EACHNEUTRAL PHASE L J DIA. LBS. (KG)MSNT2 1/0-4/0 ACSR #6-1/0 AAC OR ACSR4-11/16(119.09)3/8(9.52)7/8(22.22).64(.29)HUBBELL ® Power SystemsDA-31December 2011

SECTION DADISTRIBUTION CONNECTORSALUMINUM MID-SPAN CONNECTORTYPE MSEDA32ALUMINUMMSEFor aluminum and ACSR triplex or quadruplex conductor.Material:Body—Aluminum alloyHardware—Plated steelCATALOGNUMBERCONDUCTOR RANGE (AWG OR MCM) DIMENSIONS—INCHES (MM) APPROX.WT. EACHNEUTRAL PHASE L J DIA. LBS. (KG)MSE416981 #4-4/0 ACSR #6-1/0 AAC OR ACSR4-1/8(104.78)3/8(9.52)3/4(19.05).46(.21)ALUMINUM SUPPORT BRACKETTYPE TTSB(TRIPLEX SUSPENSION)ALUMINUMTTSBFor aluminum or ACSR triplex conductor.Can be mounted to a flat surface or to a wood pole.5/8-11T galvanized thru-bolt is not furnished.Material:Aluminum alloyCATALOGNUMBERTTSB416671CONDUCTOR RANGE(AWG OR MCM)#2 ACSR-477 MCM (AAC)DIMENSIONS—INCHES (MM)L W H2-5/16(58.72)2-3/8(60.32)3-5/16(84.12)APPROX.WT. EACHLBS. (KG).38(.17)DA-32December 2011HUBBELL ® Power Systems

DEADENDSBOLTED QUADRANT STRAIN CLAMPALUMINUMALUMINUMSLQ• For distribution construction with AAC, AAAC, & ACSR.• Spring loaded design holds keeper out of the way foreasier conductor insertion.• Side loading conductor groove makes installation mucheasier than conventional u-bolt style quadrant clamps.• 1/2” bolt allows for hand or hydraulic tool installations.• ANSI C119.4 Class 1A, normal tension connector (60% ofrated conductor strength).DA-16AMaterial: Body and Keeper—High Strength Aluminum AlloyHardware—Galvanized SteelSpring and Cotter Pin—Stainless SteelCØ.63AKBCATALOGNUMBERFITTING CLAMPING RANGEINCHESULTIMATE STRENGTHLBS. (KG)BOLTSSIZE INCHESNOMINAL DIM,INCHES (MM)TYPE CAT. NO. ACSR ALUMINUM (MM) BODY SAG NO. (MM) A B C KAPPROX.WT. EACHLBS. (KG)SLQ48N None --SLQ48S Socket SA04#6 (6/1)To2/0 (6/1)#4 (7 str) To2/0 (19 str)0.19 - 0.48(4.8 - 12.2)8,000 6,000 11/2(12.70)3.65(93)4.62(117)0.75(19)0.95(24)1.7(0.760)SLQ48C Clevis CA04NOTES: Recommended Torque on Bolt: 45 lb-ft (540 lb-in)Wrench Flat = 3/4” on 1/2” diameter BoltANDERSON HUBBELL ® POWER SYSTEMS FARGO ® APRIL 20121

DISTRIBUTION PRODUCTSINDEXSection DBoverhead line splicesSERIES DESCRIPTION PAGEautomatic/copper & aluminumGL....................... REDUCING <strong>SPLICES</strong>....................................................................................DB-4automatic/bi-metalGL....................... COPPER TO ALUMINUM..............................................................................DB-5automatic/copperGL100................. COPPER AUTOMATIC <strong>SPLICES</strong>...................................................................DB-1automatic/aluminumGL1000............... ALUMINUM AUTOMATIC <strong>SPLICES</strong> (MULTIPLE LAYER STRAND)..............DB-2GL1300............... ALUMINUM AUTOMATIC <strong>SPLICES</strong> (MULTIPLE LAYER STRAND)..............DB-3GL400................. ALUMINUM AUTOMATIC <strong>SPLICES</strong>......................................................DB-2/DB-3GLT..................... MULTIPLE LAYER STRAND CONDUCTORS...............................................DB-3automatic/GUY WIREGLS5000............. GUY WIRE AUTOMATICS.............................................................................DB-6compression/aluminum <strong>SPLICES</strong>FTA...................... FULL TENSION <strong>SPLICES</strong> (ALL ALUMINUM)..............................................DB-15FTR..................... FULL TENSION <strong>SPLICES</strong> (AAAC, ACAR & ACSR)...................................DB-16PTA...................... PARTIAL TENSION <strong>SPLICES</strong> (ALL ALUMINUM)........................................DB-13PTR..................... PARTIAL TENSION <strong>SPLICES</strong> (AAAC, ACAR & ACSR)..............................DB-14VACS................... VERSAtile MINIMUM TENSION SPLICE...................................................DB-7VACS................... TOOL & DIE INFORMATION.............................................................DB-21/DB-22VANS................... VERSAtile TRIPLEX NEUTRAL PARTIAL TENSION SPLICE.................DB-11VAUS................... VERSA-CRIMP ® MINIMUM TENSION SPLICE..................................DB-9/DB-10VCA/VCAR.......... VERSA-CRIMP ® FULL TENSION SPLICE (AAC & ACSR).........................DB-17VCJS*R............... VERSA-CRIMP ® MINIMUM TENSION SPLICE (RANGE TAKING).............DB-12VCR..................... VERSA-CRIMP ® FULL TENSION SPLICE (AAC & ACSR).........................DB-17VCSE.................. VERSA-CRIMP ® MINIMUM TENSION SPLICE.............................................DB-8VCSN.................. VERSA-CRIMP ® PARTIAL TENSION SPLICE.............................................DB-11compression ACCESSORYSEC..................... SNAP ON COVER .........................................................................................DB-8compression/copperVCC..................... VERSA-CRIMP® FULL TENSION SPLICE.................................................DB-20VHS..................... VERSAtile MINIMUM TENSION SPLICE.................................................DB-19VHS..................... TOOL & DIE INFORMATION........................................................................DB-24VHSS.................. VERSAtile MINIMUM TENSION SPLICE.................................................DB-18VHSS.................. TOOL & DIE INFORMATION........................................................................DB-23HUBBELL ® Power Systems October 2012

<strong>OVERHEAD</strong> <strong>LINE</strong> <strong>SPLICES</strong>AUTOMATICCOPPER• Fastest method of splicing copper & copperweld conductor• Inhibitor protected for optimum long term performance• Individually bagged to seal out dirt before use• Ratings:Solid Copper = 90% of Conductor RBS*Stranded Copper = 80% of Conductor RBS*Copperweld = 75% of Conductor RBS**RBS = Rated Breaking StrengthMaterial: Shell - Drawn Copper TubeJaw - Bronze Alloy+RUS ListedProduct Data & Conductor SizeCOPPERGL100CONDUCTOR RANGE APPROXIMATE CONDUCTOR O.D. DIMENSIONS INCHES (MM)COPPERCATALOGNUMBERSOLIDASTM-B258STRANDASTM-B8COPPERWELDSTRANDMIN/MAXINCHESMIN/MAXMM A BGL110 8 – – .12-.13 3.1-3.3 3.4 (86) .50 (13)GL111+ 6 – 3 #12 .16-.17 4.0-4.4 3.4 (86) .50 (13)GL112+ 4 – 8A .19-.20 4.9-5.2 3.5 (89) .56 (14)GL113 3 4 (7) 6A .22-.23 5.7-5.9 3.5 (89) .56 (14)GL114 2 3 (7), 4 (3) 5A .25-.26 6.3-6.6 4.4 (110) .75 (19)GL1140 2 or 3 3 (7), 4 (7) – .22-.26 5.7-6.6 6.5 (160) .75 (19)GL115+ 1 2 (7) 4A .28-.29 7.2-7.4 4.4 (110) .75 (19)GL116 1/0 1 (7), 2 (3) 3A .32-.33 8.1-8.3 4.4 (110) .75 (19)GL117+ 2/0 1/0 (7), 1 (3) 2A .36-.37 9.1-9.3 5.5 (140) .94 (24)GL118+ 3/0 2/0 (7) – .40-.41 10.2-10.5 5.5 (140) .94 (24)GL119+ 4/0 3/0 (7) – .45-.46 11.5-11.8 6.9 (180) 1.2 (30)GL120+ – 4/0 (7,19) – .52-.53 13.2-13.4 6.9 (180) 1.2 (30)GL121 – 250 (19,37) – .57-.58 14.4-14.7 6.9 (180) 1.2 (30)GL123 – 300 (19,37) – .62-.63 15.8-16.1 8.6 (220) 1.5 (38)GL125 – 350 (19) – .67-.68 17.0-17.2 8.6 (220) 1.5 (38)GL127 – 400 (19,37) – .71-.73 18.1-18.5 8.6 (220) 1.5 (38)GL128 – 450 (37) – .76-.77 19.4-19.6 8.6 (220) 1.5 (38)GL130 – 500 (19,37) – .80-.81 20.4-20.7 8.6 (220) 1.5 (38)Splices for Metric ConductorCATALOGAPPROXIMATE CONDUCTOR O.D.DIMENSIONS INCHES (MM)NUMBERCONDUCTORMIN/MAX INCHES MIN/MAX MM A BGL110M 6 mm 2 .10-.14 2.6-3.5 4.20 (107) .51 (13)GL111M 10 mm 2 .14-.17 3.4-4.3 4.20 (107) .51 (13)GL112M 16 mm 2 Sol. .17-.20 4.2-5.2 4.36 (111) .55 (14)GL113M 16 mm 2 Str. .20-.22 5.0-5.8 4.36 (111) .55 (14)GL114M 25 mm 2 .22-.26 5.8-6.6 5.46 (139) .71 (18)GL115M 35 mm 2 .25-.30 6.5-7.6 5.46 (139) .71 (18)GL117M 50 mm 2 .31-.37 7.9-9.4 6.48 (165) .90 (23)GL118M 70 mm 2 .37-.43 9.4-10.9 6.48 (165) .90 (23)GL119M 95 mm 2 .44-.50 11.3-12.6 7.98 (203) 1.22 (31)GL120M 120 mm 2 .50-.56 12.6-14.2 7.98 (203) 1.22 (31)DB1DB-1ANDERSON HUBBELL ® POWER SYSTEMS FARGO ® OCTOBER 2012

ALUMINUMGL400<strong>OVERHEAD</strong> <strong>LINE</strong> <strong>SPLICES</strong>AUTOMATICALUMINUMDB2• ANSI C119.4, full tension, Class A connector (95% ofconductor breaking strength unless otherwise noted)• Color coded end funnel guides for easy identification• Factory inhibitor protected• Fastest method of splicing aluminum, aluminum alloyand ACSR conductorMaterial: Shell - High Strength Aluminum AlloyJaws - Aluminum AlloyCONDUCTOR SIZEAPPROXIMATE CONDUCTORO.D.DIMENSIONS INCHES (MM)CATALOGNUMBERACSRASTM-B232AAACASTM-B399AACASTM-B231MIN/MAX.INCHESMIN./MAX.MMCOLORCODEA BGL401 6 - 4 6 - 4 6 - 4 .184-.263 4.68-6.70 Blue 14 (360) 1.0 (25)GL402A 4 4 4 .225-.250 5.59-6.35 Orange 9 (230) 0.9 (23)GL404A 2 2 2 .280-.320 7.11-8.13 Red 12 (305) 1.0 (25)GL4042A 4 - 2 4 - 2 4 - 2 .220-.320 5.59-8.13 Red- Orange 12 (305) 1.0 (25)GL406A 1/0 1/0 1/0 .355-.400 9.02-10.16 Yellow 12 (305) 1.1 (28)GL4076A 1/0-2/0 1/0-2/0 1/0-2/0 .355-.470 9.02-11.94 Yellow-Gray 18 (460) 1.4 (36)GL407 2/0 2/0 2/0 .400-.470 10.16-11.94 Gray 18 (460) 1.4 (36)GL408 3/0 3/0 3/0 .450-.530 11.43-13.46 Black 20 (510) 1.6 (41)GL4098 3/0-4/0 3/0-4/0 3/0-4/0 .450-.595 11.43-15.11 Pink-Black 22 (560) 1.7 (43)GL409A 4/0 4/0 4/0 .505-.595 12.83-15.11 Pink 17 (430) 1.6 (41)GL1185A – 1/0 1/0-2/0 .334-.415 8.5-10.56 – 9 (230) 1.0 (25)GL1195A – 2/0-3/0 3/0 .417-.532 10.59-13.51 – 10 (260) 1.2 (31)GL1205A – – *4/0-266.8 .518-.595 13.16-15.11 Natural 9 (230) 1.2 (31)*Includes compact conductor of same size - ASTM-B400Note: For conductors other than those listed, consult factory.Product Data & Conductor SizeOCTOBER 2012ANDERSON HUBBELL ® POWER SYSTEMS FARGO ®

<strong>OVERHEAD</strong> <strong>LINE</strong> <strong>SPLICES</strong>AUTOMATICALUMINUM(MULTIPLE LAYER STRAND CONDUCTORS)ALUMINUMGL400• Automatic for larger multiple layer stranded conductorused in primary distribution and transmission• ANSI C119.4, full tension, Class A connector (95% of conductorbreaking strength unless otherwise noted)• Color coded end funnel guides for easy identification• Factory inhibitor protected• Fastest method of splicing aluminum, aluminum alloy andACSR conductorDB3DB-3Material: Shell - Seamless High Strength Aluminum AlloyJaws - High Strength Aluminum AlloyNote: For conductors other than those listed, consult factory.MULTIPLE LAYER STRAND CONDUCTORS-KCMIL SIZESCONDUCTOR SIZEAPPROXIMATE CONDUCTORO.D.DIMENSIONS INCHES (MM)CATALOGNUMBERACSRASTM-B232AAACASTM-B399AACASTM-B231MIN/MAX.INCHESMIN./MAX.MMCOLORCODEA BGL410 266.8 (18/1) 312.8 *336.4 .603-.666 15.32-16.92 Brown 19 (480) 1.7 (43)GL411 336.4 (18/1) 394.5 *397.5,**336.4 .659-.724 16.74-18.39 Green 20 (510) 1.8 (46)GL412 397.5 (18/1) 465.4 *477 .720-.795 18.34-20.19 Blue 22 (560) 2.0 (51)GL413 477 (18/1) 559.5 *556.5, 500 .780-.858 19.81-21.79 White 24 (610) 2.1 (54)GLT1316A 266.8 (26/7) – – – – Natural 36 (916) 2.2 (56)GLT1317A 336.4 (26/7) – – – – Green 25 (640) 1.8 (46)GLT1319A 477 (26/7) – – – – White 36 (916) 2.2 (56)GL1333A+ 556.5 (18/1) Consult Fargo 636 .840-.920 21.34-23.37 Natural 15 (380) 2.0 (51)GL1355A+ Consult Fargo Consult Fargo 700, 715 .940-.976 23.80-24.80 Natural 16 (410) 2.0 (51)GL1385A+ Consult Fargo Consult Fargo 795 .996-1.031 25.30-26.19 Natural 16 (410) 2.0 (51)GL1441A+ Consult Fargo Consult Fargo 954 1.100-1.140 27.94-28.96 Red 16 (410) 2.0 (51)*Includes compact conductor of same size - ASTM-B400+Maximum design rating 10,000 lb./44.5 kN**Round onlyProduct Data & Conductor SizeANDERSON HUBBELL ® POWER SYSTEMS FARGO ® OCTOBER 2012

DB4REDUCINGGLCopperACSR<strong>OVERHEAD</strong> <strong>LINE</strong> <strong>SPLICES</strong>AUTOMATIC REDUCING• Allows easy splicing from one size conductor to another sizeconductor• Allows utilities the option of not stocking old conductor thatisn’t used anymore• Splice provides full strength of the weaker of the two conductorsand a resistance lower than the equivalent conductor• Same design philosophy and material as used in the copperand aluminum automatic splices.Material: CopperShell - Drawn Copper TubeJaws - Bronze AlloyAluminumShell - Aluminum AlloyJaws - Aluminum AlloyProduct Data & Conductor SizeCOPPER REDUCING <strong>SPLICES</strong>CONDUCTOR SIZEDIMENSIONS INCHES (MM)CATALOGLARGE ENDSMALL ENDNUMBERSOLID STRAND SOLID STRANDABGL150 4 – 6 – 4 (100) .56 (14)GL151 3 4 6 – 4 (100) .56 (14)GL152 3 4 4 – 4 (100) .56 (14)GL153 2 3 6 – 5 (130) .75 (19)GL154 2 3 4 – 5 (130) .75 (19)GL155 1 2 6 – 5 (130) .75 (19)GL156 1 2 4 – 5 (130) .75 (19)GL157 1 2 3 4 5 (130) .75 (19)GL158 1 2 2 3 5 (130) .75 (19)GL159 1/0 1 3 4 5 (130) .75 (19)GL160 1/0 1 2 3 5 (130) .75 (19)GL161 1/0 1 1 2 5 (130) .75 (19)GL162 2/0 1/0 3 4 6 (150) .94 (24)GL163 2/0 1/0 2 3 6 (150) .94 (24)GL164 2/0 1/0 1 2 6 (150) .94 (24)GL165 2/0 1/0 4 – 6 (150) .94 (24)GL166 2/0 1/0 1/0 1 6 (150) .94 (24)GL167 3/0 2/0 3 4 6 (150) .94 (24)GL168 3/0 2/0 2 3 6 (150) .94 (24)GL169 3/0 2/0 1 2 6 (150) .94 (24)GL170 3/0 2/0 1/0 1 6 (150) .94 (24)GL171 3/0 2/0 2/0 1/0 6 (150) .94 (24)GL172 4/0 3/0 3/0 2/0 7.4 (190) 1.3 (33)GL173 – 4/0 2/0 1/0 7.4 (190) 1.3 (33)GL174 – 4/0 3/0 2/0 7.4 (190) 1.3 (33)GL175 – 4/0 4/0 3/0 7.4 (190) 1.3 (33)GL176 – 250 – 4/0 7.4 (190) 1.3 (33)ACSR REDUCING <strong>SPLICES</strong>GL406A4042A 1/0 4 - 2 12.1 (307) 1.2 (30)GL412411 397.5 336.4 21 (530) 2.0 (51)OCTOBER 2012ANDERSON HUBBELL ® POWER SYSTEMS FARGO ®

<strong>OVERHEAD</strong> <strong>LINE</strong> <strong>SPLICES</strong>AUTOMATICBI-METAL (COPPER TO ALUMINUM)BI-METALGL• Provide a permanent electrical and mechanical connectionof copper to ACSR, aluminum or aluminum alloyconductors• Factory loaded inhibitor to ensure long term corrosionfree performance• Individually bagged to seal out dirt before useDB5DB-5Material: Shell - Aluminum AlloyJaws on side - Aluminum AlloyJaws on copper side - Plated Bronze AlloyProduct Data & Conductor SizeCONDUCTOR RANGEDIMENSIONS INCHES (MM)COPPER ENDALUMINUM ENDCATALOGNUMBERSOLID STRAND ACSR AAAC AACABGL113195A 3 4 – 2/0 - 3/0 3/0 - 4/0 8.5 (220) 1.3 (33)GL114185A 2 3 – 1/0 1/0 - 2/0 8.5 (220) 1.3 (33)GL114195A 2 3 – 2/0 - 3/0 3/0 - 4/0 8.5 (220) 1.3 (33)GL117018A 2/0 1/0 – 1/0 2/0 8.5 (220) 1.3 (33)GL118195A 3/0 2/0 – 2/0 - 3/0 3/0 - 4/0 8.5 (220) 1.3 (33)GL4042A11 6 – 2 - 4 2 - 4 2 - 4 9.4 (239) 1.0 (25)GL4042A12 4 6 2 - 4 2 - 4 2 - 4 9.4 (239) 1.0 (25)GL4042A13 3 4 2 - 4 2 - 4 2 - 4 9.4 (239) 1.0 (25)GL40615 1 2 1/0 1/0 1/0 13 (331) 1.3 (33)GL41118 3/0 2/0 336.4 (18/1) 394.5 397.5 15.5 (394) 1.8 (46)GL41223 – 300 397.5 (18/1) 465.4 477 18 (450) 2.0 (51)ANDERSON HUBBELL ® POWER SYSTEMS FARGO ® OCTOBER 2012

ALUMINUMGLS<strong>SPLICES</strong>AUTOMATICGUY WIREDB6For splicing applications with overhead or support guy wires.Fargo GLS500x series automatic splices are designed for useon High Strength (HS), Common (Com), Siemens-Martin (SM),Utilities (Util) and Bell System strand.Fargo GLS504x series automatic splices are designed for useon all guy wire types listed above, plus Extra High Strength(EHS) and Alumoweld (AW).All GLS automatic splices will hold a minimum of 90% of theguy wire rated breaking strength.Material: Shell - High Strength Aluminum AlloyJaws - Plated SteelCATALOGNUMBERGLS5000GLS5001GLS5002GLS5040GLS5041GLS5042GLS5043PRIMARY STRAND APPLICATION1/4” HS, Com, S-M, Util6.6M Strand (Bell)5/16” HS, Com, S-M, Util6M Strand (Bell)3/8” HS, Com, S-M, Util10M Strand (Bell)1/4” EHS (Plus HS, Com, S-M, Util)7#12 (6M) AW5/16” EHS (Plus HS, Com, S-M, Util)7#10 (10M), 7#11 (8M) AW3/8” EHS (Plus HS, Com, S-M, Util)3#5, 7#8, 7#9, 12.5M, 14M, 16M AW#4-2/5, #2-3/4, #1-5/2 AWAC7/16” EHS (Plus HS, Com, S-M, Util)7#7 (20M), 18M AW#2-2/5, #1-3/4, #1/0-5/2 AWACEHSProduct Data & Conductor SizeTO BE USED WITH:DIMENSIONS INCHES (MM)HS, COM,AW / S-M, UTIL,AWACBELL RANGE (IN.) RANGE (MM) A B• 0.240 - 0.253 6.11 - 6.446.40.9(163)(23)• 0.310 - 0.335 7.89 - 8.53• 0.360 - 0.405 9.16 - 10.31• • • 0.215 - 0.270 5.46 - 6.86• • • 0.270 - 0.315 6.86 - 8.00• • • 0.325 - 0.392 8.26 - 9.96• • • 0.392 - 0.458 9.96 - 11.637.3(185)8.1(206)8.3(211)8.6(218)10.0(254)11.0(279)1.1(28)1.3(33)1.13(28)1.22(31)1.48(38)1.60(41)OCTOBER 2012ANDERSON HUBBELL ® POWER SYSTEMS FARGO ®

<strong>OVERHEAD</strong> <strong>LINE</strong> <strong>SPLICES</strong>: AL AND AL-CUCOMPRESSIONVERSATILE SPLICEMINIMUM TENSIONALUMINUMVACS• ANSI C119.4, minimum tension, Class 3 connector (5%of conductor breaking strength)• For use with either VERSA-CRIMP ® or conventionalcompression tools• For aluminum to aluminum, aluminum to copper andcopper to copper (except as noted) conductor splicing• Color coded end plugs for easy die selectionLDDB7DB-7Material: Body - Aluminum Alloy-Tin PlatedFactory InhibitedAL9CU (90°C Rated)LISTED261LALUMINUM OR COPPER CONDUCTORDIMENSIONS INCHES (MM)APPROX.CATALOG NUMBERCONVENTIONAL ΔRANGEVERSA-CRIMPSYSTEM RANGEVERSA-CRIMPTOOLTYPEL DWT.EACHLBS. (KG) I.D. INCHES (MM)VACS8 #8 Str. Al/Cu #8 Str. Al/Cu1-7/8 (47.6) 7/8 (22.2) .007 (.003) .166 (4.2)VACS6 #6 Str. Al/Cu #6 Str. Al/Cu VC63501-7/8 (47.6) 7/8 (22.2) .012 (.005) .206 (5.2)VACS4 #4 Str. Al/Cu #4 Str. Al/Cu 2-1/8 (54.0) 1 (25.4) .021 (.009) .252 (6.4)VACS2 #2 Str. Al/Cu #6–#2 Str. Al/Cu2-3/8 (60.3) 1-1/8 (28.6) .03 (.013) .312 (7.3)VACS1 #1 Str. Al/Cu #4–#1 Str. Al/Cu 2-3/8 (60.3) 1-1/8 (28.6) .04 (.02) .350 (8.9)VACS10 1/0 Str. Al/Cu #8-1/0 Str. Al/Cu 2-11/16 (68.3) 1-5/16 (33.3) .05 (.02) .393 (10)VACS20 2/0 Str. Al/Cu #4-2/0 Str. Al/Cu VC62-11/16 (68.3) 1-5/16 (33.3) .06 (.03) .450 (11.4)VACS30 3/0 Str. Al/Cu #4-3/0 Str. Al/Cu (ALL)2-11/16 (68.3) 1-5/16 (33.3) .08 (.04) .502 (12.7)VACS40 4/0 Str. Al/Cu #2-4/0 Str. Al/Cu 3-3/8 (85.7) 1-5/8 (41.3) .11 (.05) .562 (14.3)VACS250 250 MCM Al/Cu 1/0-250 MCM Al/Cu 3-3/8 (85.7) 1-5/8 (41.3) .15 (.07) .605 (13.4)VACS300 300 MCM Al/Cu 1/0-300 MCM Al/Cu 3-3/8 (85.7) 1-5/8 (41.3) .19 (.08) .660 (16.8)VACS350 350 MCM Al/Cu 2/0-350 MCM Al/Cu5 (127.0) 2-7/16 (62.0) .22 (.10) .711 (18.1)VC63VACS400 400 MCM Al/Cu 3/0-400 MCM Al/Cu 5 (127.0) 2-7/16 (62.0) .27 (.12) .758 (19.2)VC6FTVACS500 500 MCM Al/Cu 4/0-500 MCM Al/Cu 5 (127.0) 2-7/16 (62.0) .36 (.16) .843 (21.4)VACS600*VACS750*600 MCM Al750 MCM Al350-600 MCM Al350-500 MCM Cu VC6FT500-750 MCM AlVC8500 MCM CuProduct Data & Conductor Size6 (152.4) 2-15/16 (74.6) .47 (.21)6 (152.4) 2-15/16 (74.6) .65 (.40).923(23.4)1.028(26.1)VACS1000* 1000 MCM Al 750-1000 MCM Al VC8 6-3/8 (161.9) 3-1/8 (79.4) .97 (.44) 1.182 (30)Δ Refer to pages DB-21 & DB-22 for recommended tool and die information.* Not for copper to copper.HIGH VOLTAGE APPLICATIONS—All Aluminum/Copper and Copper Lugs (VCEL,VACL,VHCL, VHCS and VCELC) are rated at 34.5kV. The other U.L. listed compressionconnectors (VACS, VACT, VCCT, VHSS and VHS) have a maximum UL voltage requirement of less than 2000 volts, however Anderson recommendsthese connectors for application through 34.5 KV subject to the manufacturers’ limitations and recommendations for the insulation material. For furtherinformation, contact factory.ANDERSON HUBBELL ® POWER SYSTEMS FARGO ® OCTOBER 2012

DB8ALUMINUMCATALOGNUMBERVCSE44VCSE55VCSE66VCSE77VCSE88VCSE99VCSED*VC6500 for use with aluminum conductor only in range 350-500 MCM.PLASTICSECLVERSA CRIMP SYSTEMCONDUCTOR RANGE#10(7)-1/0 (19) AAC#8 (6/1)-1/0 (6/1) ACSR#10 Sol.-1/0(19) Cu#8(7)-3/0 (19) AAC#6 (6/1)-2/0 (6/1) ACSR#8 Sol.-3/0 (19) Cu#4 (7)-266.8 (19) AAC#4 (6/1)-4/0 (6/1) ACSR#4 Sol.-250 (37) Cu2/0 (7)-350 (37) AAC2/0 (6/1)-336.4 (18/1) ACSR2/0 (7)-350 (37) Cu4/0 (7)-500 (37) AAC4/0 (6/1)-477 (18/1) ACSR4/0(7)-500(37) Cu500 (19)-750 (61) AAC477(18/1)-636 (26/7) ACSR500 (37) Cu<strong>OVERHEAD</strong> <strong>LINE</strong> <strong>SPLICES</strong>: AL AND AL-CUCOMPRESSIONVERSA-CRIMP® SPLICEMINIMUM TENSION – RANGE TAKINGProduct Data & Conductor SizeVERSA-CRIMPTOOLTYPEVC6(ALL)*VC6500VC63VC6FTVC6FTVC8• ANSI C119.4, minimum tension, Class 3 connector (5%of conductor breaking strength)• For use with VERSA-CRIMP ® tools only• For aluminum to aluminum and aluminum to copperconductorsplicing. Not for copper to copper splicing.• Aluminum alloy conductor recommendations include5005, 6201 (AAAC) and ACAR of the same maximumdiameter as a given ACSR conductor shown below. Inaddition, compressed (compact) conductor sizes withinlisted AAC range are recommended.Material: Body - Aluminum AlloyFactory inhibitedL2(50.8)3(76.2)4(101.6)5(127.0)5(127.0)6(152.4)<strong>OVERHEAD</strong> AND SERVICE ENTRANCE<strong>LINE</strong> <strong>SPLICES</strong> COMPRESSIONPLASTIC COVERDIMENSIONS INCHES (MM)D21/32(16.7)1-7/16(36.5)1-7/8(47.6)2-3/8(60.3)2-3/8(60.3)2-7/8(73.0)APPROX.WT. EACHLBS. (KG).063(.028).11(.05).18(.08).27(.12).28(.12).45(.20)**RUS ListedSnap on cover for minimum tension spliceMaterial: Black thermoplasticAPPROX.CATALOGNUMBERDESCRIPTIONWT. EACHLBS. (KG)SEC4 ** For use on any 5/8” OD splice up to 2” long .04 (.02)SEC6 ** For use on any .840 OD splice up to 4” long .06 (.03)OCTOBER 2012ANDERSON HUBBELL ® POWER SYSTEMS FARGO ®