Go Lead-Free Materials Guide - Loctite

Go Lead-Free Materials Guide - Loctite

Go Lead-Free Materials Guide - Loctite

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

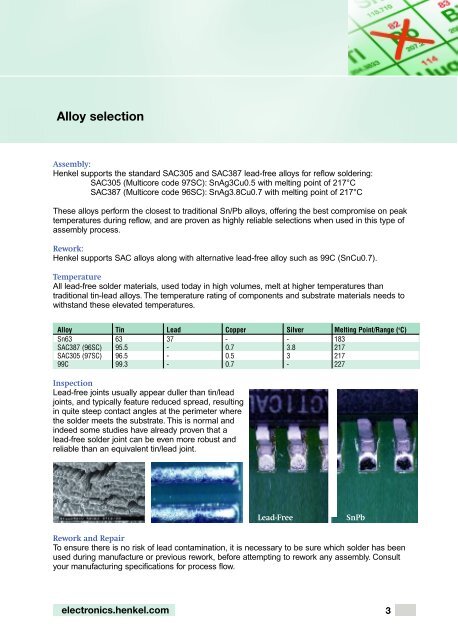

Alloy selectionAssembly:Henkel supports the standard SAC305 and SAC387 lead-free alloys for reflow soldering:SAC305 (Multicore code 97SC): SnAg3Cu0.5 with melting point of 217°CSAC387 (Multicore code 96SC): SnAg3.8Cu0.7 with melting point of 217°CThese alloys perform the closest to traditional Sn/Pb alloys, offering the best compromise on peaktemperatures during reflow, and are proven as highly reliable selections when used in this type ofassembly process.Rework:Henkel supports SAC alloys along with alternative lead-free alloy such as 99C (SnCu0.7).TemperatureAll lead-free solder materials, used today in high volumes, melt at higher temperatures thantraditional tin-lead alloys. The temperature rating of components and substrate materials needs towithstand these elevated temperatures.Alloy Tin <strong>Lead</strong> Copper Silver Melting Point/Range ( o C)Sn63 63 37 - - 183SAC387 (96SC) 95.5 - 0.7 3.8 217SAC305 (97SC) 96.5 - 0.5 3 21799C 99.3 - 0.7 - 227Inspection<strong>Lead</strong>-free joints usually appear duller than tin/leadjoints, and typically feature reduced spread, resultingin quite steep contact angles at the perimeter wherethe solder meets the substrate. This is normal andindeed some studies have already proven that alead-free solder joint can be even more robust andreliable than an equivalent tin/lead joint.<strong>Lead</strong>-<strong>Free</strong>SnPbRework and RepairTo ensure there is no risk of lead contamination, it is necessary to be sure which solder has beenused during manufacture or previous rework, before attempting to rework any assembly. Consultyour manufacturing specifications for process flow.electronics.henkel.com3