MIG/MAG pulse welding machines - Ewm-sales.co.uk

MIG/MAG pulse welding machines - Ewm-sales.co.uk

MIG/MAG pulse welding machines - Ewm-sales.co.uk

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

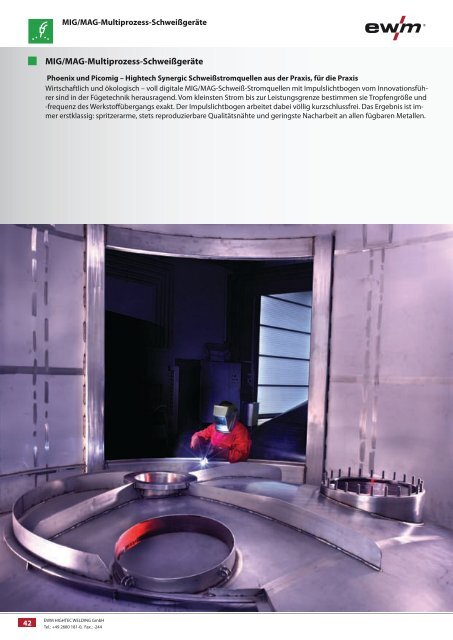

<strong>MIG</strong>/<strong>MAG</strong>-Multiprozess-Schweißgeräte<strong>MIG</strong>/<strong>MAG</strong>-Multiprozess-SchweißgerätePhoenix und Pi<strong>co</strong>mig – Hightech Synergic Schweißstromquellen aus der Praxis, für die PraxisWirtschaftlich und ökologisch – voll digitale <strong>MIG</strong>/<strong>MAG</strong>-Schweiß-Stromquellen mit Impulslichtbogen vom Innovationsführersind in der Fügetechnik herausragend. Vom kleinsten Strom bis zur Leistungsgrenze bestimmen sie Tropfengröße und-frequenz des Werkstoffübergangs exakt. Der Impulslichtbogen arbeitet dabei völlig kurzschlussfrei. Das Ergebnis ist immererstklassig: spritzerarme, stets reproduzierbare Qualitätsnähte und geringste Nacharbeit an allen fügbaren Metallen.42EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>mig <strong>pulse</strong>, portableSmall and light – perfect for <strong>co</strong>nstruction sitesPi<strong>co</strong>mig <strong>pulse</strong>• portableConstruction site, assembly, workshop, production site – the right machinefor every location and every task.HighlightsWide range of possible applications with <strong>co</strong>nvenient operationUp to 32 pre-programmed JOBs for the <strong>co</strong>mmonest <strong>welding</strong> tasks as well as Synergi<strong>co</strong>peration with self-explanatory operating panelPi<strong>co</strong>mig 180 <strong>pulse</strong> – ideal for self-shielded <strong>co</strong>red wiresCost-effective – open-air <strong>welding</strong> tasks can be performed with MMA as well as withflux <strong>co</strong>red wire in the <strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> processPi<strong>co</strong>mig 180 <strong>pulse</strong> – professionally equippedFour full <strong>welding</strong> processes: <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong>, standard, MMA and TIG (Liftarc) <strong>welding</strong>in a single machineAntistick and Arcforce – weld like a professionalExtremely easy <strong>welding</strong>: The arc burns steadily without the electrode sticking orannealing.The professional solution for <strong>co</strong>nstruction sites and assemblySmall, light, universal – the plastic casing and innovative inverter technology make thisthe perfect tool for practical applications.Innovative <strong>pulse</strong> <strong>welding</strong> for stainless steel and aluminiumThe perfect <strong>pulse</strong> <strong>welding</strong> job guarantees superb <strong>welding</strong> results when joining stainlesssteel and aluminium, thanks to <strong>co</strong>ntrolled globular transfer and targeted, adaptedheat input42EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>mig <strong>pulse</strong>, portableOvervoltage protectionNo damage to machine caused if inadvertently<strong>co</strong>nnected to 400-V mains voltagePi<strong>co</strong>mig 180 – simplest Synergic operationWith extensive functions, non-latched, latched,spot, intervalIdeal for self-shielded <strong>co</strong>redwiresTool-free pole reversal and<strong>co</strong>red wire characteristics asstandard100% suitable for <strong>co</strong>nstructionsitesPerfect for large <strong>co</strong>nstructionsites and very tough assemblywork with long mains supplyleads or <strong>co</strong>nnected directly toa generator. High tolerance tomains fluctuations ensures aperfect <strong>welding</strong> result.Powerful4-roller drive unit with largeroller diameter for reliable wireguidanceTotal <strong>co</strong>nvenienceNo tools required for rollerchange, roller is suitable for twodifferent wire diametersPractical Eurotorch <strong>co</strong>nnectorFor easy exchange of steelliners and plastic linersEasy servicing and maintenanceRapid changeover of <strong>welding</strong>accessories thanks to <strong>co</strong>nnectionsockets for <strong>welding</strong> torchesand <strong>welding</strong> leadEWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -24443

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Phoenix, modularPhoenix <strong>co</strong>vers every needPhoenix• modularConstruction site, assembly, workshop, production site – the right machinefor every location and every task. Can be expanded at any time with<strong>co</strong>oling unit and transport cart – no need for tools or specialist personnelHighlightsIntuitive, self-explanatory operating <strong>co</strong>nceptsConcept – <strong>co</strong>mpact: Direct access to all settingsConcept – de<strong>co</strong>mpact: Direct access to the most important parameters on the wirefeederProgress – de<strong>co</strong>mpact: Direct access to all settings on the wire feederPhoenix – multi-talentedPulse arc <strong>MIG</strong>/<strong>MAG</strong>, standard, forceArc, rootArc, flux <strong>co</strong>red wire as well as TIG (lift arc)MMA and air arc gouging – a wide variety of processes, one power sourceforceArc – extremely productive with un<strong>co</strong>mpromising qualityUp to 50% lower production <strong>co</strong>sts: a masterpiece of innovative <strong>MIG</strong>/<strong>MAG</strong> processengineering: powerful forced arc, deep fusion penetration and virtually spatter-freeweld seams of the highest quality.rootArc – reliable short arc <strong>welding</strong> in all positionsShort arc with easy weld modelling capabilities for easy gap-bridging and positional<strong>welding</strong>Innovative <strong>pulse</strong> <strong>welding</strong> for stainless steel and aluminiumThe perfect <strong>pulse</strong> <strong>welding</strong> job guarantees superb <strong>welding</strong> results when joining stainlesssteel and aluminium, thanks to <strong>co</strong>ntrolled globular transfer and targeted, adaptedheat inputPhoenix – wide range of accessories and optionsSimple to operate: the Power<strong>co</strong>ntrol torch allows all programs, operating modes, processesand the up/down function to be activated at the touch of a button.44EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Phoenix, modularSimply practicalMMA <strong>welding</strong> and air arc gouging with thePhoenix <strong>co</strong>nceptalso without a wire feeder or remote <strong>co</strong>ntrol.<strong>MIG</strong> lift arc ignition – high-precision,spatter-free ignitionReliable and reproducible ignition results formanual applicationsSuper <strong>pulse</strong> – <strong>co</strong>mbine <strong>welding</strong> processeseasilyManual or automatic switching between differentprocesses during <strong>welding</strong>Very high power reservesenable use of long intermediate hose packages:70 mm² up to 30 m / 95 mm² up to40 mModern, ergonomic casingThe front and rear sections ofthe machine are made of shockresistantplastic, with rounded<strong>co</strong>rners and edges.Operating elements with aparticularly clear and protectedlayoutWell thought-out: casing and<strong>co</strong>olingOptimised air ducting via bladesand fan <strong>co</strong>ntrol minimisessoiling in the machine. Thehigh-performance centrifugalpump ensures optimal <strong>welding</strong>torch <strong>co</strong>olingCombine skilfully and asrequiredEasy <strong>co</strong>mbination of <strong>co</strong>olingunit or transport cart – withoutspecialist staff and withoutopening the <strong>welding</strong> machine.Innovative and easy to expandto meet future needsIdeal for self-shielded <strong>co</strong>redwiresTool-free pole reversal and<strong>co</strong>red wire characteristics asstandardSuper-fast attachment of<strong>co</strong>oling unitThe unique fastening systemguarantees easy attachmentand detachment. The catchesare fully integrated in thecasing so there is no protrusionand therefore no risk of injury.Total <strong>co</strong>nvenienceNo tools required for rollerchange, roller is suitable for twodifferent wire diametersEWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -24445

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Phoenix, mobileThe ultimate in joining technologyPhoenix• mobile3-in-1 casing <strong>co</strong>ncept means power source, transport cart and <strong>co</strong>olingunit are <strong>co</strong>mbined in one unit for easy transport and handling. Optimisedair guidance ensures greater <strong>co</strong>oling performance, providing longer dutycycles as well as less soiling in the machine. Easy handling is guaranteedby self-explanatory <strong>co</strong>ntrols.All-round performance for tough practical useHighlightsMulti-talented<strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong>, standard, forceArc plus TIG and MMA – five processes, one powersource.Intuitive, self-explanatory operating <strong>co</strong>nceptsConcept – direct access to the most important parameters on the wire feederProgress – direct access to all settings on the wire feederExpert – either wire feed <strong>co</strong>ntrol unit M3.00 with basic functions only or M3.70 withexpanded settingsforceArc – extremely productive with un<strong>co</strong>mpromising qualityUp to 50% lower production <strong>co</strong>sts: a masterpiece of innovative <strong>MIG</strong>/<strong>MAG</strong> processengineering: powerful forced arc, deep fusion penetration and virtually spatter-freeweld seams of the highest quality.rootArc – reliable short arc <strong>welding</strong> in all positionsShort arc with easy weld modelling capabilities for easy gap-bridging and positional<strong>welding</strong>Innovative <strong>pulse</strong> <strong>welding</strong> for stainless steel and aluminiumThe perfect <strong>pulse</strong> <strong>welding</strong> job guarantees superb <strong>welding</strong> results when joining stainlesssteel and aluminium, thanks to <strong>co</strong>ntrolled globular transfer and targeted, adaptedheat inputPhoenix – wide range of accessories and optionsSimple to operate: the Power<strong>co</strong>ntrol torch allows all programs, operating modes, processesand the up/down function to be activated at the touch of a button.46EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Phoenix, mobileSuper <strong>pulse</strong> – super beadSuper <strong>pulse</strong> technology with alternating<strong>welding</strong> current is the most effective <strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> solution for many applications:visible seams with TIG appearance, secure root<strong>welding</strong>s and excellent gap bridgingMulti-voltage capability – the ideal solutionMulti-voltage version for different nationalgrids. 3 x 230 V, 400 V, 480 V (option, ex works)<strong>MIG</strong> lift arc ignition – high-precision,spatter-free ignitionReliable and reproducible ignition results formanual applicationsVery high power reservesenable use of long intermediate hose packages:70 mm² up to 30 m / 95 mm² up to40 mExtra-large 12 litre tankTrouble-free <strong>co</strong>mmissioningeven with long hose packagesand safe operation at high temperaturesand during extendedduty cycles4 lifting eyes as standard100% mobile for transportationin production halls and shipyardswith restricted accessConnected in no timeScrew and plug-in <strong>co</strong>nnectionsfor intermediate hose packagelocated externally on wire feedMobility for any locationLarge wheels for easy running– even on very uneven surfaces.Same gauge on front and rearwheels facilitates transportTotal <strong>co</strong>nvenienceNo tools required for rollerchange, roller is suitable for twodifferent wire diametersMulti-functional, ergonomichandle systemEffortless running, practical holderfor hose packages, impactprotectionEWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -24447

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> <strong>machines</strong>Overview – Phoenix – <strong>co</strong>ntrolsConceptNo electronics in the wire feed unitSetting of operating point, arc length <strong>co</strong>rrection, non-latched/latchedand standard/<strong>pulse</strong> on the wire feed unitSelection of the <strong>welding</strong> task from the JOB listSetting of all <strong>welding</strong> parameters and <strong>welding</strong> data displays on the<strong>welding</strong> machineSetting of the <strong>welding</strong> parameters via <strong>welding</strong> sequence with LEDuser menuHighlightsEasiest possible selection of the preset JOBs (<strong>welding</strong> tasks) for the differentmaterials, gas types and wire diameters via JOB list.Synergic – one-knob operationforceArc, rootArc and standard and <strong>pulse</strong> <strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> with solid and flux<strong>co</strong>red wire, MMA and TIG lift arc <strong>welding</strong>, air arc gougingProgressSelection of the <strong>welding</strong> task from the JOB listSetting of all <strong>welding</strong> parameters and <strong>welding</strong> data displays on the wirefeed unit or on <strong>co</strong>mpact <strong>welding</strong> machineSetting of the <strong>welding</strong> parameters via <strong>welding</strong> sequence with LED usermenuNo settings required on de<strong>co</strong>mpact <strong>welding</strong> machineHighlightsEasiest possible selection of the preset JOBs (<strong>welding</strong> tasks) for the differentmaterials, gas types and wire diameters via JOB listSynergic – one-knob operationforceArc, rootArc and standard and <strong>pulse</strong> <strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> with solid and flux<strong>co</strong>red wire, MMA and TIG lift arc <strong>welding</strong>, air arc gouging

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> <strong>machines</strong>Overview – Phoenix – <strong>co</strong>ntrolsExpert / M 3.00Setting of operating point, arc length <strong>co</strong>rrection, non-latched/latched,dynamics and standard/<strong>pulse</strong> on the wire feed unitSelection and display of the <strong>welding</strong> task via LED user menuSelected <strong>welding</strong> task is <strong>co</strong>nstantly visible on the <strong>welding</strong> machineSetting of all <strong>welding</strong> parameters and <strong>welding</strong> data displays on the<strong>welding</strong> machineHighlightsIdeal for changing <strong>welding</strong> tasks by selecting the JOB (<strong>welding</strong> task) fromthe menu on the <strong>welding</strong> machine for the different materials, gas typesand wire diametersSynergic – one-knob operationforceArc, rootArc and standard and <strong>pulse</strong> <strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> with solid andflux <strong>co</strong>red wire, MMA and TIG lift arc <strong>welding</strong>, air arc gougingExpert / M 3.70Setting of all <strong>welding</strong> parameters and <strong>welding</strong> data displays on the wirefeed unitSetting of the <strong>welding</strong> parameters via <strong>welding</strong> sequence with LED usermenuSelection and display of the <strong>welding</strong> task via LED user menuSelected <strong>welding</strong> task is <strong>co</strong>nstantly visible on the <strong>welding</strong> machineSetting of all <strong>welding</strong> parameters and <strong>welding</strong> data displays on the wirefeed unit and on <strong>welding</strong> machineHighlightsIdeal for changing <strong>welding</strong> tasks by selecting the JOB (<strong>welding</strong> task) from themenu on the <strong>welding</strong> machine for the different materials, gas types and wirediametersSynergic – one-knob operationforceArc, rootArc and standard and <strong>pulse</strong> <strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> with solid andflux <strong>co</strong>red wire, MMA and TIG lift arc <strong>welding</strong>, air arc gouging

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>mig/Phoenix/Phoenix Car ExpertPi<strong>co</strong>mig 180 puls TKG Phoenix 335 puls TKM Phoenix 335 puls TKMControlsPi<strong>co</strong>mig <strong>pulse</strong>, portable • – –Concept – – –Progress – • •Expert – – –Car Expert – – –Functions<strong>MIG</strong>/<strong>MAG</strong> • • •<strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> • • •TIG • • •MMA • • •EWM-forceArc – • •EWM-rootArc – • •Technical dataSetting range for <strong>welding</strong>current5 A - 180 A 5 A - 330 A 5 A - 330 ADuty cycle at ambienttemperature40 °C 25 °C 40 °C 25 °C 40 °C25 % 180 A – – – –35 % – – 330 A – 330 A40 % – 330 A – 330 A –60 % 120 A 280 A 250 A 280 A 250 A100 % 100 A 240 A 210 A 240 A 210 AOpen circuit voltage 80 V 80 V 80 VMains frequency 50 Hz / 60 Hz 50 Hz / 60 Hz 50 Hz / 60 HzMains fuses (slow-blow) 1 x 16 A 3 x 16 A 3 x 16 AMains voltage (tolerances) 1 x 230 V (-40 % - +15 %) 3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %)Max. <strong>co</strong>nnected load 6.4 kVA 12.7 kVA 12.7 kVARe<strong>co</strong>mmended generatorpower7.5 kVA 13.1 kVA 13.1 kVADrive rollers 4 4 4Wire speed 0.5 m/min - 15 m/min 0.5 m/min - 24 m/min 0.5 m/min - 24 m/minDimensions, machine,LxWxH in mm685 x 280 x 360 624 x 298 x 480 624 x 298 x 480Weight, machine 15 kg 33 kg 33 kgWeight, wire feeder – – –Weight, <strong>co</strong>oling unit – – 16.5 kgProtection classification IP 23 IP 23 IP 23Insulation class H H HCooling output – – 1000 W (1l/min)Tank capacity – – 4 lFlow rate – – 5 l/minMax. output pressure – – 3.5 barStandardsIEC 60 974-1; -5; -10 / CE / S-Safety sign / EMC class AQR Code50EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>mig/Phoenix/Phoenix Car ExpertPhoenix 405 puls TDM Phoenix 405 puls TDM Phoenix 505 puls TDM– – –• • •• • •– – –– – –• • •• • •• • •• • •• • •• • •5 A - 400 A 5 A - 400 A 5 A - 500 A25 °C 40 °C 25 °C 40 °C 25 °C 40 °C– – – – – –– – – – – –– – – – 500 A 500 A400 A 400 A 400 A 400 A 450 A 420 A390 A 360 A 390 A 360 A 390 A 360 A80 V 80 V 80 V50 Hz / 60 Hz 50 Hz / 60 Hz 50 Hz / 60 Hz3 x 35 A 3 x 35 A 3 x 35 A3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %)17.5 kVA 17.5 kVA 24.6 kVA25 kVA 25 kVA 35 kVA4 4 40.5 m/min - 24 m/min 0.5 m/min - 24 m/min 0.5 m/min - 24 m/min624 x 298 x 535 624 x 298 x 535 624 x 298 x 53541 kg 41 kg 45 kg14.1 kg 15.1 kg 14.1 kg– 16.5 kg –IP 23 IP 23 IP 23H H H– 1000 W (1l/min) –– 4 l –– 5 l/min –– 3.5 bar –IEC 60 974-1;-5; -10 / CE / S-Safety sign / EMC class AEWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -24451

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>mig/Phoenix/Phoenix Car ExpertPhoenix 505 puls TDM Phoenix 301 puls FKG Phoenix 401 puls FKWControlsPi<strong>co</strong>mig <strong>pulse</strong>, portable – – –Concept • • •Progress • – –Expert – – –Car Expert – – –Functions<strong>MIG</strong>/<strong>MAG</strong> • • •<strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> • • •TIG • • •MMA • • •EWM-forceArc • • •EWM-rootArc • • •Technical dataSetting range for <strong>welding</strong>current5 A - 500 A 5 A - 300 A 5 A - 400 ADuty cycle at ambienttemperature25 °C 40 °C 25 °C 40 °C 25 °C 40 °C40 % 500 A 500 A – – – –60 % 450 A 420 A – 300 A 400 A 400 A80 % – – 300 A – – –100 % 390 A 360 A 270 A 250 A 390 A 360 AOpen circuit voltage 80 V 100 V 80 VMains frequency 50 Hz / 60 Hz 50 Hz / 60 Hz 50 Hz / 60 HzMains fuses (slow-blow) 3 x 35 A 3 x 16 A 3 x 35 AMains voltage (tolerances) 3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %)Max. <strong>co</strong>nnected load 24.6 kVA 11 kVA 17.5 kVARe<strong>co</strong>mmended generatorpower35 kVA 16.4 kVA 25 kVADrive rollers 4 4 4Wire speed 0.5 m/min - 24 m/min 0.5 m/min - 24 m/min 0.5 m/min - 24 m/minDimensions, machine,LxWxH in mm624 x 298 x 535 930 x 460 x 730 1100 x 455 x 1000Weight, machine 45 kg 69.5 kg 119.5 kgWeight, wire feeder 15.1 kg – –Weight, <strong>co</strong>oling unit 16.5 kg – –Protection classification IP 23 IP 23 IP 23Insulation class H H HCooling output 1000 W (1l/min) – 1500 W (1l/min)Tank capacity 4 l – 12 lFlow rate 5 l/min – 5 l/minMax. output pressure 3.5 bar – –StandardsIEC 60 974-1; -5 -10 / CE / S-Safety sign / EMC class AQR Code52EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>mig/Phoenix/Phoenix Car ExpertPhoenix 401 puls FDW Phoenix 351 puls FDW Phoenix 451 puls FDW– – –• • •• • •• • •– – –• • •• • •• • •• • •• • •• • •5 A - 400 A 5 A - 350 A 5 A - 450 A25 °C 40 °C 25 °C 40 °C 25 °C 40 °C– – – – – –400 A 400 A – – – –– – – – – 450 A390 A 360 A 350 A 350 A 450 A 420 A80 V 80 V 80 V50 Hz / 60 Hz 50 Hz / 60 Hz 50 Hz / 60 Hz3 x 35 A 3 x 25 A 3 x 35 A3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %)17.5 kVA 13.9 kVA 20.7 kVA25 kVA 20.3 kVA 29.1 kVA4 4 40.5 m/min - 24 m/min 0.5 m/min - 24 m/min 0.5 m/min - 24 m/min1100 x 455 x 1000 1100 x 455 x 1000 1100 x 455 x 1000118 kg 129 kg 129 kg15.1 kg 15.1 kg 15.1 kg– – –IP 23 IP 23 IP 23H H H1500 W (1l/min) 1500 W (1l/min) 1500 W (1l/min)12 l 12 l 12 l5 l/min 5 l/min 5 l/min3.5 bar 3.5 bar 3.5 barIEC 60 974-1; -5; -10 / CE / S-Safety sign / EMC class AEWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -24453

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>mig/Phoenix/Phoenix Car ExpertPhoenix 551 puls FDWPhoenix 551 puls D FDWControlsPi<strong>co</strong>mig <strong>pulse</strong>, portable – –Concept • –Progress • •Expert • –Car Expert – –Functions<strong>MIG</strong>/<strong>MAG</strong> • •<strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> • •TIG • •MMA • •EWM-forceArc • •EWM-rootArc • •Technical dataSetting range for <strong>welding</strong>current5 A - 550 A 5 A - 550 ADuty cycle at ambienttemperature25 °C 40 °C 25 °C 40 °C60 % 550 A 550 A 550 A 550 A80 % 520 A – 520 A –100 % 450 A 420 A 450 A 420 AOpen circuit voltage 80 V 80 VMains frequency 50 Hz / 60 Hz 50 Hz / 60 HzMains fuses (slow-blow) 3 x 35 A 3 x 35 AMains voltage (tolerances) 3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %)Max. <strong>co</strong>nnected load 28 kVA 28 kVARe<strong>co</strong>mmended generatorpower39.4 kVA 39.4 kVADrive rollers 4 4Wire speed 0.5 m/min - 24 m/min 0.5 m/min - 24 m/minDimensions, machine,LxWxH in mm1100 x 455 x 1000 1100 x 680 x 1000Weight, machine 129 kg 158 kgWeight, wire feeder 15.1 kg 48 kgProtection classification IP 23 IP 23Insulation class H HCooling output 1500 W (1l/min) 1500 W (2l/min)Tank capacity 12 l 12 lFlow rate 5 l/min 20 l/minMax. output pressure 3.5 bar 4.5 barStandardsIEC 60 974-1; -5; -10 / CE / S-Safety sign / EMC class AQR Code54EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>mig/Phoenix/Phoenix Car ExpertPhoenix 551 puls 2DV FDWPhoenix 301 Car Expert puls FKG– –– –• –– –– •• •• •• –• –• –• –5 A - 550 A 5 A - 300 A25 °C 40 °C 25 °C 40 °C550 A 550 A – 300 A520 A – 300 A –450 A 420 A 270 A 250 A80 V 100 V50 Hz / 60 Hz 50 Hz / 60 Hz3 x 35 A 3 x 16 A3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %)28 kVA 11 kVA39.4 kVA 16.4 kVA4 40.5 m/min - 24 m/min 0.5 m/min - 24 m/min1100 x 680 x 1000 930 x 460 x 730158 kg 69.5 kg15.1 kg –IP 23 IP 23HH1500 W (2l/min) –12 l –20 l/min –4.5 bar –IEC 60 974-1; -5; -10 / CE / S-Safety sign / EMC class AEWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -24455

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>mig/Phoenix/Phoenix Car Expert • Options/accessoriesOptions/accessoriesWire feed unitsIntermediate drive unitIntermediate hose package, 7-polePhoenix Progress drive 4Wire feeder, water, Euro torch <strong>co</strong>nnector4-roller wire feed equipped for 1.0 mm + 1.2 mmsteel wiresSpool diameter up to 300 mmPhoenix Progress drive 4 HSWire feeder for high performance <strong>welding</strong>Can only be used on Phoenix 551 Progress4-roller wire feed equipped for 1.0 mm + 1.2 mmsteel wiresSpool diameter up to 300 mmPhoenix Progress drive 4LWire feeder, water, Euro torch <strong>co</strong>nnector4-roller wire feed equipped for 1.0 mm + 1.2 mmsteel wiresSpool diameter up to 300 mmPhoenix Progress drive 300CWire feeder, water, Euro torch <strong>co</strong>nnectorAdjustment of the gas quantity directly on the wirefeed unit4-roller wire feed equipped for 1.0 mm + 1.2 mmsteel wiresSpool diameter up to 300 mmPhoenix Progress drive 200CWire feeder, water, Euro torch <strong>co</strong>nnectorAdjustment of the gas quantity directly on the wirefeed unit4-roller wire feed equipped for 1.0 mm + 1.2 mmsteel wiresSpool diameter up to 200 mmPhoenix Progress drive 4DDouble wire feederTwo <strong>welding</strong> tasks with just one power source foralternating <strong>welding</strong> of root and final passes, solidand flux <strong>co</strong>red wire, or a variety of materials andwire thicknessesThe torch trigger is used for changeover betweenthe wire feeds; no special torch or changeover onthe machine required!4-roller wire feed equipped for 1.0 mm + 1.2 mmsteel wiresSpool diameter up to 300 mmNo changing of rollers, no torch <strong>co</strong>nversion required,changeover times are greatly reducedu Can be operated with the Phoenix Progresspuls D series only!M drive 4Z WWire feed intermediate drive, water, steel4-roller wire feed equipped for 1.0 mm + 1.2 mmsteel wiresu Special intermediate hose package availableon request!u Especially for alpha Q, Phoenix Progress,Phoenix Expert and Taurus Synergic S. Notsuitable for high-speed <strong>welding</strong>!<strong>MIG</strong> G 7POL 70MM²Intermediate hose package, gas-<strong>co</strong>oled, 7-poleIntermediate hose package, 7-poleIntermediate hose packages, 19-poleTorchesFunction torch 19-poleGouging<strong>MIG</strong> W 7POL 70MM²Intermediate hose package, water-<strong>co</strong>oled, 7-pole<strong>MIG</strong> W 19POL 70MM²Intermediate hose package, water-<strong>co</strong>oled, 19-poleMT series EZA<strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> torch, gas-<strong>co</strong>oledEquipped for 1.2 mm <strong>welding</strong> wireMT451W F EZA M9<strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> torch, water-<strong>co</strong>oled, fumeextractionEquipped for 1.2 mm <strong>welding</strong> wireTIG 150 GD 1T EZA 4MTIG <strong>welding</strong> torch, Euro torch <strong>co</strong>nnectorMT series U/D<strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> torch, 1 x up/down, water<strong>co</strong>oledEquipped for 1.2 mm <strong>welding</strong> wireMT series 2U/D<strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> torch, 2x up/down, water-<strong>co</strong>oledEquipped for 1.2 mm <strong>welding</strong> wireMT series PC1<strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> torch, Power<strong>co</strong>ntrol 1, water<strong>co</strong>oledEquipped for 1.2 mm <strong>welding</strong> wireu Not possible in <strong>co</strong>mbination with PhoenixExpert drive 4/4L M3.00!MT series PC2<strong>MIG</strong>/<strong>MAG</strong> <strong>welding</strong> torch, Power<strong>co</strong>ntrol 2, water<strong>co</strong>oledEquipped for 1.2 mm <strong>welding</strong> wireu Not possible in <strong>co</strong>mbination with PhoenixExpert drive 4/4L M3.00!GT 600 SKK95 3Gouging torchAir arc gouging torch for separating metalsu Suitable carbon electrodes can be found inthe Accessories section of the price list!56EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

Multiprocess <strong>MIG</strong>/<strong>MAG</strong> <strong>pulse</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>mig/Phoenix/Phoenix Car Expert • Options/accessoriesRemote <strong>co</strong>ntrolsR10 19POLRemote <strong>co</strong>ntrol, wire speed setting, <strong>welding</strong> voltage<strong>co</strong>rrectionRobust metal casing with rubber feet, retaining clipand holding magnet, 19-pole <strong>co</strong>nnection socketFor alpha Q, Phoenix, Taurus Synergic and TaurusSynergic SRG10 19POLRemote <strong>co</strong>ntrol to set the wire speed and <strong>welding</strong>voltagePlastic casing with retaining clip, 19-pole <strong>co</strong>nnectionsocketLight, robust and <strong>co</strong>nvenientVoltage <strong>co</strong>rrection from -10 V to +10 VInfinitely variable setting of wire-feed speed(0.5–24 m/min)With pre-fitted 5-m <strong>co</strong>nnection cableFor alpha Q, Phoenix, Taurus Synergic and TaurusSynergic S machine seriesR20 19POLRemote <strong>co</strong>ntrol, program switchingRobust metal casing with rubber feet, retaining clipand holding magnet, 19-pole <strong>co</strong>nnection socketChangeover and display of up to ten <strong>welding</strong>programmesFor alpha Q, Phoenix Progress, Phoenix Expert (notin <strong>co</strong>mbination with Phoenix Expert Drive M3.00)as well as Taurus Synergic SR40 7POLRemote <strong>co</strong>ntrol, 16 programsRobust metal casing with rubber feet, retaining clipand holding magnet, 7-pole <strong>co</strong>nnection socketSwitch between <strong>MIG</strong> standard <strong>welding</strong> and <strong>pulse</strong>darc <strong>welding</strong>For alpha Q, Phoenix Progress, Phoenix Expert andTaurus Synergic Su Cannot be used with double or two separatewire feed units!Cooling unitsTransport carts<strong>co</strong>ol50 U40Air <strong>co</strong>oling unit with centrifugal pumpModular design, tool-free assemblyTrolly 35-1Transport cartsFor Pi<strong>co</strong>mig 180, Pi<strong>co</strong>tig 180/180 MV, Tetrix 180 andPi<strong>co</strong> 180For transporting a power source and a gas cylinderTrolly 55-2Transport cartsFor transporting a power source, a <strong>co</strong>oling unit anda gas cylinderFor Tetrix 230, 270 DC, Tetrix 230 AC/DC, as well asPhoenix and Taurus 335EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -24457