energize renewables 01/2010 - GL Group

energize renewables 01/2010 - GL Group

energize renewables 01/2010 - GL Group

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

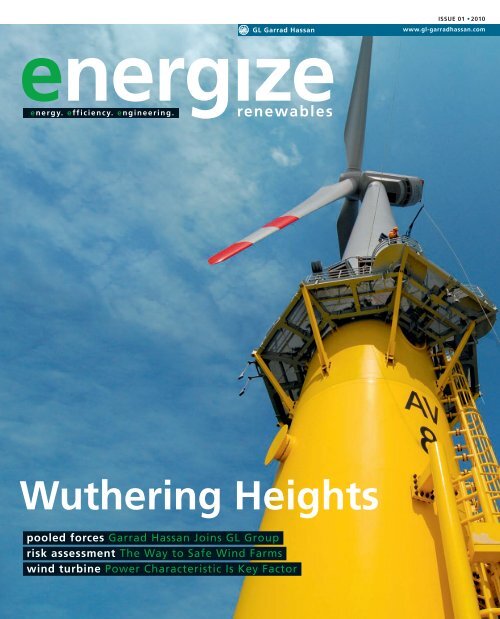

<strong>GL</strong> Garrad Hassanenergızee nergy. e fficiency. e ngineering.<strong>renewables</strong>ISSUE <strong>01</strong> • 2<strong>01</strong>0www.gl-garradhassan.comWuthering Heightspooled forces Garrad Hassan Joins <strong>GL</strong> <strong>Group</strong>risk assessment The Way to Safe Wind Farmswind turbine Power Characteristic Is Key Factor

Renewable EnergyTechnical by nature...<strong>GL</strong> Garrad Hassan is the world’s largest renewable energy consultancy. Dedicatedto serving the <strong>renewables</strong> industry it offers independent technical and engineeringservices, products, and training to the wind, wave, tidal and solar sectors. Althoughthe <strong>GL</strong> Garrad Hassan name is new, the company has a rich heritage. It was createdby the integration of specialist companies that, united under a single brand, form therenewable energy consulting division of the <strong>GL</strong> <strong>Group</strong>.www.gl-garradhassan.com

editorialTo Our ReadersRecent statistics continue to show that wind is the world’s fastest-growingsource of power generation with an average annual growth of 29 per centover the last ten years. And the future prospects of the global wind industryare even more encouraging. Offshore wind installations, for example, are nowbeing planned and constructed with over 100 turbines as standard.Looking at technical assurance and consulting, the demands frommanufacturers, operators, financiers and insurers have risen sharply:The investment costs going into wind projects are measured in billions, andthe owners and operators of the biggest wind farms are now large-scaleutility companies.Andrew GarradThese projects call for a premier supplier of engineering consultancy,certification and project management services to the renewable energyindustries. Garrad Hassan, <strong>GL</strong> and Noble Denton are pooling theirexpertise to address all key questions in <strong>renewables</strong> whether in theoptimisation of wind farm designs, improvements in the performanceof existing wind farms, measurements, inspection or certificationof turbines. Dealing with huge offshore wind farms requiresexperienced and sophisticated project management services as well asin-depth operational knowledge in the transportation, installation andproject execution. The combined <strong>renewables</strong> business will operate underthe name of <strong>GL</strong> Garrad Hassan.Our new magazine <strong>energize</strong> <strong>renewables</strong> marks this development byoffering news, projects and case studies in <strong>renewables</strong>. <strong>energize</strong> <strong>renewables</strong>will provide detailed and comprehensive coverage of best practices andoffers an insight into the spectrum of our services in the wind, solar, waveand tidal energy industries.Yours sincerely,Andrew GarradPresident of <strong>GL</strong> Garrad Hassan<strong>01</strong>/2<strong>01</strong>03

contents <strong>01</strong>/2<strong>01</strong>022EIA:The systemic approachof <strong>GL</strong> Garrad Hassanoptimises wind projectdevelopment1812148WInd FArm:mErGEr:FInAncInG:InTErvIEW:The power characteristic<strong>GL</strong> and GH readyconcepts that maymember of <strong>GL</strong>’sis a key factor into serve theencourage banks toExecutive Board Pekkaengineering a wind<strong>renewables</strong> sectorfinance offshorePaasivaara talks aboutturbineas one enterprisewind farmsthe company’s strategy4 energıze <strong>renewables</strong>

profile inbriefIn Brief:<strong>GL</strong> Garrad Hassan –Part of the <strong>GL</strong> <strong>Group</strong><strong>GL</strong> Garrad Hassan is the WOrLd’S LArGEST renewable energyconsultancy. It offers a UnIQUE LEvEL OF SErvIcE EXPErTISE and globalpresence across the whole project lifecycle.With 650 staff in 35 locations, across 20 countries <strong>GL</strong> Garrad Hassanis a <strong>GL</strong>OBAL PLAYEr In rEnEWABLES.Its technical scope covers all relevant aspects of onshore wind, offshorewind, marine <strong>renewables</strong>, and solar energy. It addresses therequirements of manufacturers, operators, investors, projects developers,authorities, and the supply industry WITH rEGArd TO ALLTEcHnIcAL ASPEcTS OF rEnEWABLE EnErGY APPLIcATIOnS.Given the current focus on wind energy, <strong>GL</strong> Garrad Hassan is ableto provide A cOmPrEHEnSIvE SET OF SErvIcES including the optimaldesign of wind parks, improvement in the performance of existingwind farms, measurement projects (wind resource, wind turbine performanceand structural behaviour), inspection and certification ofturbines all as well as a large array of software products and turbinedesign services. In addition, <strong>GL</strong> Garrad Hassan HAS GAInEd SUBSTAn-TIAL EXPErIEncE in tidal and wave power generation and is involvedin various solar projects.28rISK ASSESSmEnT:manufacturers ofwind turbines haveto ensure safe andprofitable operation31STAndArdS:<strong>GL</strong> presentsrevised guidelinesfor wind turbinecertification<strong>GL</strong> Garrad Hassan is the <strong>renewables</strong> business segment of GermanischerLloyd (<strong>GL</strong>). <strong>GL</strong> is a technical assurance and consulting companyFOr THE EnErGY IndUSTrIES And ALSO A LEAdInG cLASSIFIcATIOnSOcIETY. <strong>GL</strong> employs almost 6,900 engineers, surveyors, experts andadministrative staff. Its <strong>GL</strong>OBAL nETWOrK consists of more than 200stations in 80 countries. Customers of <strong>GL</strong> Garrad Hassan enjoy thebenefits from established industrial techniques to <strong>renewables</strong>, theapplication of existing computational techniques, the adaptation ofmaritime techniques to marine <strong>renewables</strong> and a large engineeringcapability within <strong>GL</strong>.<strong>01</strong>/2<strong>01</strong>05

Optimising wind farms:<strong>GL</strong> Garrad Hassan takes a closelook from the pre-developmentphase through to operations.From strategic consulting towind resource assessment, duediligence reviews to performanceoptimisation, <strong>GL</strong> Garrad Hassanoffers its services to projectleaders, financing institutions andinsurers of renewable energy.6energıze <strong>renewables</strong>

consulting &engıneerıngPhoto: Photocase/ Das Akki<strong>01</strong>/2<strong>01</strong>0 7

consulting & engineering interview8 energıze <strong>renewables</strong>

“We Want toBe the World’sNumber One”Germanischer LIoyd (<strong>GL</strong>) is rapidly expanding its activities in the renewable energysector. The British company Noble Denton, Canadian company Helimax, as well asthe German company WINDTEST Kaiser-Wilhelm-Koog, all fitted in with its growthstrategy and were summarily snapped up by <strong>GL</strong> <strong>Group</strong>.And the latest coup: The Garrad Hassan <strong>Group</strong> – one of the world’s most highlyrenowned consultancies in the field of renewable energies – has joined <strong>GL</strong> <strong>Group</strong>.<strong>energize</strong> spoke with Pekka Paasivaara, Member of <strong>GL</strong>’s Executive Board, about thecompany’s strategyPhoto: iStockphotoABSTRACTENERGIZE: There are lots of consultancies –why did you specifically choose Garrad Hassan?PEKKA PAASIVAARA: The <strong>GL</strong> <strong>Group</strong> has repositioned itselfstrategically in the last year. We were led by the questionof how we wanted to position ourselves in the renewableenergy market. We came to the conclusion that wewould have to build up a very wide ranging service spectrumalongside our already active turbine and project certification.<strong>GL</strong> is looking at all forms ofrenewable energy in the future.Wind and solar will play a leadingrole in the years to come.<strong>GL</strong> offers consultancy andcertification services for allcomponents of on- and offshorewind turbines.Our customers need comprehensiveadvice on all phases ofwind farm development – fromthe first studies right through tothe inauguration. We made itour aim to build up a one-stopshop, i.e. offer comprehensiveconsultancy services from oneprovider. We already knew Garrad Hassan and that wewould complement one another marvellously. At the endof July we thus agreed to become one.ENERGIZE: How do you do something like that – surely youdidn’t just phone up Garrad Hassan and ask if they wantedto become part of <strong>GL</strong>?PAASIVAARA: It was a long process. It was important thatwe were both convinced that we really fitted together. Notjust in terms of technical competence but also in termsof the business culture and employee mindsets – a veryimportant prerequisite.ENERGIZE: Garrad Hassan and the <strong>GL</strong> wind section areabout the same size, with 300 employees each. How doyou plan to bring together the two companies?PAASIVAARA: Our business culture and the way we viewthe market are very similar. In this I mean our opinionsof how we wish to position ourselves and what sort ofservices we wish to offer.<strong>01</strong>/2<strong>01</strong>09

consulting & engineering interviewCSP. ConcentratedSolar Power systemsuse lenses or mirrorsand trackingsystems to focus alarge area ofsunlight into asmall beam.ENERGIZE: Consultancy and certification from onecompany? Does that fit together? As a customer I want tohave an impartial certifier.PAASIVAARA: You’re right, the special role of certificationrequires an impartial body. It is for precisely this reason thatwe are going to keep our certification activities separatefrom our other activities in the field of renewable energies.ENERGIZE: How are you going to get this across to yourcustomers?PAASIVAARA: There is a sort of “Wall of China” betweenthe technical services and the certification department. Thecertification unit is managed separately with different personnel,different systems technology and different processmanagement. We believe that we can hold up the integrityof the certification unit in this way. We have obviously alsospoken with our customers about this. They have said thatit is alright, <strong>GL</strong> may do consulting and certification at thesame time. <strong>GL</strong> was already doing this before the takeoverof Garrad Hassan, by the way.ENERGIZE: Garrad Hassan has recently expanded its expertiseto include solar power, with the focus onConcentrated Solar Power (CSP). This is newterritory for <strong>GL</strong> – what are you going to do withthe solar section of Garrad Hassan?PAASIVAARA: We have renamed the WindPower section at <strong>GL</strong> to <strong>GL</strong> Garrad Hassan".We will thus no longer just look at windpower, but at all forms of renewable energy in the future.We see a lot of potential in Concentrated Solar Power.Apart from solar power, we are involved in manyresearch projects looking at energy generation from the seas,for example wave and tidal power plants. But if you considerthe achievable medium-term yields, then solar and wind powerwill certainly play a leading role for years to come.ENERGIZE: Have customer structures changed at all in thelast few years?PAASIVAARA: In wind power, large companies are operatingwith large investment volumes. With further sinkingproduction costs, wind power will become an increasinglyattractive energy technology. This is bringing in the largeenergy suppliers and infrastructure companies around theworld, whether it be EDF, E.ON, Iberdrola, Florida Light orVattenfall. These are our customers.ENERGIZE: Are you shifting your regional focus points?PAASIVAARA: At the moment we have a regional balancein the onshore wind power sector. The USA, Europeand India plus China each have around one third of theworld market. China is also growing very strongly this yearand we can see that China will take the lead in terms ofinstalled capacity by next year at the latest. It’s a differentsituation in the offshore sector. Europe will continue to playa very strong role here. Although there are big offshoreplans in China and the USA, implementation is going totake several years.ENERGIZE: What components of an offshore turbine doesyour certification business cover?PAASIVAARA: Our certification service covers all componentsof a wind power system, such as the turbine andfoundation structures. In the last few years we havestrengthened our competences. We are bringing in ourservices for measurement, engineering and environmentalanalysis, from Garrad Hassan comes expertise in softwaresolutions, and Noble Denton is bringing in over 100 yearsof experience in the offshore field, e.g. know-how in un-10 energıze <strong>renewables</strong>

We will nolonger justlook at windpower,but at allforms ofrenewableenergy in thefuture.Vision.Pekka Paasivaara,Member of the <strong>GL</strong>Executive Board.derwater structures and offshore installations. With thesewe are able to offer convincing concepts for the wholeproject management of an offshore wind farm. We carryout a feasibility study with all the required measurements,analyse the turbine power, check the machines’ economicviability and thus the validity of the financial models, carryout the environmental impact assessments and take on theimplementation management. That last point can have apretty varied scope, starting with an owner’s engineer, whokeeps an eye on all the work going on, right up to the completemanagement of all operative steps.ENERGIZE: What does this cost in relationship to the investmentas a whole?PAASIVAARA: This can vary a lot, because the investors canbook their desired scope of services. This may come to 0.1per cent of the investment volume, or also up to 7 per centif a complete management is booked.ENERGIZE: Doesn’t the flood of certifications make a windfarm unnecessarily expensive? Damage isn’t prevented bythis, after all, as many examples have shown.PAASIVAARA: The certification of wind farms, wind turbinesand their components reflects the current technicalstate of affairs and is compulsory for most locations aroundthe world. As far as the total costs of an offshore windfarm are concerned, the cost of a type or project certificationis marginal. But it means a big increase in security forinvestors, insurers, operators and authorities.ENERGIZE: What will the wind power business of <strong>GL</strong>Garrad Hassan look like in five year's time?PAASIVAARA: We aim to be the world’s leading technicalconsultant: the best partner for developers, investors andproject owners.JI<strong>01</strong>/2<strong>01</strong><strong>01</strong>1

consulting mergerPooled ForcesThe <strong>renewables</strong> sector continues to grow, offering a host of opportunities for<strong>GL</strong> Garrad Hassan is now ready to serve the market as one integrated technicalservices and consulting enterpriseThe world’s oceans hold an almost inexhaustiblesupply of energy. However, harnessingthat energy poses enormous technical challenges.A project worth eight million British pounds willproduce tools capable of accurately estimating the energyyield of major wave and tidal stream energy has been approvedby the Energy Technologies Institute (ETI).PerAWaT, a project led by <strong>GL</strong> Garrad Hassan, and includingEDF Energy, E.ON, theABSTRACTUniversity of Edinburgh, OxfordUniversity, Queen’s Univer-<strong>GL</strong> Garrad Hassan supports allpresent and future forms ofrenewable energy. Wind, watersity Belfast and the Universityand solar energy will play keyroles in the years to come. of Manchester will develop a<strong>GL</strong> offers consulting and certificationservices for all components ofseries of models to predict theon- and offshore wind turbines. performance of wave and tidalstream generator arrays. ETIChief Executive Dr David Clarke said: “Although the UK hashuge marine potential, investment is being held back byuncertainty about the overall costs involved and the potentialreturns on investment in wave and tidal technologies.”The PerAWaT marine energy project demonstrates that“<strong>renewables</strong>” denotes more than just wind energy. In particularsince Germanischer Lloyd, an enterprise that originatedas a provider of technical services to the shipbuilding andshipping industries, and Garrad Hassan (GH) pooled theirforces, the new enterprise faces the challenge.Growing DemandLast year the two companies announced the successfulcompletion of their merger negotiations in Hamburg. Underthe name <strong>GL</strong> Garrad Hassan they now jointly form aleading independent, global provider of consulting, engineering,turbine design, certification, measurement, projectmanagement, strategic advice and inspection services aswell as software products for the renewable energies sector.Their joint technical services portfolio covers theentire life cycle of wind, solar, marine and other renewableenergy projects, both onshore and offshore, includingthe areas of safety, integrity, reliability and performancemanagement.12 energıze <strong>renewables</strong>

New ProjectPhoto: Dreamstime“The merger of Garrad Hassan and <strong>GL</strong> is a reflection ofgrowing customer demand for a one-stop service providerwho offers solutions for challenges in technology, environmentalmatters and asset performance on a worldwidescale,” said Pekka Paasivaara, Member of the <strong>GL</strong> ExecutiveBoard. “Together we will offer a unique level of serviceexpertise and global presence across the whole projectlifecycle.”The new <strong>renewables</strong> business segment <strong>GL</strong> GarradHassan employs over 600 highly qualified engineers, technicalexperts and supporting staff working at 34 locationsaround the world. The merger follows <strong>GL</strong>’s acquisitions ofCanadian wind energy consulting and engineering companyHelimax, as well as WINDTEST, a German specialist in thefield of measurements for wind turbines and wind farms. Inaddition, the offshore wind power expertise of Noble Denton,particularly in wind project management, was addedto the <strong>GL</strong> <strong>Group</strong> in April 2009.<strong>GL</strong> has thus positioned itself as a full-service consultantwith an expanding range of services, such as optimizationof wind farm designs, performance enhancement ofexisting wind farms, measurement projects (covering windresources, wind turbine performance and structural behaviour),as well as inspection and certification of turbines.Garrad Hassan contribute their comprehensive engineeringand consulting expertise, along with a large arrayof software products and turbine design services. Themerger puts <strong>GL</strong> Garrad Hassan at the forefront in the driveto develop a greener and more sustainable energy mix forthe world.DUDGEON OFFSHORE WIND LTD have appointed <strong>GL</strong> GarradHassan to provide continued technical support as it pushesahead with Dudgeon’s 560MW Round 2 project, in parallel witha planning approval process, in order to chase a 2<strong>01</strong>3 commercialoperation date. The Dudgeon site, which is positioned northof Cromer off the coast of Norfolk, has the potential to coverthe annual electricity demands of 400,000 UK homes.<strong>GL</strong> GARRAD HASSAN’S MULTI-DISCIPLINARY OFFSHORE TEAMis utilizing its many years of experience in supporting projectdevelopers, owners and investors to provide Dudgeon withadvice related to the wind turbine and support structure procurementprocess as well as assessment of wind resource andsite conditions.Successful Combination“GH is delighted to be merging with <strong>GL</strong>. We have consideredmany potential partners but we have chosen <strong>GL</strong> becausewe share the same values of independenceand technical rigour. Both companieshave been working together for 25 years andhence know this combination will be successful.It brings benefits to our clients and employeesalike. We are now able to provide an even morecomprehensive service offering with access tomore engineers, and this will enable us to enter developingmarkets,” explained Andrew Garrad, former CEO ofGarrad Hassan, who will be President of the new, combinedrenew ables business.SG<strong>GL</strong> EXPERT:Andrew GarradPresident <strong>GL</strong> Garrad HassanPhone: +44 11 79 72 99 00E-Mail: andrew.garrad@garradhassan.comPERAWAT.“PerformanceAssessment ofWave and TidalArray Systems”is a project topredict waveand tidal energy.<strong>01</strong>/2<strong>01</strong><strong>01</strong>3

certification financingToo ManyQuestion Marks?Quite contrary to the onshore market, thereare several challenges for offshore wind powerthat have yet to be overcome. Who willfinance which component? Will the samecompany assume liability for both the windturbine and the foundation? Which method oferecting turbines is most efficient?20-20-20 – The European Union has ambitiousgoals. Energy consumption and greenhousegas emissions are to decrease by 20per cent, whereas the percentage of electricity producedfrom <strong>renewables</strong> is supposed to increase by 20 per cent.And all this by 2020. There is thus no getting round theABSTRACTtopic of offshore wind technology.Though 21 out of 40 farmsBanks are often reluctant to financeoffshore wind farms. They prefer planned have been approved ingeneral contractor agreements.Germany alone, one can hardly<strong>GL</strong> Garrad Hassan offers a fullrange of consultancy and certificationservices covering all compo-wind. Of the 70,000-some MWspeak of a stampede for offshorenents of on- and offshore windturbines.that might be installed in Europeanwaters this decade accord-Wind experts are proposing entirelynew concepts that may encourageing to EWEA estimates, only 600banks to finance new projects.MW have been connected to thegrid to date. Unresolved questions regarding financing, systemtechnology and liability are the main drags. “More newideas is what we need,” demands Wilhelm Heckmann, engineerwith <strong>GL</strong> Garrad Hassan.When it comes to financing, banks politely hold back.One reason is that general contractor agreements are theexception rather than the rule. Instead of having one companyin charge, each manufacturer is liable for its own components.“Banks prefer general/EPC contractor agreements,”explains Jochen Gassert of <strong>GL</strong> Garrad Hassan. “The more in-Offshore.Jack-up barges transportingthe wind turbinecomponents.14 energıze <strong>renewables</strong>

Photo: Alpha Ventus / Matthias Ibelerterfaces you have, the more difficult it is to find the personresponsible in the event of a problem.”Technical ExpertiseBut there are ways to overcome this dilemma. <strong>GL</strong> GarradHassan offers technical due-diligence checks to assessthe feasibility and soundness of projects. Using a specialfinancial model, <strong>GL</strong> Garrad Hassan can calculate the expectedyields as well as the maintenance and service costs.“From the banks’ point of view, that would be the ideal approach,”emphasises Jochen Gassert.Danish energy company Dong Energy prefers multicontracting,assembling wind farm components from multiplesuppliers in-house and distributing the risk among themanufacturers. This does, however, call for a high level oftechnical expertise.“Currently there are hardly any tools for accurate costestimates,” says Jochen Gassert. Making realistic predictionsis virtually impossible. The basic parameters of windprojects, such as foundation soil conditions, distances, harbourinfrastructure and available installation vessels, aretoo diverse. “Longer waiting times, smaller installation windows.The further you go out, the more expensive it gets,”says Wilhelm Heckmann.Heated DebateMoreover, there is the weather, fluctuating feed-in tariffs(outside of Germany) and uncertainties regarding thetechnical reliability of wind turbines. "Though <strong>GL</strong> GarradHassan offers a standard model, there are alwayssome variables," says Jochen Gassert. These include aerodynamicand electrical losses, and grid availability. Inparticular, a large question mark hangs above the installationmethod at sea. While there is plenty of theoreticalknowledge, practical experience with offshore systems indeep water is scarce.It is thus hardly surprising that a heated debate haserupted regarding the vessel types that should be used totransport the components to the wind farm site and installthem. Should the turbine parts be hauled in by transportvessels and then assembled by special installation craft? Orwould it be more expedient to use special vessels capableof loading the components in the port and subsequently –equipped with pile-driving machinery and a crane – erectingthe wind turbines, as well? Then there is the maintenancedebate, waged with almost sectarian fervour: Shouldengineers and spare parts be present on site or not? Forthe <strong>GL</strong> specialists, the answer is clear: “Special vessels. Weneed to have personnel constantly on site atJACK-UP BARGE.the wind farm,” says Jochen Gassert. WilhelmA barge capableHeckmann specifies: “A service JACK-UP BARGEof low ering threeor four sup portinglegs to theis the most cost-efficient solution.”Will all these question marks disappearseafloor to raisesoon? Perhaps. Some experts even go as far asitself up.claiming that installation vessels could soon be operating300 days a year. Meanwhile, wind experts are presentingentirely new concepts. One such proposal envisages windturbines being assembled and tested directly in the harbour.If everything goes according to plan, the entire windturbine would then be transported to its site and erectedin a matter of hours. If the associated assembly methodsprove successful and the wind turbines demonstrate theirseaworthiness, the banks will probably show more interest,as well.DH<strong>GL</strong> EXPERT:Jochen GassertPhone: +49 4036149-7710E-Mail: jochen.gassert@gl-group.comWilhelm HeckmannPhone: +49 4036149-7547E-Mail: wilhelm.heckmann@gl-group.com<strong>01</strong>/2<strong>01</strong><strong>01</strong>5

asiatridentconsultingThe success is measurable:<strong>GL</strong> Garrad Hassan offers anunquestionable level ofknow-how in the field of windprojects and the full range ofturbine measurement services.The combined expertise is clearlyrecognised among developers,lenders and turbine manufacturersthroughout the world.16 energıze <strong>renewables</strong>

measurementPhoto: KfW/ Rüdiger Nehmzow<strong>01</strong>/2<strong>01</strong>0 17

measurement wind farmPredictable PowerThe power characteristic is a key factor in engineering that will determine the economicsuccess of a wind turbine. To verify the guaranteed energy yield, the future operatorshould survey the proposed site and take wind measurements18 energıze <strong>renewables</strong>

Wind conditions, turbine types, infrastructure,efficiency: Before a prospective wind farmproject is ready to enter the actual planningstage, a number of essential assessment criteria must beevaluated to determine the feasibility of the project. At thispoint, it is not necessary to conduct a full-scale, detailedanalysis, which would involve significant effort and time.Instead, assessing certain key criteria summarily will providemeaningful and entirely adequate information. The resultsof this preliminary assessment form a solid basis for decidingwhether the project should proceed. Once the actualplanning process has been initiated, an extensive, in-depthstudy of all relevant aspects of the project will follow.Focus on the Power CharacteristicOne key aspect in determining the technical requirementsfor a prospective wind turbine and in assessing its longtermeconomic feasibility is the power characteristic, orpower curve, of the envisioned system. The power charac-teristic reveals the power yield to be expected under specificwind speed conditions. It serves as an indicator of theoutput behaviour of any specific wind turbine type. It allowsplanners to compare various machine types and selectthe type best suited for the given site in terms of annualpower output. The annual power yieldcan be calculated by convoluting thepower curve by the wind speed distributionat the site.Ignoring the power characteristic,on the other hand, may have severeconsequences for the operator’s liquiditysince deviations in the operating behaviourwill directly affect the financialfeasibility of the power plant.To mitigate this risk, purchasingABSTRACTagreements usually contain a clause guaranteeing that themanufacturer will compensate the operator for any damagescaused by deviations of the power characteristicComparing the power characteristicsof various wind turbine typeshelps ensure the best possibleenergy yield at the given site.Each site must be assessed asearly as possible to find suitableconditions for measuring.An AEP procedure is recommendedfor comparing themeasured and the guaranteedpower characteristics.Photos: Dreamstime<strong>01</strong>/2<strong>01</strong><strong>01</strong>9

measurement wind farmfrom the type specification. Typically, such clauses cite“95 per cent of Annual Energy Production (AEP)”, referringto the relevant technical directives.Produce EvidenceAMBIENTCONDITIONS.The “ambience” ofa turbine isdetermined by itsrotor diameter. Fora large unit, thiscan be a circlearound the towerup to six kilometresin diameter.In wording such warranty clauses, operators should makesure the contract provides for an appropriate method of verifyingconformance with the power characteristic once thepower plant is in operation. Without a contractually-agreedform of evidence, the guarantee will be essentially worthless.The only way to prove non-conformance once thewind farm is in operation is to take measurements on singleturbines located at the perimeter of the site. The directivesset clear, tight limits for AMBIENT CONDITIONSat the site under study, in particular regardingexisting obstacles in the path of the wind (i.e.buildings, trees, turbines) as well as elevationsand uneven terrain.It is therefore essential to assess the measuringconditions at the site as early as possible soas to ensure the validity of the warranty clause.In the event that the standard conditions as definedby the directives cannot be met due to theparticular situation at the site, the guaranteeclause in the contract should be adapted to reflect the actualconditions. Options include:perform a site calibration pursuant to theIEC directive prior to constructing the powerplant;negotiate site-specific deviations fromFGW TR 2 and /or IEC 61400-12-1;agree on one specific wind turbine that can bemeasured as stipulated in the directives,to be used as a reference unit for the entiresite covered by the contract;take measurements based on the currentdraft version of IEC 61400-12-2 (refer to“nacelle anemometry”).State explicitly in the guarantee clause that the powercharacteristic of the entire wind farm should be used as areference (wind farm power characteristic dependent onthe wind direction, in analogy to the draft version of IEC61400-12-3), rather than relying on the power characteristicof individual turbines.Measure the Power CharacteristicBoth the site itself and the surroundings of a wind turbineplay a critical role in determining power characteristics. Inflat terrain free of obstacles, it can be assumed that thewind speed measured on a measuring tower will be equivalentto the wind speed at the centre of the rotor area (hub).This basic assumption does not apply in complex terrain,The Initial AssessmentWhat basic questions shouldbe addressed?The following questionsshould be answered toassess the basic aspectsof a planned windfarm project:WIND RESOURCESWhat are the wind conditionsat the site?PLANNING AND TECHNICALCRITERIATURBINE TYPEWhat wind turbine type wouldbest match the site (wind situation,power characteristic, structural stability,etc.)?20 energıze <strong>renewables</strong>

Photo: Gamesa EólicaOperating. The power characteristicserves as an indicator of theoutput behaviour of any specificwind turbine type.wind speeds, since the contribution of high winds to theoverall frequency distribution – and thereby, to the extrapolation– is minimal. It makes sense to continue taking measurementsuntil the AEP criterion has been met up to thesite-specific medium wind speed. This should be defined inadvance by mutual agreement.To allow the measured power characteristic to becompared to the guaranteed characteristic it is advisableto agree on a suitable method of comparison, if possiblebased on the AEP comparison. The directives leave someroom for interpretation. Contracts should therefore containappropriate stipulations to provide a definitive referencehowever, which is why the site under investigation must becalibrated prior to building the wind farm. This is done bydetermining wind-speed-dependent correction factors usingtwo measuring towers. The resulting factors will thenbe added to the wind speed readings associated with theactual power measurements.When choosing a suitable site for a measuring tower ,every attempt should be made to avoid the lee side of obstaclesand adjacent wind turbines, apart from purely practicalconsiderations, such as property ownership or theexistence of firm ground conditions to support the towerbase. This will ensure that the free geometric sector availablefor evaluation will be as large as possible. This sectorframework.IE,CT*must be oriented towards the prevailing direction of thewind. Following these rules will help minimise the measuringtime, and thereby, the associated costs.Select the CriterionIEC 61400-12-1 offers the user two criteria for establishing*The AuthorsDr Ingo Ewald, D.I.E.-Erneuerbare Energien; Chistoph Thiel, <strong>GL</strong> Garrad Hassan<strong>GL</strong> EXPERT:Christoph ThielGlobal Head of Measurements Business DevelopmentPhone: +49 4856 9<strong>01</strong>-55E-Mail: christoph.thiel@gl-group.coma complete set of data. The first criterion involves measuringup to 1.5 times the wind speed at 85 per cent of thenominal power output. For a unit with a rated speed of12 m/sec, this would be around 17 m/sec.Since this criterion may not be practicable for follow-upmeasurements, the AEP criterion was defined as an alternative.It stipulates that the data set is considered completewhen the AEP, based on the readings, reaches a minimumof 95 per cent of the AEP extrapolated up to the cut-outspeed. This is usually easy to achieve for lower to mediumENVIRONMENTAre there any spatial requirements(distance from housing areas,technical infrastructure, environmentalconsiderations etc.)?GRID TIE-INHow can the generated electricitybe fed into the utility grid?TRAFFIC INFRASTRUCTUREHow can the site bereached by heavy trucks?PRIVATE LAWWho are the owners of theproperty? Would they bewilling to support the constructionof the wind farm?LEGAL REQUIREMENTSFOR CONSTRUCTIONIs the site legally eligible forbuilding a wind farm?GENERAL FINANCIAL FEASIBILITYWill a wind farm at the proposedsite really be profitable?<strong>01</strong>/2<strong>01</strong>021

measurement EIAOne-Stop-Shop SupportBadly sited or designed wind projects can have adverse social and environmentalimplications. <strong>GL</strong> helps clients to address these issues early in the project developmentphase and ensure that a project is compliant with regulatory requirementsEnvironmental pollution and the emission ofcarbon dioxide (CO 2) due to the use of fossilfuels represent a threat to the environment,sustainable economic growth and health. Electricity generatedby a wind turbine is produced without CO 2emissions;it also does not pollute the air or water with harmfulgases and materials. Indeed, wind turbines cause virtuallyno emissions during their operation and very little duringtheir manufacture, installation, maintenance and decommissioning.While this is the case, a wind energy project can potentiallyaffect their immediate surroundings if they arenot sited properly. In order toABSTRACTprevent environmental impacts<strong>GL</strong> Garrad Hassan offers environmentalservice ensuring the highestdue to the installation of windturbines and to obtain the developmentconsent an Environmen-energy yield and lowest social andenvironmental impacts.The Systemic Approach benefits tal Impact Assessment (EIA) hasthe clients of <strong>GL</strong> Garrad Hassanby focusing on cost efficiencyto be completed. Typically suchand risk management.a study will include detailed investigationsof the natural andhuman environment, evaluate the potential effects of thewind project on the environmental and the local community,and proposed mitigation measures to reduce or eliminateany residual impacts. If taken on early in the developmentphase, certain elements of an EIA such as constraintsanalysis and site screenings – which can quickly identifysocial or environmental critical issues – will assure the developerof a reduction of development risks.EIAs are also as essential and required for on- and offshoreprojects. However the potential impacts of on- andoffshore wind farms are distinct given the different siteconditions and environmental surroundings.Systemic Approach<strong>GL</strong> Garrad Hassan offers an environmental service ensuringthe highest energy yield is achieved while minimizingsocial and environmental impact and ensuring the regulatorycompliance of a renewable energy project. How is thisachieved? Through a systemic approach tried and tested inCanada by <strong>GL</strong> Garrad Hassan, an approach that integratesengineering, environmental sciences and the GeographicInformation Systems (GIS) and enables all specialists towork together and create an optimised project. In essence,<strong>GL</strong> Garrad Hassan‘s main advantages are the following:CUTTING-EDGE METHOD ENSURES HIGHEST ENERGY YIELD<strong>GL</strong> Garrad Hassan understands the interaction betweenenvironmental factors, turbine siting, and energy yield.EFFICIENCY IN PROJECT DESIGNBy combining engineering with environmental sciencesand GIS, <strong>GL</strong> Garrad Hassan ensures that a project isdeveloped in a cost-efficient manner. Additionally,Photo: Innergex Renewable Energy22 energıze <strong>renewables</strong>

Risks. The impact ofwind farms on thescenery, even in uninhabitedareas have tobe considered in theproject’s development.EnvironmentalServices Include:Full environmental permitting managementConstraints analysis and site screeningsIdentification of stakeholder issues andmeans to obtain community acceptancePublic consultations/hearings andorganization of presentationsPhotomontages and zones of visual impactassessmentsNoise emission and shadow effectmeasurementsInterference with communication systemsNavigation risk assessmentIce throw risk analysisBaseline monitoring of avian fauna, bats,terrestrial faunaHabitat assessmentsEnvironmental impact assessmentsEnvironmental monitoring duringconstruction and operation<strong>01</strong>/2<strong>01</strong>023

measurement EIACase Study:St. Joseph Wind FarmPhoto: Innergex Renewable EnergyTYPE OF PROJECT Environmental AssessmentCLIENTPattern Energy <strong>Group</strong>/Bowark EnergyPROVINCE ManitobaYEAR 2008 – 2<strong>01</strong>0Complete Environmental Assessment and fatal flawanalysis according to both the Manitoba provincialrequirements and the federal requirements. Furthermore,Helimax headed a multi-disciplinary team madeup of internal resources and local subcontractors, andas such was responsible directly or indirectly for theoverall budget management and all components ofthe environmental permitting process. The project willbegin construction in summer 2<strong>01</strong>0 and <strong>GL</strong> GarradHassan is managing the construction and post-constructionenvironmental monitoring program.Canada. <strong>GL</strong> Garrad Hassan has also workedon the environmental permitting of theBaie-des-Sables project in the Bas-Saint-Laurent region of the province of Québec.<strong>GL</strong>’s EIA team includes local specialists that understandthe local issues on a site-specific basis. These specificspecialists are added to the team when required.throughout the EIA of wind farms. With its knowledgeand experience, <strong>GL</strong> Garrad Hassan can become the leadingexpert for EIAs of wind farms in Europe.MTEXPERIENCEFormer Helimax, now part of <strong>GL</strong> Garrad Hassan, hassuccessfully completed EIAs for more than 3,500 MWof wind power projects. It has established itself as theCanadian leader in applying wind engineering expertise<strong>GL</strong> EXPERT:Mirjam ToméEnvironmental Impact AssessmentPhone: +49 40 36149-2748E-Mail: mirjam.tome@gl-group.comA SuccessfulApproachCREATING AN OPTIMISEDPROJECT DESIGNENVIRONMENTAL/SOCIAL FEATURESProtected areasWatercourses, wetlands, water bodiesSensitive wildlife areas/sitesHeritage/Archaeological sitesRoads, trails, houses, settlementsCommunication towers, microwave linksPermissible noise levelsLot linesRecreational areas24 energıze <strong>renewables</strong>

Persuasive BenefitsMaximise energy, minimise environmental and social impacts:a systemic approach optimises wind project developmentENERGIZE: How would youdescribe your systemic approach?PATRICK HENN. <strong>GL</strong>’sSection Head of Environmentand Permitting.PATRICK HENN: The systemicapproach is basically a projectdevelopment strategy that integratesengineering, environmental sciences and GIS to ensurethat a project’s design is optimised, i.e. that it maximisesenergy while minimises environmental and social impact.ENERGIZE: Why is the systemic approach successful in Canada?HENN: We quickly realised a few years back that windproject development was done without considering environmentalconstraints, social acceptance, local zoning, etc.This generated frustration amongst developers in that – furtherdown the development path – site constraints werereducing the amount of land available for development or,in some cases eliminated a site altogether. The systemic approachproposes looking at siting issues early in the processto reduce the risk of surprises down the line. Additionally,integrating the environmental permitting process with theengineering of a project ensures that all elements are consideredin parallel, thus creating an optimised project.ENERGIZE: How do your clients benefit?HENN: Generally speaking, the systemic approach has twomain benefits: Cost efficiency, as the whole project designis done “under one roof” and risk management, as our approachquickly identifies “showstoppers” or critical issuesthat might impact a project’s design.ENERGIZE: How many EIAs have you conducted since youstarted the environmental service?HENN: We have conducted EIAs for more than 3,500 MWof wind projects. Furthermore, if you consider the partialservices such as constraints analyses, noise impact assessments,visual assessments, electromagnetic interferencestudies, etc, we have probably carried out such studies formore than 10,000 MW of projects.ENERGIZE: How many EIA experts can you provide?HENN: Our team is growing and currently includes approximately20 in-house experts, such as environmental assessmentmanagers, land planners, noise specialists and GISstaff. We also have a very extensive network of local specialiststo address specific issues like avian fauna, bats, archaeology,etc.ENERGIZE: Do you think the systemic approach will also besuccessful in Europe?HENN: I can’t see why not! Environmental and social issuesare present in any jurisdiction and virtually all projects needto comply to a certain level of environmental regulation.The approach ensures these items are taken into accountefficiently in the development phase of a project.Land usesLand owner restrictionsVisual considerationENGINEERINGTurbine selectionTurbine layoutProximity to transmission linesSite complexity assessmentPreliminary roads layouts, electricalnetworkMETEOROLOGYMesoscaleMet towers<strong>01</strong>/2<strong>01</strong>025

certificationasiatridentconsultingCertification of wind farms,turbines and their componentsis state-of-the-art and a mustaround the world. Certificationto harmonised requirementsactively supports exports.<strong>GL</strong> Renewables Certificationoffers project and type certifications– also in other fields ofrenewable-energy exploitationfor manufacturers, banks andinsurers of wind turbines andcomponents.26 energıze <strong>renewables</strong>

Photo: iStockphoto<strong>01</strong>/2<strong>01</strong>027

certification risk assessmentThe Way toSafe Wind ProjectsTo avoid liability issues, manufacturers of wind turbines should take CE ConformityAssessment very seriously. A standardised risk assessment process and <strong>GL</strong>’scertification offering help ensure safe and profitable operationAbsTrACTDriven by the dynamic wind energy market inEurope, the issue of CE marking has movedinto focus. Market supervisory authorities nolonger turn a blind eye to the safety aspects of wind turbines.Incorporating safety criteria into the turbine designprocess is therefore imperative. Not only is it a moral obligationto protect the health and well-being of people, italso makes perfect economic sense for, manufacturers andThe EC Machinery Directives requirethe manufacturer to perform a riskassessment identifying all hazardsassociated with the machine andestimating the resulting risks.Consistent risk assessment as anintegral part of the design processis a core element of any soundsafety strategy.operators to take CE markingand safety requirements quiteseriously. Shutdowns and a damagedreputation for the manufacturerare typical consequences ofan accident caused by an illegallyCE-marked wind turbine. TheGerman Equipment and ProductSafety Act, incorporating theProduct Safety Directive into federallaw, stipulates a fine of up to € 30,000 for an illegallyapplied CE mark. Other European countries impose similarpenalties.A Passport for All of EuropeTo guarantee the free movement of goods across the singleEuropean market, more than 20 product guidelines havebeen issued since 1987 based on Article 95 of the EC Treaty.Limited to “essential requirements” that are general in natureand primarily focus on health protection, these guide-lines are compulsory for any product put into circulation.The requirements are specified by harmonised stan dardsand a risk assessment process, which must describe all risksassociated with the machine in sufficient detail, along withthe measures implemented to guard against them. Due toits importance for machine safety, this assessment is thekey element of the overall CE conformity assessment process.Upon its completion in accordance with the applicableEC guideline(s), an EC declaration of conformity is issuedand the CE mark is granted, both of which jointly constitutea “passport” that allows the machine to be sold andput into service anywhere in the single European market.A Risk Assessment How-toEvery wind turbine is subject to the terms of MachineryDirective which requires the manufacturer to perform arisk assessment identifying all hazards associated with themachine and estimating the resulting risks. The manufacturermust then design and construct the wind turbine tominimise these risks. Further guidance can be found in theharmonised basic standards (type-A standards) such as ENISO 14121-1, which describes an iterative risk assessmentprocess as shown in the flow chart, and EN ISO 12100-1, which details the identification of hazards, specific risksto account for in the design process, design guidelines, astrategy for risk minimization, and criteria for acceptableresidual risks. The risk assessment process is subdivided intofive steps (see insert).28 energıze <strong>renewables</strong>

Any residual risks that cannot be completely eliminatedby appropriate technical means must be stated in the operatingmanual and identified by warning signs on the windturbine.Photo: VestasHazards.Manufacturers andoperators should takesafety requirementsquite seriously.Multitude of StandardsWith its Guideline for the Certification of Wind Turbines,Germanischer Lloyd underscores the great importance ofwind turbine safety. The comprehensive <strong>GL</strong> certificationprocess verifies compliance with a multitude of standards,including harmonised EU standards such as EN 61400-1and EN 61400-2. Furthermore, Germanischer Lloyd requiresa systematic consideration of possible faults, “and measuresfor limiting negative consequences”. This ensures thathazards associated with a wind turbine are identified andminimised by applying state-of-the-art technology. This systematicfault analysis is largely equivalent to the risk assessmentapproach described above.Technical protective means, or machine controlEN IsO 13489-1.elements incorporating such measures, are referredto as safety-related parts of the controls.The familiarcontrol categoriesTheir operation and assessment is described inof EN 954-1 havethe harmonised standard EN IsO 13849-1. Thebeen replaced byobjective is to ensure that the safety of the controlfunctions and their behaviour in the eventthe performancelevels of EN ISOof a fault achieve the degree of risk reduction13849-1.determined by the risk assessment. To thatend EN ISO 13849-1 defines five performance levels forimplementing the controls. In the certification process,Germanischer Lloyd will check the respective performancelevels established by the manufacturer and their implementationin the turbine design. In this respect <strong>GL</strong> certificationand CE marking are congruent.The Manufacturer’s ResponsibilityThe manufacturer of a wind turbine must ensure that themachine is designed and manufactured according to the essentialrequirements of the applicable EC guidelines.<strong>01</strong>/2<strong>01</strong>029

certification risk assessmentRisk Assessment ProcessBOUNDARY DEFINITIONlishing the probability of itsDefine the limits of theoccurrence and the severity ofmachine (EN ISO 12100-1):potential harm.Space limits: clearance, workingspace, etc. Use limits: intendeduse Time limits: probable life-RISK EVALUATIONThe decision whether theresidual risk is acceptable ortime assuming proper usewhether risk reduction measuresHAZARD IDENTIFICATIONAll conceivable hazards Interactionbetween the machine& its environment Possiblemalfunctions Proper useRequirements for personnelRISK ESTIMATIONEN ISO 14121-1 lists four riskelements to be determined foreach identified hazard, estab-are necessary requires experiencedspecialists. EN ISO 12100-1 and others provide relevantguidance.RISK REDUCTIONThe Machinery Directiveprovides three guiding principlesto reduce residual risk:hazard elimination, technicalprotective measures, and userinformation.NoYesFlow chart.Iterative processfor reducing risk.The manufacturer bears the responsibility for the assessmentprocess and the conformity of the wind turbine.The principle of full liability regardless of negligence orfault relieves claimants of the need to prove the manufacturer’snegligence, requiring only evidence of the causalconnection between the turbine fault and the harm suffered.The manufacturer may not be exculpated purely onthe assertion of having done “everything in his power” toplace a safe turbine on the market, or of having compliedwith all the standards. Therefore the best way to guardagainst liability claims is to optimise product safety. A manufacturerwho implements a rigorous safety strategy canprotect himself effectively against accidents and their legalconsequences.Consistent risk assessment as an integral part of the designprocess is a core element of any sound safety strategy.Risk assessment is teamwork, involving experts from a varietyof disciplines to scrutinise many different aspects. Independent,experienced experts with in-depth knowledge of safetystandards are the best option. They will examine the safetyaspects from an external perspective, providing the turbinemanufacturer with a neutral “third opinion” and valuableadditional insight. By combination of <strong>GL</strong> certification and CEmarking the far-reaching conse quences of nonconformity andillegal CE marking can thus be avoided. Ultimately, it is in thehands of manufacturers to live up to their responsibility andinitiate the appropriate measures.HB<strong>GL</strong> EXPERT:Holger Berndt<strong>GL</strong> Renewables CertificationPhone: +49 40 36149-5256E-Mail: holger.berndt@gl-group.com30 energıze <strong>renewables</strong>

certification standardsLeading Certification Body<strong>GL</strong> presented upcoming guidelines for certification of wind turbines. The 2<strong>01</strong>0edition will describe how to obtain type and project certification.ABSTRACTDate and place were well chosen. China WindPower 2009 was the meeting place of the mostimportant companies working in wind energy.There, in Beijing Germanischer Lloyd presented the latestdevelopment of the 2<strong>01</strong>0 edition of <strong>GL</strong> Guideline for thecertification of wind turbines. ”Certification of wind turbinesis a must in most places around the world and thus astrong support for export“, said <strong>GL</strong> expert Mike Wöbbeking.”It is important for manufacturers of wind turbines and componentsas well as banks and insurers involved to know thedifferent certification processes and guidelines.“ The newedition will cover small wind turbines and latest informationon several prominent wind energy markets.In the revised <strong>GL</strong>'s guidelines, the procedures to obtaintype and project certificates will be described. Type certificationcomprises design assessment, implementation of thedesign requirements in production and erection, evaluationThe new <strong>GL</strong> Guidelines for thecertification of wind turbines willeffect future development.The Edition 2<strong>01</strong>0 is to substitutethe current Edition 2003 plusSupplement 2004.of quality management and prototypetesting. And on the basisof type certification, projectcertification is carried out thatcovers site design conditions,site-specific design assessment,surveillance during production,transport and erection as well as witnessing of commissioningand periodic monitoring.Relevant StandardsPhoto: SuzlonOnshore. Wind Park in Weihai.wind turbines and components will be evaluated all the wayin terms of their quality management. In addition PrototypeTesting will be made to guarantee the product quality andto verify the performance of the safety and control systemsof the turbines. The measurements shall be based on therelevant standards and has to be performed according toISO 17025.<strong>GL</strong> has actively been involved in the development ofnational and international standards and is an internationalleading certification body for wind turbines. Its certificationservices for wind energy products and projects are providedon the basis of the <strong>GL</strong> Guideline for the Certification ofWind Turbines. ”It will have effect on future wind turbinedevelopments worldwide,“ pointed out Mr. Woebbeking.Also available and operational in the market is the <strong>GL</strong>Guideline for the Certification of Offshore Wind Turbines(Edition 2005).SGThe most important part of the Type Certification is the assessmentof the design documentation. In addition, the implementationof the design requirements in production anderection shall be observed. Therefore, the manufacturers of<strong>GL</strong> EXPERT:Mike WöbbekingHead of Department Machinery Components and SafetyPhone: +49 40 36149-3307E-Mail: mike.woebbeking@gl-group.com<strong>01</strong>/2<strong>01</strong>031

oil&gasxxxxxxxxxxxxxxxxxxgl <strong>renewables</strong> certificationnews in briefMitsubishi Power Systems Wind turbine – <strong>GL</strong> issuesStatement of ComplianceEnvision A-DesignAssessmentshamburg Mitsubishi Power Systems Europereceived a Statement of Compliance from <strong>GL</strong>Renewables Certification for the A-DesignAssessment of their wind turbine MWT 95/2.4(50 Hz). The Statement of Compliance meansnew opportunities. “Due to the long-lastingrelationship between Mitsubishi Power Sys-tems Europe and <strong>GL</strong>, we are delighted wewere chosen by them to verify the designassessment of the newly developed windturbine. Another milestone in our cooperation,”said Christian Nath, Vice President <strong>GL</strong>Renewables Certification.The statement was issued according tothe International Standard IEC 61400-1“Wind turbine generator systems – Part 1:Safety requirements”, 2nd edition, and the“Guideline for the Certification of WindTurbines”, Edition 2003 with Supplement2004, <strong>GL</strong>.Certificate. <strong>GL</strong>’s Vice President ChristianNath (third from l.) handed overthe Statement of Compliance to MasaakiShibata, Mitsubishi Power SystemsEurope (fourth from l.).beijing <strong>GL</strong> has signed a contract on windturbine certification with Chinese EnvisionEnergy Co., Ltd. Services including A-designassessments of six turbine variants beforethe end of 2<strong>01</strong>0. The agreement comprisescertification for an onshore wind turbine of1.5 MW (EN 15-77 and EN 15-88) for both50-Hz- and 60-Hz markets and is the logicalcontinuation of the d-Design assessmentissued last year.One year ago at the same venue, theD-design assessment certificate was handedover to Envision Energy. This plausibilitycheck of the 1.5-MW wind turbine formedthe first step of certification for EnvisionEnergy and in the cooperative work of bothcompanies. Now the contract was signed atthe joint booth of Garrad Hassan and <strong>GL</strong> atthe Wind Power China in Beijing. The contractwill commence immediately.Applied Bolting TechnologyNo Special Tools Requiredchicago Applied Bolting Technology(AB) received certificate number73638 from Germanischer Lloyd. <strong>GL</strong>certify that Applied Bolting’s M32,M36 and M48 Squirter ® Direct TensionIndicators (DTIs) control bolt tensionto ±10% with a confidence factor of97.7%. <strong>GL</strong> states that this is the firstvisual bolt tension indicating systemthat doesn’t require special tools.Squirter ® Direct Tension Indicatorsare compressible washers, made withspecial slots stamped into their bottomsurface. When the DTI bumps aresufficiently compressed, indicatingthat the bolt has achieved a certainPhoto: ABTtension, an orange silicone squirts outfrom the perimeter of the DTI.The Squirter ® has been hailed byconstruction and bolting professionalsas an amazingly simple and yet revolutionaryproduct which enables someonetightening a bolt to see just when theyshould stop tightening – not too soon,and not too late. Tens of millions havebeen supplied to structural boltingapplications worldwide, and now areavailable for wind power.Bolt. Squirter ® DTI inWind Tower Flange.32 energıze <strong>renewables</strong>

Notes on Engineering Details. Load assumptions, safety system & protective and monitoring devices, rotor blades andmachinery components, support structure, electrical installations and project certification:Various Notes on Engineering Details are now available as in PDF form on the <strong>GL</strong> <strong>Group</strong> website www.gl-group.com.Photo: Marcus DewangerPioneer. Peter Quell (REpower Systems,2nd from l.) received the certificate fromDr Uwe Jönck (<strong>GL</strong>, 2nd from r.).REpower First unit certificatefor MM serieshamburg REpower Systems AG hasreceived the first unit certificate from <strong>GL</strong>Renewables Certification for new turbinesin its turbine portfolio. The certificate isthe first ever that has been issued for awind turbine (generation unit) with a double-fedgenerator system. It confirms onceagain that the technical system implementedby the company meets the high requirementsof the grid system in Germany.The measurements required for thecertification were conducted on a REpowerMM82 with a rated power of 2.05 megawatts,located at the Dollerup wind farmnear Flensburg. “The unit certification forthe wind turbine REpower MM82 is one ofthe first which has been issued by us underthe new ordinance SDLWindV,” says DrUwe Jönck, Department Machinery Componentsand Safety with <strong>GL</strong> Renewables Certification.In order to obtain certification,simulation models for the characteristics ofthe wind turbine on the grid needed to befurther developed and then validated bycomprehensive tests in real operation.Sewind <strong>GL</strong> Certifies 3.6 MWOffshore Wind Turbineshanghai China’s power giants are allrushing for wind power exploration. AlthoughChina’s output of wind energy is 1.1per cent per year, only 0.3 per cent of thatenergy is being utilised as electricity. Chinahas to improve its power grid increasinglyto reach the goal of having 8 per centelectricity provided via wind energy by2020. Shanghai Electric Wind Power EquipmentCo. Ltd. (Sewind) and <strong>GL</strong> signed acontract for type certification of their 3.6-MW offshore wind turbine.“Certified technologies will provide acompetitive advantage to Sewind and willstrengthen its position when entering theoffshore market,” said Andreas Anders,Business Development Manager <strong>GL</strong> RenewablesCertification.<strong>GL</strong> has actively been involved in thedevelopment of national and internationalstandards and is an international leadingcertification body for wind turbines.Sewind is part of Shanghai Electric PowerGeneration <strong>Group</strong> which is one of thestrongest industry groups for power generationequipment manufacturing in China.Photo: SewindGoal. In2020, China’selectricityprovided bywind turbinesis expected torise up to 8per cent.Photo: SuzlonCallback. 417 sets of S88-V2 blades around theworld have been replaced.Suzlon Blade Retrofit ProgrammeCompletedpune Wind turbine manufacturer SuzlonEnergy Limited (SEL) announced the completionof its worldwide programme to reinforceall V2-type Suzlon blades on itsS88 2.1-MW turbines. Instances of bladecracks were first discovered in late 2007 onsome Suzlon S88-wind turbines in the U.S.Suzlon responded immediately, launching adetailed root cause analysis and designing aretrofitting solution for its 417 sets of S88-V2blades around the world – a commitment ofapprox. 100 million US dollars, already providedfor in the financial year 2008–09. Priorto implementation, the solution was extensivelytested.Suzlon also introduced the next generation,S88-V3, which is consistently exceedingperformance standards at windfarmsaround the world. One of Suzlon’s S88-turbines produces enough energy to powerapproximately 500 average American homes.Christian Nath, Vice President <strong>GL</strong> RenewablesCertification, reported: “We used3-D loading and design analysis software toverify the modified blade design, goingbeyond the requirements of IEC 61400-23.”<strong>01</strong>/2<strong>01</strong>033

servicedates at a glanceConferences & FairsIMPRINTAPRIL<strong>energize</strong> <strong>renewables</strong>, issue No. <strong>01</strong>/2<strong>01</strong>0,April 2<strong>01</strong>0 Frequency <strong>energize</strong> <strong>renewables</strong>20. – 23.04.2<strong>01</strong>0EWECWarsaw, PolandMAYLisewo. The installedcapacity is 10.8 MW.is published twice a year Published byGermanischer Lloyd Aktiengesellschaft,Hamburg Editorial Director Dr OlafMager (OM), Corporate CommunicationsManaging Editor Steffi Gößling (SG)Authors of this issue Holger Berndt (HB),05. – 06.05.2<strong>01</strong>0HOWHamburg, Germany23. – 26.05.2<strong>01</strong>0WINDPOWER 2<strong>01</strong>0Hamburg. Regular meetingpoint of the wind industry.Ingo Ewald (IE), Daniel Hautmann (DH),Jörn Iken (JI), Christoph Thiel (CT), MirjamTomé (MT) Cover photo Peter AndryszakDesign and production printprojekt,Schulterblatt 58, D-20357 Hamburg LayoutOliver Lohrengel Translations AndreasKühner Prepress Fire Department PrintedDallas/Texas, USAJUNE/JULYDallas. Worldwide largestannual wind conference.by Media Cologne KommunikationsmedienGmbH, Luxemburger Straße 96, D-50354Hürth Reprint © Germanischer Lloyd07. – 09.06.2<strong>01</strong>0Offshore Wind ChinaShanghai, China27.06. – 02.07.2<strong>01</strong>02<strong>01</strong>0 Intl ConferenceYokohama, Japan29.06. – 30.06.2<strong>01</strong>0BWEA Offshore WindLiverpool, UKSEPTEMBER18. – 22.09.2<strong>01</strong>0Husum WindEnergyHusum, GermanyShanghai. Premier offshorewind power event in Asia.Liverpool. Ninth annualconference and exhibition.Yokohama. Port city onTokyo Bay.Husum. Visitors at the leadingwind energy trade fair.Aktiengesellschaft 2<strong>01</strong>0. Reprintingpermitted on explicit request – copyrequested. All information is correct to thebest of our knowledge. Contributions byexternal authors do not necessarily reflectthe views of the editors or of GermanischerLloyd Enquiries to: Germanischer Lloyd AG,Corporate Communications, Brooktorkai 18,D-20457 Hamburg, Phone: +49 40 36149-7959, Fax: +49 40 36149-250, E-Mail:pr@gl-group.comSubscription service: For addresschanges and orders please send ane-mail to publications@gl-group.comThis product wasprinted on FSCCertified PaperPhotos: Gleam, Husum Wind, Jens Schott Knudsen, Jörn Menninger, Mike Peel, Daniel Schwen34 energıze <strong>renewables</strong>

TrainingWind Farm Design5 May Bristol, England13 May Athens, Greece27 May Dallas, TX, USA2 June Oldenburg, Germany30 August Rio de Janeiro, BrasilIntroduction to GH WindFarmer6 May Bristol, England14 May Athens, Greece28 May Dallas, TX, USA3 June Oldenburg, GermanyGH Bladed Training10–14 May Bristol, EnglandIntroduction to Wave andTidal Energy Conversion18 May Aberdeen, ScotlandFinancing Your Wind Farm9 June London, EnglandWind Farm Development22–23 June Bristol, EnglandFor information on all our international training courses, please visit www.gl-garradhassan.com/trainingor contact Mr Andrew Brown at training@garradhassan.com

<strong>GL</strong> <strong>Group</strong>Head OfficeBrooktorkai 1820457 HamburgGermanyPhone: +49 40 36149-0Fax: +49 40 36149-200E-Mail: headoffice@gl-group.comwww.gl-group.comwww.gl-nobledenton.comwww.gl-garradhassan.comwww.gl-maritime-software.comwww.friendship-systems.comwww.futureship.netBristolHamburgPeterboroughMalleshwaramMelbourne<strong>GL</strong> Garrad Hassan<strong>GL</strong> RenewablesCertificationRegion North America45 Main StreetSuite 302Peterborough, NH 03458USAPhone: +1 603 924 8800Fax: +1 603 924 8805E-Mail: info.usa@garradhassan.comRegion IEMEASt Vincent’s WorksSilverthorne LaneBristol, BS2 0QDUKPhone: +44 117 972 9900Fax: +44 117 972 99<strong>01</strong>E-Mail: info@garradhassan.comRegion Asia1st Floor, 4th Cross, Sampige Road494/11 U.P. Royal BuildingMalleshwaramBangalore, 560003IndiaPhone: +91 80 4271 7979E-Mail: mste@gl-group.comRegion PacificSuite 25, Level 84<strong>01</strong> Docklands DriveDocklands, MelbourneVictoria, 3008AustraliaPhone: +61 3 9600 1993Fax: +61 3 9602 1714E-Mail: info.au@garradhassan.comBrooktorkai 1820457 HamburgGermanyPhone: +49 40 36149-707Fax: +49 40 36149-1720E-Mail: gl<strong>renewables</strong>@gl-group.com0E712 2<strong>01</strong>0-04-16