TDS_Special Fabrics - Saati

TDS_Special Fabrics - Saati

TDS_Special Fabrics - Saati

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Composites<br />

technical data<br />

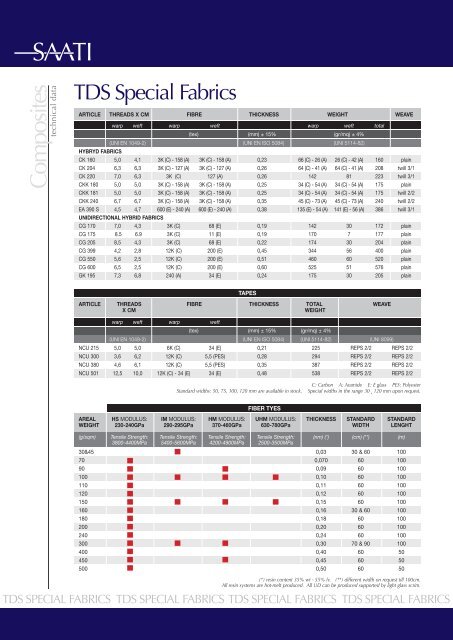

<strong>TDS</strong> <strong>Special</strong> <strong>Fabrics</strong><br />

ARTICLE THREADS X CM FIBRE THICKNESS WEIGHT WEAVE<br />

warp weft warp weft warp weft total<br />

(tex) (mm) ± 15% (gr/mq) ± 4%<br />

(UNI EN 1049-2)<br />

HYBRYD FABRICS<br />

(UNI EN ISO 5084) (UNI 5114-82)<br />

CK 160 5,0 4,1 3K (C) - 158 (A) 3K (C) - 158 (A) 0,23 66 (C) - 26 (A) 26 (C) - 42 (A) 160 plain<br />

CK 204 6,3 6,3 3K (C) - 127 (A) 3K (C) - 127 (A) 0,26 64 (C) - 41 (A) 64 (C) - 41 (A) 208 twill 3/1<br />

CK 220 7,0 6,3 3K (C) 127 (A) 0,26 142 81 223 twill 3/1<br />

CKK 180 5,0 5,0 3K (C) - 158 (A) 3K (C) - 158 (A) 0,25 34 (C) - 54 (A) 34 (C) - 54 (A) 175 plain<br />

CKK 181 5,0 5,0 3K (C) - 158 (A) 3K (C) - 158 (A) 0,25 34 (C) - 54 (A) 34 (C) - 54 (A) 175 twill 2/2<br />

CKK 240 6,7 6,7 3K (C) - 158 (A) 3K (C) - 158 (A) 0,35 45 (C) - 73 (A) 45 (C) - 73 (A) 240 twill 2/2<br />

EA 390 S 4,5 4,7 600 (E) - 240 (A) 600 (E) - 240 (A) 0,38 135 (E) - 54 (A) 141 (E) - 56 (A) 386 twill 3/1<br />

UNIDIRECTIONAL HYBRID FABRICS<br />

CG 170 7,0 4,3 3K (C) 68 (E) 0,19 142 30 172 plain<br />

CG 175 8.5 6.9 3K (C) 11 (E) 0,19 170 7 177 plain<br />

CG 205 8,5 4,3 3K (C) 68 (E) 0,22 174 30 204 plain<br />

CG 399 4,2 2,8 12K (C) 200 (E) 0,45 344 56 400 plain<br />

CG 550 5,6 2,5 12K (C) 200 (E) 0,51 460 60 520 plain<br />

CG 600 6,5 2,5 12K (C) 200 (E) 0,60 525 51 576 plain<br />

GK 195 7,3 6,8 240 (A) 34 (E) 0,24 175 30 205 plain<br />

ARTICLE THREADS FIBRE THICKNESS TOTAL WEAVE<br />

X CM WEIGHT<br />

warp weft warp weft<br />

(tex) (mm) ± 15% (gr/mq) ± 4%<br />

(UNI EN 1049-2) (UNI EN ISO 5084) (UNI 5114-82) (UNI 8099)<br />

NCU 215 5,0 5,0 6K (C) 34 (E) 0,21 225 REPS 2/2 REPS 2/2<br />

NCU 300 3,6 6,2 12K (C) 5,5 (PES) 0,28 294 REPS 2/2 REPS 2/2<br />

NCU 380 4,6 6,1 12K (C) 5,5 (PES) 0,35 387 REPS 2/2 REPS 2/2<br />

NCU 501 12,5 10,0 12K (C) - 34 (E) 34 (E) 0,48 538 REPS 2/2 REPS 2/2<br />

C: Carbon A: Aramide E: E glass PES: Polyester<br />

Standard widths: 50, 75, 100, 120 mm are available in stock. <strong>Special</strong> widths in the range 30 ¸ 120 mm upon request.<br />

FIBER TYES<br />

AREAL HS MODULUS: IM MODULUS: HM MODULUS: UHM MODULUS: THICKNESS STANDARD STANDARD<br />

WEIGHT 230-240GPa 290-295GPa 370-460GPa 630-780GPa WIDTH LENGHT<br />

(g/sqm) Tensile Strength: Tensile Strength: Tensile Strength: Tensile Strength: (nm) (*) (cm) (**) (m)<br />

3800-4400MPa 5400-5600MPa 4200-4900MPa 2500-3500MPa<br />

30&45 0,03 30 & 60 100<br />

70 0,070 60 100<br />

90 0,09 60 100<br />

100 0,10 60 100<br />

110 0,11 60 100<br />

120 0,12 60 100<br />

150 0,15 60 100<br />

160 0,16 30 & 60 100<br />

180 0,18 60 100<br />

200 0,20 60 100<br />

240 0,24 60 100<br />

300 0,30 70 & 90 100<br />

400 0,40 60 50<br />

450 0,45 60 50<br />

500 0,50 60 50<br />

(*) resin content 35% wt - 55% fv. (**) different width on request till 100cm.<br />

All resin systems are hot-melt produced. All UD can be produced supported by light glass scrim.<br />

<strong>TDS</strong> SPECIAL FABRICS <strong>TDS</strong> SPECIAL FABRICS <strong>TDS</strong> SPECIAL FABRICS <strong>TDS</strong> SPECIAL FABRICS<br />

TAPES

Composites<br />

technical data<br />

<strong>TDS</strong> <strong>Special</strong> <strong>Fabrics</strong><br />

1,000 E5<br />

10000<br />

1000<br />

100,0<br />

(n*) (Pa.s) 1,000 E6<br />

10,00<br />

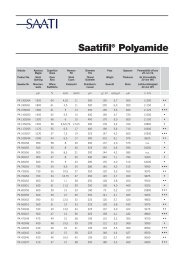

VISCO- CURING CURING GEL TG MINIMUM ASPECT RESIN FIELD OF<br />

SITY (1) TEMP. TIME TIME (DSC) (2) SHELF LIFE CARACTERISTICS APPLICATION<br />

ET 445<br />

1,000<br />

20,0 40,0 60,0 80,0 100,0 120,0 140,0<br />

Temperature (ºC)<br />

( ºC) ( min) ( min @ ºC) ( ºC) (gg) (m)<br />

ES253 low 45-60 (*) 24h-18h 2' ± 1' @ 125 200 2÷5 @ 23°C slightly High thermal Tooling<br />

yellow stability and<br />

excellent<br />

surface finishing<br />

System<br />

ET222 low 60-80 14h-7h 3' ± 1' @ 125 130 7 @ 23°C standard low cure Vacuum<br />

process bag + oven<br />

ET445 low 120-130 60-30 6' ± 2' @ 125 120 25 @ 23°C transparent very shining Aesthetical<br />

application<br />

ER440 (**) low 120-150 60 6' ± 2' @ 125 145 365 @ 23°C standard Toughened Structural<br />

application<br />

ER432 (**) low 120-130 60 12' ± 3' @ 125 120 30 @ 23°C standard Strongly Structural<br />

Toughened application<br />

ER450 low 135 120 7' ± 2' @ 125 161 45 @ 23°C standard Toughened High<br />

temperature<br />

application<br />

CE662 low 125-140 (*) 120-60 9' ± 2' @ 140 360 60 @ 23°C slightly Very high Tg Very high<br />

green temperature<br />

application<br />

FF562 NA 135-150 75-60 NA 150 30 @ 23°C standard flame Fenolic resin for<br />

retardant interiors application<br />

EF452 Medium- 125-150 90-60 9' ± 3' @ 125 150 30 @ 23°C standard flame Epoxy resin for<br />

High retardant interiors application<br />

1,000 E5<br />

10000<br />

1000<br />

100,0<br />

10,0<br />

1,000<br />

(n*) (Pa.s) 1,000 E6<br />

ER 450<br />

0,1000<br />

25,0 50,0 75,0 100,0 125,0 150,0 175,0<br />

Temperature (ºC)<br />

1,000 E7<br />

1,000 E6<br />

1,000 E5<br />

10000<br />

1000<br />

100,0<br />

10,0<br />

ET 222<br />

1,000<br />

20,0 30,0 40,0 50,0 60,0 70,0 80,0 90,0<br />

100,0<br />

Temperature (ºC)<br />

(1) measured at 80°C, frequency 1Hz - LOW: < 300Pa*s;<br />

MEDIUM-LOW: 300÷500Pa*s; MEDIUM 500÷1000Pa*s;<br />

MEDIUM-HIGH: 1000÷1500Pa*s; HIGH: >1500Pa*s<br />

1,000 E5<br />

10000<br />

1000<br />

(n*) (Pa.s) 1,000 E6<br />

100,0<br />

ER 440<br />

10,00<br />

20,0 40,0 60,0 80,0 100,0 120,0 140,0 160,0<br />

Temperature (ºC)<br />

1,000 E6<br />

1,000 E5<br />

10000<br />

1000<br />

100,0<br />

10,0<br />

1,000<br />

(n*) (Pa.s) 1,000 E7<br />

(2) heating ramp 10°C/min 25°C÷250°C, Heating ramp<br />

for Tg, 20°C/min 25°C÷300°C<br />

(*) postcure is required<br />

(**) also available with carbon nanotubes for the<br />

highest performances<br />

1,000 E6<br />

1,000 E5<br />

10000<br />

1000<br />

100,0<br />

10,0<br />

(n*) (Pa.s) 1,000 E7<br />

ER 432<br />

1,000<br />

20,0 40,0 60,0 80,0 100,0 120,0 140,0 160,0<br />

Temperature (ºC)<br />

www.saati.com<br />

World Headquarters: ITALY<br />

SAATI S.p.A.<br />

Phone: (+39) 031 9711 - Fax: (+39) 031 933392<br />

E-mail: info.IT@saatiprint.com<br />

<strong>TDS</strong> SPECIAL FABRICS <strong>TDS</strong> SPECIAL FABRICS <strong>TDS</strong> SPECIAL FABRICS <strong>TDS</strong> SPECIAL FABRICS<br />

CE 662<br />

0,1000<br />

25,0 50,0 75,0 100,0 125,0 150,0 175,0 200,0<br />

Temperature (ºC)<br />

(n*) (Pa.s)<br />

ES 253<br />

1,000 E8<br />

1,000 E7<br />

1,000 E6<br />

1,000 E5<br />

10000<br />

1000<br />

100,0<br />

10,0<br />

1,000<br />

0,1000<br />

25,0 135,0<br />

Temperature (ºC)