ARAMID FABRIC PREPREG STYLE CT736 PHF - Saati

ARAMID FABRIC PREPREG STYLE CT736 PHF - Saati

ARAMID FABRIC PREPREG STYLE CT736 PHF - Saati

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

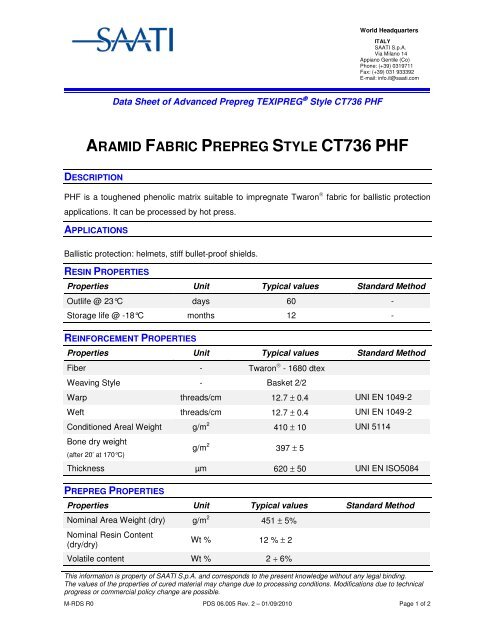

Data Sheet of Advanced Prepreg TEXIPREG Style <strong>CT736</strong> <strong>PHF</strong><br />

World Headquarters<br />

ITALY<br />

SAATI S.p.A.<br />

Via Milano 14<br />

Appiano Gentile (Co)<br />

Phone: (+39) 0319711<br />

Fax: (+39) 031 933392<br />

E-mail: info.it@saati.com<br />

<strong>ARAMID</strong> <strong>FABRIC</strong> <strong>PREPREG</strong> <strong>STYLE</strong> <strong>CT736</strong> <strong>PHF</strong><br />

DESCRIPTION<br />

<strong>PHF</strong> is a toughened phenolic matrix suitable to impregnate Twaron fabric for ballistic protection<br />

applications. It can be processed by hot press.<br />

APPLICATIONS<br />

Ballistic protection: helmets, stiff bullet-proof shields.<br />

RESIN PROPERTIES<br />

Properties Unit Typical values Standard Method<br />

Outlife @ 23°C days 60 -<br />

Storage life @ -18°C months 12 -<br />

REINFORCEMENT PROPERTIES<br />

Properties Unit Typical values Standard Method<br />

Fiber - Twaron - 1680 dtex<br />

Weaving Style - Basket 2/2<br />

Warp threads/cm 12.7 ± 0.4 UNI EN 1049-2<br />

Weft threads/cm 12.7 ± 0.4 UNI EN 1049-2<br />

Conditioned Areal Weight g/m 2 410 ± 10 UNI 5114<br />

Bone dry weight<br />

(after 20’ at 170°C)<br />

g/m 2 397 ± 5<br />

Thickness µm 620 ± 50 UNI EN ISO5084<br />

<strong>PREPREG</strong> PROPERTIES<br />

Properties Unit Typical values Standard Method<br />

Nominal Area Weight (dry) g/m 2 451 ± 5%<br />

Nominal Resin Content<br />

(dry/dry)<br />

Wt % 12 % ± 2<br />

Volatile content Wt % 2 ÷ 6%<br />

This information is property of SAATI S.p.A. and corresponds to the present knowledge without any legal binding.<br />

The values of the properties of cured material may change due to processing conditions. Modifications due to technical<br />

progress or commercial policy change are possible.<br />

M-RDS R0 PDS 06.005 Rev. 2 – 01/09/2010 Page 1 of 2

PROCESSING<br />

Data Sheet of Advanced Prepreg TEXIPREG Style <strong>CT736</strong> <strong>PHF</strong><br />

The prepreg can be processed by hot plate press.<br />

• Heat the moulding plates up to 165°C<br />

• Put the packet into the mould and apply only contact pressure<br />

• After 6’ open the plates for 5” for breathing<br />

World Headquarters<br />

ITALY<br />

SAATI S.p.A.<br />

Via Milano 14<br />

Appiano Gentile (Co)<br />

Phone: (+39) 0319711<br />

Fax: (+39) 031 933392<br />

E-mail: info.it@saati.com<br />

• Apply 10 bar pressure and kepp temperature and pressure for 9’ (up to 7 mm thickness)<br />

• Get the packet out of the mould<br />

Suggestion: handle the pre-preg only using protective gloves. Use the pre-preg in ventilated and<br />

dust-free rooms.<br />

DELIVERY FORM & PACKAGING<br />

The prepreg phenolic fabrics are rolled on 76 mm diameter cardboard cores with polyethylene<br />

film separator.<br />

Standard width: TBD<br />

Standard length: TBD<br />

HANDLING & STORAGE<br />

Stock rolls at -18 °C, sealed in original packages. Shop life at 23°C refers to rolls sealed in<br />

original packages. Before using of the prepreg, get out the roll from the freezer and let it warm<br />

up to room temperature for 6 hours sealed in its original package.<br />

SAFETY HAZARD<br />

This product contains phenolic resin. It may cause allergic reaction. Avoid prolonged contact<br />

with skin. The use of latex gloves for handling is suggested. It is also suggested to work in an<br />

aerated environment. Scraps are to be cured and discarded following national law.<br />

Note: for further information check the Material Safety Data Sheet<br />

This information is property of SAATI S.p.A. and corresponds to the present knowledge without any legal binding.<br />

The values of the properties of cured material may change due to processing conditions. Modifications due to technical<br />

progress or commercial policy change are possible.<br />

M-RDS R0 PDS 06.005 Rev. 2 – 01/09/2010 Page 2 of 2