BiomassCHP Units with Split - Turboden

BiomassCHP Units with Split - Turboden

BiomassCHP Units with Split - Turboden

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

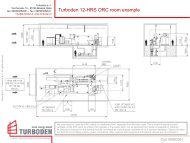

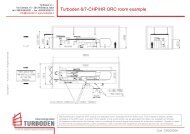

<strong>Turboden</strong> — A Pratt & Whitney Power Systems CompanyBiomass CHP <strong>Units</strong> <strong>with</strong> <strong>Split</strong>CHP <strong>Units</strong> for Cogeneration from BiomassCogeneration plants <strong>with</strong> Organic Rankine Cycle (ORC)products produce both heat and electrical power frombiomass efficiently and in a user-friendly manner. Thegenerated power ranges between 250 kW and 3 MW.ORC split systems allow maximization of electric powerproduction for a given biomass consumption due to a moreefficient exploitation of thermal power from the boiler, whilenonsplit systems maximize electrical efficiency. ORC units canbe fed by thermal oil, saturated vapor, or superheated water.Applications• District heating networks• Timber drying in sawmills• Sawdust drying in wood pellet factories• Air preheating in MDF factories• Greenhouses, swimming pools, hot springs• RefrigerationFuels• Wood biomass: sawdust, woodchips, bark, treated wood• Other biomass: dried sewage sludge, straw, green cuttings,rice husks, etc.• Waste material(Layout <strong>Turboden</strong> 10)Pratt & Whitney. It’s in our power. TM100%thermalpower fromthermal oil20%78%2%Electric powerHeat forthermal usersThermal losses

Biomass - CHP <strong>Units</strong> <strong>with</strong> <strong>Split</strong>CHP <strong>Units</strong> for Cogeneration from BiomassExample of CHP Plant in Biomass Applications (<strong>Split</strong> Type)ELECTRIC POWER OUTPUTDISTRICT HEATINGBIOMASS POWERED BOILER(PRUNING OF BRANCHES,MARCS, HUSK, WOOD CHIPS,SAW DUST, BARK)LOW TEMPERATURETHERMAL IOL LOOPDRYINGREFRIGERATIONHIGH TEMPERATURETHERMAL IOL LOOPHEAT SINKH<strong>Turboden</strong> ORC units can be also fed <strong>with</strong> saturated vapor or superheated water.Thermodynamic Principle: The ORC CycleThe turbogenerator uses the hightemperaturethermal oil to preheatand vaporize a suitable organic workingfluid in the evaporator (8>3>4).The organic fluid vapor powers theturbine (4>5) that is directly coupledto the electric generator through anelastic coupling. The exhaust vaporflows through the regenerator (5>9),where it heats the organic liquid(2>8). The vapor is then condensedin the condenser (cooled by the waterflow) (9>6>1).The organic fluid liquid is finallypumped (1>2) to the regenerator andthen to the evaporator, thus completingthe sequence of operations in theclosed-loop circuit.TEMPERATUREENTROPYTHERMAL OILWATERTHERMAL OILEVAPORATORPUMPTURBINEELECTRIC POWERGENERATORRIGENERATORWATERCONDENSER<strong>Turboden</strong>via Cernaia, 1025124 Brescia, Italy+39.030.3552.001Fax: +39.030.3552.011www.turboden.itPratt & Whitney Power Systems400 Main Street, M/S 191-13East Hartford, CT 061081-866-769-3275Outside USA: 1-860-565-0140www.pw.utc.com11-COM.B-4-rev.2