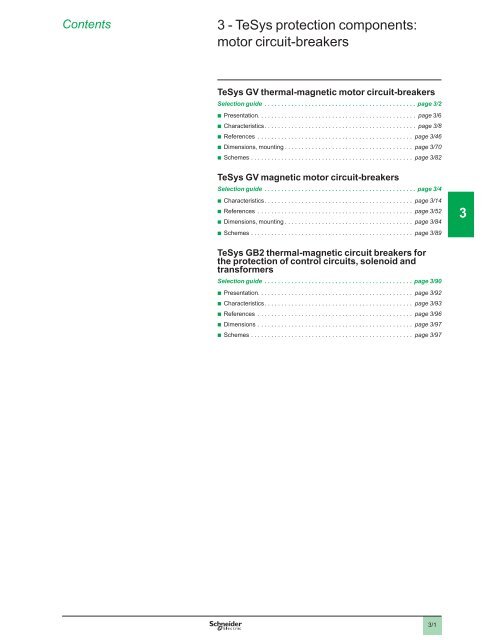

3 - TeSys protection components: motor circuit ... - MAXGroupOnline

3 - TeSys protection components: motor circuit ... - MAXGroupOnline

3 - TeSys protection components: motor circuit ... - MAXGroupOnline

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Protection of <strong>motor</strong>s with high current peakon starting12320 In47.5…110 kWUp to 11 kW12…220 A 0.25…23 A35 and 36 kA 70 kA 15…100 kA5WithWithGV7 RE GV7 RS GV2 RT63/49 3/50 and 3/51789103/3

36…14 In 8…13 In 6.3…12.5 InUp to 30 kW 37 kW 0.37…250 kW25…65 A 80 A 1.5…500 A50…100 kA 35 kA 25.7 and 150 kA 35.7…150 kA 45.7…150 kAWith With WithGV3 L GK3 EF80 NS 80 NS 100 toNS 250NS 400 andNS 6303/53 3/53 Please consult the Schneider Electric catalogue - Low Voltage Distribution3/5

Presentation<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2, GV3 and GV712526134GV2 MEwith screw clampterminals124526135GV2 MEwith spring terminalsconnections124PresentationGV2 ME, GV2 P, GV3 ME, GV3 P and GV7 R <strong>motor</strong> <strong>circuit</strong>-breakers are 3-polethermal-magnetic <strong>circuit</strong>-breakers <strong>protection</strong> of <strong>motor</strong>s, conforming to standards IEC 60947-2 and IEC 60947-4-1.ConnectionGV2GV2 ME and GV2 P <strong>circuit</strong>-breakers are designed for connection by screw clampterminals.Circuit-breaker GV2 ME can be supplied with lugs or spring terminal connections.Spring terminal connections ensure secure, permanent and durable clamping that isresistant to harsh environments, vibration and impact and are even more effectivewhen conductors without cable ends are used. Each connection can take twoindependent conductors.345261361324GV3GV3 <strong>circuit</strong>-breakers feature connection by BTR screws (hexagon socket head),tightened using a n° 4 Allen key.This type of connection uses the EverLink® system with creep compensation (1)(Schneider Electric patent).This technique makes it possible to achieve accurate and durable tightening torque,in order to avoid cable creep.GV3 <strong>circuit</strong>-breakers are also available with connection by lugs. This type ofconnection meets the requirements of certain Asian markets and is suitable forapplications subject to strong vibration, such as railway transport.56526137GV3 PGV2 P1324GV7GV7 <strong>circuit</strong>-breakers: with connection by screw clamp terminals (for bars and lugs)and by clip-on connectors.OperationControl is manual and local when the <strong>motor</strong> <strong>circuit</strong>-breaker is used on its own.Control is automatic and remote when it is associated with a contactor.GV2 ME and GV3 ME80Pushbutton control.Energisation is controlled manually by operating the Start button “I” 1.De-energisation is controlled manually by operating the Stop button “O” 2, orautomatically by the thermal-magnetic <strong>protection</strong> elements or by a voltage tripattachment.78526138132GV2 P, GV3 P and GV7 Rb Control by rotary knob: for GV2 P and GV3 Pb Control by rocker lever: for GV7 R.Energisation is controlled manually by moving the knob or rocker lever to position “I” 1.De-energisation is controlled manually by moving the knob or rocker lever to position “O” 2.De-energisation due to a fault automatically places the knob or rocker lever in the“Trip” position 3.Re-energisation is possible only after having returned the knob or rocker lever toposition “O”.(1) Creep: normal crushing phenomenon of copper conductors, that is accentuated over time.9GV7 R10Characteristics:pages 3/8 to 3/23References:pages 3/47 to 3/51Dimensions:pages 3/70 to 3/75Schemes:pages 3/76 and 3/773/6

Presentation (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2, GV3 and GV7Presentation (continued)Protection of <strong>motor</strong>s and personnelMotor <strong>protection</strong> is provided by the thermal-magnetic <strong>protection</strong> elementsincorporated in the <strong>motor</strong> <strong>circuit</strong>-breaker.The magnetic elements (short-<strong>circuit</strong> <strong>protection</strong>) have a non-adjustable trippingthreshold, which is equal to 13 times the maximum setting current of the thermaltrips.The thermal elements (overload <strong>protection</strong>) include automatic compensation forambient temperature variations.The rated operational current of the <strong>motor</strong> is displayed by means of a graduated knob 4.contact from the front panel.The addition of an undervoltage trip allows the <strong>circuit</strong>-breaker to be de-energised inthe event of an undervoltage condition. The user is therefore protected againstsudden starting of the machine when normal voltage is restored, since the Startbutton “I” has to be pressed to restart the <strong>motor</strong>.With the addition of a shunt trip, de-energisation of the unit can be remotelycontrolled.The operators on both open-mounted and enclosed <strong>motor</strong> <strong>circuit</strong>-breakers can belocked in the Stop position “O” by up to 4 padlocks.Because they are suitable for isolation, these <strong>circuit</strong>-breakers, in the open position,provide an adequate isolation distance and indicate the actual position of the movingcontacts by the position of the operators.Special featuresasymmetrical or combination rails.12345678910Characteristics:pages 3/8 to 3/23References:pages 3/47 to 3/51Dimensions:pages 3/70 to 3/75Schemes:pages 3/76 and 3/773/7

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakers3EnvironmentCircuit-breaker type GV2 ME GV2 P GV3 P GV3 ME80 GV7 RConforming to standards IEC 60947-1, 60947-2,60947-4-1,EN 60204, UL 508,CSA C 22.2 n° 14-05,NF C 63-650, 63-120, 79-130,VDE 0113, 0660UL, CSA, CCC,CEBEC,GOST, TSE,BV, GL, LROS ,DNV, PTB,EZU, SETI,RINA, ATEXUL (1), CSA,PTB, EZU,GOST, TSE,DNV, LROS,GL, BV, RINA,CCC, ATEXIEC/EN60947-1,60947-2,60947-4-1,UL 508 type E,CSA C 22.2n° 14-05 type EUL, CSA,CCC, GOST,ATEX, BV,GL, DNV, RINA,LROS (pending)IEC/EN, NFEN, BS EN,DINEN60947-2,60947-4-1UL, CSA,LROSIEC 60947-1,60947-2,60947-4-1,EN 60947-1,60947-2,EN 60947-4-1,NF C 63-650,NF C 63-120,79-130,VDE 0113,0660UL, DNV,CCCProtective treatment “TH” “TH” “TC” “TC”Degree of <strong>protection</strong> Conforming toIEC 60529Open mounted IP 20 IP 20 IP 20 IP 405 withterminalshroudsIn enclosureGV2 Mp01:IP 41GV2 Mp02:IP 55– GV3 PC01 andGV3 PC02: IP 55Shock resistance Conforming to IEC 60068-2-27 30 gn -11 ms On: 15 gn -11 msOff:30 gn -11 msVibration resistance Conforming to IEC 60068-2-6 5 gn (5…150 Hz) 4 gn(5…300 Hz)GV3 CE01:IP 5522 gn - 20 ms 15 gn -11 ms2.5 gn(0…25 Hz)–2.5 gn (25 Hz)Ambient air temperature Storage °C - 40…+ 80 - 40…+ 80 - 40…+ 80 - 40…+ 80 - 55…+ 95Operation Open mounted °C - 20…+ 60 - 20…+ 60 - 20…+ 60 (2) - 20…+ 60 - 25… + 70In enclosure °C - 20…+ 40 - 20…+ 40 - 20…+ 40 - 20…+ 40 –Temperature compensation Open mounted °C - 20…+ 60 - 20…+ 60 - 20…+ 60 - 20…+ 60 - 25… + 55 (3)In enclosure °C - 20…+ 40 - 20…+ 40 - 20…+ 40 - 20…+ 40 –Flame resistance Conforming to IEC 60695-2-1 °C 960 960 960 960Maximum operating altitude m 2000 3000 3000 2000Suitable for isolation Conforming to IEC 60947-1 § 7-1-6 Yes Yes – YesResistance to mechanical impact J 0.5 0.5 10 0.5 0.5IK 04 IK 09(in enclosure)– –Sensitivity to phase failure Yes, conforming to IEC 60947-4-1 § 7-2-1-5-2Technical characteristicsCircuit-breaker type GV2 ME GV2 P GV2 RT GV3 P GV3ME80GV7Rp20...Rp100Utilisation category Conforming to IEC 60947-2 A A A AConforming to IEC 60947-4-1 AC-3 AC-3 AC-3 AC-3Rated operational voltage Conforming to IEC 60947-2 V 690 690 690 690(Ue)Rated insulation voltage(Ui)Conforming to IEC 60947-2 V 690 690 690 750Rated voltage Conforming to CSA C22-2 n° 14,UL 508Rated operationalfrequencyRated impulse withstandvoltage (U imp)Conforming to IEC 60947-4-1UL, CSAV 600 600 600 600(B600)Hz 50/60 50/60 50/60 50/60Conforming to IEC 60947-2 kV 6 6 6 8GV7Rp150GV7Rp220Total power dissipated per pole W 2.5 8 8 5 8.7 14.5Mechanical durabilityC.O. 100 000 50 000 30 000 50 000 40 000 20 000(C.O.: Close, Open)Electrical durabilityfor AC-3 duty440 V In/2 C.O. 100 000 – 30 000 50 000 40 000 20 000440 V In C.O. – 50 000 – 30 000 20 000 10 000Duty class (maximum operating rate) C.O./h 25 25 25 25Maximum conventionalrated thermal current (Ith)Conforming to IEC 60947-4-1 A 0.16…320.16…320.40…2313…6580 12…100150 220Rated duty Conforming to IEC 60947-4-1 Continuous duty(1) UL 508 type E for GV2 PppH7(2) Leave a space of 9 mm between 2 <strong>circuit</strong>-breakers: either an empty space, or side mounting addoncontact blocks. Side by side mounting is possible up to 40 °C.References:pages 3/47 to 3/513/8Dimensions:pages 3/70 to 3/77Schemes:pages 3/78 and 3/79

Characteristics (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersMounting characteristicsOperating positionWithout derating, in relation to normal vertical mounting plane (1)90˚90˚90˚90˚Connection characteristicsConnection to screw clamp terminals or spring terminalsBare cablesh3Circuit-breaker type GV2 ME GV2 P GV3 P GV3 ME80Connection to screw clamp terminalsMin. Max. Min. Max. Min. Max. Min. Max.(2)Solid cable mm 2 2 x 1 2 x 6 2 x 1 2 x 6 2 x 1 1 x 25 and 1 x 2.5 1 x 35(Max. number of1 x 35conductors x c.s.a.)Flexible cablewithout cable endFlexible cablewith cable endmm 2 2 x 1.5 2 x 6 2 x 1.5 2 x 6 2 x 1 1 x 25 and1 x 35mm 2 2 x 1 2 x 4 2 x 1 2 x 4 2 x 1 1 x 25 and1 x 351 x 2.5 2 x 161 x 2.5 2 x 165 5Tightening torque N.m 1.7 1.7 1.7 1.7 5 5: 25 mm 28: 35 mm 2Connection to spring terminals Solid cable mm 2 2 x 1 (3) 2 x 6 – – – – – –Number of conductors x c.s.a.Flexible cablemm 2 2 x 1.5 (3) 2 x 4 – – – – – –without cable endConnection by bars or lugsBars or lugsØ6eLdLdL'Circuit-breaker type GV2 MEpp6 GV3 Ppp6 GV7GV7 Rp150 GV7 Rp220Rp20...Rp100Pitch Without spreaders mm 13.5 17.5 35 35 35With spreaders mm – – 45 45 45Bars or cables with lugs e mm y 6 y 6 y 6 y 6 y 6L mm y 9.5 y 13.5 y 25 y 25 y 25L’ mm y 9.5 y 16.5 – – –d mm y 10 y 10 y 10 y 10 y 10Screws M4 M6 M6 M8 M8Tightening torque N.m 1.7 6 10 15 15Bare cables (copper or aluminium)with connectorsHeight (h) mm – – 20 20 20C.s.a. mm 2 – – 1.5...95 1.5...95 1.5...185Tightening torque N.m – – 15 15 15(2) For <strong>motor</strong> <strong>circuit</strong>-breakers GV3 P: BTR hexagon socket head screws, EverLink ® system.Require use of an insulated Allen key, in compliance with local electrical wiring regulations.(3) For cross-sections 1 to 1.5 mm 2 , the use of an LA9 D99 cable end reducer is recommended.References:pages 3/47 to 3/51Dimensions:pages 3/70 to 3/77Schemes:pages 3/78 and 3/793/9

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 ME and GV2 PBreaking capacity of GV2 ME and GV2 PCircuit-breaker type GV2 ME GV2 P01to06Rating A 0.1to1.6Breaking capacityconforming to IEC 60947-207 08 10 14 16 20 21&2232 01to0632 0.1to1.607 08 10 14 16 20 21&222.5 4 6.3 10 14 18 23&252.5 4 6.3 10 14 18 23&2532230/240 V Icu kA g g g g g g g 50 50 g g g g g g g g gIcs % (1) g g g g g g g 100 100 g g g g g g g g g32400/415 V Icu kA g g g g g 15 15 15 10 g g g g g g 50 50 503Ics % (1) g g g g g 50 50 40 50 g g g g g g 50 50 50440 V Icu kA g g g 50 15 8 8 6 6 g g g g g 50 20 20 20Ics % (1) g g g 100 100 50 50 50 50 g g g g g 75 75 75 75500 V Icu kA g g g 50 10 6 6 4 4 g g g g 50 42 10 10 10Ics % (1) g g g 100 100 75 75 75 75 g g g g 100 75 75 75 75690 V Icu kA g 3 3 3 3 3 3 3 3 g 8 8 6 6 6 4 4 4Ics % (1) g 75 75 75 75 75 75 75 75 g 100 100 100 100 100 100 100 100Associated fuses (if required)if Isc > breaking capacity Icuconforming to IEC 60947-2230/240 V aM A g g g g g g g 80 80 g g g g g g g g ggG A g g g g g g g 100 100 g g g g g g g g g400/415 V aM A g g g g g 63 63 80 80 g g g g g g 100 100 100gG A g g g g g 80 80 100 100 g g g g g g 125 125 125440 V aM A g g g 50 50 50 50 63 63 g g g g g 50 63 80 80gG A g g g 63 63 63 63 80 80 g g g g g 63 80 100 100500 V aM A g g g 50 50 50 50 50 50 g g g g 50 50 50 50 50gG A g g g 63 63 63 63 63 63 g g g g 63 63 63 63 63690 V aM A g 16 25 32 32 40 40 40 40 g 20 25 40 40 50 50 50 50gG A g 20 32 40 40 50 50 50 50 g 25 32 50 50 63 63 63 63g > 100 kA.(1) As % of Icu.References:pages 3/47 to 3/513/10Dimensions:pages 3/70 to 3/72Schemes:page 3/78

Characteristics (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 ME and GV2 PBreaking capacity of GV2 ME and GV2 P (used in association with current limiter GV1 L3)Circuit-breaker typeGV2 ME01 to 06 07 08 10 14 16 20 21 22 32Rating A 0.1 to1.62.5 4 6.3 10 14 18 23 25 32Breaking capacityconforming to IEC 60947-2230/240 V Icu kA g g g g g g g g g gIcs % (1) g g g g g g g g g g400/415 V Icu kA g g g g g 100 100 100 100 100Ics % (1) g g g g g 50 50 40 40 40440 V Icu kA g g g g g 50 20 20 20 20Ics % (1) g g g g g 75 75 75 75 75500 V Icu kA g g g g 50 42 10 10 10 103Ics % (1) g g g g 100 100 75 75 75 75Circuit-breaker typeGV2 P01 to 06 07 08 10 14 16 20 21 22 32Rating A 0.1 to1.62.5 4 6.3 10 14 18 23 25 32Breaking capacityconforming to IEC 60947-2230/240 V Icu kA g g g g g g g g g gIcs % (1) g g g g g g g g g g400/415 V Icu kA g g g g g g g g g gIcs % (1) g g g g g g g g g g440 V Icu kA g g g g g 100 100 100 100 100Ics % (1) g g g g g 50 50 50 50 50500 V Icu kA g g g g 100 100 100 100 100 100Ics % (1) g g g g 50 50 50 50 50 50690 V (3) Icu = Ics kA g 50 50 50 50 50 50 50 50 50Circuit-breaker typeGV2 ME01 to 06 07 08 10 14 16 20 21 22 32Rating A 0.1to 1.62.5 4 6.3 10 14 18 23 25 32Cable <strong>protection</strong> againstthermal stress in theevent of short-<strong>circuit</strong>(PVC insulated copper cables)Minimumc.s.a.protectedat 40 °Cat Isc max.1 mm 2 p p p y 10 kA y 6 kA (2) (2) (2) (2) (2)1.5 mm 2 p p p y 20 kA y 10 kA (2) (2) (2) (2) (2)2.5 mm 2 p p p p p p p p p (2)4…6 mm 2 p p p p p p p p p pg > 100 kAp Cable c.s.a. protected(1) As % of Icu(2) Cable c.s.a. not protected(3) With limiter LA9 LB920References:pages 3/47 to 3/51Dimensions:pages 3/70 to 3/72Schemes:page 3/783/11

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV3 P and GV3 ME80Breaking capacity of GV3 P and GV3 ME80Motor <strong>circuit</strong>-breaker type GV3 P GV3 ME8013 18 25 32 40 50 65Rating A 13 18 25 32 40 50 65 80Breaking capacityconforming to IEC 60947-2230/240 V Icu kA 100 100 100 100 100 100 100 100Ics % (1) 100 100 100 100 100 100 100 100400/415 V Icu kA 100 100 100 100 50 50 50 15Ics % (1) 100 100 100 100 100 100 100 50440 V Icu kA 50 50 50 50 50 50 50 103Ics % (1) 100 100 100 100 100 100 100 60500 V Icu kA 12 12 12 12 12 12 12 4Ics % (1) 50 50 50 50 50 50 50 100690 V Icu kA 6 6 6 6 6 6 6 2Ics % (1) 50 50 50 50 50 50 50 100Associated fuses, if requiredif lsc > breaking capacity Icu230/240 V aM A g g g g g g g ggG A g g g g g g g g415 V aM A g g g g 125 125 125 315gG A g g g g 160 160 160 400440 V aM A 63 80 125 125 125 125 125 315gG A 80 100 160 160 160 160 160 400500 V aM A 63 63 63 63 80 80 80 200gG A 80 80 80 80 100 100 100 250690 V aM A 50 50 50 50 63 63 63 200gG A 63 63 63 63 80 80 80 250g Fuse not required: breaking capacity Icn > Isc.(1) As % of Icu.References:pages 3/47 to 3/513/12Dimensions:pages 3/73 and 3/74Schemes:pages 3/78 and 3/79

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV7 RBreaking capacity of GV7 RCircuit-breaker typeGV7RE20…RE100 RS20…RS100 RE150 RS150 RE220 RS220Rating A 12…20 to 60…100 90…150 90…150 132…220 132…220Breaking capacityconforming to IEC 60947-2230/240 V lcu kA 85 100 85 100 85 100Ics % (1) 100 100 100 100 100 100400/415 V Icu kA 36 70 35 70 35 70Ics % (1) 100 100 100 100 100 100440 V Icu kA 36 65 35 65 35 65Ics % (1) 100 100 100 100 100 100500 V Icu kA 18 50 30 50 30 503Ics % (1) 100 100 100 100 100 100690 V Icu kA 8 10 8 10 8 10Ics % (1) 100 100 100 100 100 100Cable <strong>protection</strong> againstthermal stress in theevent of short-<strong>circuit</strong>(PVC insulated copper cables)Minimumc.s.a.protectedat 40 °Cat Isc max.4 mm 2 y 6 kA y 6 kA (2) (2) (2) (2)6 mm 2 p y 25 kA (2) (2) (2) (2)10…50 mm 2 p p p p p p(1) As % of Icu.p Cable c.s.a. protected.(2) Cable c.s.a. not protected.References:pages 3/47 to 3/51Dimensions:pages 3/73 and 3/74Schemes:pages 3/78 and 3/793/13

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 LE and GV2 L1EnvironmentCircuit-breaker type GV2 LE GV2 LConforming to standards IEC 60947-1, 60947-2, EN 60204, NF C 63-650, NF C63-120, 79-130,VDE 0113, 0660. CSA, CCC CSA, CCC, BV, DNV, GL, LROS, RINAProtective treatment “TH” “TH”2Shock resistance Conforming to IEC 60068-2-27 30 gn 30 gnVibration resistance Conforming to IEC 60068-2-6 5 gn (5 to 150 Hz) 5 gn (5 to 150 Hz)Ambient air temperature Storage °C - 40…+ 80 - 40…+ 80Operation °C - 20…+ 60 - 20…+ 603Flame resistance Conforming to IEC 60695-2-1 °C 960 960Maximum operating altitude m 2000 2000Operating position45Connection(Max. number ofconductors x c.s.a)Min. Max. Min. Max.Solid cable mm 2 2 x 1 2 x 6 2 x 1 2 x 6Flexible cable without cable end mm 2 2 x 1.5 2 x 6 2 x 1.5 2 x 6Flexible cable with cable end mm 2 2 x 1 2 x 4 2 x 1 2 x 4Tightening torque N.m 1.7 1.76789Suitable for isolation Conforming to IEC 60947-1 § 7-1-6 Yes YesResistance to mechanical impact J 0.5 0.5Technical characteristicsUtilisation category Conforming to IEC 60947-2 A AConforming to IEC 60947-4-1 AC-3 AC-3Rated operationalConforming to IEC 60947-2 V 690 690voltage (Ue)Rated insulationConforming to IEC 60947-2 V 690 690voltage (Ui)Rated operational frequency Conforming to IEC 60947-2 Hz 50/60 50/60Rated impulse withstand Conforming to IEC 60947-2 kV 6 6voltage (U imp)Total power dissipated per pole W 1.8 1.8Mechanical durability For AC-3 duty C.O. 100 000 100 000(C.O.: Closing, Opening)Electrical durability for AC-3/415V dutyC.O. 100 000 100 000(C.O.: Closing, Opening)Duty classC.O./h 40 40(maximum operating rate)Rated duty Conforming to IEC 60947-4-1 Continuous duty Continuous duty10References:pages 3/52 and 3/533/14Dimensions:pages 3/83 to 3/84Schemes:page 3/87

Characteristics (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 LE and GV2 LCircuit-breaker type GV2 LE GV2 L03to0607 08 10 14 16 20 22 32 03to0506&0708 10 14 16 20 22 32Rating A 0.4 2.5 4 6.3 10 14 18 25 32 0.4 1.6 4 6.3 10 14 18 25 32to1.6to1to2.5Breaking capacity230/240 V Icu kA g g g g g g g 50 50 g g g g g g g 50 50conforming to IEC 60947-2Ics % (1) g g g g g g g 100 100 g g g g g g g 100 100400/415 V Icu kA g g g g g 15 15 15 10 g g g g g 50 50 50 5012Ics % (1) g g g g g 50 50 40 50 g g g g g 50 50 50 50440 V Icu kA g g g 50 15 8 8 6 6 g g g g 20 20 20 20 20Ics % (1) g g g 100 100 50 50 50 50 g g g g 75 75 75 75 75500 V Icu kA g g g 50 10 6 6 4 4 g g g g 10 10 10 10 103Ics % (1) g g g 100 100 75 75 75 75 g g g g 100 75 75 75 75Associated fuses (if required)if Isc > breaking capacity Icuconforming to IEC 60947-2amendment 1690 V Icu kA g 3 3 3 3 3 3 3 3 g 4 4 4 4 4 4 4 4Ics % (1) g 75 75 75 75 75 75 75 75 g 100 100 100 100 100 100 100 100230/240 V aM A g g g g g g g 80 80 g g g g g g g 100 100gG A g g g g g g g 100 100 g g g g g g g 125 125400/415 V aM A g g g g g 63 63 80 80 g g g g g 80 100 100 100gG A g g g g g 80 80 100 100 g g g g g 100 125 125 125440 V aM A g g g 50 50 50 50 63 63 g g g g 50 63 80 80 80gG A g g g 63 63 63 63 80 80 g g g g 63 80 100 100 10045500 V aM A g g g 50 50 50 50 50 50 g g g g 50 50 50 50 50gG A g g g 63 63 63 63 63 63 g g g g 63 63 63 63 63690 V aM A g 16 25 32 32 40 40 40 40 g 20 25 40 40 50 50 50 506Cable <strong>protection</strong> againstthermal stress in the eventof short-<strong>circuit</strong>(PVC insulated copper cables)Minimum c.s.a. protected at 40 °Cand at Isc max.gG A g 20 32 40 40 50 50 50 50 g 25 32 50 50 63 63 63 631 mm 2 kA p p p y10 y 6 (2) (2) (2) (2) p p p y10 y 6 (2) (2) (2) (2)1.5 mm 2 kA p p p y 20 y10 (2) (2) (2) (2) p p p y 20 y10 (2) (2) (2) (2)2.5 mm 2 p p p p p p p p (2) p p p p p p p p (2)4…6 mm 2 p p p p p p p p p p p p p p p p p pg > 100 kAp Cable c.s.a. protected(1) As % of Icu(2) Cable c.s.a. not protected78910References:pages 3/52 and 3/53Dimensions:pages 3/83 to 3/84Schemes:page 3/873/15

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV3 L and GK3 EF801EnvironmentCircuit-breaker type GV3 L GK3 EF80Conforming to standards IEC/EN 60947-1, 60947-2 IEC 60947-2, EN 60204Protective treatment “TH” “TC”Degree of <strong>protection</strong> Conforming to IEC 60529 IP 20 IP 2023Shock resistanceVibration resistanceFlame resistanceConforming toIEC 60068-2-27Conforming toIEC 60068-2-6Conforming toIEC 60695-2-1On : 15 gn -11 ms22 gn -20 msOff : 30 gn -11 ms4 gn (5…300 Hz) 2.5 gn (0…25 Hz)°C 960 960Ambient air temperature Storage °C - 40…+ 80 - 40…+ 80Operation °C - 20…+ 60 (1) - 20…+ 70 open mountedMaximum operating altitude m 3000 3000Operating positionWithout derating, in relation to normal vertical mounting plane (2)Any position45678Connection(Max. number ofconductors x c.s.a)Min. Max. Min. Max.Solid cable mm 2 2 x 1 1 x 251 x 2.5 1 x 351 x 35Flexible cablewithout cable endFlexible cablewith cable endmm 2 2 x 1 1 x 251 x 35mm 2 2 x 1 1 x 251 x 355Tightening torque N.m 5 5 : 25 mm 28 : 35 mm 2Suitable for isolationconforming to IEC 60947-1 § 7-1-6YesYesTechnical characteristics1 x 2.5 or2 x 2.51 x 2.5 or2 x 2.5Rated insulationConforming to IEC 60947-2 V 690 750voltage (Ui)Rated impulse withstand Conforming to IEC 60947-2 kV 6 10voltage (U imp)Rated operationalConforming to IEC 60947-2 V 690 690voltage (Ue)Rated operational frequency Hz 50/60 50…60Electrical durability for AC-3/415V dutyC.O. 50 000 1500(C.O.: Close - Open)Mechanical durabilityC.O. 50 000 20 000(C.O.: Closing, Opening)Maximum operating rate C.O./h 25 40Operating threshold of magnetic trips 14 I max 33631 x 25 or2 x 161 x 25 or2 x 16Utilisation category Conforming to IEC 60947-2 A A9(1) Leave a space of 9 mm between 2 <strong>circuit</strong>-breakers: either an empty space or side-mountingadd-on contact blocks. Side by side mounting is possible up to 40 °C.10References:pages 3/52 and 3/533/16Dimensions:pages 3/85 and 3/88Schemes:page 3/87

Characteristics (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV3 L and GK3 EF80Breaking capacity of GV3 L and GK3 EF80Type GV3 L25 GV3 L32 GV3 L40 GV3 L50 GV3 L65 GK3 EF80Breaking capacity of the<strong>circuit</strong>-breaker only or of the<strong>circuit</strong>-breaker combined witha thermal overload relay230/240 V Icu kA 100 100 100 100 100 50Ics % (1) 100 100 100 100 100 40400/415 V Icu kA 100 100 50 50 50 35Ics % (1) 100 100 100 100 100 25440 V Icu kA 50 50 50 50 50 2512Ics % (1) 100 100 100 100 100 30500 V Icu kA 12 12 12 12 12 15Ics % (1) 50 50 50 50 50 30690 V Icu kA 6 6 6 6 6 63Associated fuses (if required)for use with <strong>circuit</strong>-breaker onlyor <strong>circuit</strong>-breaker combined witha thermal overload relayif lsc > breaking capacityIcs % (1) 50 50 50 50 50 50230/240 V aM A g g g g g 200gG A g g g g g 315415 V aM A g g g g 125 200gG A g g g g 160 2504440 V aM A 63 80 125 125 125 160gG A 80 100 160 160 160 250500 V aM A 63 63 63 63 80 160gG A 80 80 80 80 100 2005690 V aM A 50 50 50 50 63 125gG A 63 63 63 63 80 1606Use of <strong>circuit</strong>-breakers without fusesMinimum cable length (in metres) limiting the maximum short-<strong>circuit</strong> current to 35 kAmaximum, so enabling breakers GK3 EF80 to be used without fusesCable c.s.a. mm 2 y 25 35 50 70 95 120Isc (rms) 3-phase, incoming(Ue = 415 V)50 kA m 5 6 8 10 13 1545 kA m 5 5 7 8 10 12740 kA m 5 5 5 5 8 937 kA m 5 5 5 5 5 5g Fuse not required: breaking capacity Icn > Isc.(1) As % of Icu8910References:pages 3/52 and 3/53Dimensions:pages 3/85 and 3/88Schemes:page 3/873/17

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2, GV3 P and GV3 LAuxiliary contacts3Type of contactsRated insulation voltage (Ui)(associated insulationcoordination)Conventionalthermal current (Ith)Mechanical durability(C.O.: Close - Open)Operational power and currentconforming to IEC 60947-5-1. a.c. operationInstantaneous auxiliaryGV AN, GV ADFault signallingGV AD,GV AM11 (1)Instantaneousauxiliary GV AEConforming to IEC 60947-1 V 690 690 250 (690 in relation tomain <strong>circuit</strong>)Conforming to CSA C22-2 n° 14and UL 508V 600 300 300Conforming to IEC 60947-5-1 A 6 2.5 2.5Conforming to CSA C22-2 n° 14and UL 508Rated operational voltage(Ue)Operational power,normal conditionsOperational power and currentconforming to IEC 60947-5-1. d.c. operationOccasional breaking and makingcapacities, abnormal conditionsRated operational current(Ie)Rated operational voltage(Ue)Operational power,normal conditionsLow power switching reliability of contactMinimum operational conditionsd.c. operationShort-<strong>circuit</strong> <strong>protection</strong>Cabling, screw clampterminalsOccasional breaking and makingcapacities, abnormal conditionsRated operational current(Ie)A 5 1 1C.O. 100 000 1000 100 000AC-15/100 000 C.O. AC-14/1000 C.O. AC-15/100 000 C.O.V 48 110127230240380415440 500 690 24 48 11012723024024 48 110127VA 300 500 720 850 650 500 400 36 48 72 72 48 60 120 120kVA 3 7 13 15 13 12 9 0.22 0.3 0.45 0.45 0.48 0.6 1.27 2.4A 6 4.5 3.3 2.2 1.5 1 0.6 1.5 1 0.5 0.3 2 1.25 1 0.5DC-13/100 000 C.O. DC-13/1000 C.O. DC-13/100 000 C.O.V 24 48 60 110 240(2)– – 24 48 60 – 24 48 60 –W 140 240 180 140 120 – – 24 15 9 – 24 15 9 –W 240 360 240 210 180 – – 100 50 50 – 100 50 50 –A 6 5 3 1.3 0.5 – – 1 0.3 0.15 – 1 0.3 0.15 –V 17mA 5Number of conductors 1 2Solid cable mm 2 1…2.5 1…2.5Flexible cable without cable end mm 2 0.75…2.5 0.75…2.5Flexible cable with cable end mm 2 0.75…1.5 0.75…1.5Tightening torque N.m 1.4 max 1.4 maxGV AE: Number of failures for “n” million operating cycles(17 V-5 mA): = 10 -6By GB2 CBpp <strong>circuit</strong>-breaker (rating according to operationalcurrent for Uey415 V) or by gG fuse 10 A max230240GB2 CB06 or gG fuse10 A maxCabling, spring terminalGV AN onlyconnectionsFlexible cable without cable end mm 2 0.75…2.5 0.75…2.5 – 0.75…1.5Operation of instantaneous auxiliary contacts 0 1Operation of fault signalling contactsPower poleFFFOFOFFFOGV AM11Change of state following tripping onshort-<strong>circuit</strong>.GV AD10pp and GV AD01ppChange of state following tripping onshort-<strong>circuit</strong>, overload or undervoltage.FOContact openContact closed(1) For application example of fault signalling contact and short-<strong>circuit</strong> signalling contact, see page 3/82.(2) Add an RC <strong>circuit</strong> type LA4 D to the load terminals, see page 5/81.References:page 3/55Dimensions and schemes:pages 3/70 to 3/873/18

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV3 ME80Auxiliary contactsType of contactsInstantaneous auxiliary contactsGV3 A01…A07Rated insulation voltage (Ui) Conforming to IEC 60947-1 V 690 690Fault signalling contactsGV3 A08 and A09Conventional ratedthermal current (Ith)Mechanical durability(C.O.: Close - Open)Operationalpower and currentconforming to IEC 60947-5-1a.c. operationOperational powerand currentconforming to IEC 60947-5-1d.c. operationShort-<strong>circuit</strong> <strong>protection</strong>Conforming to CSA C22-2 n° 14,UL 508V 600 (B600) 600 (B600)Conforming to IEC 60947-5-1 A 6 6Conforming to CSA C22-2 n° 14,UL 508Rated operational voltage(Ue)A 5 (B600) 5 (B600)C.O. 100 000 1000V 48 110127220240380415440 500 690 48 110127Operational power AC-11/100 000 C.O. AC-11/1000 C.O.Occasional breaking andmaking capacities220240380415440 500 690VA 350 500 800 850 700 700 400 240 460 800 850 450 450 200kVA 4 12 20 20 15 15 10 2.4 8 12 15 12 12 8Operational current (Ie) A 6 4.5 3.5 2.2 1.5 1.5 0.6 5 3.6 3.5 2.2 1 1 0.3Rated operational voltage(Ue)V 24 48 60 110 220 24 48 60 110 220Operational power DC-11/100 000 C.O. DC-11/1000 C.O.Occasional breaking andmaking capacitiesW 180 240 180 140 120 120 120 90 70 60W 240 360 240 210 180 180 180 135 105 90Operational current (Ie) A 6 5 3 1.3 0.5 5 2.5 1.5 0.7 0.3By GB2 CB08 <strong>circuit</strong>-breaker or gG fuse, 6A max3Connection Number of conductors 1 2Solid cable mm 2 1…2.5 1…2.5Flexible cable without cable end mm 2 0.75…2.5 0.75…2.5Flexible cable with cable end mm 2 0.75…2.5 0.75…1.5Contact operation 0 1GV3 A08 and A09 change state followingPower poletripping on short-<strong>circuit</strong> or overloadGV3 A01, A07GV3 A02GV3 A03GV3 A05OFFFOFFFFFGV3 A06FFContact openContact closedReferences:page 3/65Schemes:page 3/793/19

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV7Auxiliary contactsAuxiliary contact characteristicsType of contacts GV7 AE11 GV7 AB11Rated insulation voltage(Ui)(associated insulationcoordination)Conventionalthermal current (Ith)Mechanical durability(C.O.: Close - Open)Operational currentconforming to IEC 60947-5-1a.c. operationConforming to IEC 60947-1 V 690 690Conforming to IEC 60947-5-1 A 6 6Rated operationalvoltage (Ue)Rated operationalcurrent (Ie)C.O. 50 000 50 000AC-12 or AC-15. 50 000 C.O.V 24 48 110 230/240380/415AC-12 or AC-15. 50 000 C.O.440 690 24 48 110 230/240380/415440 690AC-12 A 6 6 6 6 6 6 6 5 5 5 5 5 5 5AC-15 A 6 6 5 4 3 3 0.1 5 5 4 3 2.5 2.5 0.13Operational currentconforming to IEC 60947-5-1d.c. operationRated operationalvoltage (Ue)Rated operationalcurrent (Ie)DC-12 or DC-14. 50 000 C.O.DC-12 or DC-14. 50 000 C.O.V 24 48 110 250 24 48 110 250DC-12 A 2.5 2.5 0.8 0.3 2 2 0.5 –DC-14 A 1 0.2 0.5 0.03 0.5 0.1 0.25 –Minimum operational conditionsd.c. operationV 17 12mA 5 5Short-<strong>circuit</strong> <strong>protection</strong>By GB2 CBpp <strong>circuit</strong>-breaker(rating according to operational current for Uey415 V) or gG fuse, 10 A max.Cabling Solid cable mm 2 1 x 1.5 conductor 1 x 1.5 conductorFlexible cable without cable end mm 2 1 x 1.5 conductor 1 x 1.5 conductorFlexible cable with cable end mm 2 1 x 1.5 conductor 1 x 1.5 conductorReferences:page 3/61Schemes:pages 3/793/20

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGK3 EF80Auxiliary contactsCharacteristics of Start-Stop and fault signalling contactsRated insulation voltage (Ui) Conforming to IEC 60947-1 V 500Rated operationalvoltage (Ue)Conventionalthermal current (Ith)Operationalpower and currentconforming to IEC 60947-5-1a.c. operation(C.O.: Close - Open)Operationalpower and currentconforming to IEC 60947-5-1d.c. operation(C.O.: Close - Open)Conforming to IEC 60947-1 V 500Conforming to IEC 60947-5-1 A 6AC-15. 20 000 C.O.Rated operational voltage (Ue) V 48 110/127 220/240 380/415 440 500Operational power VA 360 500 800 850 700 700Occasional breaking and making VA 4000 12 000 20 000 20 000 15 000 15 000capacitiesRated operational current (Ie) A 6 4.5 3.5 2.2 1.5 1.5DC-13. 1000 C.O.Rated operational voltage (Ue) V 24 48 60 110 220Operational power W 180 240 180 140 120Occasional breaking and W 240 280 240 210 180making capacitiesRated operational current (Ie) A 6 5 3 1.3 0.53Short-<strong>circuit</strong> <strong>protection</strong> Conforming to IEC 60947-5-1 By GB2 CB08 <strong>circuit</strong>-breaker or gG fuse, 6A maxCabling Solid cable mm 2 1 x 1…4 conductorFlexible cable without cable end mm 2 1 x 2.5 conductorFlexible cable with cable end mm 2 1 x 1…2.5 conductor or 2 x 1…2.5 conductorsTightening torque N.m 0.8References:page 3/65Dimensions:page 3/883/21

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersElectric tripsCharacteristics of electric tripsCircuit-breaker typeGV2 ME, GV2 PGV3 P, GV3 LGV2 MEonlyGV3 ME80Type of trip GV AU GV AS GV AX (1) GV3 B GV3 D GV7 AU GV7 ASRated insulation voltage (Ui) Conforming to IEC 60947-1 V 690 690 500 690 690 690 690Conforming to CSA C22-2 n° 14,UL 508Operational voltage Conforming to IEC 60947-1 V 0.85…1.1 UnDrop-out voltage V 0.7…0.35 UnGV7 RV 600 600 – 600 (B600) 600 (B600) 600 6000.7…1.1 Un0.75…0.2 Un0.85…1.1 Un0.7…0.35 Un0.8…1.1 Un0.7…0.35 UnInrush consumption a VA 12 14 12 12 < 10c W 8 10.5 8 7 < 50.85…1.1 Un0.35…0.7 Ue0.7…1.1 Un0.2…0.75 Ue3Sealed consumption a VA 3.5 5 3.5 7 < 5c W 1.1 1.6 1.1 2.5 < 5Operating time Conforming to IEC 60947-1 From the moment the voltage reaches its operational value until opening of the<strong>circuit</strong>-breaker.ms 10…15 10 15 < 50On-load factor 100 % 100 % 100 %Cabling Number of conductors 2 or 4 1 or 2 1Solid cable mm 2 1…2.5 1…2.5 1.5Flexible cable without cable end mm 2 0.75…2.5 0.75…2.5 1.5Flexible cable with cable end mm 2 0.75…1.5 0.75…2.5 1Tightening torque N.m 1.4 max 1.2 1.2Mechanical durability(C.O.: Close - Open)C.O. 30 000 (GV2 ME and GV2 P)10 000 (GV3 P and GV3 L)50 % of the mechanical durability of the<strong>circuit</strong>-breaker(1) Wiring scheme of undervoltage trip for dangerous machines (conforming to INRS) on GV2 MEonly, see page 3/82.References:page 3/61Schemes:pages 3/78 and 3/793/22

Characteristics<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic and magnetic <strong>motor</strong><strong>circuit</strong>-breakers GV2 and GV3AccessoriesCharacteristics of 3-pole busbars GV2 Gppp and GV3 Gp64GV2 GpppGV3 Gp64Rated insulation voltage (Ui) Conforming to IEC 60947-1 V 690 690ConventionalConforming to IEC 60439-1 A 63 115thermal current (Ith)PermissiblekA 11 20peak current (I peak)PermissiblekA 2 s 104 300thermal limit (I 2 t)Degree of <strong>protection</strong> Conforming to IEC 60529 IP 20 IP 20Terminal block Yes –Characteristics of terminal blocks GV2 G05 and GV1 G09 (for GV2 ME and GV2 P)Rated insulation voltage (Ui) Conforming to IEC 60947-1 V 690ConventionalConforming to IEC 60439-1 A 63thermal current (Ith)Degree of <strong>protection</strong> Conforming to IEC 60529 IP 203Connection Solid cable mm 2 1 x 1.5 to 25 conductor or 2 x 1.5 to 6 conductorsFlexible cable without cable end mm 2 1 x 1.5 to 16 conductor or 2 x 2.5 to 4 conductorsFlexible cable with cable end mm 2 1 x 1.5 to 10 conductor or 2 x 1.5 to 2 conductorsFlexible or solid cable AWG 1 AWG 4Tightening torque Connector N.m 2.2Screw clamp terminals N.m 1.7Characteristics of current limiters (GV2 ME and GV2 P)Type GV1 L3 LA9 LB920Rated insulation voltage (Ui) Conforming to IEC 60947-1 V 690 690ConventionalConforming to IEC 60947-1 A 63 63thermal current (Ith)Operating threshold rms current A 1500 (non adjustable threshold) 1000 (non adjustable threshold)Connection 1 conductor 2 conductors 1 conductor 2 conductorsSolid cable mm 2 1.5…25 1.5…10 1.5…25 1.5…10Flexible cable without cable end mm 2 1.5…25 2.5…10 1.5…25 1.5…10Flexible cable with cable end mm 2 1.5…16 1.5… 4 1.5…16 1.5… 4Tightening torque N.m 2.2References:page 3/673/23

Curves<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 ME and GV2 PThermal-magnetic tripping curves for GV2 ME and GV2 PAverage operating times at 20 °C related to multiples of the setting currentTime (s)10 000100031001012310,10,010,0011 1,5 10 100x the setting current (Ir)1 3 poles from cold state2 2 poles from cold state3 3 poles from hot stateReferences:pages 3/48 and 3/493/24Dimensions:pages 3/70 to 3/72Schemes:page 3/76

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 ME and GV2 PCurrent limitation on short-<strong>circuit</strong> for GV2 ME and GV2 P (3-phase 400/415 V)Dynamic stressI peak = f (prospective Isc) at 1.05 Ue = 435 VLimited peak current (kA)100= 0.25110= 0.7= 0.5= 0.3234563= 0.8781= 0.9cos = 0.95910110,1 0,1 1 10 15(12)100Prospective Isc (kA)1 Maximum peak current2 24 -32 A3 20 -25 A4 17 -23 A5 13 -18 A6 9 -14 A7 6 -10 A8 4 -6.3 A9 2.5 -4 A101.6 -2.5 A11 1 -1.6 A12Limit of rated ultimate breaking capacity on short-<strong>circuit</strong> of GV2 ME (14, 18, 23 and 25 A ratings)References:pages 3/48 and 3/49Dimensions:pages 3/70 to 3/72Schemes:page 3/763/25

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 METhermal limit on short-<strong>circuit</strong> for GV2 METhermal limit in kA 2 s in the magnetic operating zoneSum of I 2 dt = f (prospective Isc) at 1.05 Ue = 435 VSum of I 2 dt (kA 2 s)1001234563107891100,10,01 0,1 1 10 100Prospective Isc (kA)1 24 -32 A2 20 -25 A3 17 -23 A4 13 -18 A5 9 -14 A6 6 -10 A7 4 -6.3 A8 2.5 -4 A9 1.6 -2.5 A101 -1.6 AReferences:pages 3/48 and 3/493/26Dimensions:pages 3/70 to 3/72Schemes:page 3/76

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV3 P and GV3 ME80Current limitation on short-<strong>circuit</strong> (3-phase 400/415 V)Dynamic stressI peak = f (prospective Isc) at 1.05 Ue = 435 VLimited peak current (kA)100= 0.251= 0.33= 0.52 3456710= 0.789= 0.8= 0.911 10 15 100Prospective Isc (kA)1 Maximum peak current2 56 -80 A3 48 -65 A4 37 -50 A5 30 -40 A6 23 -32 A7 17 -25 A8 12 -18 A9 9 -13 AReferences:page 3/49Dimensions:page 3/73Schemes:page 3/773/29

Curves<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV7 RThermal-magnetic tripping curves for GV7 RAverage operating times at 20 °C related to multiples of the setting currentTime (s)10 0005000200010005002001005032010521120,50,230,10,050,020,010,0050,0020,00111,122 3 4 5 7 1020 30 4050 70100x the setting current (Ir)1 Cold state curve2 Cold state curve3 12…14 IrIn the event of total phase failure, tripping occurs after 4 s ± 20 %References:page 3/49Dimensions:page 3/73Schemes:page 3/773/31

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV7 RCurrent limitation on short-<strong>circuit</strong> (3-phase 400/415 V)Dynamic stressI peak = f (prospective Isc)For GV7 RE onlyLimited peak current (kA)1001 GV7 RE2202 GV7 RE1503 GV7 RE100380706050403020101238765423 4 5 6 1020 30 40 506070100Prospective Isc (kA)For GV7 RS onlyLimited peak current (kA)1001 GV7 RS2202 GV7 RS1503 GV7 RS10080706050403020101238765423 4 5 6 1020 30 40 506070100Prospective Isc (kA)References:page 3/503/32Dimensions:pages 3/73 to 3/75Schemes:page 3/77

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV7 RThermal limit (3-phase 400/415 V)Thermal limitSum of I 2 dt = f (prospective Isc)For GV7 RE onlySum of I 2 dt (A 2 s)10 75x10 61 GV7 RE2202 GV7 RE1503 GV7 RE1003x10 6 5 50 702x10 610 65x10 512333x10 5 3 4 6 1002x10 510 55x10 43x10 42x10 4 21020 30 40 60Prospective Isc (kA)For GV7 RS onlySum of I 2 dt (A 2 s)10 75x10 61 GV7 RS2202 GV7 RS1503 GV7 RS1003x10 6 5 50 702x10 610 65x10 51233x10 5 3 4 6 1002x10 510 55x10 43x10 42x10 4 21020 30 40 60Prospective Isc (kA)References:page 3/50Dimensions:pages 3/73 to 3/75Schemes:page 3/773/33

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV7 RThermal limit on short-<strong>circuit</strong> (3-phase 690 V)Thermal limitSum of I 2 dt = f (prospective Isc)For GV7 RE onlySum of I 2 dt (A 2 s)1 GV7 RE2202 GV7 RE150 and GV7 RE1003x10 6 12x10 610 635x10 523x10 52x10 510 52 3 4 56 81020Prospective Isc (kA)For GV7 RS onlySum of I 2 dt (A 2 s)1 GV7 RS2202 GV7 RS150 and GV7 RS1003x10 6 12x10 610 65x10 523x10 52x10 510 52 3 4 56 1020Prospective Isc (kA)References:page 3/49Dimensions:pages 3/73 to 3/75Schemes:page 3/773/35

Curves<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 L and GV2 LETripping curves for GV2 L or LE combined with thermal overload relay LRD or LR2 KAverage operating times at 20 °C related to multiples of the setting currentTime (s)10 000100010010123310,10,010,001 1 10 100x the setting current (Ir)1 3 poles from cold state2 2 poles from cold state3 3 poles from hot stateReferences:pages 3/52 and 3/53Dimensions:page 3/84Schemes:page 3/853/37

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 L and GV2 LECurrent limitation on short-<strong>circuit</strong> for GV2 L and GV2 LE only (3-phase 400/415 V)Dynamic stressI peak = f (prospective Isc) at 1.05 Ue = 435 VLimited peak current (kA)100= 0.251= 0.32310= 0.7= 0.534561= 0.8= 0.9 cos = 0.95789100,1 0,1 1 101510011Prospective Isc (kA)1 Maximum peak current2 32 A3 25 A4 18 A5 14 A6 10 A7 6.3 A8 4 A9 2.5 A101.6 A11 Limit of rated ultimate breaking capacity on short-<strong>circuit</strong> of GV2 LE (14, 18, 23 and 25 A ratings).References:pages 3/52 and 3/533/38Dimensions:page 3/84Schemes:page 3/85

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 L and GV2 LECurrent limitation on short-<strong>circuit</strong> for GV2 L and GV2 LE + thermal overload relay LRD or LR2 K (3-phase 400/415 V)Dynamic stressI peak = f (prospective Isc) at 1.05 Ue = 435 VLimited peak current (kA)1001= 0.2510= 0.8 = 0.7= 0.5= 0.323456371= 0.9cos = 0.9589100,1 0,1 1 10 1510011Prospective Isc (kA)1 Maximum peak current2 32 A3 25 A4 18 A5 14 A6 10 A7 6.3 A8 4 A9 2.5 A101.6 A11 Limit of rated ultimate breaking capacity on short-<strong>circuit</strong> of GV2 LE (14, 18, 23 and 25 A ratings).References:page 3/52Dimensions:page 3/84Schemes:page 3/853/39

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 LEThermal limit on short-<strong>circuit</strong> for GV2 LE onlyThermal limit in kA 2 s in the magnetic operating zoneSum of I 2 dt = f (prospective Isc) at 1.05 Ue = 435 VSum of I 2 dt (kA 2 s)1001 2310345678190,10,01 0,1 1 10 100Prospective Isc (kA)1 32 A2 25 A3 18 A4 14 A5 10 A6 6.3 A7 4 A8 2.5 A9 1.6 AReferences:page 3/523/40Dimensions:page 3/84Schemes:page 3/85

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 LThermal limit on short-<strong>circuit</strong> for GV2 L onlyThermal limit in kA 2 s in the magnetic operating zoneSum of I 2 dt = f (prospective Isc) at 1.05 Ue = 435 VSum of I 2 dt (kA 2 s)1001234105673810,10,01 0,1 1 10 100Prospective Isc (kA)1 25 A and 32 A2 18 A3 14 A4 10 A5 6.3 A6 4 A7 2.5 A8 1.6 AReferences:pages 3/52 and 3/53Dimensions:page 3/84Schemes:page 3/853/41

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 L and GV2 LEThermal limit on short-<strong>circuit</strong> for GV2 L and GV2 LE + thermal overload relay LRD or LR2 KThermal limit in kA 2 s in the magnetic operating zoneSum of I 2 dt = f (prospective Isc) at 1.05 Ue = 435 VSum of I 2 dt (kA 2 s)10012345310678190,1100,01 0,1 1 10 15100Prospective Isc (kA)1 32 A (GV2 LE32)2 25 A and 32 A (GV2 L32)3 18 A4 14 A5 10 A6 6.3 A7 4 A8 2.5 A9 1.6 A10Limit of rated ultimate breaking capacity on short-<strong>circuit</strong> of GV2 LE (14, 18, 23 and 25 A ratings).References:pages 3/52 and 3/533/42Dimensions:pages 3/84Schemes:page 3/85

Curves<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV3 L and GK3 EF80Tripping curves for GV3 L and GK3 EF80 combined with thermal overload relay LRD 33Time (s)10 000100010010123A310,1B0,010,001 1 10 100x the setting current (Ir)1 3 poles from cold state2 2 poles from cold state3 3 poles from hot stateA Thermal overload relay <strong>protection</strong> zoneB GK3 EF80 and GV3 L <strong>protection</strong> zoneReferences:page 3/53Dimensions:page 3/84Schemes:page 3/853/43

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV3 L and GK3 EF80Current limitation on short-<strong>circuit</strong> for GV3 L and GK3 EF80 (3-phase 400/415 V)Dynamic stressI peak = f (prospective Isc) at 1.05 Ue = 435 VLimited peak current (kA)5013345671021 1 10 1001 Maximum peak current2 GK3 EF803 GV3 L654 GV3 L505 GV3 L406 GV3 L327 GV3 L25Prospective Isc (kA)References:page 3/533/44Dimensions:page 3/84Schemes:page 3/85

Curves (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV3 L and GK3 EF80Thermal limit on short-<strong>circuit</strong> for GV3 L and GK3 EF80Thermal limit in A 2 sSum of I 2 dt = f (prospective Isc) at 1.05 Ue = 435 VSum of I2dt (A 2 s)100012345 631001011 10 1001 GK3 EF802 GV3 L653 GV3 L504 GV3 L405 GV3 L326 GV3 L25Prospective Isc (kA)References:page 3/53Dimensions:page 3/84Schemes:page 3/853/45

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 ME526134GV2 ME10Motor <strong>circuit</strong>-breakers from 0.06 to 15 kW / 400 V, with screw clamp terminalsGV2 ME with pushbutton controlStandard power ratings of 3-phase <strong>motor</strong>s50/60 Hz in category AC-3400/415 V 500 V 690 VP Icu Ics P Icu Ics (1) P Icu Ics (1)(1)Settingrangeof thermaltrips(2)MagnetictrippingcurrentId ± 20 %ReferenceWeightkW kA % kW kA % kW kA % A A kg– – – – – – – – – 0.1…0.16 1.5 GV2 ME01 0.2600.06 g g – – – – – – 0.16…0.25 2.4 GV2 ME02 0.2600.09 g g – – – – – – 0.25…0.40 5 GV2 ME03 0.26030.120.18gggg––––––0.37–g–g–0.40…0.63 8 GV2 ME04 0.2600.25 g g – – – 0.55 g g 0.63…1 13 GV2 ME05 0.2600.370.55–gg–gg–0.370.550.75gggggg–0.751.1–gg–gg1…16 22.5 GV2 ME06 0.2600.75 g g 1.1 g g 1.5 3 75 1.6…2.5 33.5 GV2 ME07 0.2601.11.5gggg1.52.2gggg2.233375752.5…4 51 GV2 ME08 0.2602.2 g g 3 50 100 4 3 75 4…6.3 78 GV2 ME10 0.26034gggg45.510101001005.57.53375756…10 138 GV2 ME14 0.2605.5–15–50–7.5–6–75–9113375759…14 170 GV2 ME16 0.2607.5 15 50 9 6 75 15 3 75 13…18 223 GV2 ME20 0.2609 15 40 11 4 75 18.5 3 75 17…23 327 GV2 ME21 0.26011 15 40 15 4 75 – – – 20…25 327 GV2 ME22 (3) 0.26015 10 50 18.5 4 75 22 3 75 24…32 416 GV2 ME32 0.260Motor <strong>circuit</strong>-breakers from 0.06 to 15 kW / 400 V, with lugsTo order thermal magnetic <strong>circuit</strong>-breakers with connection by lugs, add the digit 6 to the end of reference selectedabove.Example: GV2 ME08 becomes GV2 ME086.Thermal magnetic <strong>circuit</strong>-breakers GV2 ME with built-in auxiliary contact blockWith instantaneous auxiliary contact block (composition, see page 3/55):b AE1TQ to the <strong>motor</strong> <strong>circuit</strong>-breaker reference selected above.Example: GV2 ME01AE1TQ.b AE11TQ to the <strong>motor</strong> <strong>circuit</strong>-breaker reference selected above.Example: GV2 ME01AE11TQ.b AN11TQ to the <strong>motor</strong> <strong>circuit</strong>-breaker reference selected above.Example: GV2 ME01AN11TQ.These <strong>circuit</strong>-breakers with built-in contact block are sold in lots of 20 units in a single pack.(1) As % of Icu.(2) The thermal trip setting must be within the range marked on the graduated knob.(3) Maximum rating which can be mounted in enclosures GV2 MC or MPg > 100 kA.Characteristics:pages 3/8 to 3/123/46Dimensions:pages 3/70 to 3/72Schemes:page 3/76

References (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 ME526135Motor <strong>circuit</strong>-breakers from 0.06 to 11 kW, with spring terminal connectionsGV2 ME (1) with pushbutton controlStandard power ratings of 3-phase <strong>motor</strong>s50/60 Hz in category AC-3400/415 V 500 VP Icu Ics (2) P Icu Ics (2)Settingrangeof thermaltrips(3)MagnetictrippingcurrentId ± 20 %ReferenceWeightkW kA % kW kA % A A kg– – – – – – 0.1…0.16 1.5 GV2 ME013 0.280GV2 MEpp30.06 g g – – – 0.16…0.25 2.4 GV2 ME023 0.2800.09 g g – – – 0.25…0.40 5 GV2 ME033 0.2800.120.180.250.370.370.55gggggggggggg– – – 0.40…0.63 8 GV2 ME043 0.2800.37 g g 0.63…1 13 GV2 ME053 0.2800.370.550.75gggggg1…1.6 22.5 GV2 ME063 0.2800.75 g g 1.1 g g 1.6…2.5 33.5 GV2 ME073 0.28031.11.5gggg1.52.2gggg2.5…4 51 GV2 ME083 0.2802.2 g g 3 50 100 4…6.3 78 GV2 ME103 0.28034gggg45.510101001006…10 138 GV2 ME143 0.2805.5 15 50 7.5 6 75 9…14 170 GV2 ME163 0.2807.5 15 50 9 6 75 13…18 223 GV2 ME203 0.2809111515404011 4 75 17…23 327 GV2 ME213 0.26011 15 40 15 4 75 20…25 327 GV2 ME223 0.260Contact blocksDescription Mounting MaximumnumberInstantaneousauxiliary contactsType ofcontactsSold inlots ofUnitreferenceWeightkgFront 1 N/O + N/C 10 GV AE113 0.030N/O + N/O 10 GV AE203 0.030LH side 2 N/O + N/C 1 GV AN113 0.060N/O + N/O 1 GV AN203 0.060LA9 D99AccessoryDescription Application Sold inlots ofUnitreferenceWeightkgCable end reducer For connection of conductors from 1 to 1.5 mm 2 20 LA9 D99 –(1) For connection of conductors from 1 to 1.5 mm 2 , the use of an LA9 D99 cable end reducer is recommended.(2) Maximum rating which can be mounted in enclosures GV2 MC or MP(3) The thermal trip setting must be within the range marked on the graduated knob.g > 100 kA.Characteristics:pages 3/8 to 3/12Dimensions:pages 3/70 to 3/72Schemes:page 3/763/47

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 P, GV3 P and GV3 ME803526137GV2 P10526140526139GV3 P65GV3 P651Motor <strong>circuit</strong>-breakers from 0.06 to 30 kW / 400 VStandard power ratings of 3-phase <strong>motor</strong>s50/60 Hz in category AC-3400/415 V 500 V 690 VP Icu Ics(1)P Icu Ics(1)P Icu Ics(1)Settingrangeof thermaltrips(2)MagnetictrippingcurrentId ± 20 %ReferenceWeightkW kA % kW kA % kW kA % A A kgGV2 P: control by rotary knobScrew clamp terminals– – – – – – – – – 0.1…0.16 1.5 GV2 P01 0.3500.06 g g – – – – – – 0.16…0.25 2.4 GV2 P02 0.3500.09 g g – – – – – – 0.25…0.40 5 GV2 P03 0.3500.120.18gggg––––––0.37–g–g–0.40…0.63 8 GV2 P04 0.3500.25 g g – – – 0.55 g g 0.63…1 13 GV2 P05 0.3500.37 g g 0.37 g g – – – 1…1.6 22.5 GV2 P06 0.3500.55 g g 0.55 g g 0.75 g g0.75 g g 1.1 g g 1.5 8 100 1.6…2.5 33.5 GV2 P07 0.3501.1 g g 1.5 g g 2.2 8 100 2.5…4 51 GV2 P08 0.3502.2 g g 3 g g 4 6 100 4…6.3 78 GV2 P10 0.3503 g g 5 50 100 5.5 6 100 6…10 138 GV2 P14 0.3505.5–g–g–7.5–42–75–911661001009…14 170 GV2 P16 0.3507.5 50 50 9 10 75 15 4 100 13…18 223 GV2 P20 0.3509 50 50 11 10 75 18.5 4 100 17…23 327 GV2 P21 0.35011 50 50 15 10 75 – – – 20…25 327 GV2 P22 0.35015 35 50 18.5 10 75 22 4 100 24…32 416 GV2 P32 0.350GV3 P: control by rotary knobConnection by EverLink® BTR screw connectors (3)5.5 100 100 7.5 12 50 11 6 50 9…13 182 GV3 P13 0.9607.5 100 100 9 12 50 15 6 50 12…18 252 GV3 P18 0.96011 100 100 15 12 50 18.5 6 50 17…25 350 GV3 P25 0.96015 100 100 18.5 12 50 22 6 50 23…32 448 GV3 P32 0.96018.5 50 100 22 12 50 37 6 50 30…40 560 GV3 P40 0.96022 50 100 30 12 50 45 6 50 37…50 700 GV3 P50 0.96030 50 100 45 12 50 55 6 50 48…65 910 GV3 P65 0.960Connection by EverLink® BTR screw connectors, for assembly with a contactorTo assemble a GV3 P13 to P65 <strong>circuit</strong>-breaker with an LC1 D40A to D65A contactor, it is possible to use the<strong>circuit</strong>-breaker supplied without downstream EverLink® power terminal block. To order this product, add thedigit 1 to the end of the references selected above. Example: GV3 P65 becomes GV3 P651.Connection by lugsTo order thermal magnetic <strong>circuit</strong>-breakers with connection by lugs, add the digit 6 to the end of reference selectedabove. Example: GV3 P18 becomes GV3 P186.GV3 ME80: pushbutton control, screw clamp terminals37 15 50 45 4 100 55 2 100 56…80 GV3 ME80 (4) 0.700Motor <strong>circuit</strong>-breakers up to 50 hp / 600 V, UL 508 type EGV2 (5)To obtain a GV2 P <strong>motor</strong> <strong>circuit</strong>-breaker, UL 508 type E, combine:b a <strong>circuit</strong>-breaker GV2 Ppp (except 32 A),b and a “Large Spacing” adapter GV2 GH7.GV3 (6)To obtain a <strong>motor</strong>-<strong>circuit</strong>-breaker GV3 P, UL 508 type E, use the following with the <strong>circuit</strong>-breaker:b a “Large Spacing” cover GV3 G66,b a short-<strong>circuit</strong> signalling contact GV AM11.GV3 with connection by lugs (6)To obtain a <strong>motor</strong>-<strong>circuit</strong>-breaker GV3 P, UL 508 type E, with connection by lugs, add the digit 6 to the end ofreference selected above and use the following with the <strong>circuit</strong>-breaker:b two IP 20 covers LAD 96570,b a short-<strong>circuit</strong> signalling contact GV AM11.(1) As % of Icu.(2) The thermal trip setting must be within the range marked on the graduated knob.(3) BTR screws: hexagon socket head. Require use of an insulated Allen key, in compliance with local wiring regulations.(4) Recommended for use in association with a contactor.(5) Accessory: see page 3/67.(6) Accessories: see page 3/57.g > 100 kA.Characteristics:pages 3/8 to 3/133/48Dimensions:pages 3/70 to 3/73

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV7 R526138Thermal-magnetic <strong>circuit</strong>-breakers GV7 R with screw clamp terminalsControl by rocker leverStandard power ratings of 3-phase <strong>motor</strong>s50/60 Hz in category AC-3400/415 V 500 V 660/690 VP Icu Ics (1) P Icu Ics (1) P Icu Ics (1)Settingrangeof thermaltripsReferenceWeightkW kA % kW kA % kW kA % A kg7.5 36 100 9 18 100 11 8 100 12…20 GV7 RE20 2.0109 36 100 11 18 100 15 8 100GV7 RE407.59707010010091150501001001115101010010012…20 GV7 RS20 2.0109113636100100111518181001001518.58810010015…25 GV7 RE25 2.0105261419117070100100111518.5 36 100 18.522505018181001001001001518.5101010010015…25 GV7 RS25 2.01022 8 100 25…40 GV7 RE40 2.010318.5 70 100 18.5 50 100 22 10 100 25…40 GV7 RS40 2.01022 36 100 30 18 100 30 8 100 30…50 GV7 RE50 2.015GV7 RS22022 70 100 30 50 100 30 10 100 30…50 GV7 RS50 2.01537 36 100 4555181810010055 8 100 48…80 GV7 RE80 2.04037 70 100 4555505010010055 10 100 48…80 GV7 RS80 2.04045 36 100 – 18 100 75 8 100 60…100 GV7 RE100 2.04045 70 100 – 50 100 75 10 100 60…100 GV7 RS100 2.0405575353510010075903030100100901108810010090…150 GV7 RE150 2.020557570701001007590505010010090110101010010090…150 GV7 RS150 2.020901109011035357070100100100100110132160110132160303030505050100100100100100100160200160200881010100100100100132…220 GV7 RE220 2.350132…220 GV7 RS220 2.350(1) As % of lcuCharacteristics:page 3/13Dimensions:page 3/73Schemes:page 3/773/49

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>circuit</strong>-breakersGV2 RT526142For <strong>motor</strong>s with high current peak on startingControl by rocker leverStandard power ratings of 3-phase <strong>motor</strong>s50/60 Hz in category AC-3220/230 V400/415 V440 V 500 V 690 VSettingrangeof thermal trips(1)MagnetictrippingcurrentId ± 20 %ReferenceWeightkW kW kW kW kW A A kg0.06 0.09 0.09 – – 0.25…0.40 8 GV2 RT03 0.3500.12GV2 RT– 0.120.180.18 – 0.37 0.40…0.63 13 GV2 RT04 0.3500.090.120.250.370.250.370.37 0.55 0.63…1 22 GV2 RT05 0.35030.180.250.370.550.370.550.37 0.75 0.751.10.370.550.750.751.11…1.6 33 GV2 RT06 0.3501.1 1.5 1.6…2.5 51 GV2 RT07 0.3500.550.751.11.51.5 1.52.22.232.5…4 78 GV2 RT08 0.3501.1 2.2 2.233 4 4…6.3 138 GV2 RT10 0.3501.52.2344 45.55.57.56…10 200 GV2 RT14 0.3502.235.5 5.57.57.5 9119…14 280 GV2 RT16 0.3504 7.5 7.599 15 13…18 400 GV2 RT20 0.3505.5 91111 11 18.5 17…23 400 GV2 RT21 0.350(1) The thermal trip setting must be within the range marked on the graduated knob.Characteristics:pages 3/8 to 3/233/50Dimensions:page 3/72Schemes:page 3/76

References (continued)<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>circuit</strong>-breakersGV2 RT526142For primaries of 3-phase transformersControl by rocker leverStandard power ratingsSettingrange ofthermal trips (1)Magnetictripping currentId ± 20 %ReferenceWeight230/240 V 400/415 V 440 V 500 V 690 VkW kW kW kW kW A A kg– – – – – 0.25…0.40 8 GV2 RT03 0.350GV2 RT– – – – – 0.40…0.63 13 GV2 RT04 0.350– – 0.63 0.63 1 0.63…1 22 GV2 RT05 0.3500.4 0.63 1 1 – 1…1.6 33 GV2 RT06 0.3500.63 1 – 1.6 1.621.6…2.5 51 GV2 RT07 0.35031 1.621.6222.52.5 2.5…4 78 GV2 RT08 0.3501.622.5 452.5 2.545 56.34 456.34…6.3 138 GV2 RT10 0.350– 6…10 200 GV2 RT14 0.3504 6.3 6.3 – 1012.59…14 280 GV2 RT16 0.35056.310 10 1012.510 13…18 400 GV2 RT20 0.350Accessory (2)Description Reference WeightkgPadlockable external operator (IP 54)black handle, blue legend plateGV2 AP03 0.280(1) The thermal trip setting must be within the range marked on the graduated knob.(2) Other accessories such as mounting, cabling and marking accessories are identical to those used for GV2 ME <strong>motor</strong><strong>circuit</strong>-breakers, see page 3/57.Characteristics:pages 3/8 to 3/23Dimensions:page 3/72Schemes:page 3/763/51

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 LE526144Magnetic <strong>motor</strong> <strong>circuit</strong>-breakers from 0.06 to 15 kWGV2 L: control by rocker lever, connection by screw clamp terminalsStandard power ratings of 3-phase <strong>motor</strong>s50/60 Hz in category AC-3400/415 V 500 V 690 VP Icu Ics (1) P Icu Ics (1) P Icu Ics (1)Magnetic<strong>protection</strong>ratingTrippingcurrentId ± 20 %Use in ReferenceassociationwiththermaloverloadrelayWeightkW kA kW kA kW kA A A kg0.06 g g – – – – – – 0.4 5 LR2 K0302 GV2 LE03 0.3300.09 g g – – – – – – 0.4 5 LR2 K0304 GV2 LE03 0.330GV2 LE100.12 g g – – – 0.37 g g 0.63 8 LR2 K0304 GV2 LE04 0.33030.18 g g – – – – – – 0.63 8 LR2 K0305 GV2 LE04 0.330– – – – – – 0.55 g g 1 13 LR2 K0305 GV2 LE05 0.3300.25 g g – – – – – – 1 13 LR2 K0306 GV2 LE05 0.330– – – – – – 0.75 g g 1 13 LR2 K0306 GV2 LE05 0.3300.37 g g 0.37 g g – – – 1 13 LR2 K0306 GV2 LE05 0.3300.55 g g 0.55 g g 1.1 g g 1.6 22.5 LR2 K0307 GV2 LE06 0.330– – – 0.75 g g – – – 1.6 22.5 LR2 K0307 GV2 LE06 0.3300.75 g g 1.1 g g 1.5 3 75 2.5 33.5 LR2 K0308 GV2 LE07 0.3301.1 g g – – – – – – 2.5 33.5 LR2 K0308 GV2 LE07 0.3301.5 g g 1.5 g g 3 3 75 4 51 LR2 K0310 GV2 LE08 0.330– – – 2.2 g g – – – 4 51 LR2 K0312 GV2 LE08 0.3302.2 g g 3 50 100 4 3 75 6.3 78 LR2 K0312 GV2 LE10 0.3303 g g 4 10 100 5.5 3 75 10 138 LR2 K0314 GV2 LE14 0.3304 g g 5.5 10 100 – – – 10 138 LR2 K0316 GV2 LE14 0.330– – – – – – 7.5 3 75 10 138 LRD 14 GV2 LE14 0.330– – – – – – 9 3 75 14 170 LRD 16 GV2 LE16 0.3305.5 15 50 7.5 6 75 11 3 75 14 170 LR2 K0321 GV2 LE16 0.3307.5 15 50 9 6 75 15 3 75 18 223 LRD 21 GV2 LE20 0.3309 15 40 11 4 75 18.5 3 75 25 327 LRD 22 GV2 LE22 0.33011 15 40 15 4 75 – – – 25 327 LRD 22 GV2 LE22 0.33015 10 50 18.5 4 75 22 3 75 32 416 LRD 32 GV2 LE32 0.330(1) As % of Icu.g > 100 kA.Characteristics:pages 3/14 and 3/153/52Dimensions:page 3/84Schemes:page 3/85

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV2 L, GV3 L and GK3 EF80526146526145GV2 L10Motor <strong>circuit</strong>-breakers from 0.09 to 30 kWGV2 L: Control by rotary knob, connection by screw clamp terminalsStandard power ratings of 3-phase <strong>motor</strong>s50/60 Hz in category AC-3400/415 V 500 V 690 VP Icu Ics (1) P Icu Ics (1) P Icu Ics (1)Magnetic<strong>protection</strong>ratingTrippingcurrentId ± 20 %Use in Referenceassociationwiththermaloverloadrelay(class 10 A)WeightkW kA kW kA kW kA A A kg0.09 g g – – – – – – 0.4 5 LRD 03 GV2 L03 0.3300.12 g g – – – 0.37 g g 0.63 8 LRD 04 GV2 L04 0.3300.18 g g – – – – – – 0.63 8 LRD 04 GV2 L04 0.330– – – – – – 0.55 g g 1 13 LRD 05 GV2 L05 0.3300.25 g g – – – – – – 1 13 LRD 05 GV2 L05 0.330– – – – – – 0.75 g g 1 13 LRD 06 GV2 L05 0.3300.37 g g 0.37 g g – – – 1 13 LRD 05 GV2 L05 0.3300.55 g g 0.55 g g 1.1 g g 1.6 22.5 LRD 06 GV2 L06 0.330– – – 0.75 g g – – – 1.6 22.5 LRD 06 GV2 L06 0.3300.75 g g 1.1 g g 1.5 4 100 2.5 33.5 LRD 07 GV2 L07 0.3301.1 – – – – – – – – LRD 08 GV2 L08 0.3301.5 g g 1.5 g g 3 4 100 4 51 LRD 08 GV2 L08 0.330– – – – – – – – – LRD 08 GV2 L08 0.3302.2 g g 3 g g 4 4 100 6.3 78 LRD 10 GV2 L10 0.3303 g g 4 10 100 5.5 4 100 10 138 LRD 12 GV2 L14 0.3304 – – – – – – – – LRD 14 GV2 L14 0.330– – – – – – 7.5 4 100 10 138 LRD 14 GV2 L14 0.330– – – – – – 9 4 100 14 170 LRD 16 GV2 L16 0.3305.5 50 50 7.5 10 75 11 4 100 14 170 LRD 16 GV2 L16 0.3307.5 50 50 9 10 75 15 4 100 18 223 LRD 21 GV2 L20 0.3309 50 50 11 10 75 18.5 4 100 25 327 LRD 22 GV2 L22 0.33011 50 50 15 10 75 – – – 25 327 LRD 22 GV2 L22 0.33015 35 50 18.5 10 75 22 4 100 32 416 LRD 32 GV2 L32 0.3303GV3 L65GV3 L: control by rotary knob, connection by EverLink® BTR screw connectorsStandard power ratings of 3-phase <strong>motor</strong>s50/60 Hz in category AC-3400/415 V 500 V 690 VP Icu Ics (1) P Icu Ics (1) P Icu Ics (1)Magnetic<strong>protection</strong>ratingTrippingcurrentId ± 20 %Use in Referenceassociationwith thermaloverloadrelay(class 10 A)WeightkW kA kW kA kW kA A A kg11 100 100 15 12 50 18.5 6 50 25 350 LRD 325 GV3 L25 0.96015 100 100 18.5 12 50 22 6 50 32 448 LRD 332 GV3 L32 0.96018.5 50 100 22 12 50 37 6 50 40 560 LRD 340 GV3 L40 0.96022 50 100 30 12 50 45 6 50 50 700 LRD 350 GV3 L50 0.96030 50 100 37 12 50 55 6 50 65 910 LRD 365 GV3 L65 0.960526147Connection by EverLink® BTR screw connectors, for assembly with a contactorTo assemble a GV3 L25 to L65 <strong>circuit</strong>-breaker with an LC1 D40A to D65A contactor, it is possible to use the<strong>circuit</strong>-breaker supplied without downstream EverLink® power terminal block. To order this product, add thedigit 1 to the end of the references selected above. Example: GV3 L65 becomes GV3 L651.Connection by lugsTo order these <strong>circuit</strong>-breakers with connection by lugs, add the digit 6 to the end of reference selected above.Example: GV3 L32 becomes GV3 L326.GK3 EF80GK3: control by rotary knob, connection by screw clamp terminals37 35 25 55 15 30 – – – 80 1040 LRD 3363 GK3 EF80 0.795(1) As % of Icu. Associated current limiter or fuses, where required. See characteristics page 3/17.g > 100 kA.Characteristics:pages 3/14 and 3/15Dimensions:pages 3/84 to 3/85Schemes:page 3/853/53

GV2 AK00GV1 L33GV AXGV2 MEGV ADGV AM11GV AUGV2 PGV AM11GV ASGV2 LGV AE11, GV AE20GV ANGV ANGV AE1GV2 LEGV AE13/54

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic and magnetic <strong>motor</strong> <strong>circuit</strong>breakersGV2 with screw clamp connectionsAdd-on blocks and accessoriesContact blocksDescription Mounting MaximumnumberInstantaneousauxiliary contactsFault signalling contact +instantaneousauxiliary contactShort-<strong>circuit</strong>signalling contactType ofcontactsSold inlots ofUnitreferenceWeightkgFront (1) 1 N/O or N/C (2) 10 GV AE1 0.015N/O + N/C 10 GV AE11 0.020N/O + N/O 10 GV AE20 0.020Side(LH)Side (3)(LH)Side(LH)2 N/O + N/C 1 GV AN11 0.050N/O + N/O 1 GV AN20 0.0501 N/O (fault) + N/O 1 GV AD1010 0.055+ N/C 1 GV AD1001 0.055N/C (fault) + N/O 1 GV AD0110 0.055+ N/C 1 GV AD0101 0.0551 C/O common point 1 GV AM11 0.045Electric tripsMounting Voltage Reference WeightkgUndervoltage or shunt trips (4)Side(1 block on RH sideof <strong>circuit</strong>-breaker)24 V 50 Hz GV Ap025 0.10560 Hz GV Ap026 0.10548 V 50 Hz GV Ap055 0.10560 Hz GV Ap056 0.105100 V 50 Hz GV Ap107 0.105100…110 V 60 Hz GV Ap107 0.105110…115 V 50 Hz GV Ap115 0.10560 Hz GV Ap116 0.105120…127 V 50 Hz GV Ap125 0.105127 V 60 Hz GV Ap115 0.105200 V 50 Hz GV Ap207 0.105200…220 V 60 Hz GV Ap207 0.105220…240 V 50 Hz GV Ap225 0.10560 Hz GV Ap226 0.105380…400 V 50 Hz GV Ap385 0.10560 Hz GV Ap386 0.105415…440 V 50 Hz GV Ap415 0.105415 V 60 Hz GV Ap416 0.105440 V 60 Hz GV Ap385 0.105480 V 60 Hz GV Ap415 0.105500 V 50 Hz GV Ap505 0.105600 V 60 Hz GV Ap505 0.1053Undervoltage trip, INRS (can only be mounted on GV2 ME)Safety device for dangerous machines conforming to INRS and VDE 0113Side(1 block on RH sideof <strong>circuit</strong>-breaker GV2 ME)110…115 V 50 Hz GV AX115 0.11060 Hz GV AX116 0.110127 V 60 Hz GV AX115 0.110220…240 V 50 Hz GV AX225 0.11060 Hz GV AX226 0.110380…400 V 50 Hz GV AX385 0.11060 Hz GV AX386 0.110415…440 V 50 Hz GV AX415 0.110440 V 60 Hz GV AX385 0.110Add-on contact blocksDescription Mounting MaximumnumberReferenceWeightkgVisible isolation block (5) Front (1) 1 GV2 AK00 0.150LimitersAt top1 GV1 L3 0.130(GV2 ME and GV2 P)Independent 1 LA9 LB920 0.320LA9 LB920(1) Mounting of a GV AE contact block or a GV2 AK00 visible isolation block on GV2 P and GV2 L.(2) Choice of N/C or N/O contact operation, depending on which way round the reversible block is mounted.(3) The GV AD is always mounted next to the <strong>circuit</strong>-breaker.(4) To order an undervoltage trip: replace the dot (p) in the reference with a U, example: GV AU025.To order a shunt trip: replace the dot (p) in the reference with an S, example: GV AS025.(5) Visible isolation of the 3 poles upstream of <strong>circuit</strong>-breaker GV2 P and GV2 L.Visible isolation block GV2 AK00 cannot be used with <strong>motor</strong> <strong>circuit</strong>-breakers GV2 P32 and GV2 L32 (Ith max = 25 A).Characteristics:pages 3/18 to 3/23Dimensions and schemes:pages 3/70 to 3/893/55

33/56

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic and magnetic <strong>motor</strong> <strong>circuit</strong>breakersGV2 with screw clamp connectionsAccessoriesAccessoriesDescription Application Sold inlots ofAdapter platesFor mounting a GV2 MEFor mounting a GV2 ME or GV2 Pand contactor LC1 D09…D38with front faces alignedUnitreferenceWeightkg10 GV2 AF02 0.0211 LAD 311 0.040Height compensation plate 7,5 mm 10 GV1 F03 0.003Combination blocks Between GV2 and contactor LC1 K or LP1 K 10 GV2 AF01 0.020Motor starter adapter plateBetween GV2 and contactor LC1 D09…D38 10 GV2 AF3 0.016Between GV2 mounted on LAD 311and contactor LC1 D09…D38With 3-pole connection for mounting a GV2and a contactor LC1 D09…D2510 GV2 AF4 0.0161 GK2 AF01 0.120Description Application Pitch Reference WeightSets of 3-pole63 A busbars2 tap-offs 45 GV2 G245 0.036mmkg54 GV2 G254 0.03872 GV2 G272 0.0423 tap-offs 45 GV2 G345 0.05854 GV2 G354 0.0604 tap-offs 45 GV2 G445 0.07754 GV2 G454 0.08572 GV2 G472 0.0945 tap-offs 54 GV2 G554 0.1003Description Application Sold inlots ofUnitreferenceWeightkgProtective end cover For unused busbar outlets 5 GV1 G10 0.005Terminal blockfor supply to one or moreGV2 G busbar setsConnection from the top 1 GV1 G09 0.040(GV2 ME and GV2 P)1 GV2 G05 0.115Cover for terminal block For mounting in modular panels 10 LA9 E07 0.005Flexible 3-pole connectionfor connecting a GV2 to acontactor LC1-D09…D25Set of connectionsupstream/downstream“Large Spacing” adapterUL 508 type EClip-in marker holders(supplied with each<strong>circuit</strong>-breaker)Centre distance between mounting rails:100…120 mm10 GV1 G02 0.013For connecting GV2 ME to a printed <strong>circuit</strong> board 10 GV2 GA01 0.045For GV2 PppH7 (except 32 A) 1 GV2 GH7 0.040For GV2 P, GV2 L, GV2 LE and GV2 RT(8 x 22 mm)100 LA9 D92 0.0013/57

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic and magnetic <strong>motor</strong> <strong>circuit</strong>breakersGV2 with screw clamp connections1Extended Rotary HandleAllows a <strong>circuit</strong>-breaker or a starter-controller installed in back of an enclosureto be operated from the front of the enclosure.A rotary handle can be black or red/yellow, IP54 or IP65. It includes a functionfor locking the <strong>circuit</strong> breaker or the starter in the O (Off) or I (On) position(depending of the type of rotary handle) by means of up to 3 padlocks with a shankdiameter of 4 to 8 mm. The extended shaft must be adjusted to use in different sizethe assembling. The new Laser Square tool brings the accuracy to align the <strong>circuit</strong>breaker and the rotary handle.34Padlockable external operators for GV2P and GV2LDescription1 Kit handle + mounting system2 Universal handle3 Shaft4 Bracket5 Shaft support plate for deep enclosure6 7 Laser Square accessory32Kit handle + mounting systemDescription Item Reference WeightkgFor GV2 P/L Black handle, front plate, with trip status, IP 54 1 GV2 APN01 0.300Red handle, front plate, with trip status, IP 54 1 GV2 APN02 0.300Red handle, front plate, without trip status, IP 65 1 GV2 APN04 0.300675For GV2 LEUniversal handlePadlocking in “On” and “Off” positionBlack handle, blue front plate, IP 54- GV2 AP03 0.280For GV2 P/L Black handle, IP 54 2 GV APB54 0.140ShaftRed handle, IP 54 2 GV APR54 0.140Red handle, IP 65 2 GV APR65 0.140For GV2 P/L L = 315 mm 3 GV APA1 0.110BracketFor GV2 P/L 4 GV APH02 0.300Shaft support plate for deep enclosureFor GV2 P/L Depthu 250 mm 5 GV APK11 0.030For GV2 P/L 6 GV APP1 0.100Laser Square accessoryFor GV2 P/L 7 GV APL01 0.160StickerSold in lots ofWarning label For French 10 - GV APSFRFor English 10 - GV APSENFor German 10 - GV APSDEFor Spanish 10 - GV APSESFor Chinese 10 - GV APSCNFor Portuguese 10 - GV APSPTFor Russian 10 - GV APSRUFor Italian 10 - GV APSITPadlocking deviceDescription Reference WeightkgFor all GV2device(padlocks not included)GV2 V03 0.0923/58

3/593

GV3 G264GV3 G3643GVAM11GV3 PGVAM11GV AE113, GV AE203, GV AED 1013,GV AED 0113GV3 LGV AE11, GV AE20,GV AED 101, GV AED 011GV AE1GV AE1GV3 APN02GV2 V033/60

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV3 P and GV3 LAdd-on blocks and accessoriesGV3 G66LAD 96570LAD 96575LAD 7X3Contact blocksDescription Mounting Maximum Type ofnumber contactsInstantaneousauxiliary contactsFault signalling contact +instantaneousauxiliary contactSold inlots ofUnitreferenceWeightkgFront 1 N/O or N/C (1) 10 GV AE1 0.015N/O + N/C 10 GV AE11 (2) 0.020N/O + N/O 10 GV AE20 (2) 0.020Side(LH)2 N/O + N/C 1 GV AN11 (2) 0.050N/O + N/O 1 GV AN20 (2) 0.050Front 1 N/O (fault) + N/O 1 GV AED101 (2) 0.020N/O (fault) + N/C 1 GV AED011 (2) 0.020Side (3)(LH)1 N/O (fault) + N/O 1 GV AD1010 0.055+ N/C 1 GV AD1001 0.055N/C (fault) + N/O 1 GV AD0110 0.055+ N/C 1 GV AD0101 0.055Short-<strong>circuit</strong> signalling contact Side (LH) 1 C/O common point 1 GV AM11 0.045Electric trips - undervotlage or shunt (4)Mounting Voltage Reference WeightkgSide(1 block on RH sideof <strong>circuit</strong>-breaker)24 V 50 Hz GV Ap025 0.10560 Hz GV Ap026 0.10548 V 50 Hz GV Ap055 0.10560 Hz GV Ap056 0.105100 50 Hz GV Ap107 0.105100…110 V 60 Hz GV Ap107 0.105110…115 V 50 Hz GV Ap115 0.10560 Hz GV Ap116 0.105120…127 V 50 Hz GV Ap125 0.105127 V 60 Hz GV Ap115 0.105200 V 50 Hz GV Ap207 0.105200…220 V 60 Hz GV Ap207 0.105220…240 V 50 Hz GV Ap225 0.10560 Hz GV Ap226 0.105380…400 V 50 Hz GV Ap385 0.10560 Hz GV Ap386 0.105415…440 V 50 Hz GV Ap415 0.105415 V 60 Hz GV Ap416 0.105440 V 60 Hz GV Ap385 0.105480 V 60 Hz GV Ap415 0.105500 V 50 Hz GV Ap505 0.105600 V 60 Hz GV Ap505 0.105AccessoriesDescription Reference WeightkgSets of 3-pole2 tap-off GV3 Ppp and GV3 Lpp GV3 G264 0.150115 A busbarsPitch: 64 mm3 tap-off GV3 Ppp and GV3 Lpp GV3 G364 0.250Cover “Large Spacing” UL 508 type EGV3 Ppp GV3 G66 0.020(Only one cover required on supply side)IP 20 coverGV3 Ppp6 and GV3 Lpp6 LAD 96570 0.021(Two covers required per breaker)IP 20 coverGV3 Ppp6 and GV3 Lpp6 LAD 96575 0.010for use when mounted with <strong>circuit</strong>-breakersSize 4 Allen key, insulated, 1000 V GV3 Ppp and GV3 Lpp LAD ALLEN4 (5) 0.026Padlocking devicefor use with up to 4 padlocks (not supplied)Replacement of GV3 MEwith GV3 Ppp or GV2 PppGV3 Ppp and GV3 LppGV3 Ppp6 and GV3 Lpp6GV2 V03 0.092LAD 7X3 0.1503(1) Choice of N/C or N/O contact operation, depending on which way round the reversible block is mounted.3 at the end of the references selected above.Example: GV AED101 becomes GV AED1013.(3) The GV ADpp is always mounted next to the <strong>circuit</strong>-breaker.(4) To order an undervoltage trip: replace the dot (p) in the reference with a U, example: GV AU025.To order a shunt trip: replace the dot (p) in the reference with an S, example: GV AS025.(5) Sold in lots of 5.3/61

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakersGV3 P and GV3 LAdd-on blocks and accessories1Extended Rotary HandleAllows a <strong>circuit</strong>-breaker or a starter-controller installed in back of an enclosureto be operated from the front of the enclosure.A rotary handle can be black or red/yellow, IP54 or IP65. It includes a functionfor locking the <strong>circuit</strong> breaker or the starter in the O (Off) or I (On) position(depending of the type of rotary handle) by means of up to 3 padlocks with a shankdiameter of 4 to 8 mm. The extended shaft must be adjusted to use in different sizethe assembling. The new Laser Square tool brings the accurency to align the <strong>circuit</strong>breaker and the rotary handle.34Padlockable external operators for GV3 and GV3LDescription1 Kit handle + mounting system2 Universal handle3 Shaft4 Bracket5 Shaft support plate for deep enclosure6 7 Laser Square accessory67532Kit handle + mounting systemDescription Item Reference WeightkgFor GV3 P/L Black handle, front plate, with trip status, IP 54 1 GV3 APN01 0.300Red handle, front plate, with trip status, IP 54 1 GV3 APN02 0.300Red handle, front plate, without trip status, IP 65 1 GV3 APN04 0.300Universal handleFor GV3 P/L Black handle, IP 54 2 GV APB54 0.140ShaftRed handle, IP 54 2 GV APR54 0.140Red handle, IP 65 2 GV APR65 0.140For GV3 P/L L = 315 mm 3 GV APA1 0.110BracketFor GV3 P/L 4 GV APH03 0.300Shaft support plate for deep enclosureFor GV3 P/L Depthu300 mm 5 GV APK12 0.030For GV3 P/L 6 GV APP1 0.100Laser Square accessoryFor GV3 P/L 7 GV APL01 0.160StickerSold in lots ofWarning label For French 10 - GV APSFRFor English 10 - GV APSENFor German 10 - GV APSDEFor Spanish 10 - GV APSESFor Chinese 10 - GV APSCNFor Portuguese 10 - GV APSPTFor Russian 10 - GV APSRUFor Italian 10 - GV APSIT3/62

3/633

3GV3A01...A07GV3A08GV3A093/64

References<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong>Motor <strong>circuit</strong>-breakers GV3 ME80 andGK3 EF80Add-on blocks and accessoriesFor thermal-magnetic <strong>motor</strong> <strong>circuit</strong>-breakers GV3 ME80Contact blocksDescriptionType of standardearly break contactsInstantaneous auxiliarycontact blocks(1 per <strong>circuit</strong>-breaker)ReferenceWeightkgN/C + N/O GV3 A01 0,060N/O + N/O GV3 A02 0.060N/C + N/O + N/O GV3 A03 0.070N/O + N/O + N/O GV3 A05 0.070N/O + N/O + 2 volt-free terminals GV3 A06 0.070N/C + N/O + 2 volt-free terminals GV3 A07 0.070Fault signalling contacts (1) N/C GV3 A08 0.030N/O GV3 A09 0.030Electric tripsDescription Voltages Reference Weight50 Hz 60 Hz kgUdervoltage trips (1) 110, 120, 127 V 120, 127 V GV3 B11 0.070220, 240 V 277 V GV3 B22 0.070380, 415 V 440 V, 480 V GV3 B38 0.0703Shunt trips (1) 110, 120, 127 V 120, 127 V GV3 D11 0.070220, 240 V 277 V GV3 D22 0.070380, 415 V 440 V, 480 V GV3 D38 0.070AccessoryDescriptionPadlocking device,for locking the Start button (on open-mounted product)Sold inlots ofUnitreferenceWeightkg5 GV1 V02 0.010For magnetic <strong>circuit</strong>-breaker GK3 EF80Contact blocksDescription Number of poles Reference WeightkgAuxiliary contact blocks for On-Off signallingand “control <strong>circuit</strong> test” function(1 or 2 blocks per device)mounted on RH side of GK3 EF80Instantaneous fault signalling contact blocks(1 or 2 blocks per device)mounted on LH side of GK3 EF80N/O GK2 AX10 0.025N/O + N/O GK2 AX20 0.031N/C + N/O GK2 AX50 0.031N/O GK2 AX12 0.025N/O + N/O GK2 AX22 0.031N/C + N/O GK2 AX52 0.031AccessoriesDescription Reference WeightkgPadlocking device for padlocking the operator,using up to 3 padlocks(padlocks to be ordered separately)GK3 AV01 0.020External operator for mounting on enclosure door.Red Ø 40 knob on yellow plate, padlockable in position O(with up to 3 padlocks). Door locked when knob in position I,and when knob padlocked in position O.GK3 AP03 0.300(1) 1 voltage trip OROther versions24 to 690 V, 50 or 60 Hz voltage trips for <strong>circuit</strong>-breakers GV3 ME80.Characteristics:pages 3/18 and 3/22Dimensions:pages 3/79 to 3/883/65

31234GV7 AE11, AB11GV7 RE, RSGV7 AU, AS3/66