Catalogue 2010

Catalogue 2010

Catalogue 2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

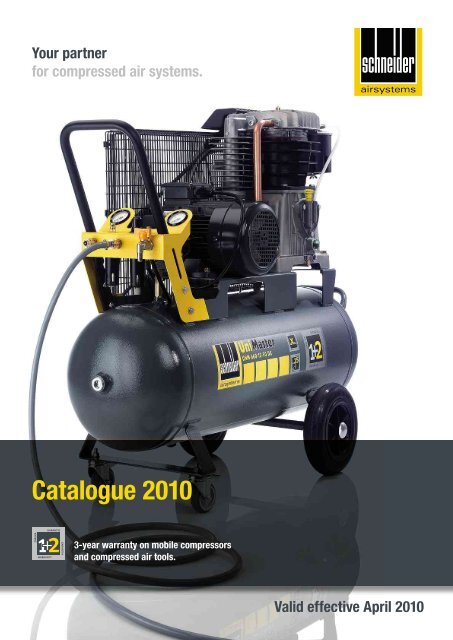

Your partner<br />

forcompressedair systems.<br />

<strong>Catalogue</strong><strong>2010</strong><br />

3-year warranty on mobile compressors<br />

and compressed air tools.<br />

Valideffective April<strong>2010</strong>

2<br />

Thetough final examination<br />

of Schneider airsystems products.<br />

Dear Customer,<br />

Do you know what it feels like to hold abrand new, dynamic and powerful<br />

product in your hands? Aproduct that thrills you on account of its enormous<br />

power and robustness and is characterised by an above-average long service<br />

life?<br />

We can help you experience this feeling.<br />

Products from Schneider airsystems stand for premium quality.<br />

We are conscious of this and it is our intention that you can depend on this<br />

premium quality. For this reason, each product –long before itreaches your<br />

hands –ismercilessly put through numerous qualification stages, where itis<br />

examined from "head to foot" and exposed under extreme conditions to the<br />

toughest of tortures.<br />

Here isasmall selection of the inspections that our products had to pass last<br />

year to find aplace in this current catalogue:<br />

Our new pipe socket successfully completed 1million load changes in the<br />

fatigue test<br />

Every one of our new staplers had to complete 200,000 shots<br />

Our new tyre pressure gauge completed 26,000 inflation and deflation cycles<br />

Our new valve connector was attached and removed 18,000 times<br />

Our impact screwdrivers performed 9780 tyre changes<br />

Our pipe socket had to survive 224 drops from adesk<br />

60ºChot water and 40 bar wereapplied successfully to our pipe sockets<br />

Our impact screwdrivers and tyre pressure gauges survived 60 drops from<br />

heights of up to 1.40 mwithout any damage<br />

6metres free fall was no problem for our pipe sockets<br />

Our new pipe sockets had to withstand -20ºC and 40 bar pressure inthe deep<br />

freezer<br />

Our tyre pressure gauges were driven over countlessly –without consequence.<br />

Following completion of all qualification stages, we are now proud to be able to<br />

present alarge number of new products in this catalogue, all of which are<br />

characterised by the typical Schneider airsystems premium quality.<br />

Your Schneider airsystems team

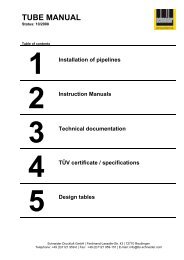

4plus modular system 8<br />

1|Generating compressed air 15-75<br />

Mobile compressors ............................................16-36<br />

UniMaster ..............................................................18-22<br />

CompactMaster ..................................................... 23-26<br />

SilentMaster .......................................................... 27-29<br />

10 + Master ............................................................. 30-31<br />

PetrolMaster .......................................................... 32-33<br />

Compressed air purification ...............................78-81<br />

Cold dryer ............................................................. 82-86<br />

Adsorption dryer..................................................... 87-88<br />

Condensate discharger ................................................89<br />

Oil-water separation devices .......................................90<br />

Maintenance units and filters ................................ 91-98<br />

Pipe systems .................................................... 100-146<br />

Plug-in system 15-28 mm.................................. 106-115<br />

Brass screw fitting system 15-28 mm ................ 116-135<br />

Pipe system, brass 32-63 mm ............................ 136-140<br />

Pipe system, plastic 32-63 mm .......................... 141-146<br />

Hoses and workshop equipment .................... 147-152<br />

Hoses ................................................................ 147-150<br />

Hose rewinder ........................................................... 151<br />

Tractions ................................................................... 152<br />

Compressed air tools ...................................... 180-251<br />

Systainer ........................................................... 180-184<br />

Impact screwdriver ............................................ 185-189<br />

Ratchet screwdriver .......................................... 190-191<br />

Rotaryscrewdriver............................................. 192-193<br />

Drills ................................................................. 194-195<br />

Grinding machines ............................................ 196-198<br />

Saws ......................................................................... 199<br />

Special cutter ............................................................ 200<br />

Riveting tongs ........................................................... 201<br />

Grease guns .............................................................. 202<br />

Oil extracting device .................................................. 203<br />

Needle descaler ................................................ 204-205<br />

MAS .....................................................................34-36<br />

Stationarycompressors ......................................37-64<br />

UniMaster ............................................................. 39-44<br />

SilentMaster ST ..................................................... 45-49<br />

10 + Master ST ........................................................ 50-55<br />

AirMaster screw compressors ............................... 56-64<br />

Vessel accessories...............................................65-75<br />

2|Purifying compressed air 77-98<br />

3|Distributing compressed air<br />

4|Using compressed air<br />

Index.................................................................................. 252-253<br />

Agencies abroad....................................................................... 254<br />

99-171<br />

Supply units/power and air supply units .................... 152<br />

Brass parts/screw fittings .............................. 153-171<br />

Screw fitting series A......................................... 166-168<br />

Quick plug-in connection series Fox .................. 169-171<br />

173-251<br />

Chisel hammers ................................................. 206-209<br />

Staplers and nail guns ....................................... 210-215<br />

Paint spray guns ................................................ 216-224<br />

Plaster spraying devices .................................... 225-227<br />

Spray guns ........................................................ 228-229<br />

Special gun ............................................................... 230<br />

Blasting devices ................................................ 231-234<br />

Pressure vessel.................................................. 235-238<br />

Cartridge guns ................................................... 239-241<br />

Blowing guns ..................................................... 242-245<br />

Tyre inflator........................................................ 246-250<br />

Accessories................................................................ 251<br />

Thecontentsofthiscatalogue correspond to thestatusatthe time of going to<br />

press (03/10). Technical details and equipment versions may deviate from the<br />

descriptions. Wetherefore reserve the right tochange the published data.<br />

3<br />

4|Using compressed air 3|Distributing compressed air<br />

2|Purifying compressed air<br />

1|Generating compressed air

Adaptedperfectly to your requirements.<br />

... for work on motor vehicles<br />

Schneider airsystems isyour system provider inthe automotive trade. Apart from our products<br />

for the generation, purification and distribution ofcompressed air, we also offer a<br />

comprehensive range of compressed air tools. Wecan therefore supply you with the most<br />

important tools for anautomotive workshop from impact screwdrivers toratchet screwdrivers,<br />

tyre inflators, grinding machines, saws and special cutters through topaint spray guns.<br />

... for working with wood<br />

Schneider airsystems isyour all-round supplier for compressed air solutions in the woodworking<br />

trade:<br />

Our products can drive screws, drill, grind, staple and nail...<br />

Furthermore, we can offer you acomplete product range for compressed air generation,<br />

purification and distribution –for aperfect compressed air system.<br />

... for painting work<br />

Schneider airsystems offers complete equipment for painters and plasterers in the compressed<br />

air area: apart from products for compressed air generation, purification and distribution,<br />

our range is rounded off with adiversified offer of tools for painters. Among other<br />

things, wecan thus offer you grinding machines, needle descalers and chisel hammers as<br />

well as paint spray guns, plaster spraying devices, pressure vessels and cartridge guns.<br />

... for working with metal<br />

Schneider airsystems isyour supplier ofhigh-grade compressed air solutions in the area of<br />

metal processing. Apart from acomprehensive range of compressors, we also supply products<br />

for compressed air conditioning and distribution as well as compressed air tools: from<br />

impact screwdrivers, ratchet screwdrivers and rotary screwdrivers, through drills, riveting<br />

tongs and needle descalers uptopaint spray guns, blasting devices and blowing guns -<br />

everything for your metal processing company.<br />

5

6<br />

Newproductsofthe year <strong>2010</strong>...<br />

The new pipe sockets<br />

Our new innovative pipe sockets are ideally tuned toyour<br />

individual requirements:<br />

Amodular system allows you toflexibly extend the number of<br />

air outlets. Five Basis sockets can be upgraded quickly and<br />

cost effectively either individually or in combination with one<br />

of three Top sockets.<br />

(More on page 116)<br />

The new couplings<br />

Our new safety quick-release couplings and steel standard<br />

couplings provide atop performance combined with along<br />

service life, low coupling force and very easy operation.<br />

The new safety quick-release coupling also comply with the<br />

ISO Standard 4414and EN 983.<br />

(More on page 151)<br />

The new AirMaster<br />

Our new V-belt-driven screw compressor impresses with its<br />

durability and robustness.<br />

These properties are attributed to particularly high-grade<br />

equipment: an innovative electronic control system with<br />

pressure sensor and arotation direction control aswell asa<br />

specially robust, electro-pneumatic intake air controller.<br />

(More on page 64)<br />

The new cold compressed air dryer<br />

Our new cold compressed air dryer is characterised, above<br />

all, by its high energy-saving potential:<br />

It has animpressive cost-effective power-saving function,<br />

efficient heat transfer and condensate discharge with<br />

constantly low pressure loss over the entire service life.<br />

(More on page 86)

... at aglance.<br />

Thenew EXTRAproducts.<br />

The new tyre pressure gauge without pressure loss<br />

Our new tyre pressure gauges impress with an absolutely<br />

impact-proof and drive-over-proof pressure, exact readability<br />

and easy and flexible one-hand operation. They are calibrated<br />

and available in 6-bar and 12-bar versions.<br />

Avoid pressure loss!<br />

The new 6-bar tyre pressure gauge is one ofour new EXTRA<br />

products –simple towork with and maximum comfort!<br />

Thanks to the new, innovative valve connector, you avoid<br />

pressure loss when disconnecting the valve. Combined with the<br />

easiest possible operation:<br />

Simply attach –check pressure –pull off –and that's it!<br />

(More on page 244)<br />

The new UniMaster compressors<br />

Handy, flexible, speciallytailoredtoyour needs–all this<br />

characterises our new product series of mobile piston<br />

compressors.<br />

The new UniMaster compressors are available in five power<br />

classes between 1.1and 4.0 kWinastandard orEXTRA<br />

version respectively.<br />

Experience the new form of mobility!<br />

Enthusiasm is generated, in particular, by the new, mobile<br />

EXTRA compressors: They impress with particularly generous<br />

equipment and ahigh degree of operating comfort –for easier<br />

handling, excellent working results and your complete<br />

satisfaction.<br />

(More on page 18ff)<br />

WARTOŚĆ DODANA<br />

WARTOŚĆ DODANA<br />

BENEFIT<br />

BENEFIT<br />

MEHRWERT<br />

MEHRWERT<br />

VALOR AÑADIDO<br />

VALOR AÑADIDO<br />

7

8<br />

The 4plus modular system –<br />

perfect compressed air solutions from asingle source.<br />

The Schneider 4plus modular system stands for aflexible<br />

system comprising the modules compressed air generation,<br />

purification, distribution and use.<br />

All modules fit in afunction perfectly together and can be<br />

combined individually with one another.<br />

In addition, we offer you the benefit of consultation and thus<br />

ensure that our solution is tuned exactly to your requirements.<br />

Schneider 4plus modular system:<br />

For better work results combined with top economy and<br />

reliability.<br />

1<br />

3<br />

Generating compressed<br />

air<br />

Piston compressors<br />

Upright or horizontal<br />

Stationary or mobile<br />

Screw compressors<br />

Directly driven or by V-belt<br />

Vessels and cold dryers<br />

Optional as amodular system<br />

Distributing compressed<br />

air<br />

Our innovative pipe system made<br />

of plastic or aluminium with<br />

diameters 15-63 mm for insertion<br />

or screwing on can adapt to any<br />

conceivable situation.<br />

ATÜV certificate validates the<br />

leak-tightness of our pipe system<br />

according to the Pressure<br />

Vessel Directive.<br />

2<br />

4<br />

Purifying compressed<br />

air<br />

Purifying devices clean the<br />

compressed air and collect the<br />

various substances that accumulate<br />

during the compression<br />

process.<br />

Important functions:<br />

Condensate discharge<br />

Oil-water separation<br />

Cold drying<br />

Filtration<br />

Using compressed air<br />

Our pneumatic tools have been<br />

proven time and again –<br />

for professional use in the<br />

handcraft sector or industrial<br />

applications.<br />

We can offer you the right tool<br />

for every application.<br />

Our motto:<br />

Easy handling for better<br />

working results.

An overviewofour pictographs.<br />

10-year rust guarantee<br />

7years spare parts<br />

warranty<br />

Oil regularly<br />

Delivered in a<br />

Systainer<br />

With integral electronic<br />

elements<br />

15-year rust guarantee<br />

12 years spare<br />

parts warranty<br />

Oiled compressed<br />

air<br />

Delivered in acase<br />

VARIO SPEED<br />

With integral electronic<br />

elements<br />

No technical<br />

inspection required<br />

Unoiled compressed<br />

air<br />

"Click it" pipeline<br />

plug-in system<br />

Safety quickrelease<br />

coupling<br />

Rubber hand grip<br />

(soft grip)<br />

BENEFIT<br />

MEHRWERT<br />

Quiet 1+2 warranty EXTRA product<br />

WARTOŚĆ DODANA<br />

VALOR AÑADIDO<br />

9

10<br />

We canhelpyou in wordsand deeds.<br />

Are you considering installing anew complete compressed air solution? Do<br />

you wish to retrofit an existing system? Or are you planning to acquire another<br />

product?<br />

Irrespective of where you require support –wewill be glad to help at any time<br />

and offer you personal advice geared specifically towards your individual<br />

company requirements.<br />

Our area-wide team of experts will support you on the telephone and with the<br />

planning ofyour compressed air system onsite.<br />

We will take close and thorough consideration of your space availability and<br />

your specific compressed air requirements. On this basis, we will then prepare<br />

the optimum perfectly matched compressed air solution –non-binding,<br />

well-founded and free of charge.<br />

We will be glad to assist you further:<br />

Telephone:+49 (0)7121 959-222 Domestic Sales<br />

+49 (0)7121 959-161 Export Sales<br />

+49 (0)7121 959-244 Service<br />

Fax: +49 (0)7121 959-151<br />

E-mail: info@tts-schneider.com<br />

Internet: www.schneider-airsystems.com<br />

A Schneider airsystems specialist dealer near you can be found easily and<br />

conveniently on our website www.schneider-airsystems.com.

Quality is ourNumber 1priority.<br />

Our claim is that we always deliver top quality products, to continuously<br />

improve ourselves and to satisfy you as our customer. All Schneider airsystems<br />

products are therefore subject to stringent quality requirements and regular<br />

inspections. The certification of our company according to DIN EN ISO 9001<br />

covers all areas –from development and production through marketing and<br />

sales on to service –and thus underscores this very high standard. We focus<br />

not only on our own design and development and our own testing laboratory,<br />

but also on our in-house production and assembly. Tohave these processes<br />

on your own premises also means that you have the value-adding and<br />

thus quality-related activities perfectly under control.<br />

However, wedonot stop there. Our quality management system continuously<br />

monitors and safeguards the high standard ofquality, e.g.with 100-percent<br />

testing. If despite this, amachine fails in operation, we analyse the failure and<br />

use it as atool to further improve our products. In the event of complaints, we<br />

guarantee aresponse time of no more than 5working days offering fast<br />

assistance without bureaucracy to get you back up and running quickly.<br />

If you have suggestions or concrete questions about quality assurance, just<br />

e-mail us at:<br />

qualitaet@tts-schneider.com<br />

11

12<br />

Youcan countonus. Guaranteed.<br />

We are convinced of the high quality of our products –tothe extent that we offer<br />

you awhole series of guarantees:<br />

1+2 warranty<br />

With our "1+2 warranty", we provide a3-year warranty on mobile compressors<br />

and compressed air tools if the product is registered online within 30 days<br />

of purchase. For you, this means more cost-effectiveness and more assurance<br />

for your work. For warranty terms and conditions and registration, visit:<br />

www.schneider-airsystems.com/warranty<br />

Warranty extension<br />

Warranty extension to 3years for all stationary systems when amaintenance<br />

contract is concluded with an authorised Schneider airsystems service location.<br />

Spare part deliveryguarantee<br />

For shorter downtimes, 98% of spare parts are delivered within 24 hours from<br />

the warehouse. The latest version of our spare parts catalogue, EKAT, is<br />

always available online at www.schneider-airsystems.com/td.<br />

Supply guarantee<br />

All spare parts remain in stock and are available for years after the date of purchase.<br />

Stationary piston and screw compressors, cold and adsorption dryers<br />

as well as control systems and star-delta switches are even offered with a<br />

12-year supply guarantee. Spare parts for compressed air tools, mobile piston<br />

compressors, accessories and other devices have guaranteed storage of 7years.<br />

Return and disposal guarantee<br />

Youcan hand over your old disused compressors to your service partner, who<br />

will dispose of them at an environmental friendly recycling centre free ofcharge.<br />

Anti-rust warranty<br />

All vessels with aburnt-in inner coating come with a15-year rust guarantee,<br />

which extends far beyond the statutory warranty. All other vessels are covered<br />

by a10-year warranty.

Ourexcellent servicewill convince you.<br />

Apart from first-class products, we also regard service as an essential element<br />

of customer satisfaction.<br />

In the rare case that repair is required on one of our products, it is therefore<br />

always very important to us to save you unnecessary downtimes.<br />

For this reason, over 60 regional service partners of our close-knit national<br />

service network ensure quick processing of service cases –regardless of<br />

whether the product is astationary compressed air system or amobile product.<br />

We offer you many different options for processing arepair order when required:<br />

Complete on-site repair processing: Particularly for stationary systems, service<br />

technicians complete the job right in your workshop. In awarranty case,<br />

this is free of charge.<br />

Drop-off repair at service partner or specialised dealer's facility: Youdrop off the<br />

machine at the service partner's location. Once the product is repaired, you<br />

are notified and can pick the unit up.<br />

Rental compressors service: So that your business continues to operate<br />

smoothly, our service partners support you with rental compressors if<br />

necessary.<br />

In addition, our service partners are glad to provide advice in all important<br />

service areas. To find aservice partner near you, visit our website:<br />

www.schneider-airsystems.com<br />

Our service team in the company head office will also gladly help you:<br />

Telephone: +49 (0) 7121 959-244<br />

Fax: +49 (0) 7121 959-269<br />

E-mail: service@tts-schneider.com<br />

13

14<br />

Available to you365 days ayear.<br />

Ourspare partscatalogue EKAT continuously updatedonline!<br />

Awide variety of services and information is at your disposal at<br />

www.schneider-airsystems.com. Here, you can access our electronic spare parts<br />

catalogue (EKAT) to find the find the spare part you need quickly and easily.<br />

Just look for the article number on the type plate and type it into the Web<br />

interface to retrieve an easy-to-understand and detailed exploded drawing<br />

with the associated spare parts list and the recommended selling prices of the<br />

spare parts:<br />

www.schneider-airsystems.com/td<br />

Youcan order the spare parts yourself from any authorised Schneider service<br />

partner orspecialised dealer.<br />

But that's not all. Our website also includes:<br />

Comprehensive product information<br />

Adealer search engine<br />

Aservice partner search engine<br />

Promotional offers<br />

Trade fair schedule<br />

News<br />

Instruction Manuals<br />

Our Newsletter registration form<br />

Youdon't want to miss anything in future?<br />

Keep up to datewithour free e-mail Newsletter

1|Generatingcompressedair<br />

Compressors

16<br />

Mobile compressors<br />

UniMaster CompactMaster<br />

The all-round genius<br />

The mobile piston compressors<br />

are equipped as standard<br />

with safety valve, vessel<br />

pressure gauge and condensate<br />

drain valve. The pressure<br />

switch with On/Off switch<br />

and start relief make automatic<br />

operation possible. The<br />

welded-on rear handle<br />

facilitates loading and<br />

transport.<br />

The UniMaster compressors<br />

are available in five power<br />

classes between 1.1 kW and<br />

4.0 kW in astandard or EXTRA<br />

version respectively.<br />

The EXTRA compressors are<br />

characterised by particularly<br />

generous equipment and<br />

enhanced operator convenience.<br />

This is how lightweight<br />

and handy a<br />

compressor can be.<br />

Their robust, compact and<br />

lightweight construction<br />

makes the CompactMaster<br />

compressor the reliable tool<br />

at construction sites and for<br />

interior fitting: they are also<br />

proven in use and also<br />

available in an oil-free version.

SilentMaster 10 + Master PetrolMaster<br />

The especially quiet<br />

type.<br />

With an especially quiet<br />

noise insulation, this portable/mobile<br />

compressor<br />

series is ideal for applications<br />

that have to be especially<br />

quiet — such as directly<br />

at the workplace. All models<br />

are technically fully equipped<br />

and also available in an oil-free<br />

version.<br />

Plenty of pressure<br />

when you need it.<br />

When high pressure ofupto<br />

15 bar is needed, the<br />

10 + Master does the job<br />

splendidly. All equipped with<br />

filter pressure reducer, mist<br />

oiler and vessel with inner<br />

coating in robust, high-quality<br />

construction. For the most<br />

difficult requirements in the<br />

trades.<br />

The declaration of<br />

independence from<br />

power outlets.<br />

This compressor series with<br />

the highest-quality craftsmanship<br />

works independently<br />

of the mains power<br />

supply — and supplies<br />

optimum and reliable performance<br />

for work up to 15 bar.<br />

Idling and speed control<br />

enable duty cycles of 100%.<br />

17

18<br />

UniMaster<br />

The traditional solution<br />

with horizontal vessel<br />

Easy transport thanks to the optimised dimensions of<br />

wheels and welded-on rear handle<br />

Convenient operation and perfect overview provided by two<br />

pressure gauges that allow you view the vessel and<br />

working pressure atthe same time<br />

Fully automatic operation thanks to On/Off switch, start<br />

relief and motor protection<br />

High safety through 10 or 15 -year warranty against rusting<br />

through of the vessel<br />

Easy tool connection with standard quick-action coupling

Our EXTRA compressors<br />

using the UNM 410-10-50 WX as an example<br />

Extra long handle<br />

simple and convenient<br />

transport<br />

Flexible operation<br />

through separate compressed<br />

outlets for unoiled and oiled<br />

compressed air, equipped with<br />

safety quick-release coupling<br />

High operating comfort<br />

through condensate<br />

drainage at operation<br />

level<br />

The EXTRA equipment<br />

User-friendly operating panel<br />

for easy reading of the pressure<br />

gauges and protection of sensitive<br />

parts<br />

Mobile use<br />

thanks to front swivel castors<br />

15-years warranty<br />

against rusting through of<br />

the vessel<br />

High driving comfort<br />

and breakdown safety<br />

through robust soft rubber<br />

wheels<br />

Our EXTRA UniMaster compressors are characterised by particularly generous equipment<br />

and ahigh degree of operating comfort –for easier handling, excellent working results and<br />

your complete satisfaction.<br />

All EXTRA products are identified at aglance by the EXTRA symbol.<br />

19

1|Generating compressed air<br />

20<br />

Compressors, mobile<br />

UniMaster<br />

Compressors for universal use<br />

Common features<br />

• Movable piston compressor with horizontal vessel<br />

• Standard features include: all safety fittings and electric connection<br />

cable with plug and Condor pressure switch<br />

• Compressed air vessel equipped with safety valve, vessel pressure<br />

gauge and condensate outlet valve<br />

• The welded-on rear handle facilitates loading and transport<br />

• Fully automatic operation due to pressure switch with start-up relief,<br />

motor protection and ON/OFF switch<br />

UNM 210-8-25 W<br />

• With upgraded equipment for universal use<br />

• Directly-flanged 1-cylinder unit and 230-V alternating current motor with integrated motor protection<br />

• Including pressure reducer for optimum control of the working pressure<br />

• In addition, with 2mequipment line with rubber sheathing and air outlet via quick-release coupling<br />

• 10-year rust guarantee on all vessels<br />

UNM 210-8-25 WXOF<br />

• With EXTRA equipment for universal use<br />

• Directly-flanged, oil-free 1-cylinder unit and 230-V alternating current motor with integrated motor<br />

protection<br />

• Savings on time and cost through less maintenance work due to oil-free operation<br />

• Filter pressure reducer for regulated compressed air and compressed air free of condensate, dirt<br />

and oil<br />

• In addition, with 2mequipment line with rubber sheathing and air outlet via quick-release coupling<br />

• Extra long lifetime thanks to new high-performance reeling pistons<br />

• 10-year rust guarantee on all vessels<br />

UNM 260-10-50 W<br />

• With upgraded equipment for universal use<br />

• Directly-flanged 1-cylinder unit and 230-V alternating current motor with integrated motor protection<br />

• Filter pressure reducer for regulated compressed air and compressed air free of condensate, dirt<br />

and oil<br />

• In addition, with 2mequipment line with rubber sheathing and air outlet via quick-release coupling<br />

• 10-year rust guarantee on all vessels<br />

UNM 260-10-50 WX<br />

• With EXTRA equipment for universal use<br />

• Directly-flanged 1-cylinder unit and 230-V alternating current motor with integrated motor protection<br />

• Filter pressure reducer for regulated compressed air and compressed air free of condensate, dirt<br />

and oil<br />

• In addition, with 4mequipment line with rubber sheathing and air outlet via 2quick-release couplings<br />

• The front guide rolls and the longer handle increase mobility<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels

Compressors, mobile<br />

UNM 410-10-50 W<br />

• With upgraded equipment for universal use<br />

• With V-belt drive, 2cylinders with in-line configuration for particularly smooth running and 230-V<br />

alternating current motor with external motor protection<br />

• Low compressor speed, which is gentle on the compressor components and also reduces the<br />

noise level and vibrations<br />

• Large ventilator flywheel for optimal cooling<br />

• Filter pressure reducer for regulated compressed air and compressed air free of condensate, dirt<br />

and oil<br />

• In addition, with 2mequipment line with rubber sheathing and air outlet via quick-release coupling<br />

• 10-year rust guarantee on all vessels<br />

UNM 410-10-50 WX<br />

• With EXTRA equipment for universal use<br />

• Condensate drainage at operating height<br />

• With V-belt drive, 2cylinders with in-line configuration for particularly smooth running and 230-V<br />

alternating current motor with external motor protection<br />

• Low compressor speed, which is gentle on the compressor components and also reduces the<br />

noise level and vibrations<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil, and amist oiler for oiled compressed air<br />

• Optimised operating panel with user-friendly reading of the pressure gauge and protection for<br />

sensitive parts<br />

• In addition, with 4mequipment line with rubber sheathing and air outlet via 2safety quick-release<br />

couplings<br />

• The front guide rolls and the longer handle increase mobility<br />

• The rear wheels are made of soft rubber. This combines the breakdown safety of asynthetic<br />

wheel with the driving comfort of inflated tyres<br />

• Large ventilator flywheel for optimal cooling<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels<br />

UNM 510-10-90 D<br />

• With upgraded equipment for universal use<br />

• With V-belt drive, 2cylinders with in-line configuration for particularly smooth running and 400-V<br />

three-phase current motor with external motor protection<br />

• Low compressor speed, which is gentle on the compressor components and also reduces the<br />

noise level and vibrations<br />

• Large ventilator flywheel for optimal cooling<br />

• Filter pressure reducer for regulated compressed air and compressed air free of condensate, dirt<br />

and oil<br />

• In addition, with 2mequipment line with rubber sheathing and air outlet via quick-release coupling<br />

• Equipment line with phase alternator<br />

• 10-year rust guarantee on all vessels<br />

UNM 510-10-90 DX<br />

• With EXTRA equipment for universal use<br />

• Condensate drainage at operating height<br />

• With V-belt drive, 2cylinders with in-line configuration for particularly smooth running and 400-V<br />

three-phase current motor with external motor protection<br />

• Low compressor speed, which is gentle on the compressor components and also reduces the<br />

noise level and vibrations<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil, and amist oiler for oiled compressed air<br />

• Optimised operating panel with user-friendly reading of the pressure gauge and protection for<br />

sensitive parts<br />

• In addition, with 4mequipment line with rubber sheathing and air outlet via 2safety quick-release<br />

couplings<br />

• Equipment line with phase alternator<br />

• The front guide rolls and the longer handle increase mobility<br />

• The rear wheels are made of soft rubber. This combines the breakdown safety of asynthetic<br />

wheel with the driving comfort of inflated tyres<br />

• Large ventilator flywheel for optimal cooling<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels<br />

21<br />

1|Generating compressed air

1|Generating compressed air<br />

22<br />

Compressors, mobile<br />

Type Art. no.<br />

Pressure<br />

(bar)<br />

Suction<br />

capacity<br />

(l/min)<br />

Filling<br />

capacity<br />

(l/min)<br />

Drive power<br />

(kW)<br />

UNM 210-8-25 W A711000 8 200 110 1,1 230 2850 24 25 95 655x365x595<br />

UNM 210-8-25 WXOF A711001 8 210 120 1,1 230 2850 24 24 95 655x365x635<br />

UNM 260-10-50 W A712000 10 260 160 1,5 230 2850 50 32 95 770x425x640<br />

UNM 260-10-50 WX A712001 10 260 160 1,5 230 2850 50 33 95 770x425x640<br />

UNM 410-10-50 W A713000 10 410 295 2,2 230 1210 50 64 96 820x410x810<br />

UNM 410-10-50 WX A713001 10 410 295 2,2 230 1210 50 68 96 885x410x870<br />

UNM 510-10-90 D A714000 10 510 390 3,0 400 1240 90 80 97 1070x495x895<br />

UNM 510-10-90 DX A714001 10 510 390 3,0 400 1240 90 84 97 1100x505x935<br />

UNM 660-10-90 D A715000 10 660 520 4,0 400 1000 90 102 97 1070x495x1000<br />

UNM 660-10-90 DX A715001 10 660 520 4,0 400 1000 90 106 97 1100x505x1000<br />

1) Sound power level according to DIN EN ISO 3744 (RL 2000/14/EC)<br />

UNM 660-10-90 D<br />

• With upgraded equipment for universal use<br />

• With V-belt drive, 2-stage compressing unit with V-belt drive, 2cylinders with in-line configuration<br />

and 400-V three-phase current motor with external motor protection<br />

• Low compressor speed, which is gentle on the compressor components and also reduces the<br />

noise level and vibrations<br />

• Large ventilator flywheel for optimal cooling<br />

• Filter pressure reducer for regulated compressed air and compressed air free of condensate, dirt<br />

and oil<br />

• In addition, with 2mequipment line with rubber sheathing and air outlet via quick-release coupling<br />

• Equipment line with phase alternator<br />

• 10-year rust guarantee on all vessels<br />

UNM 660-10-90 DX<br />

• With EXTRA equipment for universal use<br />

• Condensate drainage at operating height<br />

• With V-belt drive, 2-stage compressing unit with V-belt drive, 2cylinders with in-line configuration<br />

and 400-V three-phase current motor with external motor protection<br />

• Low compressor speed, which is gentle on the compressor components and also reduces the<br />

noise level and vibrations<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil<br />

• Optimised operating panel with user-friendly reading of the pressure gauge and protection for<br />

sensitive parts<br />

• In addition, with 4mequipment line with rubber sheathing and air outlet via 2safety quick-release<br />

couplings<br />

• Equipment line with phase alternator<br />

• The front guide rolls and the longer handle increase mobility<br />

• The rear wheels are made of soft rubber. This combines the breakdown safety of asynthetic<br />

wheel with the driving comfort of inflated tyres<br />

• Large ventilator flywheel for optimal cooling<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels<br />

Voltage<br />

(V)<br />

Speed<br />

(min-1 )<br />

Tank vol.<br />

(l)<br />

Weight<br />

(kg)<br />

Noise<br />

(dB(A)) 1)<br />

Dimensions<br />

(W xDxH)

CompactMaster<br />

Light and handy –<br />

ideal for the construction<br />

site<br />

An example of the particular product highlights:<br />

CPM 342-10-20 W<br />

Ideal for mobile use at construction sites and in interior fitting<br />

due to lightweight, compact design<br />

Outstanding transportation characteristics due to heightadjustable<br />

bracket with special clamping mechanism for<br />

ease of use<br />

Easy transportation up stairs due to large, perfectly positioned<br />

wheels<br />

Extremely robust design with optimum protection of all<br />

fragile parts such as pressure switch, pressure gauge,<br />

and fittings<br />

Less moisture in the compressed air means alonger life of the<br />

connected tools (condensate separated by aftercooler and<br />

filter pressure reducer)<br />

Convenient operation and perfect overview provided by two<br />

pressure gauges that allow you view the vessel and<br />

working pressure atthe same time<br />

Optimal working results and operation with outlet for unoiled<br />

compressed air and outlet for oiled compressed air via<br />

quick-release couplings<br />

Extra-long service life of the vessel, made of zinc-phosphated<br />

high-quality steel with burnt-in inner coating —accompanied<br />

by 15-year warranty against rust-through<br />

23

1|Generating compressed air<br />

24<br />

Compressors, mobile<br />

CompactMaster<br />

Compressors for special requirements –<br />

Lightweight and compact<br />

Common features<br />

• Piston compressor<br />

• Applications: suitable for mobile use on building sites and for interior<br />

fitting<br />

• Standard features include: all safety fittings and electric connection<br />

cable with plug and Condor pressure switch<br />

• Fully automatic operation due to pressure switch with start-up relief,<br />

motor protection and ON/OFF switch<br />

• Compressed air vessel equipped with safety valve, vessel pressure<br />

gauge and condensate outlet valve<br />

• Air outlets with quick release coupling for easy connection of<br />

compressed air devices<br />

• All fragile parts, such as pressure switches, pressure gauges, fittings,<br />

etc. are well protected<br />

CPM 300-10-20 W<br />

• Portable and mobile<br />

• 1cylinder<br />

• Directly-flanged power unit<br />

• Outstanding transportation characteristics due to height-adjustable bracket with special clamping<br />

mechanism for ease of use<br />

• Can be transported vertically and horizontally<br />

• Easy transportation up stairs due to large, perfectly positioned wheels<br />

• User-friendly fittings unit with all-round protection<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil, and amist oiler for oiled compressed air<br />

• High flexibility thanks to a4mlong equipment line with rubber sheathing<br />

• Cable rewinder ensures unobstructed freedom of movement<br />

• Twopressure gauges for vessel pressure and working pressure<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels<br />

CPM 342-10-20 W<br />

• Portable and mobile<br />

• 1cylinder<br />

• Directly-flanged power unit<br />

• The low speed of rotation reduces vibrations, preserves the compressor components and reduces<br />

noise levels<br />

• Good start-up characteristics<br />

• Outstanding transportation characteristics due to height-adjustable bracket with special clamping<br />

mechanism for ease of use<br />

• Can be transported vertically and horizontally<br />

• Easy transportation up stairs due to large, perfectly positioned wheels<br />

• User-friendly fittings unit with all-round protection<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil, and amist oiler for oiled compressed air<br />

• High flexibility thanks to a4mlong equipment line with rubber sheathing<br />

• Cable rewinder ensures unobstructed freedom of movement<br />

• Twopressure gauges for vessel pressure and working pressure<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels<br />

CPM 160-8-2 W-oilfree<br />

• Portable, extremely handy and lightweight<br />

• 1cylinder<br />

• Directly-flanged power unit<br />

• Oil-free operation saves on maintenance. No oil changes, no oil in the condensate<br />

• Pressure reducer for setting the working pressure<br />

• 10-year rust guarantee on all vessels

Compressors, mobile<br />

CPM 160-8-6 W-oilfree<br />

• Portable, extremely handy and lightweight<br />

• 1cylinder<br />

• Directly-flanged power unit<br />

• Oil-free operation saves on maintenance. No oil changes, no oil in the condensate<br />

• Pressure reducer for setting the working pressure<br />

• Solid frame with 6lvessel<br />

• 10-year rust guarantee on all vessels<br />

CPM 212-10-2 W<br />

• Portable<br />

• 1cylinder<br />

• Directly-flanged power unit<br />

• Filter pressure reducer for regulated compressed air and compressed air free of condensate, dirt<br />

and oil<br />

• 10-year rust guarantee on all vessels<br />

CPM 200-8-12 W-oilfree<br />

• Portable<br />

• 1cylinder<br />

• Directly-flanged power unit<br />

• Can be transported vertically and horizontally<br />

• Service life up to ten times longer than traditional oil-free compressors due to the high quality,<br />

wear-resistant materials used<br />

• Oil-free operation saves on maintenance. No oil changes, no oil in the condensate<br />

• Inflation performance improved by up to 32% due to high-performance reeling pistons<br />

• Filter pressure reducer for regulated compressed air and compressed air free of condensate, dirt<br />

and oil<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels<br />

CPM 250-10-12 W<br />

• Portable and mobile<br />

• 1cylinder<br />

• Directly-flanged power unit<br />

• Can be transported vertically and horizontally<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil, and amist oiler for oiled compressed air<br />

• Guard with non-slip protection<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels<br />

CPM 320-10-18 W<br />

• Mobile<br />

• 2cylinders, Vlayout<br />

• Directly-flanged power unit<br />

• Vessel with zinc-phosphate and plastic coating<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil, and amist oiler for oiled compressed air<br />

• The low speed of rotation reduces vibrations, preserves the compressor components and reduces<br />

noise levels<br />

• Stable steel frame with cover plate<br />

• 10-year rust guarantee on all vessels<br />

25<br />

1|Generating compressed air

1|Generating compressed air<br />

26<br />

Compressors, mobile<br />

Type Art. no.<br />

Pressure<br />

(bar)<br />

Suction<br />

capacity<br />

(l/min)<br />

Filling<br />

capacity<br />

(l/min)<br />

Drive power<br />

(kW)<br />

CPM 300-10-20 W A222012 10 300 195 2,0 230 2850 20 37,0 97 490x490x830<br />

CPM 342-10-20 W A222011 10 340 265 2,2 230 1465 20 49,0 95 490x490x830<br />

CPM 160-8-2 W-oilfree A222002 8 160 70 1,1 230 2850 2,0 11,0 94 330x250x420<br />

CPM 160-8-6 W-oilfree A22<strong>2010</strong> 8 160 70 1,1 230 2850 6,0 13,0 94 340x280x510<br />

CPM 212-10-2 W A222003 10 200 125 1,1 230 2850 2,4 18,5 93 530x300x400<br />

CPM 200-8-12 W-oilfree A222007 8 200 110 1,1 230 2800 12 21,0 94 430x350x660<br />

CPM 250-10-12 W A222006 10 240 155 1,5 230 2850 12 26,0 97 430x350x660<br />

CPM 320-10-18 W A222001 10 310 240 1,9 230 1420 18 48,0 92 610x610x530<br />

CPM 400-10-20 W A222009 10 390 300 2,2 230 1430 20 77,0 91 800x670x640<br />

CPM 560-10-20 D A222008 10 560 450 3,0 400 1440 20 74,0 95 800x670x640<br />

1) Sound power level according to DIN EN ISO 3744 (RL 2000/14/EC)<br />

CPM 400-10-20 W<br />

• Mobile<br />

• 2cylinders, Vlayout<br />

• Vessel with zinc-phosphate and plastic coating<br />

• Directly-flanged power unit<br />

• The low speed of rotation reduces vibrations, preserves the compressor components and reduces<br />

noise levels<br />

• User-friendly fittings unit with all-round protection<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil, and amist oiler for oiled compressed air<br />

• Stable steel frame with cover plate<br />

• 10-year rust guarantee on all vessels<br />

CPM 560-10-20 D<br />

• Mobile<br />

• 2cylinders, Vlayout<br />

• Vessel with zinc-phosphate and plastic coating<br />

• Directly-flanged power unit<br />

• The low speed of rotation reduces vibrations, preserves the compressor components and reduces<br />

noise levels<br />

• User-friendly fittings unit with all-round protection<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil, and amist oiler for oiled compressed air<br />

• Stable steel frame with cover plate<br />

• 10-year rust guarantee on all vessels<br />

• 400 V: Cekon connector with phase alternator<br />

Voltage<br />

(V)<br />

Speed<br />

(min-1 )<br />

Tank vol.<br />

(l)<br />

Weight<br />

(kg)<br />

Noise<br />

(dB(A)) 1)<br />

Dimensions<br />

(W xDxH)

SilentMaster<br />

When quiet operation<br />

is required<br />

An example of the particular product highlights: SEM 320-10-60 W<br />

Quiet due to special sound insulation<br />

Increased efficiency and inflation performance due to 2-cylinder<br />

Vpower unit with single-stage compression<br />

Less moisture in the compressed air means alonger life of the<br />

connected tools (condensate separated by aftercooler and<br />

filter pressure reducer)<br />

Stability during use and safe transport provided by rubber<br />

suction feet and optimally sized wheels<br />

High inflation performance due to decreased friction loss of<br />

directly coupled design<br />

Extra-long service life of the vessel, made of zinc-phosphated<br />

high-quality steel with burnt-in inner coating — accompanied<br />

by 15-year warranty against rust-through<br />

Convenient operation and perfect overview provided by two<br />

pressure gauges that allow you view the vessel and<br />

working pressure atthe same time<br />

Optimal working results and operation with outlet for unoiled<br />

compressed air and outlet for oiled compressed air via<br />

quick-release couplings<br />

27

1|Generating compressed air<br />

28<br />

Compressors, mobile<br />

SilentMaster<br />

Common features<br />

• Piston compressor<br />

• Directly-flanged power unit<br />

• 1 cylinder<br />

Compressors for special requirements –<br />

Quiet due to special sound insulation<br />

• Standard features include: all safety fittings and electric connection<br />

cable with plug<br />

• Compressed air vessel equipped with safety valve, vessel pressure<br />

gauge and condensate outlet valve<br />

• Quiet due to special sound insulation<br />

SEM 30-8-4 W<br />

• Portable<br />

• Fully automatic operation via pressure switch<br />

• Air outlet with quick release coupling for easy connection of compressed air devices<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil<br />

• Pressure gauge for working pressure<br />

• Virtually silent operation. Specially designed to be used directly at the workplace<br />

• Suitable for airbrush work<br />

• 10-year rust guarantee on all vessels<br />

SEM 50-8-9 W<br />

• Portable<br />

• Fully automatic operation via pressure switch<br />

• Air outlet with quick release coupling for easy connection of compressed air devices<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil<br />

• Pressure gauge for working pressure<br />

• Virtually silent operation. Specially designed to be used directly at the workplace<br />

• Suitable for airbrush work<br />

• Pressure switch for start-up relief<br />

• With special head for lower operating temperatures and therefore particularly small amounts of<br />

residual oil in the compressed air<br />

• 10-year rust guarantee on all vessels<br />

SEM 100-8-6 W-oilfree<br />

• Portable<br />

• Fully automatic operation with pressure switch and relief valve<br />

• Pressure reducer for setting the working pressure<br />

• Quiet due to special casing on the power unit<br />

• The low speed of rotation reduces vibrations, preserves the compressor components and reduces<br />

noise levels<br />

• Extremely long service life compared to traditional oil-free compressors due to the high quality,<br />

wear-resistant materials used<br />

• Inflation performance improved by up to 32% due to high-performance reeling pistons<br />

• Oil-free operation saves on maintenance. No oil changes, no oil in the condensate<br />

• Air outlet with quick release coupling for easy connection of compressed air devices<br />

• 10-year rust guarantee on all vessels<br />

SEM 200-8-6 W-oilfree<br />

• Portable and mobile<br />

• Compact, flat design -requires little space<br />

• Fully automatic operation with pressure switch and relief valve<br />

• Pressure reducer for setting the working pressure<br />

• Integrated accessory compartment with spiral hose 8x1mm, length 4mand blowing gun<br />

• Quiet due to special casing on the power unit<br />

• Extremely long service life compared to traditional oil-free compressors due to the high quality,<br />

wear-resistant materials used<br />

• Inflation performance improved by up to 32% due to high-performance reeling pistons<br />

• Oil-free operation saves on maintenance. No oil changes, no oil in the condensate<br />

• Air outlet with quick release coupling for easy connection of compressed air devices<br />

• 10-year rust guarantee on all vessels

Compressors, mobile<br />

Type Art. no.<br />

Pressure<br />

(bar)<br />

SEM 255-10-50 W<br />

• Mobile<br />

• Fully automatic operation due to pressure switch with start-up relief, motor protection and ON/<br />

OFF switch<br />

• Large compressed air aftercooler for reduced moisture inthe compressed air<br />

• Air outlets with quick safety coupling for simple connection and safe disconnection of<br />

compressed air tools<br />

• Sound-insulated power unit<br />

• Twopressure gauges for vessel pressure and working pressure<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil<br />

• 10-year rust guarantee on all vessels<br />

SEM 320-10-60 W<br />

• Vibration-free operation and extended service life due to low rotation speed<br />

• Large ventilator flywheel for optimal cooling<br />

• Large compressed air aftercooler for reduced moisture inthe compressed air<br />

• Fully automatic operation with special start-up relief, motor protection and ON/OFF switch<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil, and amist oiler for oiled compressed air<br />

• Air outlets with quick safety coupling for simple connection and safe disconnection of<br />

compressed air tools<br />

• Twopressure gauges for vessel pressure and working pressure<br />

• Soundproofed power unit with integrated electric extractor fan<br />

• 2cylinders, Vlayout<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels<br />

Suction<br />

capacity<br />

(l/min)<br />

Filling<br />

capacity<br />

(l/min)<br />

Drive power<br />

(kW)<br />

SEM 30-8-4 W A333005 8 30 19 0,2 230 2900 4 19 31 1) 410x190x435<br />

SEM 50-8-9 W A333004 8 50 36 0,34 230 2900 9 22 33 1) 360x360x480<br />

SEM 100-8-6 W-oilfree A333002 8 95 50 0,55 230 1420 6 14 87 2) 380x210x430<br />

SEM 200-8-6 W-oilfree A333003 8 200 110 1,1 230 2850 6 19 89 2) 460x220x650<br />

SEM 255-10-50 W A333001 10 255 165 1,5 230 2850 50 56 87 2) 1000x390x770<br />

SEM 320-10-60 W A333006 10 310 240 1,9 230 1410 60 90 85 2) 970x480x770<br />

1) Sound pressure level at distance of 4maccording to 79/113 EEC, L(PA4) 2) Sound power level according to DIN EN ISO 3744 (RL 2000/14/EC)<br />

Voltage<br />

(V)<br />

Speed<br />

(min-1 )<br />

Tank vol.<br />

(l)<br />

Weight<br />

(kg)<br />

Noise<br />

(dB(A))<br />

Dimensions<br />

(W xDxH)<br />

29<br />

1|Generating compressed air

30<br />

10 + Master<br />

For plenty ofpressure<br />

up to 15 bars<br />

An example of the particular product highlights: ZPM 500-15-90 D<br />

Enables compressed air applications up to 15 bar with<br />

high-performance units ideally matched to heavy-duty<br />

requirements<br />

Quiet running and optimal cooling provided by large fan<br />

wheel with tried-and-tested V-belt drive<br />

Less moisture in the compressed air means alonger life of the<br />

connected tools (condensate separated by aftercooler and<br />

filter pressure reducer)<br />

Even better performance and higher efficiency due to optimised<br />

2-cylinder units with single-stage or two-stage<br />

compression<br />

Extra-long service life of the vessel, made of zinc-phosphated<br />

high-quality steel with burnt-in inner coating —accompanied<br />

by 15-year warranty against rust-through<br />

Stability during use and safe transport provided by rubber<br />

suction feet and large, air-filled tyres<br />

Optimal working results and operation with outlet for unoiled<br />

compressed air and outlet for oiled compressed air via<br />

quick-release couplings<br />

Convenient operation and perfect overview provided by two<br />

pressure gauges that allow you view the vessel and<br />

working pressure atthe same time

Compressors, mobile<br />

10+Master<br />

Compressors for special requirements –<br />

If more than 10 bar is required<br />

Common features<br />

• Piston compressor<br />

• Standard features include: all safety fittings and electric connection<br />

cable with plug<br />

Type Art. no.<br />

Pressure<br />

(bar)<br />

Suction<br />

capacity<br />

(l/min)<br />

Filling<br />

capacity<br />

(l/min)<br />

Drive power<br />

(kW)<br />

• Fully automatic operation due to pressure switch with start-up relief,<br />

motor protection and ON/OFF switch<br />

• Compressed air vessel equipped with safety valve, vessel pressure<br />

gauge and condensate outlet valve<br />

ZPM 97-15-2 W A555004 15 87 50 0,55 230 1420 2,4 21 87 530x300x430<br />

ZPM 500-15-50 D A555002 15 500 400 4,0 400 850 50 92 93 1040x450x880<br />

ZPM 500-15-90 D A555003 15 500 400 4,0 400 850 90 109 94 1120x480x960<br />

1) Sound power level according to DIN EN ISO 3744 (RL 2000/14/EC)<br />

ZPM 97-15-2 W<br />

• Portable<br />

• 1cylinder<br />

• Directly-flanged power unit<br />

• The low speed of rotation reduces vibrations, preserves the compressor components and reduces<br />

noise levels<br />

• Pressure upto15bar<br />

• One additional air outlet with quick release coupling for maximum pressure<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil<br />

• 10-year rust guarantee on all vessels<br />

ZPM 500-15-50 D<br />

• Mobile<br />

• 2cylinders, layout designed for particularly quiet operation<br />

• Two-stage compressing power unit for pressures up to 15 bar<br />

• 400 V: Cekon connector with phase alternator<br />

• V-belt drive<br />

• Low speed of rotation<br />

• Large ventilator flywheel for optimal cooling<br />

• Large compressed air aftercooler for reduced moisture inthe compressed air<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil, and amist oiler for oiled compressed air<br />

• Air outlets with quick release coupling for easy connection of compressed air devices<br />

• 2air-filled tyres and 2rubber supports for extra stability<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels<br />

ZPM 500-15-90 D<br />

• Mobile<br />

• 2cylinders, layout designed for particularly quiet operation<br />

• Two-stage compressing power unit<br />

• 400 V: Cekon connector with phase alternator<br />

• V-belt drive<br />

• Low speed of rotation<br />

• Large ventilator flywheel for optimal cooling<br />

• Large compressed air aftercooler for reduced moisture inthe compressed air<br />

• Fitting unit with filter pressure reducer for regulated compressed air and compressed air free of<br />

condensate, dirt and oil, and amist oiler for oiled compressed air<br />

• Air outlets with quick release coupling for easy connection of compressed air devices<br />

• 2air-filled tyres and 2rubber supports for extra stability<br />

• Technical inspections are mandatory due to the size of the vessel<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels<br />

Voltage<br />

(V)<br />

Speed<br />

(min-1 )<br />

Tank vol.<br />

(l)<br />

Weight<br />

(kg)<br />

Noise<br />

(dB(A)) 1)<br />

Dimensions<br />

(W xDxH)<br />

31<br />

1|Generating compressed air

32<br />

PetrolMaster<br />

Mobile and independent from<br />

the mains power supply<br />

An example of the particular product highlights: PEM 500-15-50 B<br />

Independence from the mains power supply through compressors<br />

with petrol motor<br />

Duty cycles of 100% possible with idling and speed control<br />

Less moisture in the compressed air means alonger life of the<br />

connected tools (condensate separated by aftercooler and<br />

filter pressure reducer)<br />

Convenient operation and perfect overview provided by two<br />

pressure gauges that allow you view the vessel and<br />

working pressure atthe same time<br />

Even better performance and higher efficiency due to 2-cylinder<br />

units with single-stage or two-stage compression<br />

Extra-long service life of the vessel, made of zinc-phosphated<br />

high-quality steel with burnt-in inner coating —accompanied<br />

by 15-year warranty against rust-through<br />

Stability during use and safe transport provided by rubber<br />

suction feet and perfectly sized wheels<br />

Optimal working results and operation with outlet for unoiled<br />

compressed air and outlet for oiled compressed air via<br />

quick-release couplings<br />

Enables compressed air applications up to 15 bar with<br />

high-performance units ideally matched to heavy-duty<br />

requirements<br />

Quiet running and optimal cooling provided by large fan<br />

wheel with tried-and-tested V-belt drive

Compressors, mobile<br />

PetrolMaster<br />

Common features<br />

• Piston compressor<br />

• Independent from the mains power supply due to petrol drive<br />

• Equipped with all the necessary safety fittings<br />

• Compressed air vessel equipped with safety valve, vessel pressure<br />

gauge and condensate outlet valve<br />

Type Art. no.<br />

Pressure<br />

(bar)<br />

Compressors for special requirements –<br />

Independent from the mains power supply due to petrol drive<br />

Suction<br />

capacity<br />

(l/min)<br />

Filling<br />

capacity<br />

(l/min)<br />

Drive power<br />

(kW)<br />

• Fitting unit with filter pressure reducer for regulated compressed air<br />

and compressed air free of condensate, dirt and oil, and amist oiler<br />

for oiled compressed air<br />

• Air outlets with quick release coupling for easy connection of<br />

compressed air devices<br />

• Operation in closed rooms not permitted<br />

PEM 240-10-10 B A444001 10 230 140 3,0 3400 10 31 97 0,6 450x520x730<br />

PEM 500-15-50 B A444002 15 500 400 6,6 1140 50 114 97 1,1 1060x490x960<br />

1) Sound power level according to DIN EN ISO 3744 (RL 2000/14/EC)<br />

PEM 240-10-10 B<br />

• Suitable for use on building sites<br />

• Portable and mobile<br />

• 1cylinder<br />

• Directly-flanged power unit<br />

• Idling control<br />

• 10-year rust guarantee on all vessels<br />

PEM 500-15-50 B<br />

• Mobile<br />

• 2cylinders, layout designed for particularly quiet operation<br />

• Two-stage compressing power unit for pressures up to 15 bar<br />

• Idling and speed regulation<br />

• V-belt drive<br />

• Low speed of rotation<br />

• Large ventilator flywheel for optimal cooling<br />

• Large compressed air aftercooler for reduced moisture inthe compressed air<br />

• Vessel with composite inner coating (zinc-phosphate and plastic)<br />

• 15-year rust guarantee on all vessels<br />

Speed<br />

(min-1 )<br />

Tank vol.<br />

(l)<br />

Weight<br />

(kg)<br />

Noise<br />

(dB(A)) 1)<br />

Oil quantity<br />

(l)<br />

Dimensions<br />

(W xDxH)<br />

33<br />

1|Generating compressed air

34<br />

Mobile air system<br />

The mobile air system for<br />

professional businesses<br />

Easy handling and maximum operating convenience provided<br />

by clearly arranged operating panel with readily accessible<br />

connexions and controls<br />

Optimal working results and operation with outlet for unoiled<br />

compressed air and outlet for oiled compressed air via<br />

quick-release couplings<br />

Optimal maintenance for along service life with standard<br />

operating hours counter for assured compliance with all<br />

service intervals<br />

Easy to connect electrical devices due to two integrated<br />

230-V connections<br />

No danger of injury from thrashing hoses thanks to quickrelease<br />

safety couplings that decouple only when bled<br />

(depressurised)<br />

Good manoeuvrability and secure,stable position during<br />

operation due to ergonomically positioned travel/steering<br />

handle and two large wheels and swivel castors<br />

Tools always at the ready due to Systainer-sized, non-slip<br />

rubber storage surfaces<br />

Extremely quiet in operation due to all-round panelling with<br />

special noise insulation that reduces compressor operating<br />

noise to as low as 69 dB*<br />

No maintenance effort and no additional disposal costs with<br />

automatic drainage of condensate from vessel and<br />

filter-water separator incl. subsequent automatic evaporation<br />

No TÜV inspection required due to optimised vessel size<br />

*Measured in accordance with DIN 45635 T13<br />

Indoor guideline (as for stationary compressors)

Compressors, mobile<br />

Mobile Air System MAS<br />

Type Art. no.<br />

Pressure<br />

(bar)<br />

Common features<br />

• Mobile compressed air system for<br />

professional businesses<br />

• Piston compressor with proven V-belt drive<br />

and vertical vessel<br />

• Motor with 2cylinders, layout designed for<br />

particularly quiet operation<br />

• 3 KW version with single-stage compressor<br />

and 4KWversion with two-stage compressing<br />

power unit<br />

• The low speed of rotation and springmounted<br />

power unit reduce vibrations and<br />

preserve the compressor components<br />

• Additional compressed air aftercooler for<br />

reduced moisture inthe compressed air<br />

• Large ventilator for optimal cooling<br />

• Standard features include: all safety fittings<br />

and electric connection cable with Cekon<br />

connector and phase inverter<br />

• Fully automatic operation due to pressure<br />

switch with start-up relief, motor protection<br />

and ON/OFF switch<br />

• 15-year rust guarantee on the vessel. Inner<br />

coating provides effective protection<br />

• Frame with 2large wheels and 2guide rollers<br />

with parking brakes<br />

• Standard features include water separator<br />

with filter (with float valve for automatic<br />

condensate drainage), mist oiler, 2pressure<br />

gauges for vessel and working pressure, 2<br />

safety quick-action couplings ½“, operating<br />

hour meter, 2x230 Vpower outlets, 2cables<br />

(230 and 400 V) each 5minlength<br />

Suction<br />

capacity<br />

(l/min)<br />

Filling<br />

capacity<br />

(l/min)<br />

Drive power<br />

(kW)<br />

• All tools and materials are stored in the direct<br />

vicinity of the work place close at hand. No<br />

more time wasted searching for what you<br />

need<br />

• Operating elements are all within easy reach<br />

and display elements are easy to read, largely<br />

excluding the possibility of operational errors<br />

• Users can arrange and extend the machine<br />

according to the layout of their work place<br />

and their personal requirements<br />

• Operating the compressed air system in the<br />

workshop is aviable option because of the<br />

low level of noise generated. No additional<br />

soundproofing measures required<br />

• Automatic Condensate Extractor (ACE):<br />

Time-consuming condensate drainage is no<br />

longer required due to the automatic condensate<br />

drain. Full vessel capacity available at<br />

all times. The automatic evaporator saves on<br />

disposal costs<br />

• Silent versions with automatic belt tensioning<br />

function require minimal maintenance<br />

MAS 500-10-60 D A888005 10 500 390 3,0 400 1240 60 136 75 730x850x1140<br />

MAS 500-10-60 D-Silent A888007 10 500 390 3,0 400 1240 60 142 69 730x850x1140<br />

MAS 650-10-90 D A888008 10 650 520 4,0 400 950 90 175 75 730x935x1260<br />

MAS 575-15-60 D A888009 15 575 460 4,0 400 850 60 172 75 730x935x1260<br />

MAS 650-10-90 D-Silent A888010 10 650 520 4,0 400 950 90 183 69 730x935x1260<br />

Voltage<br />

(V)<br />

Speed<br />

(min-1 )<br />

Tank vol.<br />

(l)<br />

Weight<br />

(kg)<br />

Noise<br />

(dB(A))<br />

Dimensions<br />

(W xDxH)<br />

35<br />

1|Generating compressed air

1|Generating compressed air<br />

Compressors, mobile<br />

36<br />

MAS modules<br />

Accessory modules for the Mobile Air System<br />

MAS-Panel<br />

• Perforated rear wall panel for maximum organisation at the work place<br />

• With fastening hooks<br />

• Time savings, everything is close at hand<br />

• Height 350 mm<br />

• With mounting hardware<br />

MAS-Store<br />

• Tool holder with storage space for compressed air tools, accessories and consumable material for<br />

maximum organisation at the work place<br />

• Time savings, everything is close at hand<br />

• With 3quick-release couplings and 4partitions<br />

MAS-Tank<br />

• Easy to install auxiliary vessel, can be retrofitted if compressed air requirements change<br />

• Machines fitted with an additional vessel are exempt from compressed air inspections. The type<br />

test specified in the Ordinance on Industrial Safety and Health §17ANstipulates that an inspection<br />

by aqualified person (technical expert) is sufficient<br />

• Vessel with inner coating for along service life<br />

• 15-year rust guarantee on all vessels<br />

• With safety valve and pressure gauge as standard<br />

• Volume 60 l<br />

• Dimensions (W xDxH): 385 x410 x1000 mm<br />

• Weight 20 kg<br />

• 11 bar<br />

MAS-Dryer<br />

• Compressed air conditioned in line with the application, even on mobile units<br />

• Easy to install cold dryer as an immediate expansion level or retrofit for ahigher degree of air<br />

quality<br />

• Volume flow (at pressure dew point +3°C) 400 l/min<br />

• Power input 0.27 kW<br />

• Dimensions (W xDxH): 315 x410 x745 mm<br />

• Weight 34 kg<br />

MAS-Hose rewinder<br />

• No more dangerous obstacles or tangled hoses on the floor with the additional hose retractor<br />

• PUR compressed air hose with woven fabric inlay<br />

• Inner dia. 8mm<br />

• Extendable length: 9+1m<br />

Type Art. no.<br />

MAS-Panel B060000<br />

MAS-Store B060001<br />

MAS-Tank H110610<br />

MAS-Dryer H611000<br />

MAS-Hose rewinder B312511

Screw or piston compressor?<br />

Or both?<br />

Determining the requirements<br />

When analysing the amount of compressed air you need, several parameters<br />

must be considered. Of course, the compressed air consumers are the first<br />

variable that represent acertain basic requirement. Beyond that, however, the<br />

pressure level, line losses and buffer quantities must be taken into account.<br />

The required compressed air quality is classified as another important<br />

component of the requirements analysis (including properties such as<br />

moisture, oil content, particles etc.).<br />

The system components<br />

For compressing the air, awide variety of compressors are available. The<br />

positive displacement compressors include two main principles: piston<br />

compressors and screw compressors.<br />

One of the most important features of piston compressors is intermittent<br />

operation. This means that their duty cycle should not exceed 70 percent an<br />

hour.<br />

Screw compressors, onthe other hand, are the marathon runners among<br />

compressors. They perform best for continuous air requirements. Continuous<br />

switching cycles diminish their service life, as they cause the necessary<br />

operating temperature tobenot reached or not maintained —condensate<br />

forms in the oil circuit. The consequences are increased wear and shorter<br />

maintenance intervals.<br />

In most cases, the compressed air system requirement in trades and industry<br />

consists of abase load and apeak load. Here, both compressor systems can<br />

be combined ideally. The screw compressor covers the base load, and the<br />

piston compressor covers the peak load.<br />

Project engineering, installation and maintenance of com-<br />

pressed air systems<br />

Acompressed air system is ahighly complex system. Factors such as<br />

available space, room temperature, air intake and exhaust, ambient conditions,<br />

accessibility for maintenance work, and noise development should also<br />