BrushCAST® Copper Beryllium Casting Alloys - Materion

BrushCAST® Copper Beryllium Casting Alloys - Materion

BrushCAST® Copper Beryllium Casting Alloys - Materion

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

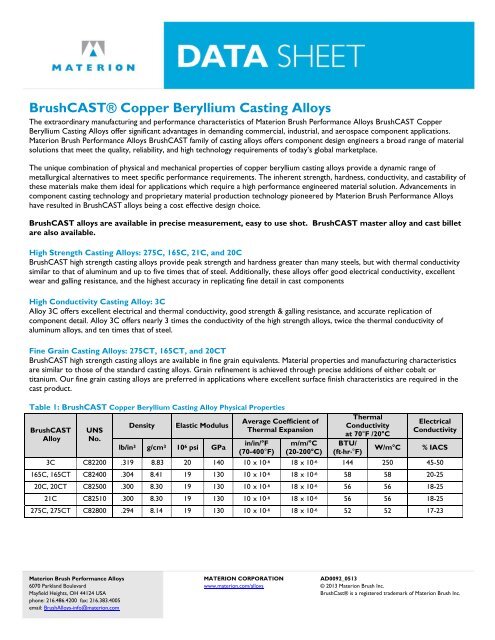

BrushCAST® <strong>Copper</strong> <strong>Beryllium</strong> <strong>Casting</strong> <strong>Alloys</strong>The extraordinary manufacturing and performance characteristics of <strong>Materion</strong> Brush Performance <strong>Alloys</strong> BrushCAST <strong>Copper</strong><strong>Beryllium</strong> <strong>Casting</strong> <strong>Alloys</strong> offer significant advantages in demanding commercial, industrial, and aerospace component applications.<strong>Materion</strong> Brush Performance <strong>Alloys</strong> BrushCAST family of casting alloys offers component design engineers a broad range of materialsolutions that meet the quality, reliability, and high technology requirements of today’s global marketplace.The unique combination of physical and mechanical properties of copper beryllium casting alloys provide a dynamic range ofmetallurgical alternatives to meet specific performance requirements. The inherent strength, hardness, conductivity, and castability ofthese materials make them ideal for applications which require a high performance engineered material solution. Advancements incomponent casting technology and proprietary material production technology pioneered by <strong>Materion</strong> Brush Performance <strong>Alloys</strong>have resulted in BrushCAST alloys being a cost effective design choice.BrushCAST alloys are available in precise measurement, easy to use shot. BrushCAST master alloy and cast billetare also available.High Strength <strong>Casting</strong> <strong>Alloys</strong>: 275C, 165C, 21C, and 20CBrushCAST high strength casting alloys provide peak strength and hardness greater than many steels, but with thermal conductivitysimilar to that of aluminum and up to five times that of steel. Additionally, these alloys offer good electrical conductivity, excellentwear and galling resistance, and the highest accuracy in replicating fine detail in cast componentsHigh Conductivity <strong>Casting</strong> Alloy: 3CAlloy 3C offers excellent electrical and thermal conductivity, good strength & galling resistance, and accurate replication ofcomponent detail. Alloy 3C offers nearly 3 times the conductivity of the high strength alloys, twice the thermal conductivity ofaluminum alloys, and ten times that of steel.Fine Grain <strong>Casting</strong> <strong>Alloys</strong>: 275CT, 165CT, and 20CTBrushCAST high strength casting alloys are available in fine grain equivalents. Material properties and manufacturing characteristicsare similar to those of the standard casting alloys. Grain refinement is achieved through precise additions of either cobalt ortitanium. Our fine grain casting alloys are preferred in applications where excellent surface finish characteristics are required in thecast product.Table 1: BrushCAST <strong>Copper</strong> <strong>Beryllium</strong> <strong>Casting</strong> Alloy Physical PropertiesBrushCASTAlloyUNSNo.DensityElastic Moduluslb/in 3 g/cm 3 10 6 psi GPaAverage Coefficient ofThermal Expansionin/in/°F(70-400°F)m/m/°C(20-200°C)ThermalConductivityat 70°F /20°CBTU/W/m°C(ft•hr•°F)ElectricalConductivity% IACS3C C82200 .319 8.83 20 140 10 x 10 -6 18 x 10 -6 144 250 45-50165C, 165CT C82400 .304 8.41 19 130 10 x 10 -6 18 x 10 -6 58 58 20-2520C, 20CT C82500 .300 8.30 19 130 10 x 10 -6 18 x 10 -6 56 56 18-2521C C82510 .300 8.30 19 130 10 x 10 -6 18 x 10 -6 56 56 18-25275C, 275CT C82800 .294 8.14 19 130 10 x 10 -6 18 x 10 -6 52 52 17-23<strong>Materion</strong> Brush Performance <strong>Alloys</strong> MATERION CORPORATION AD0092_05136070 Parkland Boulevard www.materion.com/alloys © 2013 <strong>Materion</strong> Brush Inc.Mayfield Heights, OH 44124 USABrushCast® is a registered trademark of <strong>Materion</strong> Brush Inc.phone: 216.486.4200 fax: 216.383.4005email: Brush<strong>Alloys</strong>-info@materion.com

Table 2: BrushCAST <strong>Copper</strong> <strong>Beryllium</strong> <strong>Casting</strong> Alloy Mechanical PropertiesBrushCASTAlloy3C165C, 165CT20C, 20CT,21C275C, 275CTTemperAs CastAs Cast & AgedSolution Annealed & AgedAs CastAs Cast & AgedSolution Annealed & AgedAs CastAs Cast & AgedSolution Annealed & AgedAs CastAs Cast & AgedSolution Annealed & AgedYield Strength(0.2% Offset)Tensile Strength(ksi) (MPa) (ksi) (MPa)25-45 170-240 55-60 380-41040-55 280-380 60-75 410-52070-80 480-550 90-100 620-69035-4065-75135-14540-5070-75120-15050-6060-70165-180240-280450-520930-1000280-345480-520830-1030345-410410-4801140-124070-7595-105145-15575-85100-105150-17585-9095-105180-195655-720450-5201000-1070520-590690-7201030-1210590-620655-7201240-1340Elongation(percent)15-2510-205-1020-2510-202-415-3010-201-35-2510-150.5-3RockwellHardnessB55-65B75-90B92-100B74-82C20-24C34-39B80-85C20-24C38-43B80-90C20-25C43-47Safe Handling of BrushCAST <strong>Copper</strong> <strong>Beryllium</strong> <strong>Alloys</strong>Handling BrushCAST copper beryllium alloys in solid form poses no special health risk. Like many industrial materials, berylliumcontainingmaterials may pose a health risk if recommended safe handling practices are not followed. Inhalation of airborne berylliummay cause a serious lung disorder in susceptible individuals. The Occupational Safety and Health Administration (OSHA) has setmandatory limits on occupational respiratory exposures. Read and follow the guidance in the Material Safety Data Sheet (MSDS)before working with this material. For additional information on safe handling practices or technical data on BrushCAST contact<strong>Materion</strong> Brush Performance <strong>Alloys</strong> Customer Technical Service Department at 800-375-4205.RELATED INFORMATIONAdditional technical (melting, casting, heat treating, etc.) or safe handling information on BrushCast <strong>Alloys</strong> may be obtained byphoning 800-375-4205. For pricing and availability, phone 800-521-8800, or the local sales number listed on the bottom of this page.North American Service Centers – Sales InquiriesFor bar, tube, plate/sheet >0.060” (1.5 mm) thickand rod >0.5” (12.7 mm) diameter:Warren, MITOLL FREE: 800-521-8800LOCAL: +(1) 586-772-2700FAX: +(1) 586-772-2472International Sales OfficesCHINA/HONG KONGTEL: + (852) 2318-1960 / 1907brushalloysHK-info@materion.comCHINA/SHANGHAITEL: + (86) 21-5237-2328brushalloysCN-info@materion.comGERMANYTEL: + (49) 711-830-930brushalloysDE-info@materion.comJAPANTEL: + (81) 33 230 2961brushalloysJP-info@materion.comREPUBLIC OF KOREATEL: + (82) 32-811-2171brushalloysKR-info@materion.comSINGAPORE/ASEANTEL: + (65) 6842-4456brushalloysSG-info@materion.comTAIWAN, R.O.C.TEL: + (886) 2-2747-8800 x-121brushalloysTW-info@materion.comUNITED KINGDOM & IRELANDTEL: + (44) 118-930-3733brushalloysUK-info@materion.comTo obtain a complete list of our global Distributor/Agent network, visit us online at www.materion.com/Brush<strong>Alloys</strong>/ContactUs<strong>Materion</strong> Brush Performance <strong>Alloys</strong> MATERION CORPORATION AD0092_05136070 Parkland Boulevard www.materion.com/alloys © 2013 <strong>Materion</strong> Brush Inc.Mayfield Heights, OH 44124 USABrushCast® is a registered trademark of <strong>Materion</strong> Brush Inc.phone: 216.486.4200 fax: 216.383.4005email: Brush<strong>Alloys</strong>-info@materion.com