Above Ground magazine - Goldcorp

Above Ground magazine - Goldcorp

Above Ground magazine - Goldcorp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FORGING FUTURES>“It’s a celebration of our diversity as well as the cooperative spirit between theCree, the French, local communities and <strong>Goldcorp</strong>. We keep it informal, fun and for thepeople. It’s their day – no serious work talk or lectures. Employees get off work early toenjoy family activities, contests and food in a festive setting where friendships are forged,similarities are shared and kinship develops.”Daniel Guay, Human Resources Coordinator, Éléonore projectA very touching moment occurred when <strong>Goldcorp</strong> executives unveileda commemorative tribute to the Cree Nation of Wemindji’s legacy. SaysBelleau, “Michael was really touched, especially since it was placed asa monument at the old camp, which is close to where he was born. Hebecame teary-eyed and was so obviously grateful.”The mood was lightened later when both Mayappo and Belleau took tothe stage to address the attendees. As Chief Mark recalls, “We have abig hockey culture here like so much of Canada. And Michael and Guyhave a running rivalry – one is a fan of the Boston Bruins and the otherthe Montréal Canadiens (Habs). Michael told me that he was going towear his Bruins jersey and make fun of Guy for having to wear a shirtand tie. But after Michael’s speech, Guy came out to join him wearing aHabs uniform. It was a very funny moment.”Chief aimsAs head of the Cree Nation of Wemindji and spokesperson of the GrandCouncil of the Cree, which sets the vision for economic development,health, education and essential progress, Chief Mark collaborates with<strong>Goldcorp</strong> to optimize sustainable training, employment and businesspotential on behalf of his people. The ultimate goal is a balance betweenretaining identity and embracing opportunity.Chief Mark looks forward to mixing with people and sharing customs onCultural Day every year. The diversity of people working at Éléonore hasbecome more multicultural every year, reflecting the French, the Cree,trappers, loggers and miners – people who have survived the agesand the climate, and adapted to conditions. So I hope one day it will becalled “Multicultural Day” to encompass the humanity of us all.”“I also look forward to even more community members attending in thefuture, and that will happen naturally as more local people are employedwhen mine operations actually begin.”For Chief Mark, the highlight of this annual celebration is the traditionalfeast. “I love the food. I leave the moose- and goose-calling contests tothe others,” he says. “Last fall, I tried calling a moose and it still hasn’tshown up.”Notable NuggetsA “Tallyman” is the caretakerof a traditional territory andthe traplines of that region.People must receive permissionto hunt, fish and mine on theTallyman’s land. Tallymenare informally called “beaverbosses” by the Cree.And the winners are...Moose calling 2010Goose calling 2010Fishing derby 2010Benoît GermainTrent Georgekish-MarkHugo Deschênes////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// aboveGROUND issue 02 p5

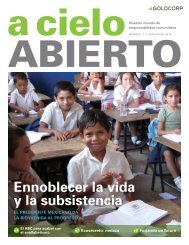

a world of goodHuasco Valley, Chile – It’s like the arrivalof the new kid in town who looks a littledifferent, wears unfamiliar clothes and talkswith an accent. Reactions are mixed – somelocals are curious while others take thedefensive. Everyone is waiting to see whatthe stranger will do.The scenario is similar when <strong>Goldcorp</strong>arrives in a new country and region. So agreat deal of homework is done to gainan understanding of the local customs,history, perspectives, environment, lives andlivelihoods, and what hopes and aspirationsthe community shares.From the moment <strong>Goldcorp</strong> arrives, themission is to meet face-to-face with peopleto learn what they need, want and expect.Sometimes it’s visible on the surface. Othertimes it takes a little digging.When <strong>Goldcorp</strong> acquired the El Morro projectin the Atacama Desert region of the ChileanAndes in early 2010, the former owners hadmade inroads, but significant work remainedto be done. Barry Olson, Senior Vice Presidentof Project Development, says, “It was likewe were handed a box of parts and pieces.Some of them were familiar, others weren’t,and no assembly instructions were included.Yet from this we had to build mutual trustand strong relationships.”So he and his Community Relations teamhit the ground running, visiting cities, towns,government officials and local leaders,and going door to door to introduce theCompany, inviting people to open houses andencouraging community input. It’s a unique,two-way approach the Chileans have dubbed“codiseños” – Spanish for “co-designing” –which gives everyone a hand in shapingfuture progress.Olson says, “When a corporation comes inand says, ‘we’re planning to build in the area,’people feel strongly. Some immediatelythink of jobs and opportunities, others areskeptical. We want to hear from all of themand answer questions directly,” says Olson.A member of Olson’s team, who can fieldqueries from the heart, is Frank Sanchez,El Morro’s Manager of Project Developmentand a veteran of mining life and culture.“I speak to people from my experience asa peer, colleague and employer. I was bornand raised in mining communities – my fatherwas a smelter worker – so I understand thedifferent perspectives of indigenous people aswell as workers. I recall how my neighboursand my family felt, and I draw from that. I’vealso worked with many other companies andI know <strong>Goldcorp</strong> is refreshingly different inboth attitude and action.”////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// aboveGROUND issue 02 p11

a world of goodThe person in charge of ensuring that the <strong>Goldcorp</strong>standard of corporate citizenship and mutualprosperity informs every aspect of the processis Valerie Pascale, Director of Corporate SocialResponsibility (CSR) at El Morro. She helped create<strong>Goldcorp</strong>’s CSR policy and now puts it into practiceat the grass roots level.“We work to put plans in place that will sustainfuture generations. It’s not enough to just build aschool, stock it with books and walk away. We workin partnership with governments, Non-GovernmentalOrganizations, and local communities to ensure thatdevelopment plans and projects are sustainableover the long term. When various groups takejoint responsibility for maintaining and supporting aproject, it is more effective for ongoing function andsuccess. Our goal is to benefit the most people forthe longest time possible.”Once the <strong>Goldcorp</strong> team collects feedback oncommunity needs and priorities, action is swift.The El Morro team has already worked with a localcommunity to build a much-desired library and islaunching a water monitoring program to gaugeand maintain water quality and environmentalhealth. Locals also expressed concern over preciousfresh water supplies in the desert, so <strong>Goldcorp</strong> hascommitted to pumping and desalinating sea water formine usage (see Water Works feature story).At this early stage, 30 jobs have already been created,with projections for as many as 5,000 during theconstruction phase and 2,000 permanent positionsonce operations ramp up.For Sanchez, the best part is still to come. “I realizepeople fear the unknown, but I also know that miningboosts local economies and provides employment,and the infrastructure we build becomes publicamenities and conveniences that jump-start others.As roads are built, little stands and businessespop up. People learn to drive. Wages increaseopportunities for families. This will happen hereover the next few years to enhance lives.”Pascale has enjoyed supporting the local CSR teamat El Morro. “We are working together to develop aworld-class project, using international best practices,open dialogue and transparency.”Notable NuggetsA “green field” mining projectlike El Morro is one that has noexisting infrastructure – accessroads, power lines, water andseptic systems must all be built.“Brown field” means there is asmall operation already in placeor facilities nearby.><strong>Goldcorp</strong>’s Corporate Social Responsibility workshops are a series of sessionsdemonstrating how to live and apply the Company’s CSR valuesin the field. Employees can choose any aspect of operations and presentcreative ideas for improvement.p12 aboveGROUND issue 02 ///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Special Feature1. Water sampling at Marlin mine1Water WorksInnovative water initiatives are just a drop in thebucket of <strong>Goldcorp</strong>’s worldwide commitment toenvironmental and sustainable practices.We’re making significant advances in the waythe mining industry sources, utilizes, recycles,treats and tests this precious global resource.Cerro Blanco, Guatemala – When the CerroBlanco team found themselves in hot water atthe project in southwestern Guatemala, theyknew just what to do: use it as a source ofpower to accomplish sustainable good.Located in the famous Ring of Fire volcanicregion, this mine is a classic hot springs golddeposit, which creates both problems andpositive potential.Underground excavation and construction isextremely hot, with temperatures around 80°C.State-of-the-art ventilation systems are requiredto keep conditions safely cool for workers.However, these sweltering conditions enablethe mine to self-produce electricity.Geothermal energy has been used by Romansand Native Americans for thousands of years,but today’s environmental focus has renewedinterest in producing heat and electricity bydigging deep wells and pumping the hotunderground water or steam to the surface.Geothermal power plants have a smallerenvironmental footprint than other power plantsand the energy is clean, reliable and renewable.Studies into Cerro Blanco’s capabilities forgeothermal power generation were conductedin 2008. And according to Christian Roldan,General Manager of Cerro Blanco, by theend of 2010, “four production wells willenable generation of 15 MW of electricity forunderground cooling. A power plant is slatedfor construction next year with expansion to a50 MW capacity.”The two basic methods for creating geothermalelectricity are a flash technique, which emitswater vapour into the environment, and a binaryprocess, which produces zero emissions.<strong>Goldcorp</strong> uses the latter, explains Roldan.“Underground water is pumped up into a heatexchanger to create vapours that produceenough pressure to drive a turbine, which spinsto generate electricity. After vaporization, thewater goes back underground so we can repeatthe process sustainably.”Geothermal plants are intensive in construction,requiring about 250 contractors, mostly locals,as Guatemala progresses to become a worldleader in geothermal energy. The countryoperates several plants and is expert atdesigning highly efficient power generation.Notable Nuggets“Hydrothermal” (water [hydro] + heat[thermal]) energy is also called “geothermal”(earth + heat). The first power plant wasbuilt in 1904 in Larderello, Italy, and is still inoperation today.////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// aboveGROUND issue 02 p13

and Ministry of Energy and Mines (MEM) also perform randominspections and sampling.Lab results from all tests conducted by AMAC, MEM and MARN remainconsistent with the mine’s own data and show no negative impactrelated to Marlin operations.<strong>Goldcorp</strong> meticulously monitors water consumption. The process plantrequires fresh water, but most of this is recycled, and, every year,<strong>Goldcorp</strong> strives to increase the percentage of recycled water anddecrease fresh water use.Marlin, Guatemala – Situated in two sub-watersheds, whichultimately drain into the Gulf of Mexico, Marlin mine is committed toenvironmental stewardship.<strong>Goldcorp</strong>’s monitoring program here entails measurement of ambientair quality, ambient noise levels, forest cover, ground water elevationand quality, surface water quantity and quality, and terrestrial biology(whatever is not in the water). Independent specialists also conductaquatic biology surveys twice a year in both dry and rainy seasons,collecting data on fish, macro invertebrates and habitats.In the mine’s open pit area, stringent sediment controls, like drainagesystems, diversion ditches and sump pumps, prevent watershed impact.<strong>Goldcorp</strong> tests ground water and surface water at both upstream anddownstream points to ensure early indication of any water qualityproblems resulting from mining. To date, all water quality data indicatesthat the environmental management plans are all functioning as expected.The Water Treatment Plant (WTP) at Marlin was designed to guaranteecompliance with all Guatemalan and World Bank standards andguidelines. The WTP operates as needed, using oxidation, clarification,and filtration to achieve these standards. The treated water caneither be piped back to the tailings impoundment for recycled use,or be discharged to the environment after the water quality has beenverified. A second WTP was installed in 2010 to optimize treatmentand recycling capabilities.Efficiency rates at Marlin are an impressive 89%, which means 89% ofall water consumed is recycled back into operations. The same tailingswater is treated and reused over and over. Better yet, <strong>Goldcorp</strong> believes itcan achieve higher levels of conservation and is looking to improve wateruse efficiency to recover more water and continue to increase the waterrecycling rate to even higher than 89%.This diligence is confirmed externally by the Asociación de MonitoreoAmbiental Comunitario (AMAC), an independent community groupthat conducts environmental checks with the assistance of third-partyexperts, including a civil engineer/geologist and chemist from theFaculty of Engineering at the University of San Carlos in Guatemala.AMAC samples water around the mine, along river drainage basins andat well sites, sending samples to an independent lab for testing. TheGuatemalan Ministry of Environment and Natural Resources (MARN)El Morro, Chile – High in the Andes,<strong>Goldcorp</strong>’s El Morro mine overlooks the ruggedAtacama Desert, dotted with goat and cattlefarms, rare pockets of vegetation and the hardycommunities of the Huasco Valley. Rainfallis scarce here – averaging less than 0.004inches per year – so just as gold resources areprecious, fresh water is too. Despite mountainsnowfall and glaciers, more water is lostthrough evaporation than is gained.Hence <strong>Goldcorp</strong>’s quest for alternate sources,and there, directly west, lay the Pacific Ocean.The answer was as clear as brine.Explains Lisa Wade, Director of Environment,“We decided the best option would be tobuild a deep-sea water plant on the coast andpump desalinated ocean water 200 kilometresto the mine so as not to impact the farmersand the region’s groundwater levels.”Led by Senior Vice President of ProjectDevelopment Barry Olson, <strong>Goldcorp</strong> isembarking on this major initiative to build apumping plant miles away at sea level,install and operate complex salt-extractionequipment and processes, and build extensivepipelines to move the water through the valleyand 4,000 metres up the mountain. “Thisproject will be expensive and labour intensive,but it’s the right thing to do,” says Olson.Wade says that <strong>Goldcorp</strong> will implementrevolutionary technology that decreasesthe impact on marine life. “The pumps arespecially engineered with several smallerintake points with less intense suction so asnot to harm vulnerable sea creatures. Ourunderstanding is that even shrimp and smallaquatic life will be able to swim by withoutgetting drawn in.”The intent is to reduce operational impactabove ground as well, says Olson. “We willneed a lengthy network of piping to transportthe water from the coast up to the mine site.But we have to build roads up the mountainanyway, so we will design the pipe systemalong the roadway. It’s the cost of doingenvironmentally sound business.”p14 aboveGROUND issue 02 ///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Red Lake, Canada – The Cochenour mine is lessthan eight kilometres from <strong>Goldcorp</strong>’s Red Lakemine, the largest gold mine in Canada and therichest in the world. When <strong>Goldcorp</strong> acquired theCochenour property in the late 90s, one of thefirst priorities was to address how the water wasbeing treated.To filter out solids, sludge and other potentialcontaminants from tailings water, an advancedbiological treatment plant was built. It proved tobe highly efficient through spring and summer,but come winter, it was evident that the extremehot and cold of Canadian seasons dramaticallychanged the water chemistry throughout theyear, resulting in inconsistency. It was a time- andcost-consuming setback.“We essentially had to change direction,” saysDavid Gelderland, Environmental Manager atRed Lake. “We were still probably several yearsaway from effectively having a proven biologicaltreatment facility.”Back at the drawing board, <strong>Goldcorp</strong> investigatedseveral state-of-the-art technologies before pilottesting a sand-ballasted flocculation and clarificationprocess. In plain words, this system uses sand asa bottom weight while solids are suspended andclotted in the water for easy removal. The sand iscleaned and re-injected after every cycle.The trials were a success, eliminating solidsand contaminants while clarifying water beyond<strong>Goldcorp</strong>’s objectives and exceeding environmentalrequirements. So, once again, <strong>Goldcorp</strong> overhauledthe tailings facility and installed two of thesesystems for optimal treatment capacity andrecycling capabilities.An added bonus is the equipment’s small footprint –the units are five to 20 times smaller than normalyet work at rapid speed and top efficiency. “Webuilt the entire treatment plant in half of theexisting building,” says Gelderland. The spaceremaining allowed for the addition of a new contacttank for pre-conditioning water before it enters theclarification process.This enhancement refined the procedure to suchan impressive extent that two of the same systemsare in the works for the Red Lake mine.Best of all, today, water is treated so thoroughly itconsistently meets all regulations and is given thegreen light to be released back into the environment.Special FeatureWharf, United States –<strong>Goldcorp</strong>’s South Dakotaoperations are award-winningin the areas of water andenvironmental stewardship.No less than seven mountainstreams orginate in, or passthrough, the property, soaggressive monitoring programsare routine practice. These includeair quality, water quality, aquatichabitats and wildlife.The aptly named Ron Waterland,Wharf Environmental Manager,says that over 40 surface andgroundwater locations aresampled on a regular basis. “Wemeasure stream bed and riverbankparameters and conduct detailedsurveys on fish, benthic (insects)and periphyton (microscopicplants). We also monitor pH levelsduring low flow.”All data is compared to previousmeasurements and crossreferencedwith results fromindependent consultants who alsoperform additional checks on theaquatic health of the rivers.Inside operations are equallythorough. The sophisticatedtreatment plant clarifies water tomeet or exceed state requirementsand has been certified as safe fordirect release into Annie Creek,a cold water trout fishery.For these and many otherindustry-leading initiatives,Waterland and his team receiveda prestigious award for Excellencein Maintaining Surface Water,recognizing the mine’s excellencein protecting water quality, aquaticlife and habitats.////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// aboveGROUND issue 02 p15

SECOND NATUREA Community AbuzzShania Twain’s hometown is a hive of activity as <strong>Goldcorp</strong> does a clean sweep –enriching habitat, raising honeybees and creating trails.In the 100-year-old city of Timmins, Ontario (the “City with a Heartof Gold”), resides another centenarian – <strong>Goldcorp</strong>’s Porcupine GoldMines (PGM). Since its discovery in 1910, PGM is North America’slongest continually operating gold mine – a testament to the mineralrichness of this region.Hence the allure to companies over the century – some digging inthen ducking out, others going bankrupt and too many leaving unsafelands behind. Over 20 abandoned mines blighted the PGM site fordecades, until <strong>Goldcorp</strong> acquired the complex in 2006 and committed toresurrecting the lands as wildlife habitats, nature trails, green fields andeven a new and improved sliding hill.“We are not just here to take the resources and not give back,” saysDave Bucar, Strategic Development Manager for PGM. “In the pastthree years, we’ve spent upwards of $24 million just on reclamation ofproperties that we may never mine again... but it’s our duty to go in andclean these up.”PGM Environmental Manager László Götz agrees. “We don’t operate theway the old mining companies used to, which is to pack up and leavesites as is. We’ve committed to extensive rehabilitation across the city.”The first of these major projects was the historical Coniaurum mine, whichnow features a bee-keeping operation and habitat creation. The workcontinues today with major reclamation of the old Hollinger tailings andmine site.p16 aboveGROUND issue 02 ///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SECOND NATUREIn a letter to the local newspaper, Timmins resident William Litchfieldexpressed thanks on behalf of his community and praised <strong>Goldcorp</strong> as acorporate citizen that cares. “The Company... is making a genuine effortto remove any blights inherited from properties that have been closedfor years... and the effects of <strong>Goldcorp</strong>’s aims and objectives will befelt for generations to come.”The pros & ConiaurumLatin for “constant gold”, Coniaurum was mined for decades and thenabandoned in 1961, long before <strong>Goldcorp</strong> came on the scene. Butas part of the Porcupine portfolio, Coniaurum was the first site to bereclaimed, serving as a learning ground for projects to come.Götz says his team made a list of environmental and public priorities,and then formulated a plan to eliminate metallic seepage into thePorcupine River. “Coniaurum looked like a mini Grand Canyon, posingpublic danger to four-wheelers and cyclists who frequented the area.”“We blasted bedrock, contoured the site by piling tailings to createslopes and valleys, and constructed storm drains. We also partneredwith AbitibiBowater Pulp & Paper Co. to recycle wood-fibre waste andput it to good use as topcover for vegetation.”Today, the site features hills, trees, wildflowers and fields supportingthousands of species – completely different from the barren landscapeit was a few years ago, says Götz. “We invited the elders of the nearbyFirst Nations to view the site, and one woman got very excited and said‘There are medicinal plants growing here that I have not seen since Iwas a little girl.’ Once the growth is more mature, we will create trailshere for walkers and hikers to enjoy.”Winner of the 2008 Nova Award for outstanding reclamation,Coniaurum remains an off-road favourite of local outdoor enthusiasts.The site is safer, but there are snags, says Bucar. “This is a large landmass, much of which is open and inviting to four-wheelers. Wood-fibrebiomass is mucky and spongy for the first few years, making it easyto get stuck. We can’t patrol 24/7, so sometimes riders are mired for awhile before we arrive to help them out.”This is just another community service courtesy of <strong>Goldcorp</strong>.////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// aboveGROUND issue 02 p17

SECOND NATURE>“A big part of being sustainable is continuing to learn.The other part is to use what we have learned to ensure a better future for all.”Chris Cormier, General Manager, Porcupine Gold MinesThe bees kneesTo diversify the Coniaurum ecosystemfurther, PGM and the Porcupine WatchfulEye, a community group partnering with<strong>Goldcorp</strong> to create positive change,resurrected a bee program originally initiatedten years ago at another old PGM site.The goal then was to enhance the area’splants and flowers through pollination. Nowthere is another critical aim – replenish thedwindling bee population across North America.A decade ago, the first colony got off to a great start, but never reachedfruition because bears got in, destroyed the hives and ate the honey.This time around, an eco-friendly, solar-panelled electric fence waserected. A local beekeeper supplied hives, equipment and the knowhowto run the operation.Months later, says Bucar, “We harvested over 50 pounds of premiumhoney in time for PGM’s 100th anniversary. We called it “Liquid Gold”and had it pasteurized and bottled by Ivyridge Honey Farm in Consecon,Ontario. The yield filled 96 jars which needed labels, so we held a staffcontest for design ideas. The winner was Rod Turnbull, whose wife is aPGM exploration geologist.”The other big winner is the Coniaurum habitat. Götz explains, “Theeffect of the bees was a huge diversification in the ecosystem in justone year. We proved that we could successfully return these lands tonature and enhance the bee population for environmental sustainability.”To benefit other wildlife, Porcupine Watchful Eye and PGM starteda duckbox program to create a seasonal habitat. Local high schoolstudents built nesting boxes and placed them in wetland areas adjacentto Coniaurum.To benefit creatures and citizens alike, a batbox program is also in place.Again, students built roosts to boost the number of these friendly flierswho eat millions of mosquitoes – now that’s a great “batting” average.Eco-tobogganingBucar remembers the sliding hill in Timmins as a heap of winter fun.At the turn of the century, mining technology was basic at best, socompanies simply piled tailings into the nearest valley. Over the years,the heap grew and when snow covered the mound, children descended.But in spring, summer and fall, residents complained that the hill was aneyesore. The remaining metallic content was rusting, turning it an uglyorange colour, and nothing grew on or around the mound. <strong>Goldcorp</strong>’sconcern was the environmental impact – without vegetation, the hillwould continue to erode and could pose safety hazards.“So while we were reclaiming the areas around here, <strong>Goldcorp</strong> offeredto clean and revegetate the hill for the city and the residents,” saysGötz. “We scraped it clean, covered it with organic soil and planted it,and now it’s a nicely sloped grassy spot that complements the adjacentGillies Lake Recreational Area.”Bucar adds, “Being able to create a safe and fun family attraction inthe city far outweighs the cost involved for <strong>Goldcorp</strong>. It’s a positiveinvestment in the community.”Happy Hollinger trailsSimilar to the success of Coniaurum, a project of greater magnitude isHollinger... Once again PGM will turn deserted and neglected land into alush, green, productive habitat. – William Russell, Chairman, PorcupineWatchful EyeAn underground operation from 1910 to 1968, Hollinger mine’s tailingsarea was a complex clean-up, but a priority for <strong>Goldcorp</strong> because the sitespans the headwaters of the town creek, which flows through Timmins.Götz says, “When we were characterizing all the old Porcupineproperties, we saw here that the surface rocks had turned into craterslike the surface of the moon. The earth was badly damaged. But welearned a lot from Coniaurum, so we knew what we could do.”The tailings area had to be contoured to promote proper drainagefrom the property, but first, the overlying acidic tailings were scrapeddown to bedrock and relocated to a containment area to preventongoing seepage into the environment. Acidic residue was coveredwith lime – a precaution proven in previous reclamation projects.p18 aboveGROUND issue 02 ///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SECOND NATURE1. Coniaurum Reclamation1PGM also rerouted the hiking and biking trails that run from the hospitalto Hersey Lake to ensure safety during construction. To thoroughlyclean the area, the whole downstream area was dug up, hundreds ofthousands of tonnes of tailings were moved out, and clean earth wasmoved back in to allow for revegetation.Bucar says that <strong>Goldcorp</strong> also extended trail sections and enhanced theentire network as a result of community feedback. “We held severalmeetings and an open house and, based on that input, we incorporatedmore emphasis on safety and conservation with well-marked pathwaysand interpretive signposts.”In total, <strong>Goldcorp</strong> spent nearly $9 million last year alone rehabilitatingformer mine sites to create clean and safe city recreational areas.Shania toursMining tours have always been popular in this gold-rich area and whilethe focus used to be open pit activities and heavy-duty equipment,today there is growing interest in environmental stewardship.Bucar says, “People have always seen the front end of our operations.Now we also showcase the backyard we’ve created. Groups can seethe before and after and visit various sites which demonstrate all thestages of our ongoing projects.”fans. Last year, the famous singer’s followers represented fan clubsfrom the US, Sweden, Denmark and other European nations, all curiousto learn about the superstar’s hometown.Another tour group was curious about the biomass PGM uses to jumpstartgrowth, says Götz. “Several scientists visited and were scepticalabout the realism of the lush landscape. They said it looked like sci-fiterrain. I had to explain that the wood-fibre topping we spread is sonutrient rich that, for the first few years, the vegetation is ultra verdantbut eventually fades once all the nutrients are absorbed.”The scientists departed, green with envy.Notable NuggetsTailings are crushed rock residue left over from the process ofextracting gold from ore.Porcupine Gold Mines sponsored the creation of a book calledVeins of Gold by author Karen Bachmann to commemorate the100th anniversary of Timmins.Götz conducts guided tours of rehabilitated mine sites for groups ofschool students, technical professionals, engineers and Shania Twain>“ We don’t operate the way the old mining companies used to, which is to pack upand leave sites as is. We’ve committed to extensive rehabilitationacross the city.”László Götz, Environmental Manager, Porcupine Gold Mines////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// aboveGROUND issue 02 p19

in your element1. Mary Boyden, Aboriginal Affairs Manager, with Chief Walter Naveau of the MattagamiFirst Nation and László Götz2. Employees of Porcupine Gold Mines2From Underground to<strong>Above</strong> <strong>Ground</strong>Meet Mary – a future-changer and trailblazer.The day of our interview, Mary Boyden cancels due to anunfortunate encounter with a moose on the road. She’s fine,but her truck is not.When we reconnect, I learn that Boyden, Aboriginal Affairs Managerfor <strong>Goldcorp</strong>’s Porcupine Gold Mines near Timmins, Ontario, is aptlychosen for this role and embraces it with gusto.1With both industry experience and Native roots, Boyden is in herelement. “Growing up in the city, I was disconnected from myAboriginal culture. Living rurally, I know how people can feel cutoff from mainstream society. All of this helps me do my job.”Boyden cultivates partnerships and mutual goals with and betweenthe Cree, Ojibwe and Algonquin communities around Porcupine GoldMines. “I collaborate with our neighbours, help them connect witheach other to become stronger, and leverage the ways that <strong>Goldcorp</strong>can help create economic independence and develop transferable skills,especially for the youth who are our future. Everybody benefits.”She also supports a new movement called “cultural reclamation”. Justas <strong>Goldcorp</strong> is committed to site reclamation instead of leaving landsbarren like others did in the past, First Nations are turning the tide onformer times when they were told to forget their culture and move on.“Elders seek to reclaim their lost identity and legacy. I’m helping themfind ways of merging traditional practices with new mining science andtechnology to create the best of both worlds.”Aboriginal by birth, Boyden was born and raised in Toronto. Aftermarrying, she moved to Elliot Lake for her husband’s mining job.Although a young mother, she remained intent on building a careeroutside the home, but the only course open at the local college wasmine ventilation technician training. Undaunted, she earned hercredentials and, when the family moved to Timmins, she became thefirst woman to work underground at the mine.Boyden later joined the faculty of Northern College. Giving a studenta ride home to an Aboriginal community one day, she met the locals,began reconnecting with her heritage and took on a new job as theMining Initiatives Development Officer for the Wahgoshig First Nations.That role primed Boyden for her <strong>Goldcorp</strong> position.Until then, small steps can be giant strides. Says Boyden, “We visited achief who hoped to start a youth program to instill pride in First Nationsland and history. So László Götz, Porcupine Environmental Manager,arranged for <strong>Goldcorp</strong> to buy ten canoes, paddles and life vests, whichwe donated for eco-adventures. The Chief was ecstatic.”As the interview ends, I ask the fate of the stricken moose. Boydenwas leaving a First Nations town when the collision happened, andshe rushed back and found a man to put the animal out of its misery.“Afterwards, he told me his grandmother had recently died and hisfamily had yet to host the community feast in her honour. He lookedat the moose, looked at me and then I got it. So, in the end, I helped afamily fulfill a traditional rite and the poor moose did not die in vain.”p20 aboveGROUND issue 02 ///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Our World of Community ResponsibilityContact us at aboveground@goldcorp.comFor more information on <strong>Goldcorp</strong>’s responsible mining initiatives around the globe, visit:www.goldcorp.com/corporate_responsibility