Chemical Resistance of Garlock Compressed Sheet & GYLON

Chemical Resistance of Garlock Compressed Sheet & GYLON

Chemical Resistance of Garlock Compressed Sheet & GYLON

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

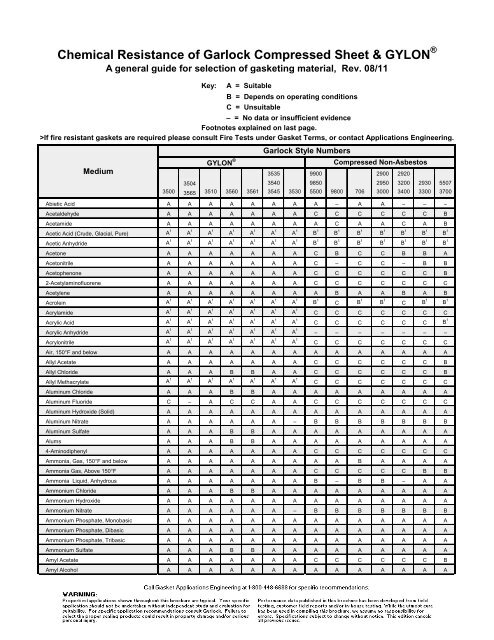

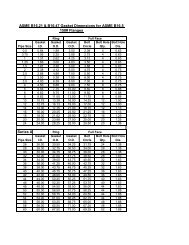

<strong>Chemical</strong> <strong>Resistance</strong> <strong>of</strong> <strong>Garlock</strong> <strong>Compressed</strong> <strong>Sheet</strong> & <strong>GYLON</strong> ®A general guide for selection <strong>of</strong> gasketing material, Rev. 08/11Key: A = SuitableB = Depends on operating conditionsC = Unsuitable– = No data or insufficient evidenceFootnotes explained on last page.>If fire resistant gaskets are required please consult Fire Tests under Gasket Terms, or contact Applications Engineering.Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Abietic Acid A A A A A A A A – A A – – –Acetaldehyde A A A A A A A C C C C C C BAcetamide A A A A A A A A C A A C A BAcetic Acid (Crude, Glacial, Pure) A 1 A 1 A 1 A 1 A 1 A 1 A 1 B 1 B 1 B 1 B 1 B 1 B 1 B 1Acetic Anhydride A 1 A 1 A 1 A 1 A 1 A 1 A 1 B 1 B 1 B 1 B 1 B 1 B 1 B 1Acetone A A A A A A A C B C C B B AAcetonitrile A A A A A A A C – C C – B BAcetophenone A A A A A A A C C C C C C B2-Acetylamin<strong>of</strong>luorene A A A A A A A C C C C C C CAcetylene A A A A A A A A B A A B A BAcrolein A 1 A 1 A 1 A 1 A 1 A 1 A 1 B 1 C B 1 B 1 C B 1 B 1Acrylamide A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CAcrylic Acid A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C B 1Acrylic Anhydride A 1 A 1 A 1 A 1 A 1 A 1 A 1 – – – – – – –Acrylonitrile A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CAir, 150°F and below A A A A A A A A A A A A A AAllyl Acetate A A A A A A A C C C C C C BAllyl Chloride A A A B B A A C C C C C C BAllyl Methacrylate A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CAluminum Chloride A A A B B A A A A A A A A AAluminum Fluoride C – A C C A A C C C C C C CAluminum Hydroxide (Solid) A A A A A A A A A A A A A AAluminum Nitrate A A A A A A – B B B B B B BAluminum Sulfate A A A B B A A A A A A A A AAlums A A A B B A A A A A A A A A4-Aminodiphenyl A A A A A A A C C C C C C CAmmonia, Gas, 150°F and below A A A A A A A A A B A A A AAmmonia Gas, Above 150°F A A A A A A A C C C C C B BAmmonia Liquid, Anhydrous A A A A A A A B – B B – A AAmmonium Chloride A A A B B A A A A A A A A AAmmonium Hydroxide A A A A A A A A A A A A A AAmmonium Nitrate A A A A A A – B B B B B B BAmmonium Phosphate, Monobasic A A A A A A A A A A A A A AAmmonium Phosphate, Dibasic A A A A A A A A A A A A A AAmmonium Phosphate, Tribasic A A A A A A A A A A A A A AAmmonium Sulfate A A A B B A A A A A A A A AAmyl Acetate A A A A A A A C C C C C C BAmyl Alcohol A A A A A A A A A A A A A A

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Aniline, Aniline Oil A A A A A A A C C C C C C BAniline Dyes A A A A A A A C B C C B B Bo-Anisidine A A A A A A A C C C C C C CAqua Regia A A A B B A C C C C C C C CAroclors A A A A A A A C C C C C C CAsphalt A A A A A A A A C A A C B CAviation Gasoline A A A A A A A B C B B C B CBarium Chloride A A A B B A A A A A A A A ABarium Hydroxide A A A A A A A A A A A A A ABarium Sulfide A A A A A A A A A A A A A ABaygon A A A A A A A C C C C C – –Beer 10 A A A A A A A A A A A A A ABenzaldehyde A A A A A A A C C C C C C BBenzene, Benzol A A A A A A A C C C C C C CBenzidine A A A A A A A C C C C C C –Benzoic Acid A A A A A A A B B B B B B BBenzonitrile A A A A A A A C – C C – – CBenzotrichloride A A A C C A A C C C C C C CBenzoyl Chloride A A A – – A A C – C C – C CBenzyl Alcohol A A A A A A A C – C C – B BBenzyl Chloride A A A – – A A C C C C C C BBio-diesel (B100) A A A A A A A A A A A A - -Biphenyl A A A B B A A C C C C C C CBis(2-chloroethyl)ether A A A – – A A C C C C C C CBis(chloromethyl)ether A A A – – A A C C C C C C BBis(2-ethylhexyl)phthalate A A A A A A A C C C C C C BBlack Sulfate Liquor C B A C A A A C C C C C C CBlast Furnace Gas A A A A A A A B C B B C B CBleach (Sodium Hyprochlorite) A A A B B A – C – C C – C CBoiler Feed Water A A A A A A A A A A A A A ABorax A A A A A A A A A A A A A ABoric Acid A A A A A A A A A A A A A ABrine (Sodium Chloride) A A A B B A A A A A A A A ABromine A A A C C A – C C C C C C CBromine Trifluoride C C C C C C C C C C C C C CBrom<strong>of</strong>orm A A A A A A A C C C C C C CBromomethane A A A A A A A C C C C C C CButadiene A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C – CButane A A A A A A A A C B A C B C2-Butanone A A A A A A A C C C C C C CButyl Acetate A A A A A A A C C C C C C BButyl Alcohol, Butanol A A A A A A A A A A A A A An-Butyl Amine A A A A A A A B – B B – C Btert-Butyl Amine A A A A A A A B – B B – C BButyl Methacrylate A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CButyric Acid A A A A A A A A A A A A A ACalcium Bisulfite A A A A A A A B – B B – B CCalcium Chloride A A A B B A A A A A A A A A

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Calcium Cyanamide A A A A A A A B B B B B B BCalcium Hydroxide – A A – A A A A A A A A A ACalcium Hypochlorite A A A B B A – B B B C C C C 2Calcium Nitrate A A A – – A C – – – – – – –Calflo AF A A A A A A A A C A A C – CCalflo FG A A A A A A A A C A A C – CCalflo HTF A A A A A A A A C A A C – CCalflo LT A A A A A A A A C A A C – CCane Sugar Liquors A A A A A A A A A A A A A ACaprolactam A A A A A A A C C C C C C BCaptan A A A A A A A C C C C C C CCarbaryl A A A A A A A C C C C C C CCarbolic Acid, Phenol A A A A A A A C C C C C C BCarbon Dioxide, Dry A A A A A A A A A A A A A ACarbon Dioxide, Wet A A A A A A A A A A A A A ACarbon Disulfide A A A A A A A C C C C C C CCarbon Monoxide A A A A A A A B B B B B B BCarbon Tetrachloride A A A B B A A C C C C C C CCarbonic Acid A A A A A A A A A A A A A ACarbonyl Sulfide A A A – – A A C C C C C C CCastor Oil A A A A A A A A C A A C B BCatechol A A A A A A A C B C C B – –Caustic Soda C B A 6 C A 6 A 11 A 6 C C C C C C CCetane (Hexadecane) A A A A A A A A C A A C B CChina Wood Oil A A A A A A A A C A A C B CChloramben A A A – – A A C C C C C C CChlorazotic Acid (Aqua Regia) A A A B B A C C C C C C C CChlordane A A A – – A A C C C C C C CChlorinated Solvents, Dry A A A A A A A C C C C C C CChlorinated Solvents, Wet A A A C C A A C C C C C C CChlorine, Dry A A A A A A A – – – – – – –Chlorine, Wet A A A C C A A C C C C C C CChlorine Dioxide A A A – – A C C C C C C C CChlorine Trifluoride C C C C C C C C C C C C C CChloroacetic Acid A A A C C A A C B C C B C B2-Chloroacetophenone A A A B B A A C C C C C C CChloroazotic Acid (Aqua Regia) A A A B B A C C C C C C C CChlorobenzene A A A A A A A C C C C C C CChlorobenzilate A A A – – A A C C C C C C CChloroethane A A A A A A A C C C C C C CChloroethylene A A A A A A A C C C C C C CChlor<strong>of</strong>orm A A A A A A A C C C C C C CChloromethyl Methyl Ether A A A – – A A C C C C C C CChloronitrous Acid (Aqua Regia) A A A B B A C C C C C C C CChloroprene A A A B B A A C C C C C C CChlorosulfonic Acid A A A – – A – C C C C C C CChrome Plating Solutions – 5 – 5 A – 5 B A A C C C C C C CChromic Acid A A A B B A C C C C C C C C

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Chromic Anhydride A A A B B A C C C C C C C CChromium Trioxide A A A B B A C C C C C C C CCitric Acid A A A A A A A A A A A A A ACoke Oven Gas A A A A A A A C C C C C C CCopper Chloride A A A C C A A A A A A A A ACopper Sulfate A A A A A A A A A A A A A ACorn Oil 10 A A A A A A A A C A A C B BCotton Seed Oil 10 A A A A A A A A C A A C B BCreosote A A A A A A A B C B B C B CCresols, Cresylic Acid A A A A A A A C C C C C C CCrotonic Acid A A A – – A A C C C C C C CCrude Oil A A A B B A A A B A A B B CCumene A A A A A A A C C C C C C CCyclohexane A A A A A A A A C A A C B CCyclohexanone A A A A A A A C C C C C C B2,4-D, Salts and Esters A A A – – A A C C C C C C CDetergent Solutions B 13 B 13 A A A A A B 13 B 13 B 13 B 13 B 13 B 13 B 13Diazomethane A A A A A A A – – – – – – –Dibenz<strong>of</strong>uran A A A A A A A C C C C C C CDibenzylether A A A A A A A C C C C C C C1,2-Dibromo-3-chloropropane A A A B B A A C C C C C C CDibromoethane A A A A A A A C C C C C C CDibutyl Phthalate A A A A A A A C C C C C C BDibutyl Sebacate A A A A A A A C C C C C C Bo-Dichlorobenzene A A A A A A A C C C C C C C1,4-Dichlorobenzene A A A A A A A C C C C C C C3,3-Dichlorobenzidene A A A – – A A C C C C C C CDichloroethane (1,1 or 1,2) A A A A A A A C C C C C C C1,1-Dichloroethylene A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CDichloroethyl Ether A A A – – A A C C C C C C CDichloromethane A A A A A A A C C C C C C C1,2-Dichloropropane A A A A A A A C C C C C C C1,3-Dichloropropene A A A B B A A C C C C C C CDichlorvos A A A B B A A C C C C C C CDiesel Oil A A A A A A A A B A A B B CDiethanolamine A A A A A A A B B B B B B BN,N-Diethylaniline A A A – – A A C C C C C C CDiethyl Carbonate A A A – – A A C – C C – C –Diethyl Sulfate A A A A A A A C C C C C – C3,3-Dimethoxybenzidene A A A A A A A C C C C C – –Dimethylaminoazobenzene A A A A A A A – – – – – – –N,N-Dimethyl Aniline A A A – – A A C C C C C C C3,3-Dimethylbenzidine A A A A A A A C C C C C C CDimethyl Carbamoyl Chloride A A A C C A A C C C C C C CDimethyl Ether A A A A A A A B C B B C B BDimethylformamide A A A – – A A C C C C C C CDimethyl Hydrazine, Unsymmetrical A A A A A A A C B C C B B BDimethyl Phthalate A A A A A A A C C C C C C B

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Dimethyl Sulfate A A A A A A A C C C C C – C4,6-Dinitro-o-Cresol and Salts A A A A A A A C C C C C C C2,4-Dinitrophenol A A A – – A A C C C C C C C2,4-Dinitrotoluene A A A A A A A C C C C C C CDioxane A A A A A A A C C C C C C B1,2-Diphenylhydrazine A A A A A A A C B C C B – –Diphyl DT A A A A A A A C C C C C C CDowfrost A A A A A A A B B B B B – BDowfrost HD A A A A A A A B B B B B – BDowtherm 4000 A A A A A A A B B B B B B BDowtherm A A A A A A A A C C C C C C CDowtherm E A A A A A A A C C C C C C CDowtherm G A A A A A A A C C C C C C CDowtherm HT A A A A A A A C C C C C C CDowtherm J A A A A A A A C C C C C C CDowtherm Q A A A A A A A C C C C C C CDowtherm SR-1 A A A A A A A B B B B B B BEpichlorohydrin A A A A A A A C C C C C C BE85 (85% Ethanol, 15% Gas) A A A A A A A A A A A A - -1,2-Epoxybutane A A A A A A A – C – – C C CEthane A A A A A A A A B B A B B CEthanol, Ethyl Alcohol 10 A A A A A A A A A A A A A AEthers A A A A A A A B C B B C B BEthyl Acetate A A A A A A A C C C C C C CEthyl Acrylate A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C B 1Ethyl Alcohol 10 A A A A A A A A A A A A A AEthylbenzene A A A A A A A C C C C C C CEthyl Carbamate A A A A A A A C C C C C B BEthyl Cellulose A A A A A A A A A A A A A AEthyl Chloride A A A A A A A C C C C C C CEthyl Ether A A A A A A A B C B B C B BEthyl Hexoate A A A A A A A C – C C – – BEthylene A A A A A A A A B B A B B CEthylene Bromide A A A A A A A C C C C C C CEthylene Dibromide A A A A A A A C C C C C C CEthylene Dichloride A A A A A A A C C C C C C CEthylene Glycol A A A A A A A A A A A A A AEthyleneimine – – A – – A A C C C C C C CEthylene Oxide A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CEthylene Thiourea A A A A A A A – – – – – C CEthylidine Chloride A A A A A A A C C C C C C CFerric Chloride A A A C C A A A A A B B B B 4Ferric Phosphate A A A – – A A B B B B B B BFerric Sulfate A A A B B A A A A A A A A AFluorine, Gas - - - - - A 14 C C C C C C C CFluorine, Liquid - - - C C - C C C C C C C CFluorine Dioxide C C C C C C C C C C C C C CFormaldehyde A 1 A 1 A 1 A 1 A 1 A 1 A 1 A 1 B 1 A 1 A 1 B 1 B 1 A 1

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Formic Acid A A A B B A A C – C C – B BFuel Oil A A A A A A A A B A A B B CFuel Oil, Acid A A A A A A A A B A A B B CFurfural A A A A A A A C C C C C B BGasoline, Refined A A A A A A A A C A A B B CGasoline, Sour A A A A A A A A C A A B B CGelatin A A A A A A A A A A A A A AGlucose A A A A A A A A A A A A A AGlue, Protein Base A A A A A A A A A A A A A AGlycerine, Glycerol A A A A A A A A A A A A A AGlycol A A A A A A A A A A A A A AGrain Alcohol 10 A A A A A A A A A A A A A AGrease, Petroleum Base A A A A A A A A C A A C – CGreen Sulfate Liquor C B A – A A A C C C C C C CHeptachlor A A A – – A A C C C C C C CHeptane A A A A A A A A C A A C B CHexachlorobenzene A A A A A A A C C C C C C CHexachlorobutadiene A A A A A A A C C C C C C CHexachlorocyclopentadiene A A A A A A A C C C C C C CHexachloroethane A A A – – A A C C C C C C CHexadecane A A A A A A A A C A A C B CHexamethylene Diisocyanate A A A A A A A – C – – C – CHexamethylphosphoramide A A A A A A A – C – – C – –Hexane A A A A A A A A C A A C B CHexone A A A A A A A C C C C C C BHydraulic Oil, Mineral A A A A A A A A B A A B B CHydraulic Oil, Synthetic (Phosphate Esters) A A A A A A A C C C C C C BHydrazine A A A A A A A C B C C B B BHydrobromic Acid A A A C C A A C C C C C C CHydrochloric Acid A A A C C A A C C C C C C CHydrocyanic Acid A A A A A A A A B A A B B AHydr<strong>of</strong>luoric Acid, Anhydrous C C C C C A A C C C C C C CHF Acid, Less than 65%, Above 150°F C C A C C A A C C C C C C CHF Acid, 65% to Anhydrous,Above 150°F C C – C C A A C C C C C C CHF Acid, Up to Anhydrous,150°F & below C C A C C A A C C C C C C CHydr<strong>of</strong>luorosilicic Acid C C A C C A A C C C C C C CHydr<strong>of</strong>luosilicic Acid C C A C C A A C C C C C C CHydrogen A A A A A A A A A B A A A AHydrogen Bromide A A A – – A A C C C C C C CHydrogen Fluoride C C C C C A A C C C C C C CHydrogen Peroxide, 10% A A A A A A A B B B B B B BHydrogen Peroxide, 10-90% A A A B B A C B – B B – C BHydrogen Sulfide, Dry or Wet A A A A A A A B B B B B B BHydroquinone A A A A A A A C B C C B C CIodine Pentafluoride – – – – – – C C C C C C C CIodomethane A A A A A A A C C C C C B –Isobutane A A A A A A A A C B A C B CIsooctane A A A A A A A A C A A C B C

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Isophorone A A A A A A A C C C C C C BIsopropyl Alcohol A A A A A A A A A A A A A AJet Fuels (JP Types) A A A A A A A A C A A C B CKerosene A A A A A A A A C A A C B CLacquer Solvents A A A A A A A C C C C C C CLacquers A A A A A A A C C C C C C CLactic Acid, 150°F and below A A A A A A A A A A A A A ALactic Acid, Above 150°F A A A A A A A – – – – – – –Lime Saltpeter (Calcium Nitrates) A A A – – A C B B B B B B BLindane A A A B B A A C C C C C C CLinseed Oil A A A A A A A A B A A B A BLiquified Petroleum Gas (LPG) A A A A A A A A B C A B B CLithium Bromide A A A A A A A A – A A – A ALithium, Elemental C C C C C C C C C C C C C CLubricating Oils, Refined A A A A A A A A B A A B B CLubricating Oils, Mineral or Petroleum Types A A A A A A A A B A A B B CLubricating Oils, Sour A A A A A A A B B B B B B CLye C B A 6 C A 6 A 11 A 6 C C C C C C CMagnesium Chloride A A A B B A A A A A A A A AMagnesium Hydroxide A A A A A A A B B B B B B BMagnesium Sulfate A A A A A A A A A A A A A AMaleic Acid A A A A A A A B B B B B B AMaleic Anhydride A A A A A A A C – C C – C CMercuric Chloride A A A C C A A A A A A A B AMercury A A A A A A A A A A A A A AMethane A A A A A A A A B B A C B CMethanol, Methyl Alcohol A A A A A A A A A A A A A AMethoxychlor A A A A A A A C C C C C C CMethylacrylic Acid A A A – – A A C C C C C C CMethyl Alcohol A A A A A A A A A A A A A A2-Methylaziridine – – A – – A A C C C C C C CMethyl Bromide A A A A A A A C C C C C C CMethyl Chloride A A A B B A A C C C C C C CMethyl Chlor<strong>of</strong>orm A A A A A A A C C C C C C C4,4 Methylene Bis(2-chloroaniline) A A A – – A A C C C C C C CMethylene Chloride A A A A A A A C C C C C C C4,4-Methylene Dianiline A A A A A A A C C C C C C –Methylene Diphenyldiisocyanate A A A – – A A C C C C C C –Methyl Ethyl Ketone A A A A A A A C C C C C C CMethyl Hydrazine A A A A A A A C B C C B B BMethyl Iodide A A A A A A A C C C C C B –Methyl Isobutyl Ketone (MIBK) A A A A A A A C C C C C C BMethyl Isocyanate A A A A A A A – C - – C – –Methyl Methacrylate A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CN-Methyl-2-Pyrrolidone A A A A A A A C B C C B – –Methyl Tert. Butyl Ether (MTBE) A A A A A A A B C B B B C CMilk 10 A A A A A A A A A A A A A AMineral Oils A A A A A A A A B A A B B C

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Mobiltherm 600 A A A A A A A A C A A C – CMobiltherm 603 A A A A A A A A C A A C – CMobiltherm 605 A A A A A A A A C A A C – CMobiltherm Light A A A A A A A C C C C C C CMolten Alkali Metals C C C C C C C C C C C C C CMonomethylamine A A A A A A A C B C C B A BMultiTherm 100 A A A A A A A A C A A C B CMultiTherm 503 A A A A A A A A C A A C – CMultiTherm IG-2 A A A A A A A A C A A C B CMultiTherm PG-1 A A A A A A A A C A A C B CMuriatic Acid A A A C C A A C C C C C C CNaphtha A A A A A A A A C A A C B CNaphthalene A A A A A A A C C C C C C CNaphthols A A A – – A A – – – – – – –Natural Gas A A A A A A A A B B A B B BNickel Chloride A A A B B A A A A A A A A ANickel Sulfate A A A A A A A A A A A A A ANitric Acid, Less than 30% A A A A A A C C C C C C C CNitric Acid, Above 30% A A A A A A C C C C C C C CNitric Acid, Crude A A A – – A C C C C C C C CNitric Acid, Red Fuming A A A B B A C C C C C C C CNitrobenzene A A A A A A A C C C C C C C4-Nitrobiphenyl A A A A A A A C C C C C C C2-Nitro-Butanol A A A – – A – C – C C – C –Nitrocalcite (Calcium Nitrate) A A A – – A C B B B B B B BNitrogen A A A A A A A A A A A A A ANitrogen Tetroxide A A A – – A – C C C C C C CNitrohydrochloric Acid (Aqua Regia) A A A B B A C C C C C C C CNitromethane A A A A A A A C – C C – C –2-Nitro-2-Methyl Propanol A A A – – A – C – C C – C –Nitromuriatic Acid (Aqua Regia) A A A B B A C C C C C C C C4-Nitrophenol A A A – – A A C C C C C C C2-Nitropropane A A A A A A A C – C C – C CN-Nitrosodimethylamine A A A A A A A B B B B B – –N-Nitroso-N-Methylurea A A A – – A A – – – – – – –N-Nitrosomorpholine A A A A A A A C – C C – C –Norge Niter (Calcium Nitrate) A A A – – A C B B B B B B BNorwegian Saltpeter (Calcium Nitrate) A A A – – A C B B B B B B BN-Octadecyl Alcohol A A A A A A A A A A A A – AOctane A A A A A A A A C A A C B COil, Petroleum A A A A A A A A B A A B B COils, Animal and Vegetable 10 A A A A A A A A C A A C B BOleic Acid A A A A A A A B – B B – C COleum A – C C C A – C C C C C C COrthodichlorobenzene A A A A A A A C C C C C C COxalic Acid A A A B B A A C – C C – B BOxygen, Gas See Note 7C C C C C C COzone See Note 7C C C C C C C C

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Palmitic Acid A A A A A A A A B A A B B AParaffin A A A A A A A A B A A B B CParatherm HE A A A A A A A A C A A C B CParatherm NF A A A A A A A A C A A C – CParathion A A A A A A A C C C C C C CParaxylene A A A A A A A C C C C C C CPentachloronitrobenzene A A A – – A A C C C C C C CPentachlorophenol A A A A A A A C C C C C C CPentane A A A A A A A A C A A C B CPerchloric Acid A A A C C A C C C C C C C CPerchloroethylene A A A A A A A C C C C C C CPetroleum Oils, Crude A A A A A A A A B A A B B CPetroleum Oils, Refined A A A A A A A A B A A B B CPhenol A A A A A A A C C C C C C Bp-Phenylenediamine A A A A A A A C C C C C – –Phosgene A A A B B A A C – C C – – BPhosphate Esters A A A A A A A C C C C C C BPhosphine A A A A A A A – – – – – – –Phosphoric Acid, Crude C C A C B A A C C C C C C CPhosphoric Acid, Less than 45% A A A A A A A C C C C C C CPhosphoric Acid, Above 45%, to 150°F B B A B B A A C C C C C C CPhosphoric Acid, Above 45%, Above 150°F C B A C B A A C C C C C – –Phosphorus, Elemental A A A A A A A C C C C C C CPhosphorus Pentachloride A A A B B A A C C C C C C CPhthalic Acid A A A A A A A C – C C – B –Phthalic Anhydride A A A A A A A C – C C – C BPicric Acid, Molten – – – – – – – – – – – – – –Picric Acid, Water Solution A A A A A A A B B B B B B BPinene A A A A A A A A C A A C B CPiperidine A A A A A A A C C C C C C CPolyacrylonitrile A A A A A A A A A A A A A APolychlorinated Biphenyls A A A A A A A C C C C C C CPotash, Potassium Carbonate A A A A A A A A A A A A A APotassium Acetate A A A A A A A A A A A A A APotassium Bichromate A A A A A A C A B A A B B APotassium Chromate, Red A A A A A A C A B A A B B APotassium Cyanide A A A A A A A A A A A A A APotassium Dichromate A A A A A A C A B A A B B APotassium, Elemental C C C C C C C C C C C C C CPotassium Hydroxide C B A 6 C A 6 A 11 A 6 C C C C C C CPotassium Nitrate A A A A A A – B B B B B B BPotassium Permanganate A A A A A A – B – B B – B BPotassium Sulfate A A A A A A A A A A A A A AProducer Gas A A A A A A A A C B A C B CPropane A A A A A A A A C B A C B C1,3-Propane Sultone A A A – – A A – – – – – – –Beta-Propiolactone A A A A A A A C C C C C C BPropionaldehyde A A A A A A A C C C C C – –

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Propoxur (Baygon) A A A A A A A C C C C C – –Propyl Alcohol A A A A A A A A A A A A A APropyl Nitrate A A A A A A A C C C C C C CPropylene A A A A A A A C C C C C C CPropylene Dichloride A A A A A A A C C C C C C CPropylene Glycol A A A A A A A A A A A A - APropylene Oxide A A A A A A A C C C C C C B1,2-Propylenimine – – A – – A A C C C C C C CPrussic Acid, Hydrocyanic Acid A A A A A A A A B A A B B APyridine A A A B B A A C C C C C C BQuinoline A A A B B A A C C C C C C CQuinone A A A A A A – – – – – – – –RefrigerantsSee Specific Ratings BelowR 10 A A A B B A A C C C C C C CR 11 A A A A A A A A C B A C C CR 12 A A A A A A A A A B A A A AR 13 A A A A A A A A A B A A A AR 13B1 A A A A A A A A A B A A A AR 21 A A A A A A A C C C C C A CR 22 A A A A A A A B B B B B A AR 23 A A A A A A A C A C C A A AR 31 A A A A A A A C A C C A A AR 32 A A A A A A A A A B A A A AR 112 A A A A A A A A C B A C A CR 113 A A A A A A A A A B A A A CR 114 A A A A A A A A A B A A A AR 114B2 A A A A A A A A C B A C A CR 115 A A A A A A A A A B A A A AR 123 A A A A A A A C 3 C C 3 C 3 C A 3 CR 124 A A A A A A A C A C C A A AR 125 A A A A A A A – A – – A A AR 134a A A A A A A A B A B B A A AR 141b A A A A A A A A – B A – A –R 142b A A A A A A A A A B A A A AR 143a A A A A A A A – A – – A A AR 152a A A A A A A A A A B A A A AR 218 A A A A A A A A A B A A A AR 290 (Propane) A A A A A A A A C B A C B CR 500 A A A A A A A A – B A – A –R 502 A A A A A A A A A B A A A –R 503 A A A A A A A C A C C A A AR 507 A A A A A A A B - C B - A AR 717 (Ammonia) A A A A A A A B - C B - A AR 744 (Carbon Dioxide) A A A A A A A A A A A A A AC316 A A A A A A A A A B A A A AC318 A A A A A A A A A B A A A AHP62 A A A A A A A A – B A – A –HP80 A A A A A A A – – – – – A –

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700HP81 A A A A A A A – – – – – A –Salt Water A A A B B A A A A A A A A ASaltpeter, Potassium Nitrate A A A A A A – B B B B B B B2,4-D Salts and Esters A A A – – A A C C C C C C CSewage A A A A A A A A B A A B B BSilver Nitrate A A A A A A – B A B B A A ASkydrols A A A A A A A C C C C C C BSoap Solutions A A A A A A A A A A A A A ASoda Ash, Sodium Carbonate A A A A A A A A A A A A A ASodium Bicarbonate, Baking Soda A A A A A A A A A A A A A ASodium Bisulfate (Dry) A A A A A A A A A A A A A ASodium Bisulfite A A A B B A A A A A A A A ASodium Chlorate A A A A A A A C – C C – C CSodium Chloride A A A B B A A A A A A A A ASodium Cyanide C C A C C A A C C C C C C CSodium, Elemental C C C C C C C C C C C C C CSodium Hydroxide C B A 6 C A 6 A 11 A 6 C C C C C C CSodium Hypochlorite A A A B B A – C – C C – C CSodium Metaborate Peroxyhydrate A A A B B A C B B B B B B BSodium Metaphosphate B A A B A A A A A A A A A ASodium Nitrate A A A A A A – B B B B B B BSodium Perborate A A A B B A C B B B B B B BSodium Peroxide A A A A A A C C C C C C C CSodium Phosphate, Monobasic A A A A A A A B B B B B B BSodium Phosphate, Dibasic B B A B A A A B B B B B B BSodium Phosphate, Tribasic C B A C A A A C C C C C C CSodium Silicate B B A B A A A B B B B B B B 4Sodium Sulfate A A A A A A A A A A A A A ASodium Sulfide A A A A A A A A A A A A A ASodium Superoxide A A A A A A C C C C C C C CSodium Thiosulfate, “Hypo” A A A A A A A A A A A A A ASoybean Oil 10 A A A A A A A A C A A C B BStannic Chloride A A A C C A A B B B B B – BSteam, Saturated, to 150 psig 12 A A A A A A A A 12 A 12 A 12 B 9 B 9 B 9 B 9Steam, Superheated – – – – – – – C C A C C C CStearic Acid A A A A A A A A A A A A A AStoddard Solvent A A A A A A A A C A A C B CStyrene A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CStyrene Oxide A A A A A A A C C C C C C CSulfur Chloride A A A C C A A C C C C C C CSulfur Dioxide A A A A A A A C C C C C C BSulfur, Molten A A A A A A A C C C C C B CSulfur Trioxide, Dry A A A A A A – C C C C C C CSulfur Trioxide, Wet A A A B B A B C C C C C C CSulfuric Acid, 10%, 150°F and below A A A B B A – C C C C C C CSulfuric Acid, 10%, Above 150°F A A A C C A – – C – – C C CSulfuric Acid, 10-75%, 500°F and below A A A C C A – – C – – C C CSulfuric Acid, 75-98%, 150°F and below A A B C C A C C C C C C C C

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Sulfuric Acid, 75-98%, 150°F to 500°F A B B C C A C C C C C C C CSulfuric Acid, Fuming A – C C C A C C C C C C C CSulfurous Acid A A A B B A – B B B B B – –Syltherm 800 A A A A A A A B B B B B B BSyltherm XLT A A A A A A A B B B B B B BTannic Acid A A A – 8 – 8 A A A A A A A A ATar A A A A A A A C A A A C B CTartaric Acid A A A A A A A A A A A A A A2,3,7,8-TCDB-p-Dioxin A A A – – A A C C C C C C CTertiary Butyl Amine A A A A A A A B – B B – C BTetrabromoethane A A A A A A A C C C C C C CTetrachlorethane A A A A A A A C C C C C C CTetrachloroethylene A A A A A A A C C C C C C CTetrahydr<strong>of</strong>uran, THF A A A A A A A C C C C C C CTherminol 44 A A A A A A A C C C C C C CTherminol 55 A A A A A A A C C C C C C CTherminol 59 A A A A A A A C C C C C C CTherminol 60 A A A A A A A C C C C C C CTherminol 66 A A A A A A A C C C C C C CTherminol 75 A A A A A A A C C C C C C CTherminol D12 A A A A A A A B C B B C B CTherminol LT A A A A A A A C C C C C C CTherminol VP-1 A A A A A A A C C C C C C CTherminol XP A A A A A A A A C A A C B CThionyl Chloride A A A C C A A C C C C C C CTitanium Sulfate A A A A A A A C C C C C C CTitanium Tetrachloride A A A C C A A B C B C C C CToluene A A A A A A A C C C C C C C2,4-Toluenediamine A A A A A A A – C – – C C C2,4-Toluenediisocyanate A A A – – A A C C C C C C BToluene Sulfonic Acid A A A – – A A C C C C C C Co-Toluidine A A A A A A A C C C C C C CToxaphine A A A – – A A C C C C C C CTransformer Oil (Mineral Type) A A A A A A A A C A A C B CTransmission Fluid A A A A A A A A A C A A C B CTrichloroacetic Acid A A A C C A A C C C C C C C1,2,4- Trichlorobenzene A A A A A A A C C C C C C C1,1,2-Trichloroethane A A A A A A A C C C C C C CTrichloroethylene A A A A A A A C C C C C C C2,4,5-Trichlorophenol A A A – – A A C C C C C C C2,4,6-Trichlorophenol A A A – – A A C C C C C C CTricresylphosphate A A A A A A A C C C C C C BTriethanolamine A A A – – A A B B B B B B BTriethyl Aluminum A A A – – A A C – C C – C –Triethylamine A A A A A A A B B B B B B ATrifluralin A A A A A A A C C C C C C C2,2,4-Trimethylpentane A A A A A A A A C A A C B CTung Oil A A A A A A A A C A A C B C

Medium<strong>GYLON</strong> ®<strong>Garlock</strong> Style Numbers<strong>Compressed</strong> Non-Asbestos3535 9900 2900 29203504 3540 9850 2950 3200 2930 55073500 3565 3510 3560 3561 3545 3530 5500 9800 706 3000 3400 3300 3700Turpentine A A A A A A A A C A A C C CUCON Heat Transfer Fluid 500 A A A A A A A A B A A B B BUCON Process Fluid WS A A A A A A A A B A A B B BUrea, 150ºF and below A A A A A A A B – – B – A AUrea, above 150ºF A A A A A A A – – – – – – –Varnish A A A A A A A B C B B C C CVegetable Oil 10 A A A A A A A A C A A C B BVinegar 10 A A A A A A A B B B B B A AVinyl Acetate A 1 A 1 A 1 A 1 A 1 A 1 A 1 B 1 C B 1 B 1 C B 1 B 1Vinyl Bromide A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CVinyl Chloride A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CVinylidene Chloride A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CVinyl Methacrylate A A A A A A A C C C C C C CWater, Acid Mine, with Oxidizing Salt A A A C C A – B – B B – B –Water, Acid Mine, No Oxidizing Salts A A A A A A A A – A A – B AWater, Distilled A A A A A A A A A A A A A AWater, Return Condensate A A A A A A A A A A A – – AWater, Seawater A A A B B A A A A A A A A AWater, Tap A A A A A A A A A A A A A AWhiskey and Wines 10 A A A A A A A A A A A A A AWood Alcohol A A A A A A A A A A A A A AXceltherm 550 A A A A A A A B C B B C B CXceltherm 600 A A A A A A A A C A A C B CXceltherm MK1 A A A A A A A C C C C C C CXceltyherm XT A A A A A A A C C C C C C CXylene A A A A A A A C C C C C C CZinc Chloride A A A B B A A A A A A A A AZinc Sulfate A A A A A A A A A A A A A AKey: A = Suitable; B = Depends on operating conditions; C = Unsuitable; - = No data or insufficient evidence>If fire resistant gaskets are required please consult Fire Tests under Gasket Terms, or contact Applications Engineering.NOTES:1. Consult the factory regarding your specific applications. See “Monomers”in Gasketing catalog Terms section.2. IFG® Style 5507 is rated “B”.3. There have been conflicting field reports concerning the suitability <strong>of</strong> NBRand neoprene bound gaskets in 123. End users should take note.4. IFG® Style 5507 is rated “A”.5. Some chromium plating baths contain fluorides that can attack silica andsilicate type fillers in some <strong>GYLON</strong>® styles. If the bath is known to containlittle or no fluoride, all <strong>GYLON</strong>® styles should be suitable for use.6. These <strong>GYLON</strong>® styles can be expected to be suitable to 60%concentration at temperatures up to 250°F (121°C).7. Use <strong>GYLON</strong>® styles 3502, 3503, 3505, 3562, 3563. These styles arespecially processed, cleaned and packaged for oxygen service.8. This <strong>GYLON</strong>® contains a stainless steel insert. There is a possibility thatthis might contribute traces <strong>of</strong> iron to form iron tannates, resulting inundesirable color in the tannic acid.9. These styles are not preferred choices for steam service, but aresuccessful when adequately compressed.10. If a gasketing material that conforms to FDA requirements is desired,contact factory for specific recommendations.11. These <strong>GYLON</strong>® gasket styles can be expected to be suitable to 75%concentration at temperatures up to 400°F (204°C).12. Minimum recommended assembly stress = 4,800psi.Preferred assembly stress = 6,000-10,000psi.Gasket thickness <strong>of</strong> 1/16” strongly preferred.For saturated steam above 150psig, consult <strong>Garlock</strong> Engineering.13. Some detergent solutions are strongly alkaline and/or may containbleach. Please contact Applications Engineering.14. Gylon 3545 is suitable for up to 200°F wet or dry fluorine gas. Abovethis please consult Applications Engineering.15. If lead chromate is also present please consult ApplicationsEngineering.15. If lead chromate is present, please contact Applications Engineering.