Polyester Resin Daily VOC Calculator - Air Pollution Control District

Polyester Resin Daily VOC Calculator - Air Pollution Control District

Polyester Resin Daily VOC Calculator - Air Pollution Control District

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

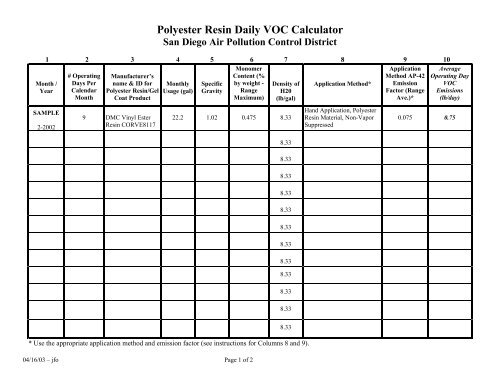

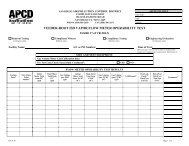

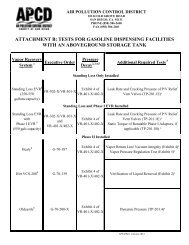

Month /Year<strong>Polyester</strong> <strong>Resin</strong> <strong>Daily</strong> <strong>VOC</strong> <strong>Calculator</strong>San Diego <strong>Air</strong> <strong>Pollution</strong> <strong>Control</strong> <strong>District</strong>1 2 3 4 5 6 7 8 9 10MonomerApplication# Operating Manufacturer’sContent (%Method AP-42Days Per name & ID for Monthly Specific by weight - Density of Application Method* EmissionCalendar <strong>Polyester</strong> <strong>Resin</strong>/Gel Usage (gal) Gravity Range H20Factor (RangeMonth Coat ProductMaximum) (lb/gal)Ave.)*SAMPLE2-20029 DMC Vinyl Ester<strong>Resin</strong> CORVE811722.2 1.02 0.475 8.338.338.338.338.338.33Hand Application, <strong>Polyester</strong><strong>Resin</strong> Material, Non-VaporSuppressedAverageOperating Day<strong>VOC</strong>Emissions(lb/day)0.075 0.758.338.338.338.338.338.33* Use the appropriate application method and emission factor (see instructions for Columns 8 and 9).04/16/03 – jfo Page 1 of 28.33

<strong>Polyester</strong> <strong>Resin</strong> <strong>Daily</strong> <strong>VOC</strong> <strong>Calculator</strong>San Diego <strong>Air</strong> <strong>Pollution</strong> <strong>Control</strong> <strong>District</strong>INSTRUCTIONS FOR COMPLETING FORMThis form will help you track daily <strong>VOC</strong> emissions from the use of polyester resins. <strong>District</strong> Rule 11(d)(13)(vi) exempts from permit requirements polyester resinoperations where <strong>VOC</strong> emissions average less than five pounds per day, averaged over the operating days of a calendar month. In addition, <strong>District</strong> CompliancePolicy No. 3.20 exempts polyester resin operations where <strong>VOC</strong> emissions average less than five pounds per day, averaged over the operating days of a calendarmonth, from the requirements of <strong>District</strong> Rule 67.12.Column 1:Column 2:Column 3:Column 4:Column 5:Column 6:Column 10:Enter the calendar month and calendar yearEnter the number of days during the calendar month thatpolyester resin materials were used.Enter the manufacturer and manufacturer's ID for each polyesterresin material used.Enter the total amount of each polyester resin material usedduring the calendar month in gallons.Enter the specific gravity for each polyester resin material used.This information can usually be found on the material safetydata sheet (MSDS) in the "Physical Properties" section or can beobtained from the manufacturer or supplier.Enter the monomer content for each polyester resin material interms of percent by weight. This may also be found on theMSDS.This is your average daily <strong>VOC</strong> emissions in pounds per day,averaged over the operating days per calendar month.If you are using the Excel Spreadsheet, this will be calculatedautomatically.If you are doing the calculations by hand (using the PDFformat), multiply Columns 4, 5, 6, 7, and 9 together, then divideby Column 2.Columns 8 & 9:Enter the appropriate application method and corresponding emission factor from thelist below:Hand Application, Solvent Material, Clean Up 1.0Hand Application, Gelcoat Material, Non-Vapor Suppressed 0.305Hand Application, Gelcoat Material, Vapor Suppressed 0.165Hand Application, <strong>Polyester</strong> <strong>Resin</strong> Material, Non-Vapor Suppressed 0.075Hand Application, <strong>Polyester</strong> <strong>Resin</strong> Material, Vapor Suppressed 0.045Spray Application, Solvent Material, Clean Up 1.0Spray Application, Gelcoat Material, Non-Vapor Suppressed 0.305Spray Application, Gelcoat Material, Vapor Suppressed 0.165Spray Application, <strong>Polyester</strong> <strong>Resin</strong> Material, Non-Vapor Suppressed 0.11Spray Application, <strong>Polyester</strong> <strong>Resin</strong> Material, Vapor Suppressed 0.06Lamination, Solvent Material, Clean Up 1.0Lamination, <strong>Polyester</strong> <strong>Resin</strong> Material, Non-Vapor Suppressed 0.055Lamination, <strong>Polyester</strong> <strong>Resin</strong> Material, Vapor Suppressed 0.03Pultrusion, Solvent Material, Clean Up 1.0Pultrusion, <strong>Polyester</strong> <strong>Resin</strong> Material, Non-Vapor Suppressed 0.055Pultrusion, <strong>Polyester</strong> <strong>Resin</strong> Material, Vapor Suppressed 0.03Filament Winding, Solvent Material, Clean Up 1.0Filament Winding, <strong>Polyester</strong> <strong>Resin</strong> Material, Non-Vapor Suppressed 0.075Filament Winding, <strong>Polyester</strong> <strong>Resin</strong> Material, Vapor Suppressed 0.045Marble Casting, Solvent Material, Clean Up 1.0Marble Casting, <strong>Polyester</strong> <strong>Resin</strong> Material, Non-Vapor Suppressed 0.02Marble Casting, <strong>Polyester</strong> <strong>Resin</strong> Material, Vapor Suppressed 0.015Closed Mold Casting, Solvent Material, Clean Up 1.0Closed Mold Casting, <strong>Polyester</strong> <strong>Resin</strong> Material, Non-Vapor Suppressed 0.02Closed Mold Casting, <strong>Polyester</strong> <strong>Resin</strong> Material, Vapor Suppressed 0.015Page 2 of 2