flotation tyres

flotation tyres

flotation tyres

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

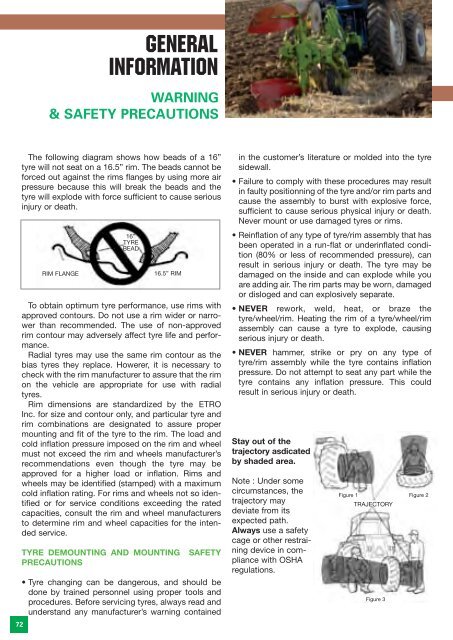

gEnEralinformationWARNING& SAFETY PRECAUTIONS72The following diagram shows how beads of a 16”tyre will not seat on a 16.5” rim. The beads cannot beforced out against the rims flanges by using more airpressure because this will break the beads and thetyre will explode with force sufficient to cause seriousinjury or death.RIM FLANGE16”TYREBEAD16.5” RIMTo obtain optimum tyre performance, use rims withapproved contours. Do not use a rim wider or narrowerthan recommended. The use of non-approvedrim contour may adversely affect tyre life and performance.Radial <strong>tyres</strong> may use the same rim contour as thebias <strong>tyres</strong> they replace. Howerer, it is necessary tocheck with the rim manufacturer to assure that the rimon the vehicle are appropriate for use with radial<strong>tyres</strong>.Rim dimensions are standardized by the ETROInc. for size and contour only, and particular tyre andrim combinations are designated to assure propermounting and fit of the tyre to the rim. The load andcold inflation pressure imposed on the rim and wheelmust not exceed the rim and wheels manufacturer’srecommendations even though the tyre may beapproved for a higher load or inflation. Rims andwheels may be identified (stamped) with a maximumcold inflation rating. For rims and wheels not so identifiedor for service conditions exceeding the ratedcapacities, consult the rim and wheel manufacturersto determine rim and wheel capacities for the intendedservice.TYRE DEMOUNTING AND MOUNTING SAFETYPRECAUTIONS• Tyre changing can be dangerous, and should bedone by trained personnel using proper tools andprocedures. Before servicing <strong>tyres</strong>, always read andunderstand any manufacturer’s warning containedin the customer’s literature or molded into the <strong>tyres</strong>idewall.• Failure to comply with these procedures may resultin faulty positionning of the tyre and/or rim parts andcause the assembly to burst with explosive force,sufficient to cause serious physical injury or death.Never mount or use damaged <strong>tyres</strong> or rims.• Reinflation of any type of tyre/rim assembly that hasbeen operated in a run-flat or underinflated condition(80% or less of recommended pressure), canresult in serious injury or death. The tyre may bedamaged on the inside and can explode while youare adding air. The rim parts may be worn, damagedor disloged and can explosively separate.• NEVER rework, weld, heat, or braze thetyre/wheel/rim. Heating the rim of a tyre/wheel/rimassembly can cause a tyre to explode, causingserious injury or death.• NEVER hammer, strike or pry on any type oftyre/rim assembly while the tyre contains inflationpressure. Do not attempt to seat any part while thetyre contains any inflation pressure. This couldresult in serious injury or death.Stay out of thetrajectory asdicatedby shaded area.Note : Under somecircumstances, thetrajectory maydeviate from itsexpected path.Always use a safetycage or other restrainingdevice in compliancewith OSHAregulations.Figure 1 Figure 2TRAJECTORYFigure 3