flotation tyres

flotation tyres

flotation tyres

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

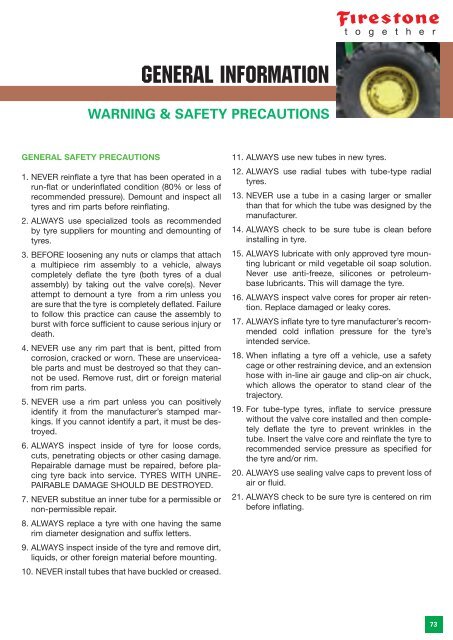

general informationWARNING & SAFETY PRECAUTIONSGENERAL SAFETY PRECAUTIONS1. NEVER reinflate a tyre that has been operated in arun-flat or underinflated condition (80% or less ofrecommended pressure). Demount and inspect all<strong>tyres</strong> and rim parts before reinflating.2. ALWAYS use specialized tools as recommendedby tyre suppliers for mounting and demounting of<strong>tyres</strong>.3. BEFORE loosening any nuts or clamps that attacha multipiece rim assembly to a vehicle, alwayscompletely deflate the tyre (both <strong>tyres</strong> of a dualassembly) by taking out the valve core(s). Neverattempt to demount a tyre from a rim unless youare sure that the tyre is completely deflated. Failureto follow this practice can cause the assembly toburst with force sufficient to cause serious injury ordeath.4. NEVER use any rim part that is bent, pitted fromcorrosion, cracked or worn. These are unserviceableparts and must be destroyed so that they cannotbe used. Remove rust, dirt or foreign materialfrom rim parts.5. NEVER use a rim part unless you can positivelyidentify it from the manufacturer’s stamped markings.If you cannot identify a part, it must be destroyed.6. ALWAYS inspect inside of tyre for loose cords,cuts, penetrating objects or other casing damage.Repairable damage must be repaired, before placingtyre back into service. TYRES WITH UNRE-PAIRABLE DAMAGE SHOULD BE DESTROYED.7. NEVER substitue an inner tube for a permissible ornon-permissible repair.8. ALWAYS replace a tyre with one having the samerim diameter designation and suffix letters.9. ALWAYS inspect inside of the tyre and remove dirt,liquids, or other foreign material before mounting.10. NEVER install tubes that have buckled or creased.11. ALWAYS use new tubes in new <strong>tyres</strong>.12. ALWAYS use radial tubes with tube-type radial<strong>tyres</strong>.13. NEVER use a tube in a casing larger or smallerthan that for which the tube was designed by themanufacturer.14. ALWAYS check to be sure tube is clean beforeinstalling in tyre.15. ALWAYS lubricate with only approved tyre mountinglubricant or mild vegetable oil soap solution.Never use anti-freeze, silicones or petroleumbaselubricants. This will damage the tyre.16. ALWAYS inspect valve cores for proper air retention.Replace damaged or leaky cores.17. ALWAYS inflate tyre to tyre manufacturer’s recommendedcold inflation pressure for the tyre’sintended service.18. When inflating a tyre off a vehicle, use a safetycage or other restraining device, and an extensionhose with in-line air gauge and clip-on air chuck,which allows the operator to stand clear of thetrajectory.19. For tube-type <strong>tyres</strong>, inflate to service pressurewithout the valve core installed and then completelydeflate the tyre to prevent wrinkles in thetube. Insert the valve core and reinflate the tyre torecommended service pressure as specified forthe tyre and/or rim.20. ALWAYS use sealing valve caps to prevent loss ofair or fluid.21. ALWAYS check to be sure tyre is centered on rimbefore inflating.73