Service Manual - internetMED

Service Manual - internetMED

Service Manual - internetMED

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Service</strong> <strong>Manual</strong>

<strong>Service</strong> <strong>Manual</strong>

CapnoLine ® is a U.S. registered trademark of Oridion Medical Ltd.DRYLINE is a trademark of Artema Medical ABDurasensor ® is a U.S. registered trademark of Nellcor Puritan Bennett Inc.Edwards ® is a U.S. registered trademark of Edwards Lifesciences Corp.FilterLine ® is a U.S. registered trademark of Oridion Medical Ltd.LNCS ® is a U.S. registered trademark of Masimo Corp.LNOP ® is a U.S. registered trademark of Masimo Corp.Masimo SET ® is a U.S. registered trademark of Masimo Corp.Max-Fast is a trademark of Nellcor Puritan Bennett Inc.miniMediCO ®2 is a U.S. registered trademark of Oridion Medical Ltd.Microstream ® is a U.S. registered trademark of Oridion Medical Ltd.Navigator is a U.S. trademark of Mindray DS USA, Inc.Nellcor is a U.S. trademark of Nellcor Puritan Bennett Inc.NIV Line is a trademark of Oridion Medical Ltd.Oxiband ® is a U.S. registered trademark of Nellcor Puritan Bennett Inc.OxiMax is a U.S. trademark of Nellcor Puritan Bennett Inc.Oxisensor ® is a U.S. registered trademark of Nellcor Puritan Bennett Inc.Passport V is a U.S. trademark of Mindray DS USA, Inc.Velcro ® is a registered trademark of Velcro Industries B.V.Viewstation OR is a U.S. trademark of Mindray DS USA, Inc.Windows ® is a registered trademark of Microsoft Corp.Copyright © Mindray DS USA, Inc., 2009. All rights reserved. Contents of this publication may not be reproduced in anyform without permission of Mindray DS USA, Inc.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705

Table of ContentsForeword.......................................................................................................................................................vWarnings, Cautions, and Notes .......................................................................................................................vWarnings ......................................................................................................................................................vCautions ........................................................................................................................................................vNotes ............................................................................................................................................................viTheory of Operation ......................................................................................................... 1 - 1Introduction....................................................................................................................................................1 - 1System Connections ........................................................................................................................................1 - 2Mounting the Patient Monitor ....................................................................................................................1 - 2Connectors for Peripheral Devices .............................................................................................................1 - 2Main Unit ......................................................................................................................................................1 - 3Input System ...........................................................................................................................................1 - 4Output System.........................................................................................................................................1 - 4Processing and Communications System.....................................................................................................1 - 6Power Management System ......................................................................................................................1 - 6Equipment Interface System.......................................................................................................................1 - 8Parameter modules ..................................................................................................................................1 - 10Block Diagrams ................................................................................................................ 2 -1Introduction....................................................................................................................................................2 - 1Block Diagram................................................................................................................................................2 - 2Repair Information ........................................................................................................... 3 - 1Introduction....................................................................................................................................................3 - 1Safety Precautions...........................................................................................................................................3 - 1Troubleshooting Guidelines ..............................................................................................................................3 - 2Special Tools Required ....................................................................................................................................3 - 2Disassembly Instructions...................................................................................................................................3 - 2Removal of the Key Panel and Keys ...........................................................................................................3 - 3Removal of the Front Housing Assembly .....................................................................................................3 - 4Removal of the Main Board ......................................................................................................................3 - 5Removal of the Inverter.............................................................................................................................3 - 6Removal of the LCD Panel.........................................................................................................................3 - 7Removal of the Keyboard .........................................................................................................................3 - 8Removal of the Alarm LED Board ...............................................................................................................3 - 9Removal of the Encoder............................................................................................................................3 - 9Removal of the Multi-parameter Board Assembly .........................................................................................3 - 10Removal of the Parameter Front Panel Assembly ..........................................................................................3 - 12Removal of the Multi-parameter board........................................................................................................3 - 13Removal of the CO 2 Module.....................................................................................................................3 - 13Removal of the Masimo SpO 2 Module .......................................................................................................3 - 14Removal of the Nellcor SpO 2 Module ........................................................................................................3 - 14Removal of the NIBP Assembly ..................................................................................................................3 - 15Removal of the Recorder Assembly ............................................................................................................3 - 15Removal of the Recorder Cover (if needed) .................................................................................................3 - 16Removal of the Main Frame and Multi-parameter Board Assembly .................................................................3 - 16Removal of the Speaker Assembly .............................................................................................................3 - 17Removal of the Fan Assembly....................................................................................................................3 - 18Removal of the CF Card Assembly .............................................................................................................3 - 19Removal of the Power Board .....................................................................................................................3 - 19Removal of the Li-ion Battery Interface Board Assembly.................................................................................3 - 21Removal of the Interface Board Assembly ...................................................................................................3 - 23Removal of the Wireless AP ......................................................................................................................3 - 25Nurse Call Cable............................................................................................................................................3 - 27Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 i

Table of ContentsP/N 8000-21-10361 ..............................................................................................................................3 - 27Analog Output Cable ......................................................................................................................................3 - 27P/N 6100-20-86360 ..............................................................................................................................3 - 27Defib Synch Cable ..........................................................................................................................................3 - 28P/N 6100-20-86361 ..............................................................................................................................3 - 28Serial Port to Gas Module 3 Cable ...................................................................................................................3 - 29P/N 0012-00-1276-XX ............................................................................................................................3 - 29Null Modem Cable .........................................................................................................................................3 - 30P/N 0012-00-1275-01............................................................................................................................3 - 30Universal ECG Lead Wires ..............................................................................................................................3 - 31P/N 0012-00-1503-XX ............................................................................................................................3 - 31ECG Cable, 3/5-lead (ESIS and Non ESIS)........................................................................................................3 - 32P/N 0012-00-1745-XX ............................................................................................................................3 - 3212-pin 3-lead Neo ECG Trunk Cable (IEC/AHA) ................................................................................................3 - 32P/N 040-000072-00 ..............................................................................................................................3 - 32IBP Cable.......................................................................................................................................................3 - 33P/N 040-000052-00 ..............................................................................................................................3 - 33P/N 040-000053-00 ..............................................................................................................................3 - 33P/N 040-000054-00 ..............................................................................................................................3 - 33P/N 040-000096-00 ..............................................................................................................................3 - 34Temperature Cable .........................................................................................................................................3 - 341.15.1 P/N 040-000055-00 ...................................................................................................................3 - 34P/N 040-000056-00 ..............................................................................................................................3 - 34P/N 040-000057-00 ..............................................................................................................................3 - 35P/N 040-000058-00 ..............................................................................................................................3 - 35P/N 040-000091-00 ..............................................................................................................................3 - 35P/N 040-0000100-00 ............................................................................................................................3 - 36P/N 040-000224-00 ..............................................................................................................................3 - 36Troubleshooting Menus....................................................................................................................................3 - 37ECG Troubleshooting ...............................................................................................................................3 - 37NIBP Troubleshooting...............................................................................................................................3 - 39SpO 2 Troubleshooting..............................................................................................................................3 - 40Temperature Troubleshooting ....................................................................................................................3 - 42Resp Troubleshooting ...............................................................................................................................3 - 43IBP Troubleshooting .................................................................................................................................3 - 44CO 2 Troubleshooting ...............................................................................................................................3 - 45Gas Module Troubleshooting ....................................................................................................................3 - 48Trends Troubleshooting.............................................................................................................................3 - 50Printer/Recorder Troubleshooting ..............................................................................................................3 - 50Monitor/Display Troubleshooting ..............................................................................................................3 - 52Remote View Troubleshooting ...................................................................................................................3 - 52Installation Menu ............................................................................................................................................3 - 53Installation Mode.....................................................................................................................................3 - 53Advanced Installation Setup Menu .............................................................................................................3 - 56Options Menu.........................................................................................................................................3 - 57Trend Storage ................................................................................................................................................3 - 57Software Download ........................................................................................................................................3 - 58Isometric Drawings and Parts List ..................................................................................... 4 - 1Introduction....................................................................................................................................................4 - 1Top Level Assembly .........................................................................................................................................4 - 2Main Unit Assembly ........................................................................................................................................4 - 4Front Housing Sub-assembly.............................................................................................................................4 - 5ii 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Table of ContentsRear Housing Sub-assembly .............................................................................................................................4 - 6Main Chassis Sub-assembly .............................................................................................................................4 - 7Interface Connector PCB Assembly....................................................................................................................4 - 9Parameter Sub-assembly ..................................................................................................................................4 - 10Patient Connector Sub-assembly........................................................................................................................4 - 11NIBP Module Assembly ...................................................................................................................................4 - 12Microstream CO 2 Module Assembly .................................................................................................................4 - 13DPM CO 2 Module Assembly............................................................................................................................4 - 14Masimo SpO 2 PCB Assembly ...........................................................................................................................4 - 15Nellcor SpO 2 Module Assembly .......................................................................................................................4 - 16Calibration Procedure ....................................................................................................... 5 - 1Introduction....................................................................................................................................................5 - 1Warnings and Guidelines................................................................................................................................5 - 1Test Equipment and Special Tools Required........................................................................................................5 - 2<strong>Service</strong>s.........................................................................................................................................................5 - 2ECG Channels Check ..............................................................................................................................5 - 3NIBP Maintenance...................................................................................................................................5 - 4NIBP Accuracy Test .........................................................................................................................5 - 4NIBP Leakage Test ...........................................................................................................................5 - 5NIBP Calibration .............................................................................................................................5 - 5IBP Calibration ........................................................................................................................................5 - 6CO 2 Calibration .....................................................................................................................................5 - 6Gas Calibration ......................................................................................................................................5 - 8Monitor Log ............................................................................................................................................5 - 11Verification ....................................................................................................................................................5 - 12Initial Set-up ............................................................................................................................................5 - 12ECG ......................................................................................................................................................5 - 13Initialization ....................................................................................................................................5 - 13Leads OFF ......................................................................................................................................5 - 13Pacer Detect ...................................................................................................................................5 - 13Performance Test .............................................................................................................................5 - 14IBP 1 and IBP 2 Verification ......................................................................................................................5 - 14Temperature Verification...........................................................................................................................5 - 14SpO 2 Verification ....................................................................................................................................5 - 14NIBP Verification .....................................................................................................................................5 - 14Battery Operation Verification...................................................................................................................5 - 15CO 2 Operation Verification......................................................................................................................5 - 15Leakage Current Tests ..............................................................................................................................5 - 15Preventative Maintenance................................................................................................. 6 - 1User Preventative Maintenance Introduction .......................................................................................................6 - 1Preventative Maintenance Schedule ..................................................................................................................6 - 2Mechanical / Physical / Visual Inspection - Annually ...................................................................................6 - 2Visual test ...............................................................................................................................................6 - 2Power on test ..........................................................................................................................................6 - 2Perform NIBP Verification and Calibration – Annually ..................................................................................6 - 2Perform CO 2 Verification and Calibration -- Annually...................................................................................6 - 2Perform IBP Verification and Calibration – Annually.....................................................................................6 - 2Perform ECG Verification – Annually..........................................................................................................6 - 2Perform Verification and Gas Calibration – Annually ...................................................................................6 - 3Temperature Perform Verification – Annually ...............................................................................................6 - 3SpO 2 Perform Verification – Annually ........................................................................................................6 - 3Electrical Safety Tests – Annually ...............................................................................................................6 - 3Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 iii

Table of ContentsCare and Cleaning of the Monitor ....................................................................................................................6 - 4Decontamination of the Monitor ................................................................................................................6 - 4Care and Cleaning of SpO 2 Sensors.................................................................................................................6 - 5Cleaning and Re-use of a Nellcor ® Sensor..................................................................................................6 - 5Cleaning CO 2 Sensors, Adapters and Sampling Components ..............................................................................6 - 6Sterilization and Cleaning of Cuffs....................................................................................................................6 - 7Reusable Cuffs with Bladders ....................................................................................................................6 - 7Reusable Bladderless Cuffs .......................................................................................................................6 - 8Disposable Blood Pressure Cuffs................................................................................................................6 - 8Care and Cleaning of Gas Module...................................................................................................................6 - 9Care and Cleaning of 3- and 5-lead ECG Cables and Leadwires .........................................................................6 - 10Battery Replacement and Maintenance ..............................................................................................................6 - 11Battery Replacement ................................................................................................................................6 - 11Battery Maintenance ................................................................................................................................6 - 11Recorder Maintenance ....................................................................................................................................6 - 12Cleaning the Recorder Printhead ...............................................................................................................6 - 12Recorder Paper Replacement ....................................................................................................................6 - 12Care and Storage of Thermal Chart Paper..................................................................................................6 - 12Warranty Statements.......................................................................................................................................6 - 14USA, Canada, Mexico, and Puerto Rico.....................................................................................................6 - 14International (excluding North America) .....................................................................................................6 - 15Phone Numbers and How To Get Help ......................................................................................................6 - 16Manufacturer’s Responsibility ....................................................................................................................6 - 16iv 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

ForewordIntroductionForewordThe Passport V <strong>Service</strong> <strong>Manual</strong> is intended as a guide for technically qualified personnelduring repair and calibration procedures. This publication may have been updated to reflectproduct design changes and/or manual improvements.Warnings, Cautions, and NotesPlease read and adhere to all warnings, cautions, and notes listed here and in theappropriate areas throughout this manual.A WARNING is provided to alert the user to potential serious outcomes (death, injury, orserious adverse events) to the patient or the user.A CAUTION is provided to alert the user to use special care necessary for the safe andeffective use of the device. They may include actions to be taken to avoid effects on patientsor users that may not be potentially life threatening or result in serious injury, but about whichthe user should be aware. Cautions are also provided to alert the user to adverse effects onthis device of use or misuse and the care necessary to avoid such effects.A NOTE is provided when additional general information is applicable.WarningsWARNING:WARNING:WARNING:WARNING:The Passport V operates on line voltages. Therefore, anelectric shock hazard may exist when the instrument coversare removed. Repair and calibration procedures should onlybe performed by qualified personnel who proceed with careand follow proper servicing techniques. Warnings are givenin various chapters, as well as in other appropriatelocations.Internal Electrical Shock Hazard - This unit does not containany user-serviceable parts. Do not remove instrumentcovers. Refer Servicing to qualified personnel.Whenever the monitor is opened for calibration or repair, arisk (leakage) current safety check and a verification ofbasic functions of all parameters should be performedbefore the monitor is returned to Clinical use. See“Verification” on page 5-12.Do not clean the monitor while it is powered on and/orplugged in.WARNING:CautionsPerform the decontamination process with the unit poweredoff and the power cord removed.CAUTION:CAUTION:Calibration is not to be performed while monitoring apatient.A functional tester cannot be used to assess the accuracy ofthe pulse oximeter probe or a pulse oximeter monitor.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 v

IntroductionNotesCAUTION:CAUTION:CAUTION:CAUTION:CAUTION:CAUTION:CAUTION:CAUTION:CAUTION:When cleaning the monitor, do not allow cleaning solutionsinto the vent openings.When cleaning sensors, do not use excessive amounts ofliquid. Wipe the sensor surface with a soft cloth dampenedwith cleaning solution. Do not attempt to sterilize.Some disinfectants may cause skin irritation. Please rinsecuff thoroughly with water to remove any residualdisinfectants.Using dark colored soaks may stain the cuffs. Test a singlecuff to ensure that no damage will occur.When ironing or pressing the cuffs, be aware that theVelcro ® fasteners can melt at temperatures above 325°F(162°C).Disposable cuffs can be cleaned using a mild soap solutionand dried with a clean cloth.Do not clean the Gas Module while it is on and/or pluggedin.The internal sampling system of the Gas Module does notneed to be cleaned or sterilized. There is no reverse flowback to the patient. If the internal sampling system issuspected to be clogged or dirty, the module should beserviced by an authorized service person only.To avoid permanent damage, do not expose metalcomponents (e.g., pins, sockets, snaps) to disinfectants,soaps, or chemicals.CAUTION: Recharge batteries in the Passport V.CAUTION:CAUTION:CAUTION:NotesNOTE:Remove the batteries if the Passport V is not likely to beused for an extended period of time.Never pull the recorder paper with force when a recordingis in process; it may cause damage to the recorder.Do not leave the recorder door open unless reloading paperor troubleshooting.Unauthorized servicing may void the remainder of thewarranty. Check with the factory or with a local authorizedrepresentative to determine the warranty status of aparticular instrument.vi 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

1.0 Theory of Operation1.1 IntroductionThis patient monitor is intended to be used for monitoring, displaying, reviewing, storing,and transferring of multiple physiological parameters including: ECG, respiration (Resp),temperature (Temp), SpO 2 , pulse rate (PR), non-invasive blood pressure (NIBP), invasiveblood pressure (IBP), End tidal CO 2 value (EtCO 2 ) and anesthetic gas (AG) of single adult,pediatric, and neonatal patients.FIGURE 1-1 The Passport V MonitorPassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 1 - 1

System ConnectionsTheory of OperationAdditional Passport V features:• Provides audible and visual alarm indications.• Incorporates multiple input devices such as a keypad and knob.• Enables program upgrade over the network.1.2 System Connections1.2.1 Mounting the Patient MonitorThe Passport V can be mounted on a wall mount bracket, a rolling stand, or a bedrailhook, which can be ordered optionally. Each type of mounting solution is delivered with acomplete set of mounting hardware and instructions. Refer to the documentation deliveredwith the mounting hardware for instructions on assembling mounts.1.2.2 Connectors for Peripheral DevicesOn the back of the Passport V are the connectors for peripheral devices.FIGURE 1-2 Connectors for Peripheral Devices1 - 2 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Theory of OperationMain Unit1.3 Main Unit1. Auxiliary OutputA standard BNC connector, through which defibrillator synchronization signals, analogoutput signals, and nurse call signals can be outputted, depending on how the monitor isconfigured.2. SB ConnectorA connector for an external storage device.3. VGA ConnectorA connector for a standard SVGA color monitor.4. Network ConnectorAn RJ45 connector, through which an Ethernet network or a PC can be connected.5. RS232 serial portA DB9 connector, used to connect a PC for data or a Gas Module 3, depending on howthe monitor is configured.6. RS232 serial portA DB9 connector, used to connect a PC for data or a Gas Module 3, depending on howthe monitor is configured.7. AC Power ConnectorA connector for an AC power source (100 to 240 VAC, 50/60Hz).8. Equipotential lugA connector for common ground with other equipment.The Passport V consists of the following:• Input system:keypad, knob, and power switch.• Output system:LCD panel, alarm LED board, recorder, speaker, AC/battery status LEDs).• Processing and communications system:CPU board, Power management and interface board.• Power management system:battery, battery interface board, power board (AC/DC), Power management andinterface board.• Equipment interface system:power management and interface board, Ethernet-wireless adapter.• Parameter modules:multi-parameter board, CO 2 module, OEM SpO 2 module, NIBP module.Additionally, the patient monitor can also connect a DPM SB storage device, a GasModule 3, or a PC for data transfer.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 1 - 3

Theory of OperationMain UnitAlarm LampThe monitor has an alarm lamp on the front panel. The alarm LED board converts the electricsignals into visual signals and then sends the visual signals to the alarm lamp through a lightpipe. The alarm lamp illuminates either red or yellow, depending on how the alarm isconfigured.RecorderThe recorder receives data coming from the CPU board through a UART and then sends themto the thermal print head for printing. The recorder has a hard key (starting/stoppingrecordings) and a green LED on its front. It connects to the power management and interfaceboard.The following diagram shows its operating principle.MAIN BOARDRECORDERKEY BOARDPOWERSUPPLYINTERFACESIGNALINTERFACEKEY & LEDINTERFACEPOWERMODULEPOWERSUPPLYCONTROLCPUMOTORCONTROLDRIVECIRCUITFPC INTERFACETHERMAL PRINT HEADFIGURE 1-4 Operating principleMODULEPower supply interfacePower moduleCPUSignal interfaceDrive circuitRecorder key boardFPC interfaceDESCRIPTIONIntroduces a DC from the CPU board.Converts the input power into voltages that fit each module andthen forwards them to each module.Controls the communications between modules.Controls the communications between the CPU board and therecorder CPU.Receives control signals from the CPU and then forwards them tothe stepper motor.Sends key commands to the CPU and receives commands fromthe CPU to control the LED on the recorder.Sends the thermal print head information to the CPU andreceives commands from the CPU to control the thermal printhead.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 1 - 5

Main UnitTheory of OperationSpeakerThe speaker provides sound for alarms, key strokes, heart beats, pulse, and so on. It is drivendirectly by the CPU board.AC and battery status LEDsThe AC status LED and the battery status LED, located at the keypad, are controlled by theMCU on the power management and interface board. The driving signals come from thepower management and interface board and then go to the keypad via the CPU board.1.3.3 Processing and Communications SystemCPU boardThe CPU board is the heart of the patient monitor. It implements a series of tasks includinginput and output control, data storage and processing, display processing, system control,communication management, print management, alarming, etc.The CPU board has a CPU system comprising the CPU, FLASH, memory, real-time clock,EEPROM, FPGA, etc. Among them, FPGA deals with audio, video, and interfacing signals.Also, it provides interfaces to other boards, modules, and devices.Connections and communications with other components are implemented via the CPUboard, which provides interfaces to:• A built-in display• The power management and interface board. Between this board and the CPU board,the signals of USB+Network+UART+SVGA+I2C+Speaker+GPIO are communicated.Among them, UART signals finally go to the parameter boards.• The keypad. Between the keypad and the CPU board, there are two signal wires: one isthe UART signal wire and another is the AC power and battery status signal wire.• The alarm LED boardPower management and interface boardThe power management and interface board is a multi-functional board. It transmits UARTsignals to several boards and modules (e.g., multi-parameter board, CO 2 module, OEMSpO 2 module, NIBP module, recorder module, etc.).1.3.4 Power Management SystemBatteryThe monitor uses two rechargeable lithium-ion batteries (11.1 V, 4400 mAh). The batterycompartment door is located at the left-bottom of the patient monitor. The battery power isintroduced to the power module via the battery interface board, and then processed anddistributed to each component by the power management and interface board.Battery interface boardThe battery interface board serves as an interface between the batteries and the powermanagement and interface board.1 - 6 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Theory of OperationMain UnitPower board (AC/DC)The power board (AC/DC) converts the input AC power to DC power (16.8V DC), whichthen serves as the input of the power management and interface board.Power management and interface boardThis board is responsible for power management and interfaces. Power management canperform the functions below:1. Auto-select the DC source between the power board and the two batteries.2. Convert the DC source into 12V, 5V, and 3.3V DC and then output them to other boardsand modules.3. Provide over-voltage and under-voltage protection for 12V, 5V, and 3.3V DC.4. Detect the power switch status and control power on/off.5. Detect the battery capacity and control battery charge/discharge.6. Control the LED for battery and AC status.7. Control the fan and detect its running status (the complex control algorithm isimplemented via the CPU board).8. Detect the internal temperature of the patient monitor.On this board there are four sub-boards: 3.3V and 5V DC board, 12V DC board, and twobattery charge boards. The 3.3V and 5V DC board converts the DC source into 5V and3.3V. The 12V DC board converts the DC source into 12V DC. Both of them have an overcurrentprotection mechanism. Each of the two battery charge boards controls the chargingof a battery.The DC power system is illustrated below:Powerboard(AC/DC)16.8VBatteryinterfaceboard11.1VPower managementand interface boardDC sourceauto-select16.8V/11.1V3.3VDC/DC5VDC/DC12VDC/DC3.3V5V12VCPUboarddigital circuitKnobNIBPAlarmindicatorMulti-ParameterboardInterfaceboarddigital circuitCF controlboardOEM SpO2moduleLCD digitalcircuitRecorderWirelessAdapterCO2moduleBacklightboardFIGURE 1-5 DC power systemPassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 1 - 7

Main UnitTheory of Operation1.3.5 Equipment Interface SystemPower management and interface boardThis board is also responsible for digital interfaces.A USB HUB is located at the board. It receives USB signals from the CPU and then distributesthem to three USB ports, of which two connect the USB sockets, and the other connects theCF control board.FIGURE 1-6 The USB hubThis board provides connections for both wired network and wireless adapter. In the figurebelow, switch 2 always stays off during normal use. The operator can switch between wirednetwork and wireless adapter through the software UI. Then, the CPU applies the operator’sselection by controlling switch 1. In configuration mode, the CPU turns off switch 1 and thenturns on switch 2 so that the operator can connect a PC to the wired network to configure thewireless adapter.The Ethernet wireless adapter enables the patient monitor to go wireless.FIGURE 1-7 The ethernet wireless adapter1 - 8 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Theory of OperationMain UnitThe CPU generates analog signals by controlling the DAC chip on the power managementand interface board via the I2C bus. The analog signals are transmitted to the BNC socketvia the amplifier circuit.FIGURE 1-8 The amplifier circuitThe signal r_flag from the multi-parameter board goes to the power management andinterface board. The CPU can select the source of defibrillator synchronization signals bycontrolling the output of the DAC. The signal r_flag also goes to the CPU for a self-test.Two UART interfaces (serial port 1 and serial port 2) from the CPU board are extended astwo RS232-level ports via the power management and interface board. Both interfaces canbe configured to accommodate a PC for data or an AG module.FIGURE 1-9 The serial portsPassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 1 - 9

Main UnitTheory of Operation1.3.6 Parameter modulesMulti-Parameter boardThe multi-parameter board incorporates multiple parameters, such as ECG, RESP, DPMSPO 2 , 2-channel IBP, TEMP, etc. Details include the following:• The multi-parameter board employs a high-speed DSP, making digital filtering, arrhythmiaanalysis, and ST analysis faster and more effective.• The DSP is in charge of 3- and 5-lead ECG monitoring, arrhythmia and ST analysis, RESPmonitoring, and communicating with the CPU board.• The multi-parameter board also employs an MCU, which supports 1-channel temperaturemeasurement, DPM SpO 2 , and 2-channel IBP measurement. The MCU transfers all themeasurement data to the DSP.• Respiration rate is monitored using the impedance method and can only be measuredwith two ECG leads.• The multi-parameter board integrates the DPM SpO 2 circuit. If a monitor is configuredwith an OEM SpO 2 module, then DPM SpO 2 functions are overridden.CO 2 Module• There are two types of CO 2 modules: DPM CO 2 and Microstream CO 2 .• The DPM CO 2 module measures the CO 2 concentration using the NDIR technology. Itperforms a zero calibration periodically to ensure accurate measurements for a longperiod of time. An appropriate compensation can be applied according to the patientenvironment, thus preventing measurements from being influenced by interfering gases.• The Microstream CO 2 module ensures that measurements will not be affected by othergases and the accuracy can be maintained without any gas compensation. Additionally,the module has a very low sample flow rate, reducing its effect on the patient and theenvironment to a minimum.OEM SpO 2 ModuleThere are two types of OEM SpO 2 modules: Masimo-2013 SpO 2 module and Nellcor SpO 2module.An isolation power board is attached to each of them and used to isolate the DC power andthe UART signal of the OEM SpO 2 modules from other circuits in the main unit. The UARTsignal comes from the CPU board and passes through the power management and interfaceboard.1 - 10 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Theory of OperationMain UnitNIBP ModuleThe figure below shows the NIBP module parameter board diagram.CUFFPRESSURESENSORFORPROTECTPRESSURESIGNALAMPLIFIERCIRCUITSFORPROTECTOVERPRESSUREPROTECTCIRCUITWATCHDOGCPUASYCHRONOUSSERIALCOMMUNICATIONPRESSURESENSORPRESSURESIGNALAMPLIFIERCIRCUITSPRESSURESIGNALA/DCONVERTERMANIFOLDMOTOR CONTROLFEEDBACK SIGNALVALVESAND PUMPPUMP ANDVALVECONTROLCIRCUITFLASHDRAMFIGURE 1-10 The NIBP module parameter boardThe Passport V calculates NIBP values using the oscillometric method of noninvasive bloodpressure measurement. These measurements correspond to comparisons with auscultatoryvalues, measured using the fifth Korotkoff sound within ANSI/AAMI SP10 standards foraccuracy.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 1 - 11

Main UnitTheory of OperationThis page intentionally left blank.1 - 12 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

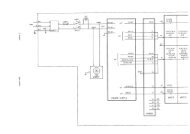

2.0 Block Diagrams2.1 IntroductionThe Block Diagrams indicate the internal organization of the instrument. The block diagrams are used togain both familiarity with the instrument and to locate malfunctioning PC boards as readily as possible.DESCRIPTIONPART NUMBERNIBP Module 6100-30-86329Masimo SpO 2 Module 6100-30-86335Nellcor SpO 2 Module 6100-30-86336Microstream CO 2 Module 6100-30-86333DPM CO 2 Module 6100-30-86334Power board(AC/DC) 9211-30-87311Alarm LED Board 9211-30-87306Battery interface board assembly 9211-30-87331Keypad OverlayKeypad6100-20-86264-XX or6100-20-86341-XX6100-20-86265-XXMain board 9211-20-87303Power management and interface board 6100-20-86294Back light board 022-000001-00LCD Display 0000-10-11092Recorder 6101-30-46619Wireless AP Module 6100-30-86332CF card assembly 6100-30-86330Power Switch with Cable Assembly 6100-21-86306Speaker 020-000001-00Fan Assembly 6100-21-86315NOTE:See Isometric Drawings and Parts List for a complete list ofPart Numbers.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 2 - 1

3.0 Repair Information3.1 IntroductionThis chapter provides the necessary technical information to perform repairs on thePassport V. The most important prerequisites for effective troubleshooting are a thoroughunderstanding of the instrument functions as well as understanding the theory of operation.3.2 Safety PrecautionsIn the event the instrument covers are removed, observe the following warnings andguidelines.1. Do not short component leads together.2. The instrument covers must not be removed by anyone other than qualified technicalpersonnel who have received supplementary instructions regarding maintenance ofmedical equipment or have equivalent experience in this area.WARNING:WARNING:Internal Electrical Shock Hazard - This unit does not containany user-serviceable parts. Do not remove instrumentcovers. Refer Servicing to qualified personnel.Whenever the monitor is opened for calibration or repair, arisk (leakage) current safety check and a verification ofbasic functions of all parameters should be performedbefore the monitor is returned to Clinical use. See“Verification” on page 5-12.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 1

Troubleshooting GuidelinesRepair Information3.3 Troubleshooting Guidelines1. Identify the problemDue to the wide variety of potential symptoms, certain problems may be more subtlethan others. One approach to troubleshooting is to set up the instrument as described inChapter 5.0. Following the guidelines of the tests will help determine the problem if oneexists.2. Avoid shorting component leadsDuring repair procedures, it can become tempting to make a series of quickmeasurements. Always turn the power off before connecting and disconnecting the testleads and probes. The accidental shorting of leads can easily stress the components andcause a second failure (aside from the safety risk).3. Use the Proper equipmentThe equipment listed below is suggested to fulfill a wide range of troubleshootingrequirements. It is imperative to use the designated equipment in order to ensure properresults of any and all test procedures.4. Clean up the repair areaAfter any repair, especially after any soldering or desoldering, clean off the repair areawith alcohol and a stiff brush. This will remove any residual solder flux, in turn allowingthe instrument to return to its original appearance.3.4 Special Tools Required• Digital Voltmeter• Digital Mercury Manometer – 0 to 300 mmHg• Safety Analyzer• Patient Simulator• Test Chamber / Dummy Cuff (P/N 0138-00-0001-01 (700 cc) or -03 (500 cc))• Desktop PC or notebook PC.• Microsoft Windows 2000/XP operating system• Intel Pentium CPU, above 500MHz• Above 128M memory• At least one network card and at least one USB port• CAT-5 crossover cable• USB cable or DPM SB storage device3.5 Disassembly InstructionsBefore disassembling the unit, perform the following:• Power down the unit and remove the line cord.• Remove all cable assemblies from the left side, right side, and rear of the unit.• Remove any batteries that were installed.• Perform all work on a properly grounded ESD workstation.3 - 2 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions3.5.1 Removal of the Key Panel and Keys1. Place the unit on a protective surface.2. Carefully remove the knob with a pair of pliers that have protection on the jaws. Somepliers may damage the knob.FIGURE 3-1 Remove the knob3. Release the key panel’s four clips from the bottom of the unit with a flat-bladedscrewdriver.FIGURE 3-2 Release the key panel clips4. Remove the key panel from the front.5. Remove the keys and place to the side with the key panel.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 3

Disassembly InstructionsRepair Information3.5.2 Removal of the Front Housing Assembly1. Place the unit face down on a protective surface.2. Remove the six screws from the rear of the unit.FIGURE 3-3 Remove the screws from the rear of the unit3. Turn the unit over and carefully separate the front housing assembly and rear housingassembly.4. Disconnect the 50-pin ribbon cable from the front housing assembly.FIGURE 3-4 Disconnect the ribbon cable from the front housing assembly5. Remove the front housing assembly.3 - 4 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions3.5.3 Removal of the Main Board1. Remove the front housing assembly as stated in “Removal of the Front HousingAssembly” on page 3-4.2. Remove the keyboard cable.3. Remove the inverter cable.4. Remove the LCD panel cable.5. Remove the alarm LED board cable.6. Remove the five screws that secure the main board to the front housing bracket.7. Remove the main board carefully.FIGURE 3-5 Remove the main boardPassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 5

Disassembly InstructionsRepair Information3.5.4 Removal of the Inverter1. Remove the front housing assembly as stated in “Removal of the Front HousingAssembly” on page 3-4.2. Remove the inverter cable.3. Remove the two backlight board cable from the inverter.4. Remove the two screws that secure the inverter to the front housing bracket.5. Remove the inverter carefully.FIGURE 3-6 Remove the inverter3 - 6 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions3.5.5 Removal of the LCD Panel1. Remove the front housing assembly as stated in “Removal of the Front HousingAssembly” on page 3-4.2. Remove the two backlight board cables from the inverter.3. Remove the keyboard cable.4. Remove the alarm LED board cable.5. Remove the LCD panel cable.6. Remove the eight screws that secure the front housing bracket.7. Remove the front housing bracket and place to the side.FIGURE 3-7 Remove the LCD panelPassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 7

Disassembly InstructionsRepair Information8. Remove the four screws that secure the LCD panel.9. Remove the LCD panel carefully.FIGURE 3-8 Remove the LCD panel3.5.6 Removal of the Keyboard1. Remove the front housing assembly as stated in “Removal of the Front HousingAssembly” on page 3-4.2. Remove the keyboard cable.3. Remove the encoder cable.4. Remove the four screws that secure the keyboard to the front housing.5. Remove the four keyboard pads.6. Release the clip on the right side of the keyboard and remove the keyboard carefully.FIGURE 3-9 Remove the Keyboard3 - 8 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions3.5.7 Removal of the Alarm LED Board1. Remove the front housing assembly as stated in “Removal of the Front HousingAssembly” on page 3-4.2. Remove the alarm LED board cable.3. Remove the two screws that secure the board to the front housing.4. Remove the alarm LED board and light conducting pipe carefully.FIGURE 3-10 Remove the alarm LED board3.5.8 Removal of the Encoder1. Remove the front housing assembly as stated in “Removal of the Front HousingAssembly” on page 3-4.2. Remove the encoder cable from the keyboard.FIGURE 3-11 Disconnect the encoder cablePassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 9

Disassembly InstructionsRepair Information3. Carefully remove the knob with a pair of pliers that have protection on the jaws. Somepliers may damage the knob.4. Remove the nut that secures the encoder.5. Remove the encoder carefully.FIGURE 3-12 Remove the encoder3.5.9 Removal of the Multi-parameter Board Assembly1. Remove the front housing assembly as stated in “Removal of the Front HousingAssembly” on page 3-4.2. Disconnect the 50-pin ribbon cable from the interface board.3. Disconnect the cable from J15 of the interface board.4. Disconnect the NIBP communication cable from the interface board.FIGURE 3-13 Disconnect the cables from the multi-parameter board3 - 10 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions5. Remove the four screws that secure the assembly to the rear housing and main frame.6. Disconnect the CO 2 tubing and cable from the multi-parameter board assembly (if CO 2module is configured).7. Remove the multi-parameter board assembly carefully.FIGURE 3-14 Remove the multi-parameter board assemblyPassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 11

Disassembly InstructionsRepair Information3.5.10 Removal of the Parameter Front Panel Assembly1. Remove the multi-parameter board assembly as stated in “Removal of the MultiparameterBoard Assembly” on page 3-10.2. Unplug the tubing from the NIBP connector.FIGURE 3-15 Unplug the tubing from the NIBP connector3. Unfasten the two screws that secure the SpO 2 connector and then remove the connector(if Masimo or Nellcor SpO 2 module is configured).FIGURE 3-16 Masimo SpO 2 FIGURE 3-17 Nellcor SpO 24. Remove the three screws that secure the parameter front panel.5. Remove the parameter front panel.FIGURE 3-18 Remove the parameter front panel3 - 12 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions3.5.11 Removal of the Multi-parameter board1. Remove the parameter front panel assembly as stated in “Removal of the ParameterFront Panel Assembly” on page 3-12.2. Remove the three screws that secure the multi-parameter board.3. Remove the multi-parameter board.FIGURE 3-19 Remove the multi-parameter board3.5.12 Removal of the CO 2 Module1. Remove the multi-parameter board assembly as stated in “Removal of the MultiparameterBoard Assembly” on page 3-10.2. Remove the two screws that secure the module to the main frame.3. Remove the CO 2 module.FIGURE 3-20 DPM CO 2 FIGURE 3-21 Microstream CO 24. Remove the water trap connector assembly or microstream CO 2 connector fixtureassembly from the parameter front panel assembly (if necessary).Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 13

Disassembly InstructionsRepair Information3.5.13 Removal of the Masimo SpO 2 Module1. Remove the multi-parameter board assembly as stated in “Removal of the MultiparameterBoard Assembly” on page 3-10.2. Disconnect the SpO 2 communication cable from the multi-parameter board.3. Cut the tie of flexible cable.4. Unfasten the screw that secures the Masimo SpO 2 module to the multi-parameter boardinstallation frame.5. Unfasten the two screws that secure the Masimo SpO 2 connector.6. Remove the Masimo SpO 2 module.FIGURE 3-22 Remove the Masimo SpO 2 module3.5.14 Removal of the Nellcor SpO 2 Module1. Remove the multi-parameter board assembly as stated in “Removal of the MultiparameterBoard Assembly” on page 3-10.2. Disconnect the SpO 2 communication cable from the multi-parameter board.3. Cut the tie of flexible cable.4. Unfasten the screw that secures the Nellcor SpO 2 module to the multi-parameter boardinstallation frame.5. Unfasten the two screws that secure the Nellcor SpO 2 connector.6. Remove the Nellcor SpO 2 module.FIGURE 3-23 Remove the Nellcor SpO 2 module3 - 14 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions3.5.15 Removal of the NIBP Assembly1. Remove the multi-parameter board assembly as stated in “Removal of the MultiparameterBoard Assembly” on page 3-10.2. Unplug the tubing from the NIBP gas nipple.3. Disconnect the NIBP communication cable from the NIBP board.4. Unfasten the screws that secure the NIBP assembly to the multi-parameter boardinstallation frame.5. Remove the NIBP assembly.FIGURE 3-24 Remove the NIBP assembly3.5.16 Removal of the Recorder Assembly1. Remove the two screws that secure the recorder.2. Release the two clips and pull out the recorder.FIGURE 3-25 Remove the recorder assembly3. Disconnect the recorder cable.4. Remove the recorder.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 15

Disassembly InstructionsRepair Information3.5.17 Removal of the Recorder Cover (if needed)1. Pry up the recorder cover with a flat-bladed screwdriver.FIGURE 3-26 Remove the recorder cover3.5.18 Removal of the Main Frame and Multi-parameter Board Assembly1. Remove the front housing assembly as stated in “Removal of the Front HousingAssembly” on page 3-4.2. Remove the recorder assembly (if installed) as stated in “Removal of the RecorderAssembly” on page 3-15.3. Disconnect the power switch cable from the interface board.4. Remove the eight screws that secure the main frame and multi-parameter boardassembly to the rear housing.FIGURE 3-27 Remove the screws and cables from the main frame3 - 16 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions5. Remove the two screws that secure the main frame from the bottom.6. Remove the main frame and multi-parameter board assembly.FIGURE 3-28 Remove the main frame and multi-parameter board assembly3.5.19 Removal of the Speaker Assembly1. Remove the main frame and multi-parameter board assembly as stated in “Removal ofthe Main Frame and Multi-parameter Board Assembly” on page 3-16.2. Cut the clamp that secures the speaker cable.3. Disconnect the speaker cable from the interface board.FIGURE 3-29 Disconnect the speaker cable from the interface board4. Remove the three screws that secure the speaker.5. Remove the speaker assembly.FIGURE 3-30 Remove the speaker assemblyPassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 17

Disassembly InstructionsRepair Information3.5.20 Removal of the Fan Assembly1. Remove the main frame and multi-parameter board assembly as stated in “Removal ofthe Main Frame and Multi-parameter Board Assembly” on page 3-16.2. Cut the clamp that secures the fan cable.3. Disconnect the fan cable from the interface board.FIGURE 3-31 Disconnect the fan cable from the interface board4. Remove the fan EVA cushion.5. Remove the two screws that secure the fan.FIGURE 3-32 Remove the fan assembly6. Remove the fan.3 - 18 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions3.5.21 Removal of the CF Card Assembly1. Remove the main frame and multi-parameter board assembly as stated in “Removal ofthe Main Frame and Multi-parameter Board Assembly” on page 3-16.2. Remove the two screws that secure the CF card assembly.3. Disconnect the CF card cable.4. Remove the CF card assembly.FIGURE 3-33 Remove the CF card assembly3.5.22 Removal of the Power Board1. Remove the main frame and multi-parameter board assembly as stated in “Removal ofthe Main Frame and Multi-parameter Board Assembly” on page 3-16.2. Remove the two screws that secure the recorder connecting board and then remove the board.FIGURE 3-34 Remove the screws securing the recorder connecting boardPassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 19

Disassembly InstructionsRepair Information3. Disconnect the power board connecting cable from the interface board.FIGURE 3-35 Disconnect the power board connecting cable4. Remove the three screws that secure the power socket support from the back of the mainframe.5. Remove the screw that secures the grounding wire.FIGURE 3-36 Remove the screws that secure the power socket3 - 20 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions6. Disconnect the power socket cable from the power board.7. Remove the four screws that secure the power board.8. Remove the power board.FIGURE 3-37 Remove the power board3.5.23 Removal of the Li-ion Battery Interface Board Assembly1. Remove the front housing assembly as stated in “Removal of the Front HousingAssembly” on page 3-4.2. Remove the recorder assembly (if installed) as stated in “Removal of the RecorderAssembly” on page 3-15.3. Remove the two screws that secure the recorder connecting board and then remove theboard.FIGURE 3-38 Remove the screws securing the recorder connecting boardPassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 21

Disassembly InstructionsRepair Information4. Disconnect the Li-ion battery interface board cable from the interface board.FIGURE 3-39 Disconnect the Li-ion battery interface board cable5. Remove the four nuts that secure the Li-ion battery interface board assembly.6. Remove the Li-ion battery interface board assembly.FIGURE 3-40 remove the Li-ion battery interface board assembly3 - 22 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions3.5.24 Removal of the Interface Board Assembly1. Remove the multi-parameter board assembly as stated in “Removal of the MultiparameterBoard Assembly” on page 3-10.2. Remove the recorder assembly (if installed) as stated in “Removal of the RecorderAssembly” on page 3-15.3. Disconnect the power switch cable from the interface board.4. Remove the six screws that secure the main frame to the rear housing.FIGURE 3-41 Remove the screws from the main frame5. Remove the two screws that secure the main frame from the bottom.6. Remove the main frame assembly and place to the side.FIGURE 3-42 Remove the screws securing the main frame7. Disconnect the Li-ion battery interface board cable from the interface board.8. Disconnect the power cable from the interface board.9. Disconnect the recorder cable from the interface board.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 23

Disassembly InstructionsRepair InformationFIGURE 3-43 Disconnect the cables from the interface board10. Disconnect the speaker cable from the interface board.11. Disconnect the fan cable from the interface board.12. Disconnect the CF card cable from the interface board.13. Disconnect the wireless AP (if installed) cable from the interface board.FIGURE 3-44 Disconnect the cables from the interface board14. Remove the two screws that secure the interface board assembly to the main frame.15. Remove the interface board assembly.FIGURE 3-45 Remove the interface board assembly3 - 24 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationDisassembly Instructions3.5.25 Removal of the Wireless AP1. Remove the multi-parameter board assembly as stated in “Removal of the MultiparameterBoard Assembly” on page 3-10.2. Remove the recorder assembly (if installed) as stated in “Removal of the RecorderAssembly” on page 3-15.3. Disconnect the power switch cable from the interface board.4. Remove the six screws that secure the main frame to the rear housing.FIGURE 3-46 Remove the screws from the main frame5. Remove the two screws that secure the main frame from the bottom.6. Remove the main frame assembly.FIGURE 3-47 Remove the screws securing the main framePassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 25

Disassembly InstructionsRepair Information7. Remove the nut that secures the wireless AP to the main frame.FIGURE 3-48 Remove the nut securing the wireless AP to the main frame8. Disconnect the wireless AP cable from the wireless AP.9. Remove the wireless AP.FIGURE 3-49 Disconnect the cables from the wireless AP3 - 26 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationNurse Call Cable3.6 Nurse Call Cable3.6.1 P/N 8000-21-10361FIGURE 3-50 Nurse Call Cable3.7 Analog Output Cable3.7.1 P/N 6100-20-86360FIGURE 3-51 Analog Output CablePassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 27

Defib Synch CableRepair Information3.8 Defib Synch Cable3.8.1 P/N 6100-20-86361FIGURE 3-52 Defib Synch Cable3 - 28 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Null Modem CableRepair Information3.10 Null Modem Cable3.10.1 P/N 0012-00-1275-01FIGURE 3-54 Null Modem Cable3 - 30 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationUniversal ECG Lead Wires3.11 Universal ECG Lead Wires3.11.1 P/N 0012-00-1503-XXDESCRIPTION DASH #10 24", snap, 5-lead set, Domestic -0211 24", snap, 3-lead set, Domestic -0512 24", snap, 5-lead set, International -1113 24", snap, 3-lead set, International -14FIGURE 3-55 Universal ECG Lead WiresPassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 31

ECG Cable, 3/5-lead (ESIS and Non ESIS)Repair Information3.12 ECG Cable, 3/5-lead (ESIS and Non ESIS)3.12.1 P/N 0012-00-1745-XXFIGURE 3-56 ECG Cable, 3/5-lead (ESIS and Non ESIS)3.13 12-pin 3-lead Neo ECG Trunk Cable (IEC/AHA)3.13.1 P/N 040-000072-00FIGURE 3-57 12-pin 3-lead Neo ECG Trunk Cable (IEC/AHA)3 - 32 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationIBP Cable3.14 IBP Cable3.14.1 P/N 040-000052-00FIGURE 3-58 5-pin IBP Cable (IM2301, Hospira)3.14.2 P/N 040-000053-00FIGURE 3-59 5-pin IBP Cable (IM2302, BD)3.14.3 P/N 040-000054-00FIGURE 3-60 5-pin IBP Cable (IM2303, Edwards)Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 33

Temperature CableRepair Information3.14.4 P/N 040-000096-00FIGURE 3-61 IBP Adapter Cable (5-pin to 6-pin)3.15 Temperature Cable3.15.1 1.15.1 P/N 040-000055-00FIGURE 3-62 5-pin Esophageal/Rectal Temp Probe (Adult)3.15.2 P/N 040-000056-00FIGURE 3-63 5-pin Esophageal/Rectal Temp Probe (Pediatric/Infant)3 - 34 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationTemperature Cable3.15.3 P/N 040-000057-00FIGURE 3-64 5-pin Skin Temp Probe (Adult)3.15.4 P/N 040-000058-00FIGURE 3-65 5-pin Skin Temp Probe (Pediatric/Infant)3.15.5 P/N 040-000091-00FIGURE 3-66 5-pin Temp Cable for 400 Series Disposable SensorPassport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 35

Temperature CableRepair Information3.15.6 P/N 040-0000100-00FIGURE 3-67 5-pin Temp Adapter Cable (5-pin to 6.35 Phone)3.15.7 P/N 040-000224-00FIGURE 3-68 5-pin Temp Cable for MRS Disposable Sensor (5.5 DC Jack)3 - 36 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationTroubleshooting Menus3.16 Troubleshooting Menus3.16.1 ECG TroubleshootingMESSAGE/PROBLEM REASON SOLUTIONNoisy ECG traces 1 Loose or dry electrodes.2 Defective electrode wires.3 Patient cable or leads arerouted too close to otherelectrical devices.Excessive Electro-surgicalInterference1 Apply fresh, moistelectrodes.2 Replace wires asnecessary.3 Eliminate 60Hzinterference.1 Wrong ECG cable used. 1 Use ESIS ECG cable withinternal filter block.Muscle Noise 1 Inadequate skinpreparation prior toapplication of electrode,tremors, tense subject,and/or poor electrodeplacement.Excessive alarms: heart rate,lead fault1 Electrodes dry2 Alarm limits set too closeto patient's normal heartrate.3 R-wave wrong size.4 Excessive patientmovement or muscletremor.ECG Noise 1 External interference.2 Patient movement.No ECG Waveform 1 Gain set too low.2 Lead wires and patientcable not fully or properlyinserted.3 Cable or lead wiresdamaged.NOTE: Respirationmonitoring via theECG electrodes willnot be availablewhen using an ESISECG cable.1 Repeat skin preparationand electrode locationprocedures.2 Apply fresh, moistelectrodes.3 Avoid areas of the torsothat are very muscular.1 Re-prep skin and applyfresh, moist electrodes.2 Readjust.3 Must have a higheramplitude than the otherECG waves, like the Pand T waves.4 Reposition electrodes andsecure with tape, ifnecessary.1 Check patient.2 Check electrode contacts/reposition electrodes/cable.3 Check environment forsource of interference.1 Readjust as required (Setvia the Size key).2 Check for properinsertion.3 Check with leadcontinuity tester.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 37

Troubleshooting MenusRepair InformationMESSAGE/PROBLEM REASON SOLUTIONBase Line Wander 1 Patient movingexcessively.2 Patient's respiration.Electrodes dry or loose.3 Static build up aroundpatient.4 ECG Filter set to “ST” or“Diagnose” mode.ECG Artifact 1 Electrical interferencefrom auxiliary devices.2 Patient movement.Self Test Error 1 During power-on of theunit, if ECG module cannot self-test successfully,this message will display.Communication Stop 1 As the ECG modulecommunication stops, thedata packets sent by themodule can not bereceived.Communication Error 1 The ECG modulecommunication error. Thecommand can not be sentcorrectly.ESU-Resp Off 1 The high frequencyelectrosurgery unitinterference signal isdetected.ECG Signal Invalid 1 Connections not tight orproperly secured.2 Electrodes dry or loose.3 Cable or lead wiresdamaged.Pacer Rejection On 1 When Pacer Reject is setto On.Learning 1 Displayed when alearning cycle has beenrequested for Arrhythmiaor ST.No Arrhythmia Detection atCentral1 Central Station does nothave arrhythmia Analysiscapability.1 Secure lead wires andcable to patient.2 Reposition electrodes.3 Re-prep skin and applyfresh, moist electrodes.4 Check with localbiomedical personnel.5 Set ECG Filter to“Monitor” mode.1 Check patient.2 Check Electrode Contacts/reposition electrodes/cable.3 Check for electricalinterference, replacewires as necessary.1 Power cycle unit. Ifmessage reappears,contact TechnicalSupport.1 Contact TechnicalSupport.1 Contact TechnicalSupport.1 Wait until the highfrequency electrosurgeryunit interferencedisappears.1 Ensure properconnection. (Electrode tolead, lead to cable, cableto monitor).2 Re-prep skin and applyfresh, moist electrodes.3 Check with continuitytester.1 This is normal operation.When Pace Reject is setto Off, this messagedisappears.//3 - 38 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>

Repair InformationTroubleshooting MenusMESSAGE/PROBLEM REASON SOLUTIONECG Channels Checking... 1 Appears when the ECGModule is calibrating.Initialization Error 1 During the ECG modulepower-on, as the ECGmodule communicationstops, system fails tocommunicate withmodule.3.16.2 NIBP Troubleshooting1 This is normal operation.Turn off ECG modulecalibration and themessage will be cleared.1 Contact TechnicalSupport.MESSAGE/ PROBLEM REASON SOLUTIONNIBP: Self Test Error 1 Failed self-test.2 Sensor or A/D samplingmay have error.NIBP: Communication Error 1 NIBP modulecommunication error. Thecommand can not be sentcorrectly.NIBP: System Error 1 System error. After startup,the inflating pump,A/D sampling unit orpressure sensor may haveerror or the pointer mayhave error when thesoftware is running.2 Power supply is not stableor circuit failure leads tovoltage error.NIBP: Cuff Overpressure 1 The hardwareoverpressure limit hasbeen exceeded.2 Overpressure. The cuffpressure exceeds 297mmHg in ADU mode,240 mmHg in PED modeor 147 mmHg in NEOmode.NIBP: Pneumatic Leak 1 Leakage. In Pneumaticcheck, air leakage isfound in hose.NIBP: Unable to Measure 1 Unable to makemeasurement after threeautomatic retries.1 Power cycle unit. Ifmessage reappears,contact TechnicalSupport.1 Power cycle unit. Ifmessage reappears,contact TechnicalSupport.1 Power cycle unit. Ifmessage reappears,contact TechnicalSupport.1 Power cycle unit.Ifmessage reappears,contact TechnicalSupport.1 Change the cuff.1 Check Patient.2 Retry measurement. Ifmessage reappears,power cycle unit. Ifmessage reappears,contact TechnicalSupport.NIBP: Reset Failed 1 Reset failed. 1 Power cycle unit.Ifmessage reappears,contact TechnicalSupport.Passport V <strong>Service</strong> <strong>Manual</strong> 0070-10-0705 3 - 39

Troubleshooting MenusRepair InformationMESSAGE/ PROBLEM REASON SOLUTIONNIBP: Retry Pump Higher 1 A measurement has beenattempted but no readingwas possible. This resultsfrom inadequate cuffinflation pressure.NIBP: Retry 1 Cuff is loosely wrapped.The cuff may be tooloosely wrapped or notattached at all.2 Weak signal. The pulse ofthe patient may be tooweak or the cuff is looselywrapped.3 Excessive motion. Inmeasurement, signalscontain motion artifact ortoo much interference.4 Time-out. Measurementtakes more than 120seconds in ADU/PEDmode and 90 seconds inNEO mode.5 Retry Overpressure orbad measurement.NIBP: Initialization Error 1 During the IBP modulepower-on, as the IBPmodule communicationstops, system fails tocommunicate withmodule.NIBP: Communication Stop 1 As the Resp modulecommunication stops, thedata packets sent by themodule can not bereceived.3.16.3 SpO 2 Troubleshooting1 Retry will be attempted.2 Check that appropriatepatient size is set.3 Pre-set initial inflationpressure.1 Retry will be attempted.Check for leaks andquality of peripheralpulses. Decrease patientmovement. Switch cuff toanother limb.1 Contact TechnicalSupport.1 Contact TechnicalSupport.MESSAGE/ PROBLEM REASON SOLUTIONSpO 2 : No Sensor 1 Sensor is not plugged into the monitor.SpO 2 : Sensor Off 1 Sensor may not beconnected to the patient.SpO 2 : Interference(Masimo/Nellcor Only)1 Noise detected on thepulse signal preventspulse discrimination.SpO 2 : Pulse Search 1 Hardware settings arebeing adjusted in order todiscriminate a pulsewaveform.SpO 2 : No Pulse (DPM/NellcorOnly)1 No detectable pulse ismeasured.1 Plug the sensor into themonitor.1 Check patient connection.1 Decrease patient motion,check sensor.1 Change to site wherepulse is stronger if patientis vasoconstricted.2 Change or readjustsensor if loose.1 Check to patientconnection and patientstatus.3 - 40 0070-10-0705 Passport V <strong>Service</strong> <strong>Manual</strong>