Series 811 Mighty Mouse High Density (HD) Connectors - Glenair, Inc.

Series 811 Mighty Mouse High Density (HD) Connectors - Glenair, Inc.

Series 811 Mighty Mouse High Density (HD) Connectors - Glenair, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

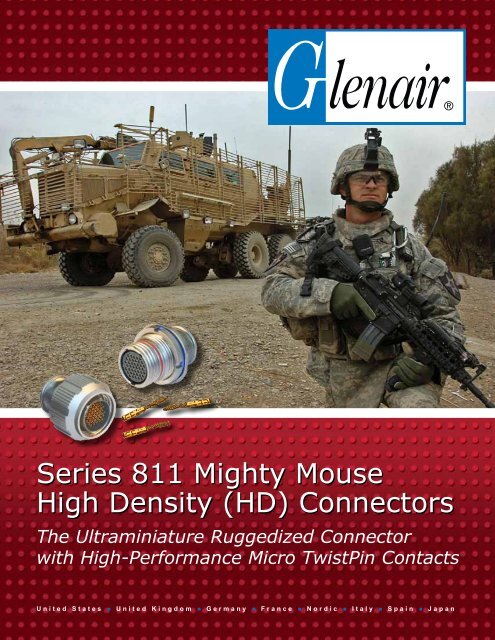

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong> (<strong>HD</strong>) <strong>Connectors</strong>The Ultraminiature Ruggedized Connectorwith <strong>High</strong>-Performance Micro TwistPin ContactsU n i t e d S t a t e s • U n i t e d K i n g d o m • G e r m a n y • F r a n c e • N o r d i c • I t a l y • S p a i n • J a p a n

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Introduction<strong>811</strong>-001-06ME9-42SA<strong>Series</strong> <strong>811</strong> Plug<strong>811</strong>-003-07ME9-42PA<strong>Series</strong> <strong>811</strong> ReceptacleNew <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong>Connector Delivers Size and WeightSavings and Outstanding Performance• <strong>High</strong> <strong>Density</strong> Micro TwistPinContact System• 600 VAC DWV Rating• 7 to 42 Contacts• 3 Amp Current Rating• Water Resistant to 1 MeterNew <strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong> connector features highperformance TwistPin contacts for increased circuit density andoutstanding shock and vibration performance. <strong>High</strong> density .050 inch (1.27mm) contactspacing essentially doubles the pincount compared to our standard <strong>Mighty</strong> <strong>Mouse</strong>. The unique springconstruction of the pin contact results in excellent resistance to high levels of shock and vibration. Threeconfigurations are available: pre-wired pigtail cable assemblies with insulated hookup wire, shieldedcordsets, and printed circuit board versions. <strong>Connectors</strong> are backpotted with epoxy and are suitable forhostile environment applications. The <strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong> connector is a double-start ACMEthreaded version, available with 7, 12, 22, 30 and 42 contacts for size #26 to #30 AWG wire.<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong> with <strong>High</strong> Performance TwistPins#26 - #30 AWG WireInsulatorCouplingNutDouble-Start ThreadPeripheralSealShellEpoxy PottingCompoundShield Terminationand OvermoldingPlatformEpoxy PottingCompoundShellSocketContactPlugInterfacialSealTwistPinContactReceptacleDimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com2E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Introduction<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>About TwistPin ContactsWidely used for radars, missiles, avionics, and space vehicles, the MicroTwistPin is a spring pin composed of helically wound strands of copper alloywire, welded into a bundle, then "bulged" and crimped to a copper alloysleeve. These gold over nickel plated pins and sockets offer low, stable contactresistance even when subjected to temperature extremes and vibration.Designers of soldier systems electronics equipment have turned to the TwistPincontact in order to reduce the size and weight of warfighter electronics.Unlike other microminiature contact systems, the TwistPin contact isterminated to wire with a military-approved four-indent crimp joint. Crimpingresults in a gas tight connection between the wire and the contact .TwistPin ContactTwistPinSocket<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong> CONTACT ARRANGEMENTSPin insert shown, use reverse order for socket inserts.1 23 4 56 71 2 34 5 6 78 9 1011 121 2 3 45 6 7 8 910 11 12 1314 15 16 17 1819 20 21 221 2 3 45 6 7 8 910 11 12 13 14 1516 17 18 19 20 2122 23 24 25 2627 28 29 301 2 3 4 56 7 8 9 10 1112 13 14 15 16 17 1819 20 21 22 23 2425 26 27 28 29 30 3132 33 34 35 36 3738 39 40 41 425-77 Contacts6-1212 Contacts7-2222 Contacts8-3030 Contacts9-4242 ContactsPIN NO.MIL-STD-681NUMBERBase Color First Stripemil-std-681 color code chartSecondStripePIN NO.Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com3E-Mail: sales@glenair.com11 - JULY - 2013MIL-STD-681NUMBERBase Color First StripeSecondStripe1 0 BLK 22 903 WHT BLK ORN2 1 BRN 23 904 WHT BLK YEL3 2 RED 24 905 WHT BLK GRN4 3 ORN 25 906 WHT BLK BLU5 4 YEL 26 907 WHT BLK VIO6 5 GRN 27 908 WHT BLK GRY7 6 BLU 28 912 WHT BRN RED8 7 VIO 29 913 WHT BRN ORN9 8 GRY 30 914 WHT BRN YEL10 9 WHT 31 915 WHT BRN GRN11 90 WHT BLK 32 916 WHT BRN BLU12 91 WHT BRN 33 917 WHT BRN VIO13 92 WHT RED 34 918 WHT BRN GRY14 93 WHT ORN 35 923 WHT RED ORN15 94 WHT YEL 36 924 WHT RED YEL16 95 WHT GRN 37 925 WHT RED GRN17 96 WHT BLU 38 926 WHT RED BLU18 97 WHT VIO 39 927 WHT RED VIO19 98 WHT GRY 40 928 WHT RED GRY20 901 WHT BLK BRN 41 934 WHT ORN YEL21 902 WHT BLK RED 42 935 WHT ORN GRN

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Double-Start ACME ThreadsGeneral Information, Connector Selection Guide<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong> with Double-Start ACME MatingThread and .050" pitch (1.27mm) TwistPin Contact<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong> connector is a high density version of the <strong>Mighty</strong> <strong>Mouse</strong> <strong>Series</strong> 801 connector.The <strong>Series</strong> <strong>811</strong> connector features a quick-mating, damage-resistant double-start thread with the <strong>Glenair</strong>twistpin contact system for increased circuit density.<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong> Connector selectorPre-Wired PlugsPage 8Square Flange ReceptaclesPage 10Jam Nut ReceptaclesPage 12In-Line ReceptaclesPage 9Square Flange PCB ReceptaclesPage 15Jam Nut PCB ReceptaclesPage 14Overmolded CordsetsPage 17Jam Nut Tightening ToolTightening tools fit <strong>Series</strong> <strong>811</strong> spannernuts supplied with jam nut receptacleconnectors. Use with square drive torquewrench. Torque to 20-25 inch-pounds (2.2– 2.8 N m). Carbon steel, nickel plated.ShellSizeJam Nut ToolPart NumberDrive Square5 600-146-02 ¼" Drive6 600-146-03 ¼" Drive7 600-146-05 3/8" Drive8 600-146-05 3/8" Drive9 600-146-06 3/8" DriveDimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com4E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Specifications<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>Application Note:Sand and DustExposure<strong>Glenair</strong> TwistPincontacts can be damagedby sand and dust.Unmated connectorsshould be covered toprevent debris andcontamination fromaccumulating inside thecontact cavities. Pleasesee our metal and rubberprotective cover offeringsstarting on page 19.specificationsCurrent Rating3 AMPSDielectric Withstanding Voltage 600 VAC sea level, 150 VAC at 70,000 ft.Insulation Resistance5000 megohms minimumOperating Temperature -65° C. to +150° C.Contact Resistance8 milliohms maximumLow Level Contact Resistance 32 milliohms maximumWater Immersion, MatedMIL-STD-810G, Method 512.51 meter for 1 hourWater Ingress, Mated Ingress protection 67Helium Leak rate, Sealed PC tailReceptacles (<strong>811</strong>-006)1 x 10 -4 cc/sec at 1 atmos. pressure differential,following 5 cycles of thermal shockShock 300 g's (MIL-DTL-38999 para. 4.5.21.1)Vibration, Sine 60 g's (MIL-DTL-38999 para. 4.5.23.2.1)Vibration, Random 23 g's (MIL-DTL-38999 para. 4.4.23.1)HumidityEIA-364-31, Cond. IVAltitude-Low TemperatureEIA-364-105Durability2000 cycles of matingMagnetic Permeability2 µ maximumElectroless Nickel finish (ME) 96 hoursCorrosion (Salt Spray)Nickel-PTFE finish (MT) 500 hoursBlack Zinc-Nickel (ZR) 500 HoursShielding Effectiveness55 dB minimum from 100MHz to 1000MHz.materials and finishesShell, Jam Nut, Coupling Nut Aluminum alloyContactCopper alloy, 50 µ inch gold over nickel platedInsulatorGlass-reinforced thermoplasticInterfacial Seal, O-ring, PeripheralSealFluorosilicone rubber<strong>Series</strong> <strong>811</strong> Recommended Torque valuesCoupling TorqueJam Nut TighteningIn-Lbs. N-m In-Lbs. N-mLayout Min. Max. Min. Max. Min. Max. Min. Max.5-7 25 35 2.8 4.0 20 25 2.2 2.86-12 35 40 4.0 4.5 20 25 2.2 2.87-22 35 40 4.0 4.5 20 25 2.2 2.88-30 40 50 4.5 5.7 20 25 2.2 2.89-42 40 50 4.5 5.7 20 25 2.2 2.8key positionsPosition A° B°A 140° 220°B 65° 220°B°C 85° 240°A°D 130° 285°E 65° 285°F 85° 220°PlugA°ReceptacleB°Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com5E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Connector Material and Finish OptionsConnector FinishesThree standard plating finishes are available for <strong>Series</strong> <strong>811</strong> connectors: nickel, nickel-PTFE and black zinc-nickel.Other finishes are readily available; however, these three finishes are recommended for most operating environments.Choose electroless nickel (ME) for best shielding performance where connectors are not likely to be subjected tocorrosive environments.Nickel-PTFE (code MT) is an extremely durable, conductive finish now replacing olive-drab cadmium in corrosiveenvironments. The gun metal grey color is compatible with most equipment.Black Zinc-Nickel (Code ZR) is intended for tactical equipment where a non-reflective finish is preferred.Connector MaterialsFor most applications, aluminum alloy is the preferred material choice for connector bodies, coupling nuts andjam nuts. However, <strong>Series</strong> <strong>811</strong> connectors are also available in stainless steel or marine bronze. Refer to the table belowfor alternate material choices. Replace the standard material/finish code with the desired code from the table.<strong>Series</strong> <strong>811</strong> Material and Finish CodesCode Material FinishFinishSpecificationHrs. SaltSprayElectricalConductivityOperatingTemp. RangeRoHSComplianceAB Marine Bronze Unplated 1000 Conductive -65 to +200°C AL Aluminum AlumiPlate MIL-DTL-83488 1000 Conductive -65 to +175°C C Aluminum Anodize, Black AMS-A-8625 336 Non-Conductive -65 to +175°C E Aluminum Chem Film MIL-DTL-5541 168 Conductive -65 to +175°CG2 Aluminum Anodize, Hardcoat AMS-A-8625 336 Non-Conductive -65 to +200°C JF Aluminum Cadmium, Gold SAE-AMS-QQ-P-416 1000 Conductive -65 to +175°CLF Aluminum Cadmium, Clear SAE-AMS-QQ-P-416 1000 Conductive -65 to +175°CME Aluminum Electroless Nickel AMS-C-26074 96 Conductive -65 to +200°C MT Aluminum Nickel-PTFE GMF-002 1000 Conductive -65 to +175°C NC Aluminum Zinc-Cobalt, Olive Drab ASTM B 840 350 Conductive -65 to +175°CNF Aluminum Cadmium, Olive Drab SAE-AMS-QQ-P-416 1000 Conductive -65 to +175°CP Stainless Steel Electrodeposited Nickel SAE-AMS-QQ-N-290 500 Conductive -65 to +200°C UC Aluminum Zinc-Cobalt, Black ASTM B 840 350 Conductive -65 to +175°CUCR Aluminum Zinc-Cobalt, Black (RoHS) ASTM B 840 350 Conductive -65 to +175°C Z1 Stainless Steel Passivate SAE-AMS-QQ-P-35 1000 Conductive -65 to +200°C Z2 Aluminum Gold MIL-DTL-45204 48 Conductive -65 to +200°C ZC Stainless Steel Zinc-Cobalt, Black ASTM-B840 1000 Conductive -65 to +175°CZCR Stainless Steel Zinc-Cobalt, Black (RoHS) ASTM-B840 1000 Conductive -65 to +175°C ZL Stainless Steel Electrodeposited Nickel SAE-AMS-QQ-N-290 1000 Conductive -65 to +200°C ZM Stainless Steel Electroless Nickel AMS-C-26074 1000 Conductive -65 to +200°C ZMT Stainless Steel Nickel-PTFE GMF-002 1000 Conductive -65 to +175°C ZN Aluminum Zinc-Nickel, Olive Drab ASTM B841 1000 Conductive -65 to +175°CZNU Aluminum Zinc-Nickel, Black ASTM B841 1000 Conductive -65 to +175°CZR Aluminum Zinc-Nickel, Black ASTM B841 1000 Conductive -65 to +175°C ZU Stainless Steel Cadmium, Black SAE-AMS-QQ-P-416 1000 Conductive -65 to +175°CZW Stainless Steel Cadmium, Olive Drab SAE-AMS-QQ-P-416 2000 Conductive -65 to +175°CDimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com6E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Guidelines for Space-Grade Applications<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Connectors</strong> for Space FlightThe <strong>Series</strong> <strong>811</strong> connector is well-suited for space-flight applications. <strong>High</strong>density TwistPin contacts and other materials are already used in the NASAapproved<strong>Glenair</strong> Micro-D connector. The standard <strong>Series</strong> <strong>811</strong> connectorwith nickel plated aluminum shells is considered to be "flight-ready", butoptional NASA screening is also available.Application Note:OutgassingThe <strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong><strong>HD</strong> connector is suitable for usein space applications; however,the fluorosilicone seal exceeds theoutgassing limits of ASTM E595. Asimple oven bakeout is sufficient toremove volatile materials. Specialthermal vacuum outgassing isavailable using the suffix codesshown at right. A second optionis to remove the interfacial sealfrom the socket connector, thuseliminating the need for specialoutgassing processing.how to order space grade series <strong>811</strong> connectorsStep 1: Find a Standard Part NumberElectroless nickel plated shells are preferred for space flight. Cadmiumplating is prohibited.Step 2: Select a NASA Screening LevelThe term “Screening Level” refers to the final inspection procedure.Level 1 for mission-critical highest reliabilityLevel 2 for high reliabilityLevel 3 for standard reliabilityStep 3: Choose Outgassing ProcessingThe fluorosilicone rubber seals commonly used on aerospace-gradeconnectors such as MIL-DTL-38999 and <strong>Series</strong> 80 connectors, alongwith certain bonding agents and inks, do not meet NASA outgassingrequirements unless the connector is specially processed. <strong>Glenair</strong>outgassing tests have shown oven baking or thermal vacuumoutgassing processing are sufficient to reduce outgassing levelsto NASA standards. Oven baking is more economical than thermalvacuum outgassing.Step 4: Select the Mod 429 Code that Matches theDesired Level of Screening and OutgassingUse the following table to choose the right modification code. Add themod code to the connector part number. Example: <strong>811</strong>-001-06ME5-7PA-429C429C7PA-429C7PA-429CNASA Screening Levelnasa screening levels and modification codesSpecial Screening Plus OutgassingProcessingSpecial Screening,Connector Suppliedwith Interfacial SealSpecial Screening,Connector Suppliedwithout Interfacial SealDimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com7E-Mail: sales@glenair.com22 – 11 JANUARY - JULY - 2013 – 201448 Hour Oven Bake175° C.Thermal VacuumOutgassing24 hrs. 125° C.Level 1 <strong>High</strong>est Reliability Mod 429B Mod 429F Mod 429J Mod 429CLevel 2 <strong>High</strong> Reliability Mod 429 Mod 429D Mod 429K Mod 429ALevel 3 Standard Reliability (Use standard P/N) Mod 432 Mod 186 Mod 186M

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Pre-Wired Plug <strong>Connectors</strong><strong>811</strong>-001-06Pre-Wired Plug <strong>Connectors</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> plugs feature damage-resistant double-start ACMEmating threads and integral shielding/overmolding platforms. These plugs are factoryterminatedto insulated wire and backpotted with epoxy. The TwistPin contact systemmeets requirements of MIL-DTL-83513 and provides outstanding resistance to high levelsof shock and vibration. Choose Type K general purpose Teflon® wire or Type J lightweightspace-grade Tefzel® wire. 3A current rating, 600 VAC dielectric withstanding voltage.How To Order <strong>Series</strong> <strong>811</strong> PlugsSample Part Number<strong>811</strong>-001-06 MT 5-7 P A 6 K 7 –18<strong>Series</strong>ShellMaterial andFinishShell Size -Insert Arr.ContactTypeKeyPositionWireSizeWire TypeWireColorWireLength(<strong>Inc</strong>hes)<strong>811</strong>-001-06<strong>Series</strong> <strong>811</strong> PlugConnector with<strong>High</strong> <strong>Density</strong>TwistPins, PrewiredPigtails,Double-StartThreadMEElectrolessNickelMTNickel-PTFEZRBlack Zinc-Nickel5-77 Contacts6-1212 Contacts7-2222 Contacts8-3030 Contacts9-4242 ContactsPPinContactsSSocketContactsaNormalAlternateKeyPositionsbcdef6#268#28(Colorcode 1 or7 only)0#30(WireType J,colorcode 1 or7 only)kPTFEinsulation,silver-coated,200°C,(M22759/11)JTefzel®insulation,high strengthlightweightsilver-coated,200°C,(M22759/33)1White5Color codeper MIL-STD-681(striped)*710 Solidcolors,repeating–12–18–36–72Specify anylength from 2inches to 144inches.950 (24.13)MAXWIRE LENGTH .535 (3.59)Ø CCOUPLING NUT WITHSTRAIGHT KNURLCAVITY #1PIN INSERTMASTER KEYCAVITY #1SOCKET INSERTØ AHARNESSWIREShellSizeB T<strong>HD</strong>dimensionsØ AØ CIn. mm. B Thread In. mm.5 .540 13.72 .3125-.05P-.1L-2B .246 6.256 .600 15.24 .375-.05P-.1L-2B .286 7.267 .730 18.54 .4375-.05P-.1L-2B .391 9.938 .800 20.32 .5000-.05P-.1L-2B .443 11.25Dimensions 9 .862 in <strong>Inc</strong>hes 21.89 (millimeters) .5625-.05P-.1L-2B are subject to change without .498 notice. 12.65*Size 28 AWG and Size 30AWG J type wire not available instriped color code 5© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com8E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Pre-Wired In-Line Receptacle <strong>Connectors</strong><strong>811</strong>-003-01<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>In-Line Pigtail Receptacles<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> in-line receptacles feature damage-resistantdouble-start ACME mating threads and integral shielding/overmolding platforms.These receptacles are factory-terminated to insulated wire and backpotted with epoxy.The TwistPin contact system meets requirements of MIL-DTL-83513 and providesoutstanding resistance to high levels of shock and vibration. Choose Type K generalpurpose Teflon® wire or Type J lightweight space-grade Tefzel® wire. 3A current rating,600 VAC dielectric withstanding voltage.How To Order <strong>Series</strong> <strong>811</strong>-003-01 In-Line receptaclesSample Part Number<strong>811</strong>-003-01 MT 5-7 S A 8 K 7 -18<strong>Series</strong>ShellMaterial andFinishShell Size -Insert Arr.ContactTypeKeyPositionWireSizeWire TypeWireColorWireLength(<strong>Inc</strong>hes)<strong>811</strong>-003-01<strong>Series</strong> <strong>811</strong> In-Line ReceptacleConnector with<strong>High</strong> <strong>Density</strong>TwistPins, Pre-Wired Pigtails,Double-StartThreadMEElectrolessNickelMTNickel-PTFEZRBlack Zinc-Nickel5-77 Contacts6-1212 Contacts7-2222 Contacts8-3030 Contacts9-4242 ContactsPPinContactsSSocketContactsaNormalAlternateKeyPositionsbcdef6#268#28(Colorcode 1 or7 only)0#30(WireType J,colorcode 1 or7 only)kPTFEinsulation,silver-coated,200°C,(M22759/11)JTefzel®insulation,high strengthlightweightsilver-coated,200°C,(M22759/33)1White5Color codeper MIL-STD-681(striped)*710 Solidcolors,repeating–12–18–36–72Specify anylength from 2inches to 144inchesCAVITY #1PIN INSERTBMASTER KEYWAYC THREADCAVITY #1SOCKET INSERT1.000 (25.4) MAX.375 (9.53).225 (5.72)WIRE LENGTHØ DØ ARED FULL MATEINDICATOR STRIPESHIELDTERMINATIONBAND PLATFORMdimensionsShell Ø A B FlatØ DSize In. mm. In. mm. C Thread In. mm.5 .375 9.53 .350 8.89 .3125-.05P-.1L-2A .246 6.256 .415 10.54 .390 9.91 .3750-.05P-.1L-2A .286 7.267 .500 12.70 .475 12.07 .4375-.05P-.1L-2A .391 9.938 .580 14.73 .555 14.10 .5000-.05P-.1L-2A .443 11.259 Dimensions .635 16.13 in <strong>Inc</strong>hes .610 (millimeters) 15.49 are subject .5625-.05P-.1L-2A to change without notice. .498 12.65HARNESSWIRE*Size 28 AWG and Size30 AWG J type wire notavailable in striped colorcode 5© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com9E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Pre-Wired Square Flange Receptacle <strong>Connectors</strong><strong>811</strong>-003-02 and <strong>811</strong>-004-02Square Flange Pigtail Receptacles<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> panel mount receptacles feature damageresistantdouble-start ACME mating threads. These receptacles are factory-terminatedto insulated wire and backpotted with epoxy. The TwistPin contact system meetsrequirements of MIL-DTL-83513 and provides outstanding resistance to high levels ofshock and vibration. Choose Type K general purpose Teflon® wire or Type J lightweightspace-grade Tefzel® wire. 3A current rating, 600 VAC dielectric withstanding voltage.How To Order <strong>Series</strong> <strong>811</strong> square flange pigtail receptaclesSample Part Number<strong>811</strong>-003-02 MT 5-7 P A 6 K 7 -18<strong>Series</strong>ShellMaterialand FinishShell Size -Insert Arr.ContactTypeKeyPositionWireSizeWire TypeWireColorWireLength(<strong>Inc</strong>hes)<strong>811</strong>-003-02Panel Mount SquareFlange ReceptacleConnector withTermination Platform forShield Attachment orOvermolding<strong>811</strong>-004-02Low Profile PanelMount Square FlangeReceptacle ConnectorMEElectrolessNickelMTNickel-PTFEZRBlack Zinc-Nickel5-77 Contacts6-1212 Contacts7-2222 Contacts8-3030 Contacts9-4242 ContactsPPinContactsSSocketContactsaNormalAlternateKeyPositionsbcdef6#268#28(Colorcode1 or 7only)0#30(WireType J,colorcode1 or 7only)kPTFEinsulation,silver-coated,200°C,(M22759/11)JTefzel®insulation,high strengthlightweightsilver-coated,200°C,(M22759/33)1White5Color codeper MIL-STD-681(striped)*710 Solidcolors,repeating12183672Specify anylength from2 inches to144 inches*Size 28 AWG and Size 30AWG J type wire not available instriped color code 5Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com10E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Pre-Wired Square Flange Receptacle <strong>Connectors</strong><strong>811</strong>-003-02 and <strong>811</strong>-004-02<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>CAVITY #1PIN INSERTBMASTER KEYWAYØ CE T<strong>HD</strong>1.000 (25.40) MAX.370(9.40).060 (1.52)WIRE LENGTHØ FACAVITY #1SOCKET INSERTØ DRED FULL MATEINDICATOR STRIPESHIELDTERMINATIONBAND PLATFORMHARNESSWIRE<strong>811</strong>-003-02With Termination PlatformPANEL (REF).100 (25.4) MAXCAVITY #1PIN INSERTBMASTER KEYWAYØ CE T<strong>HD</strong>.625 (15.88).370(9.40).060 (1.52)Ø GWIRE LENGTHACAVITY #1SOCKET INSERTØ DRED FULL MATEINDICATOR STRIPEHARNESSWIRE<strong>811</strong>-004-02Low ProfilePANEL (REF).100 (25.4) MAXdimensionsShell A Square B Square Ø C Ø DØ F Ø GSize In. mm. In. mm. In. mm. In. mm. E Thread In. mm. In. mm.5 .625 15.88 .440 11.18 .825 20.96 .093 2.36 .3125-.05P-.1L-2A .246 6.25 .320 8.136 .725 18.42 .530 13.46 .950 24.13 .093 2.36 .3750-.05P-.1L-2A .286 7.26 .375 9.537 .800 20.32 .600 15.24 1.050 26.67 .093 2.36 .4375-.05P-.1L-2A .391 9.93 .480 12.198 .850 21.59 .650 16.51 1.125 28.58 .093 2.36 .5000-.05P-.1L-2A .443 11.25 .540 13.729 .950 24.13 .750 19.05 1.250 31.75 .093 2.36 .5625-.05P-.1L-2A .498 12.65 .600 15.24Ø RGB4X Ø DDimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com11E-Mail: sales@glenair.com11 - JULY - 2013panel cutoutShell Ø RSize In. mm.5 .350 8.896 .390 9.917 .500 12.708 .560 14.229 .620 15.75

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Pre-Wired Jam Nut Receptacle <strong>Connectors</strong><strong>811</strong>-003-07 and <strong>811</strong>-004-07Jam Nut Pigtail ReceptaclesHow To Order <strong>Series</strong> <strong>811</strong> jam nut pigtail receptaclesSample Part Number<strong>811</strong>-003-07 MT 5-7 P A 6 K 7 -18<strong>Series</strong>ShellMaterialand Finish<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> rear panel mount jam nut receptacles featuredamage-resistant double-start ACME mating threads. These receptacles are factoryterminatedto insulated wire and backpotted with epoxy. The TwistPin contact systemmeets requirements of MIL-DTL-83513 and provides outstanding resistance to high levelsof shock and vibration. Choose Type K general purpose Teflon® wire or Type J lightweightspace-grade Tefzel® wire. 3A current rating, 600 VAC dielectric withstanding voltage.Shell Size -Insert Arr.ContactTypeKeyPositionWireSizeWire TypeWireColorWireLength(<strong>Inc</strong>hes)<strong>811</strong>-003-07Panel Mount Jam NutReceptacle Connectorwith Band Platform forShield Attachment orOvermolding<strong>811</strong>-004-07Low Profile Panel MountJam Nut ReceptacleConnector with No BandPlatformMEElectrolessNickelMTNickel-PTFEZRBlack Zinc-Nickel5-77 Contacts6-1212 Contacts7-2222 Contacts8-3030 Contacts9-4242 ContactsPPinContactsSSocketContactsaNormalAlternateKeyPositionsbcdef6#268#28(Colorcode1 or 7only)0#30(WireType J,colorcode1 or 7only)kPTFEinsulation,silver-coated,200°C,(M22759/11)JTefzel®insulation,high strengthlightweightsilver-coated,200°C,(M22759/33)1White5Color codeper MIL-STD-681(striped)*710 Solidcolors,repeating12183672Specify anylength from2 inches to144 inches*Size 28 AWG and Size 30AWG J type wire not available instriped color code 5Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com12E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Pre-Wired Jam Nut Receptacle <strong>Connectors</strong><strong>811</strong>-003-07 and <strong>811</strong>-004-07<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>CAVITY #1PIN INSERTCMASTER KEYWAYD T<strong>HD</strong>1.000 (25.40) MAX.537 (13.64) .060 (1.52)JAM NUTWIRE LENGTHØ FBCAVITY #1SOCKET INSERTØ ARED FULL MATEINDICATOR STRIPEE T<strong>HD</strong>O-RING<strong>811</strong>-003-07With Band Platform.100 (2.54) MAXPANEL THICKNESSSHIELDTERMINATIONBAND PLATFORMHARNESSWIREMASTER KEYWAYWIRE LENGTHCAVITY #1 CPIN INSERT .537 (13.64) .060 (1.52)D T<strong>HD</strong> JAM NUTBCAVITY #1SOCKET INSERTØ ARED FULL MATEINDICATOR STRIPEE T<strong>HD</strong>HARNESSWIRE<strong>811</strong>-004-07Low ProfileO-RING.100 (2.54) MAXPANEL THICKNESSdimensionsShell Ø A B CE T<strong>HD</strong> Ø FSize In. mm. In. mm. In. mm. D Thread UN-2A In. mm.5 .575 14.61 .350 8.89 .545 13.84 .3125-.05P-.1L-2A .375-28 .246 6.256 .635 16.13 .410 10.41 .595 15.11 .3750-.05P-.1L-2A .4375-28 .286 7.267 .755 19.18 .536 13.61 .723 18.36 .4375-.05P-.1L-2A .5625-32 .391 9.938 .755 19.18 .536 13.61 .723 18.36 .5000-.05P-.1L-2A .5625-32 .443 11.259 .830 21.08 .596 15.14 .790 20.07 .5625-.05P-.1L-2A .625-28 .498 12.65AØ BShellSizepanel cutoutAB ØIn.±.002 mm.±0.05 In.±.002 mm.±0.055 .356 9.04 .385 9.786 .416 10.57 .447 11.357 .542 13.77 .572 14.538 .542 13.77 .572 14.539 .602 15.29 .635 16.13Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com13E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Jam Nut PCB Receptacle <strong>Connectors</strong><strong>811</strong>-005-07 and <strong>811</strong>-006-07 With Straight PC TailsJam Nut PC Tail ReceptaclesHow To Order <strong>Series</strong> <strong>811</strong>-005-07 and <strong>811</strong>-006-07 jam nut PC tail receptaclesSample Part Number<strong>811</strong>-005-07 MT 5-7 P A 3 -.125<strong>Series</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> jam nut PCB receptacles have straight PC tailsfor termination to flex circuits or rigid boards. These receptacles are backpotted withepoxy. The TwistPin contact system meets requirements of MIL-DTL-83513 and providesoutstanding resistance to high levels of shock and vibration. Choose solder-dippedor gold-plated tails. Select <strong>811</strong>-006-07 with enhanced waterblocking for open face(unmated) immersion requirements. Molded plastic endcap has standoffs. 3A currentrating, 600 VAC dielectric withstanding voltage.Shell Materialand FinishShell Size -Insert Arr.ContactTypeKeyPositionPC Tail FinishPC TailLength<strong>811</strong>-005-07<strong>Series</strong> <strong>811</strong> Rear PanelMount Jam Nut Receptacle,Straight PC Tails, StandardEpoxy Sealing<strong>811</strong>-006-07<strong>Series</strong> <strong>811</strong> Rear PanelMount Jam Nut Receptacle,Straight PC Tails, EnhancedWaterblocking for OpenFace (Unmated) WaterImmersionMEElectrolessNickelMTNickel-PTFEZRBlack Zinc-Nickel5-77 Contacts6-1212 Contacts7-2222 Contacts8-3030 Contacts9-4242 ContactsPPinContactsSSocketContactsaNormalAlternate KeyPositionsbcdef3Solder-Dipped in63/37 Tin-Lead4Gold Plated.090.125.250(Other lengthsare readilyavailable)CAVITY #1PIN INSERTBCMASTER KEYWAYD T<strong>HD</strong>CAVITY #1SOCKET INSERT.870 (22.10).060 (1.52)JAM NUT.325(8.26)4X .020 (0.51)Ø.018/.022(0.46/0.56)Ø FGØ HØ ARED FULL MATEINDICATOR STRIPEE T<strong>HD</strong>O-RING.100 (2.54) MAX PANEL THICKNESSdimensionspanel cutoutShell Ø A B CE T<strong>HD</strong> Ø F Shell GH ØSize In. mm. In. mm. In. mm. D Thread UN-2A In. mm. Size In.±.002 mm.±0.05 In.±.002 mm.±0.055 .575 14.61 .350 8.89 .545 13.84 .3125-.05P-.1L-2A .375-28 .350 8.89 5 .356 9.04 .385 9.786 .635 16.13 .410 10.41 .602 15.29 .3750-.05P-.1L-2A .4375-28 .490 12.45 6 .416 10.57 .447 11.357 .755 19.18 .536 13.61 .723 18.36 .4375-.05P-.1L-2A .5625-32 .600 15.24 7 .542 13.77 .572 14.538 .755 19.18 .536 13.61 .723 18.36 .5000-.05P-.1L-2A .5625-32 .670 17.02 8 .542 13.77 .572 14.539 .830 21.08 .596 15.14 .791 20.09 .5625-.05P-.1L-2A .625-28 .770 19.56 9 .602 15.29 .635 16.13Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com14E-Mail: sales@glenair.com11 - JULY - 2013TAIL LENGTH± .015 (0.38)PLASTIC ENDCAP W/MOLDED STANDOFFS

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)PCB Receptacle Connector Hole Patterns<strong>811</strong>-005 and <strong>811</strong>-0061 23 4 56 7Pin InsertEngaging Face 5-71 2 34 5 6 78 9 1011 12Component Mounting Side of PCB1 23 4 56 7.0375 (0.95).075 (1.91).075 (1.91)Pin Connector.050(1.27)1 2 34 5 6 78 9 1011 12.0375 (0.95).075 (1.91)5274613.0375 (0.95).075 (1.91).075 (1.91)Socket ConnectorPin InsertEngaging Face 6-12 Pin Connector Socket Connector.075(1.91).025(0.635)73106122951<strong>811</strong>4.0375 (0.95).075 (1.91).025(0.635).075(1.91)1 2 3 45 6 7 8 910 11 12 1314 15 16 17 1819 20 21 22Pin InsertEngaging Face 7-2251 2 346 7 8 910 11 12 13 14 1516 17 18 19 20 2122 23 24 25 2627 28 29 30Pin InsertEngaging Face 8-30.0375 (0.95)1 2 3 45 6 7 810 11 12 1314 15 16 17 1819 20 21 22.0375 (0.95).075 (1.91)Pin Connector1 2 3 45 6 7 810 11 12 13 14 15916 17 18 19 20 2122 23 24 25 2627 28 29 309.075 (1.91)Pin Connector.075(1.91).0375(0.95).075(1.91)94837261513 12 11 1018 17 16 15 1422 21 20 19Socket Connector.0375 (0.95)94837215 14 13 1265111 1021 20 19 18 1726 25 24 2330 29 282722.0375 (0.95).075 (1.91).075 (1.91)16Socket Connector.075(1.91).0375(0.95).075(1.91).0375 (0.95).075 (1.91).0375 (0.95).075 (1.91)1 2 3 4 56 7 8 9 10 1112 13 14 15 16 17 1819 20 21 22 23 2425 26 27 28 29 30 3132 33 34 35 36 3738 39 40 41 421 2 3 4 56 7 8 9 10 1112 13 14 15 16 17 1819 20 21 22 23 2425 26 27 28 29 30 3132 33 34 35 36 3738 39 40 41 42.075(1.91)5 4 3 2 110 11 9 8 7 618 17 16 15 14 13 1224 23 22 21 20 1931 30 29 28 27 26 2537 36 35 34 33 3242 41 40 39 38.075(1.91)Pin InsertEngaging Face 9-42Pin ConnectorDimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.Socket Connector© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com16E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Harsh Environment Cordsets<strong>811</strong>-007<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>Harsh Environment CordsetsOvermolded <strong>Series</strong> <strong>811</strong> cordsets withstand abrasion and chemical exposure. Cableconstruction features silver coated stranded conductors with TFE insulation, tinnedcopper braid shield and extruded black polyurethane jacket. Choose single-endedpigtails or double-ended "back-to-back" cables. Semi-rigid polyamide overmoldprovides strain relief and environmental sealing.• Tough polyurethane jacket,low-smoke, zero halogen• Water-resistant to 1 meter• 100% electrically tested• Shielded with 90% minimumtinned copper braid• Straight or right angle• Easy to order, quick deliveryHow To Order <strong>Series</strong> <strong>811</strong>-007 cordsetsSample Part Number<strong>811</strong>-007 -A S C S 6 MT 5-7 P A -60<strong>Series</strong>End "A"ConnectorEnd "A"Config.End "B"ConnectorEnd "B"Config.WireSizeShellFinishLayoutProtectiveCoverKeyPos.Lengthin<strong>Inc</strong>hes<strong>811</strong>-007<strong>Series</strong> <strong>811</strong>OvermoldedCordset-APlug withFemaleSocketContacts-BPlug withMale PinContacts-cReceptaclewithMale PinContacts-dReceptaclewithFemaleSocketContactssStraightrRightAngleAPlug withFemaleSocketContactsBPlug withMale PinContactscReceptaclewithMale PinContactsdReceptaclewithFemaleSocketContactssStraightrRightAngleOmit forSingleendedPigtail6#26AWGMEElectrolessNickelMTNickelPTFEZRBlack ZincNickel5-77Contacts6-1212Contacts7-2222Contacts8-3030Contacts9-4242ContactsPMetalProtectiveCovers<strong>Inc</strong>ludedNNoProtectiveCoversaNormalAlternateKeyPositionsbcdefOverallLength in<strong>Inc</strong>hes(12 <strong>Inc</strong>hMinimum)nNoConnector(Single-EndedPigtail)Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com17E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Harsh Environment Cordsets<strong>811</strong>-007A MAXLENGTH + 2.00/ -0.00(+50.1 / -0.0)12 INCH (300 MM.) MINIMUMB MAXOPTIONAL PROTECTIVECOVERD MAXSHIELDED, JACKETEDCABLEWATER-RESISTANTOVERMOLDLENGTH + 2.00/ -0.00(+50.1 / -0.0)12 INCH (300 MM.) MINIMUMC MAXSHIELDED, JACKETEDCABLEWATER-RESISTANTOVERMOLDMASTER KEY LOCATED 180°FROM CABLE EXITShellSizedimensionsA Max. B Max. C Max. D Max.In. mm. In. mm. In. mm. In. mm.5 2.50 63.5 0.60 15.3 2.20 55.9 1.50 38.16 2.50 63.5 0.60 15.3 2.20 55.9 1.50 38.17 2.50 63.5 0.70 17.8 2.40 61.0 1.50 38.18 2.60 66.0 0.75 19.1 2.50 63.5 1.60 40.79 2.90 73.7 0.85 21.6 2.70 68.6 1.90 48.3<strong>Series</strong> <strong>811</strong> cordset specificationsCable Jacket MaterialThermoplastic Polyurethane,Black, Low-Smoke, Zero-HalogenCable ShieldTin-Coated Copper Braid, 90%Minimum CoverageConductorsSilver Coated Stranded Wire, TFEInsulated, Per M22759/11BAND-IT® ShieldTermination BandStainless SteelCurrent Rating 3 A.Test Voltage (DielectricWithstanding Voltage)600 VAC Sea LevelInsulation Resistance 200 megohms minimumOperating Temperature -30° C. to +105° C.Solvent Resistance,Polyamide OvermoldExcellent Resistance to MostSolvents, Fuels, and Oils; PoorResistance to Strong Acids andBipolar Solvents (Alcohol)Shielding Effectiveness50 dB minimum from 100MHz to1000MHz.Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com18E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Metal Protective Covers667-347 and 667-218<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>Protect <strong>Connectors</strong> From DamageMachined aluminum covers have rubbergaskets for a watertight fit.Stainless Steel Fittings and Rings Choosesmall diameter eye fittings for panelattachment. Larger rings fit under the jamnut or over cable jackets. Split rings canbe installed on fully assembled cables.Polyurethane-Coated SST Wire Ropeoffers high strength, excellent abrasionresistance and good flexibility. Or, chooseTeflon ® jacket for high temperatureexposure.Braided Nylon Rope provides excellentflexibility and good abrasion resistance,and can be ordered with slip knot fittingsfor easy installation on any size cable.how to orderSample Part Number667-347 -M -G 9 04 -6<strong>Series</strong>Shell Material / FinishAttachmentTypeShellSizeAttachment CodeAttachmentLength in<strong>Inc</strong>hes667-347ProtectiveCover for usewith <strong>Series</strong><strong>811</strong> Plugs667-218ProtectiveCover foruse with<strong>Series</strong> <strong>811</strong>ReceptaclesMEAluminum / ElectrolessNickelRoHS CompliantMTAluminum / Nickel-PTFERoHS CompliantZRAluminum / Zinc-Nickelwith Black Chromate-GNylon Rope-HSST Wire Rope,Teflon® Jacket-NNo Attachment-SSST Sash Chain-SKNylon Rope WithSlip Knot-TSST Wire Rope,No Jacket-USST Wire Rope,PolyurethaneJacket"SST" =Stainless Steel56789Omit for attachment Types N (No Attachment)and SK (Slip Knot)Small RingLarge RingSplit Ring01 – .126 (3.20) I.D.02 – .145 (3.68) I.D.04 – .188 (4.78) I.D.06 – .197 (5.00) I.D.14 – .385 (9.78) I.D.15 – .445 (11.30) I.D.16 – .570 (14.48) I.D.17 – .635 (16.13) I.D.18 – .695 (17.65) I.D.19 – .885 (22.48) I.D.20 – 1.070 (27.17) I.D.21 – 1.135 (28.83) I.D.22 – 1.210 (30.73) I.D.23 – 1.275 (32.39) I.D.24 – 1.375 (34.94) I.D.50 – .420 (10.67) I.D.52 – .480 (12.19) I.D.54 – .635 (16.13) I.D.56 – .745 (18.92) I.D.58 – .885 (22.48) I.D.60 – 1.010 (25.65) I.D.64 – 1.125 (28.58) I.D.68 – 1.345 (34.16) I.D.Omit forattachmentType N (NoAttachment)Example"-6" equals sixinch lengthDimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com19E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Metal Protective CoverDimensions and Attachments667-347 and 667-218Attaching a 667-218 Receptacle Cover to aRear Panel Mounted Jam Nut ReceptacleATTACHMENT RINGFITS UNDER JAM NUTPROTECTIVECOVER667-218PANELRECEPTACLECONNECTORSTYLE 07Attaching a Cover to a Panel With a ScrewJAMNUTRing I.D.Ring O.D.Dia.CodeShellSizeIn. mm. In. mm.± .010 ±0.25 ± .015 ± 0.38Solid Ring14 5 .385 9.78 .510 12.9515 6 .445 11.30 .565 14.3516 7, 8 .570 14.48 .685 17.4017 9 .635 16.13 .760 19.30Small Ringfor AttachingReceptacle Coversto a Panel with aScrewRing I.D. Ring O.D.Dia. Screw In. mm. In. mm.Code Size ±.005 ±0.13 Max. Max.01 #4, M3 .126 3.20 .31 7.902 #6 .145 3.68 .31 7.904 #8, M4 .188 4.78 .31 7.906 #10 .197 5.00 .31 7.9Attaching a Cover to a Cable Assemblywith a Solid RingINSTALL RING BEFOREMOLDING OR BACKSHELLINSTALLATIONAttaching a Cover to a CableUsing a Split RingINSTALL SPLITRING OVER CABLEJACKET#4-40 FILL.<strong>HD</strong>. SCREW#4-40LOCKNUTAND SPLITWASHERSolid RingDia.CodeShellSizeRing I.D.Ring O.D.In. mm. In. mm.± .010 ±0.25 ± .015 ± 0.3814 5,6 .385 9.78 .510 12.9515 7 .445 11.30 .565 14.3516 8, 9 .570 14.48 .685 17.40Large Split Ring forAttaching Covers toCablesDia.CodeMax.CableDia. (in.)Ring DiameterMin. ID Max. ODIn. mm. In. mm.50 .410 .420 10.67 .580 14.7352 .470 .480 12.19 .640 16.2654 .625 .635 16.13 .796 20.2256 .735 .745 18.92 .905 22.9958 .875 .885 22.48 1.046 26.5760 1.000 1.010 25.65 1.171 29.7464 1.115 1.125 28.58 1.285 32.6468 1.335 1.345 34.16 1.505 38.23Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com20E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Metal Protective CoverDimensions and Attachments667-347 and 667-218<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>GASKET.800 (20.3)MAX.800 (20.3)MAXGASKET .600 (15.2)MAXABC THREAD-2ALENGTH± .25 (6.4)C THREAD-2BLENGTH± .25 (6.4)667-347 Plug Cover 667-218 Receptacle CoverDimensionsShell A Max. B Max.Size In. mm. In. mm. C5 .465 11.81 .488 12.40 .3125-.05P-1L6 .525 13.34 .555 14.10 .375-.05P-1L7 .590 14.99 .615 15.62 .4375-.05P-1L8 .653 16.59 .675 17.15 .5000-.05-.1L9 .715 18.16 .840 21.34 .5625-.05P-.1LNylon RopeLanyard OptionsPolyurethane Coated Wire Rope-55° to +100°C., black, veryflexible, very good abrasionresistance, good resistance tofuels, .120" (3mm) diameterBlack polyurethane over stainlesssteel rope, -55° to +125°C.,very flexible, excellent abrasionresistance, excellent resistance tofuels, .080" (2mm) diameterMaterials and FinishesCover Aluminum alloy or stainless steelGasket Silicone rubberWire,Hardware Stainless steel, passivatedTeflon ® Jacketed Wire RopeSash ChainSlip Knot (SK)for Attaching Covers to CableTranslucent FEP jacket overstainless steel, -55° to +200°C.,fair flexibility, good abrasionresistance, .100" diameterStainless steel, #8 chain, .240"(6mm)55° to +100°C., black, veryflexible, very good abrasionresistance, good resistance tofuels, .120" (3mm) diameter.Length includes .5" (13mm)diameter loop.Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com21E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Rubber Protective Covers809-190 and 809-191These splashproof molded rubber coversfit all <strong>Series</strong> <strong>811</strong> plugs and receptacles.Braided black nylon lanyard is availablewith metal rings, cable tie or slipknot forattachment to panel or to cable. -400 to+1200 C operating temperature, fungusresistant per MIL-STD-810G Method 508.6.MaterialsCoverNeoprene rubberblend, blackLanyard.062" (1.57) diameternylon cord, blackCable Tie6/6 nylon, black, SSTlocking tabRingStainless steel, blackzinc-cobalt finishCrimp SleeveCopper Alloy, blackzinc-cobalt finishhow to orderSample Part Number809-191 - 05 G 6 - SCS C<strong>Series</strong>ShellSizeLanyardTypeLanyardLengthAttachment CodeConductiveRubber809-190Protective Cover foruse with <strong>Series</strong> <strong>811</strong>Receptacles-05-06-07-08-09-GNylon Rope(Omit for nolanyard)Length in<strong>Inc</strong>hes-WSNylon Cable Tie, 1.77 <strong>Inc</strong>h (45mm) Maximum WireBundle Diameter-SCSAdjustable Slip Knot with Crimp Sleeve. The sleevecan be crimped with pliers for a permanent attachment.Omit forStandardNeopreneCConductiveRubber-00Lanyard With No Attachment (Fused End)Lug Terminals and Rings809-191Protective Cover foruse with <strong>Series</strong> <strong>811</strong>PlugsLug TerminalSolid Ring-01 – .126 (3.20) I.D.-02 – .145 (3.68) I.D.-06 – .188 (4.78) I.D.-07 – .197 (5.00) I.D.-08 – .385 (9.78) I.D.-09 – .445 (11.30) I.D.-10 – .516 (13.11) I.D.-11 – .570 (14.48) I.D.-12 – .583 (14.81) I.D.-13 – .635 (16.13) I.D.-14 – .695 (17.65) I.D.-15 – .776 (19.71) I.D.-16 – .885 (22.48) I.D.-17 – .896 (25.76) I.D.-18 – 1.015 (25.78) I.D.-19 – 1.070 (27.18) I.D.-20 – 1.135 (28.83) I.D.-21 – 1.141 (28.98) I.D.Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com22E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Rubber Protective CoverDimensions and Attachments809-190 and 809-191<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>Attaching a 809-190 Receptacle Cover to aRear Panel Mounted Jam Nut ReceptacleAttaching a Cover to a Panel with a ScrewPROTECTIVECOVER809-190ATTACHMENT RINGFITS UNDER JAM NUTPANELRECEPTACLECONNECTORSTYLE 07LUGTERMINALSCREWCONNECTORSolid RingDia.CodeJAMNUTShellSizeRing I.D. Ring O.D.In. mm. In. mm.± .010 ±0.25 ± .015 ± 0.3808 5 .385 9.78 .510 12.9509 6 .445 11.30 .565 14.3511 7, 8 .570 14.48 .685 17.4013 9 .635 16.13 .760 19.30Lug Terminalfor AttachingReceptacle Coversto a Panel with aScrewPROTECTIVECOVER809-190Ring I.D. Ring O.D.Dia. Screw In. mm. In. mm.Code Size ±.005 ±0.13 Max. Max.01 #4, M3 .126 3.20 .31 7.902 #6 .145 3.68 .31 7.906 #8, M4 .188 4.78 .31 7.907 #10 .197 5.00 .31 7.9Attaching a Cover to a Cable Assemblywith Type WS Cable TieAttaching a Cover to a Cable Assemblywith a Solid RingBLACK NYLON CABLE TIEWITH SST LOCKING TABINSTALL RING BEFOREMOLDING OR BACKSHELLINSTALLATIONSST SCREW WITHSELF-LOCKING NUTAttaching a Cover to a Cable Assemblywith Type SCS Slip KnotDia.CodeShellSizeRing I.D. Ring O.D.In. mm. In. mm.± .010 ±0.25 ± .015 ± 0.3808 5,6 .385 9.78 .510 12.95FRICTION/CRIMP SLEEVE09 7 .445 11.30 .565 14.35Large Ring11 8, 9 .570 14.48 .685 17.40Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com23E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Rubber Protective CoverDimensions and Attachments809-190 and 809-191SOLID RINGø ALUG TERMINALNO LUG, FUSED END (00)SLIP KNOT WITH CRIMP SLEEVE (SCS)ø.50REFLENGTH MEASUREDAT.50 DIAMETERø BCABLE TIE (WS)CDLENGTH(SEE PART NUMBER DEVELOPMENT)809-190 Receptacle CoverShell Ø A Ø B C DSize In. mm. In. mm. In. mm. In. mm.05 .28 7.1 .41 10.4 .31 7.9 .62 15.706 .35 8.9 .47 11.9 .31 7.9 .62 15.707 .41 10.4 .53 13.5 .31 7.9 .62 15.708 .47 11.9 .60 15.2 .31 7.9 .62 15.709 .53 13.5 .66 16.8 .31 7.9 .62 15.7809-191 Plug CoverShell Ø A Ø B C DSize In. mm. In. mm. In. mm. In. mm.05 .51 13.0 .70 17.8 .375 9.5 .875 22.206 .57 14.5 .76 19.3 .375 9.5 .875 22.207 .66 16.8 .85 21.6 .375 9.5 .875 22.208 .72 18.3 .91 23.1 .375 9.5 .875 22.209 .78 19.8 .97 24.6 .375 9.5 .875 22.2Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com24E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong><strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong>AccessoriesHex Nuts 809-035 / Flange Gasket 809-255<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>Hex Jam Nuts for <strong>Mighty</strong> <strong>Mouse</strong> ReceptaclesReplace low-profile spanner-style jam nuts with hex nuts for applications where jam nuts must be safety-wired to preventloosening. These hex nuts fit all standard <strong>Series</strong> <strong>811</strong> jam nut receptacles. Use <strong>Glenair</strong> Modification Code 501 to specify hex nuts tobe supplied with connector. The jam nut tightening torque for <strong>Series</strong> <strong>811</strong> connectors is 20 in-lbs minimum to 25 in-lbs maximum.THREAD(SEE TABLE).100 ±.005(2.54 ± 0.13)Aø BHOLE FOR .032 (0.81) MAX DIASAFETY WIRE (3 @ 120°)Part NumberDimensionsAluminumStainless SteelShellElectroless Olive Drab Black ZincBlack Zinc-A Hex B Dia.Size Thread Size Nickel Cadmium Nickel Nickel-Ptfe Passivated Cobalt in. mm. in. mm.5 .3750-28 UN 809-035M04W 809-035NF04W 809-035ZNU04W 809-035MT04W 809-035Z104W 809-035ZC04W .500 12.70 .547 13.896 .4375-28 UNEF 809-035M05W 809-035NF05W 809-035ZNU05W 809-035MT05W 809-035Z105W 809-035ZC05W .5625 14.29 .620 15.757 and 8 .5625-32 UN 809-035M07W 809-035NF07W 809-035ZNU07W 809-035MT07W 809-035Z107W 809-035ZC07W .6875 17.46 .755 19.189 .6250-28 UN 809-035M08W 809-035NF08W 809-035ZNU08W 809-035MT08W 809-035Z108W 809-035ZC08W .750 19.05 .830 21.08Flange Gaskets for <strong>Series</strong> <strong>811</strong>-003-02 and <strong>811</strong>-004-02 <strong>Mighty</strong> <strong>Mouse</strong> ReceptaclesCTYPABSCD DIA4 PLACESThese flange gaskets provide sealingbetween square flange receptacles andthe mounting panel. Choose fluorosilicone,Viton ® , or conductive fluorosiliconematerial (Chomerics 1298 silver-filled).Gaskets are .032” (0.8) thick.E RADB DIAPart NumberDimensionsConductive A Bsc. B Dia. C Square. D Dia. E Rad.Shell Size Fluorosilicone Viton ® Fluorosilicone In. mm. In. mm. In. mm. In. mm. In. mm.5 809-255F01 809-255V01 809-255X01 .440 11.17 .350 8.89 .625 15.87 .093 2.36 .093 2.366 809-255F02 809-255V02 809-255X02 .530 13.46 .390 9.91 .725 18.41 .093 2.36 .093 2.367 809-255F03 809-255V03 809-255X03 .600 15.24 .500 12.70 .800 20.32 .093 2.36 .093 2.368 809-255F04 809-255V04 809-255X04 .650 16.51 .560 14.22 .850 21.59 .093 2.36 .093 2.369 809-255F05 809-255V05 809-255X05 .750 19.05 .620 15.75 .950 24.13 .093 2.36 .093 2.36Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com25E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> Accessoriesand Replacement O-Ring for Jam Nut ReceptacleFlange Gasket 809-255 / O-RingFlange Gaskets for <strong>Series</strong> <strong>811</strong>-005-02 and <strong>811</strong>-006-02 <strong>Mighty</strong> <strong>Mouse</strong> ReceptaclesCTYPABSCB DIAD DIA4 PLACESE RADThese flange gaskets provide sealingbetween square flange receptacles andthe mounting panel. Choose fluorosilicone,Viton ® , or conductive fluorosiliconematerial (Chomerics 1298 silver-filled).Gaskets are .032” (0.8) thick.Part NumberDimensionsConductive A Bsc. B Dia. C Square. D Dia. E Rad.Shell Size Fluorosilicone Viton ® Fluorosilicone In. mm. In. mm. In. mm. In. mm. In. mm.5 809-255F11 809-255V11 809-255X11 .440 11.17 .360 9.14 .625 15.87 .093 2.36 .093 2.366 809-255F12 809-255V12 809-255X12 .530 13.46 .410 10.41 .725 18.41 .093 2.36 .093 2.367 809-255F13 809-255V13 809-255X13 .600 15.24 .520 13.21 .800 20.32 .093 2.36 .093 2.368 809-255F14 809-255V14 809-255X14 .650 16.51 .570 14.47 .850 21.59 .093 2.36 .093 2.369 809-255F15 809-255V15 809-255X15 .750 19.05 .660 16.76 .950 24.13 .093 2.36 .093 2.36O-Rings for <strong>Mighty</strong> <strong>Mouse</strong> Jam Nut ReceptaclesReplace lost or damaged O-rings with standard fluorosilicone O-rings. Or, choose EPDM o-rings for improved resistance tohydraulic fluids. Upgrade to silver-filled conductive O-rings for improved EMI protection.CROSS-SECTIONINSIDEDIAMETERO-rings for <strong>Series</strong> <strong>811</strong> Jam Nut Receptacles (Style 07)Part NumberDimensionsShell Fluoro-ConductiveSiliconeConductiveFluorosiliconeInsideDiameterCross-SectionSize silicone EPDM Cho-Seal 1285 Cho-Seal 1298 In. mm. In. mm.5 809-054-05F 809-054-05E 249-003-801-05B 249-003-801-05C .394 10.01 .047 1.196 809-054-06F 809-054-06E 249-003-801-06B 249-003-801-06C .459 11.66 .049 1.247 809-054-07F 809-054-07E 249-003-801-07B 249-003-801-07C .578 14.68 .040 1.028 809-054-08F 809-054-08E 249-003-801-08B 249-003-801-08C .578 14.68 .040 1.029 809-054-09F 809-054-09E 249-003-801-09B 249-003-801-09C .650 16.51 .045 1.14Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com26E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Shrink Boots809S060, 809SL060, 809A060, 809B060 and 809SU060<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>Shrink Boots – Straight, Long Tail, 90°, 45° and USB for <strong>Series</strong> <strong>811</strong> <strong>Connectors</strong>Protect Your Cable Harness with heat-shrinkable boots. These easy-to-use bootsprovide excellent electrical, mechanical and environmental protection. Heatingthe boot causes the boot to shrink onto the connector and cable . An adhesivelining bonds the boot to the connector and cable and fills small gaps for acomplete seal. Choose straight cable exit or right angle exit. These lipped bootsattach directly to <strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong> connectors with integral bandplatform. After shrinking, the boot lip locks into groove. Choose Type 1 highperformance elastomer for extreme temperatures and excellent resistance tofuels and oils or Type 2 non-halogenated flame-retardant polyolefin for usewhere limited fire hazard is required.Material Selection GuideAttributeType 1<strong>High</strong> PerformanceSemi-RigidElastomerType 2Zero HalogenPolyolefinType 9Low-TempFlexible Polyolefin– USB ONLY –Continuous Operating Temp. -75° to +150°C -40° to +130°C -40° to +100°CResistance to Fuels, Oils Excellent Very Good Very GoodLow Toxicity, Zero Halogen No Yes NoBOOT LIPCONNECTORLIPPED BOOTHEATSHRINKBOOTType 1 <strong>High</strong> performance ElastomerSemi-rigid high performance boots combine excellent resistance to fuels, oilsand solvents with superior performance at extreme temperatures. Rated for3000 hours continuous operation at +150° C, these boots fit most standardboot adapters for circular connectors. Material meets the requirements ofVG95343 Type 6, BSG 198-5-DE, EN62329-102 and SAE AS5258 Type H. Theseboots are recommended for demanding applications such as military vehiclesand petrochemical exploration. Standard Black color.Type 2 Zero halogenHalogen-free polyolefin boots meet low smoke and toxicity requirements ofshipboard, transit and aircraft systems. These Low Smoke/Zero Halogen (LSZH)boots fit most standard shrink boot adapters, including M85049 types alongwith <strong>Glenair</strong> <strong>Series</strong> 31 and <strong>Series</strong> 44 adapters. Oxygen index greater than 30%,smoke index less than 20, and toxicity index under 3 per 100 grams. Materialmeets requirements of NAVSEA 5617649, VG95343 Part 29, BSG 198-5-DF,EN62329-101 and SAE AS5258 Type G. Resistance to oils, fuels and solvents. Theboots provide strain relief and environmental protection to connector/cabletransitions. Temperature rating -40° C to +130° C. Standard Black color.Type 9 Low Temp Installable Flexibile Polyolefin (Standard for USB)Lipped Straight USB Shrink Boots are available only in Type 9 FlexiblePolyolefin which is designed for a low installation temperature of less than80°C. Operating temperature range of -40°C to 100°C. Standard Black color.Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com27E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Shrink BootsBoot Material PropertiesAdhesive Lined Boot Material PropertiesHeat-shrink boots are not watertight unless equipped with factory-installed or user-installed adhesives. Whenheat is applied to the boot, the adhesive melts and fixes the boot to the adapter and cable jacket to provide thenecessary sealing as well as mechanical strain-relief. Hot melt thermoplastic polyamide adhesive is compatiblewith most cable jackets, economical and easy to install.PropertyShrink Boot Typical Material PropertiesType 1<strong>High</strong> PerformanceElastomerType 2Zero HalogenPolyolefinFlexibility Semi-rigid Semi-flexible Flexible* Note: Type 9 Low-Temp Flexible Polyolefin is the standard materialfor the USB Shrink Boot.Type 9*Low TemperatureFlexible PolyolefinOperating Temperature Range -75°C to +150°C -40°C to +130°C -40°C to +100°CShrink Temperature (min.) 135°C 135°C

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Shrink Boots809S060, 809A060 and 809B060<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>Lipped Straight Shrink Boots- Type I <strong>High</strong> Performance Elastomer• -75° C to +150° C• Excellent resistance to fuels, oils,solvents and heat.Shell SizePart NumberBootSize<strong>Series</strong> <strong>811</strong><strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong>Pre-Coated with W1 Hi-TempHot-Melt Adhesive1 5/6 809S060-12 7 809S060-23 8, 9 809S060-3Lipped Straight Shrink Boots- Type 2 Zero Halogen• Low Smoke, Zero Halogen• M e e t s U . S . a n d E . U . t ox i c i t yrequirements.Shell SizePart NumberBootSize<strong>Series</strong> <strong>811</strong><strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong>Pre-Coated with W1 Hi-TempHot-Melt Adhesive1 5/6 809S060-1H2 7 809S060-2H3 8, 9 809S060-3HLipped 90° Right Angle Shrink Boots- Type I <strong>High</strong> Performance Elastomer• -75° C to +150° C• Excellent resistance to fuels, oils,solvents and heat.Shell Size<strong>Series</strong> <strong>811</strong><strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong>1 5/6 809A060-12 7 809A060-23 8, 9 809A060-3BootSizePart NumberPre-Coated with W1 Hi-TempHot-Melt AdhesiveLipped 90° Right Angle Shrink Boots- Type 2 Zero Halogen• Low Smoke, Zero Halogen• M e e t s U . S . a n d E . U . t o x i c i t yrequirements.Shell Size<strong>Series</strong> <strong>811</strong><strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong>1 5/6 809A060-1H2 7 809A060-2H3 8, 9 809A060-3HBootSizePart NumberPre-Coated with W1 Hi-TempHot-Melt AdhesiveLipped 45° Angle Shrink Boots- Type I <strong>High</strong> Performance Elastomer• -75° C to +150° C• Excellent resistance to fuels, oils,solvents and heat.Shell Size<strong>Series</strong> 800, 801, 802,803, 8041 5/6 809B060-12 7 809B060-23 8, 9 809B060-3BootSizePart NumberPre-Coated with W1 Hi-TempHot-Melt Adhesive© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com29E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Shrink Boots809B060, 809SL060 and 809SU060Lipped 45° Angle Shrink Boots- Type 2 Zero Halogen• Low Smoke, Zero Halogen• M e e t s U . S . a n d E . U . t ox i c i t yrequirements.Shell Size<strong>Series</strong> <strong>811</strong><strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong>1 5/6 809B060-1H2 7 809B060-2H3 8, 9 809B060-3HBootSizePart NumberPre-Coated with W1 Hi-TempHot-Melt AdhesiveLipped Straight Long Tail Shrink Boots- Type I <strong>High</strong> Performance Elastomer• -75° C to +150° C• Excellent resistance to fuels, oils,solvents and heat.BootSizeShell SizePart NumberPre-Coated with W1 Hi-Temp Hot-Melt Adhesive<strong>Series</strong> <strong>811</strong><strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong>1 5/6 809SL060-12 7 809SL060-23 8/9 809SL060-3Lipped Straight Long Tail Shrink Boots- Type 2 Zero Halogen• Low Smoke, Zero Halogen• M e e t s U . S . a n d E . U . t ox i c i t yrequirements.Shell Size<strong>Series</strong> <strong>811</strong><strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong>1 5/6 809SL060-1H2 7 809SL060-2H3 8/9 809SL060-3HBootSizePart NumberPre-Coated with W1 Hi-Temp Hot-Melt AdhesiveLipped Straight USB Shrink Boots- Type 9 Low-Temp Flexibile Polyolefin• -40° C to +100° C• Same excellent physical propertieswithin a limited temperature range.BootSizeShell Size<strong>Series</strong> <strong>811</strong><strong>Mighty</strong> <strong>Mouse</strong> <strong>HD</strong>1 7/8 809SU060-1Part NumberPre-Coated withW2 Hot-Melt AdhesiveDimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com30E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Shrink Boots809S060 and 809A060<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong>Lipped Straight Shrink Boots- Dimensions<strong>HD</strong>FABCEAS SUPPLIED(EXPANDED)AFTER SHRINKING(FULLY RECOVERED)BootSizeA Min. B Min. C Max. D Ref. E Max. F Ref. H Ref. Cable RangeMaximum MinimumIn. mm. In. mm. In. mm. In. mm. In. mm. In. mm. In. mm.In. mm. In. mm.1 .390 9.91 .390 9.91 .260 6.60 1.370 34.80 .080 2.03 .030 0.76 .750 19.05 .230 5.84 .100 2.542 .669 16.99 .669 16.99 .300 7.62 1.500 38.10 .140 3.56 .032 0.81 .750 19.05 .500 12.70 .170 4.323 .945 24.00 .945 24.00 .390 9.91 1.500 38.1 .200 5.08 .035 0.89 .750 19.05 .800 20.32 .240 6.10Lipped 90° Right Angle Shrink Boots- DimensionsGFABEDAS SUPPLIED(EXPANDED)AFTER SHRINKING(FULLY RECOVERED)CBootSizeA Min. B Min. C Max. D Ref. E Max. F Ref. G Ref. Cable RangeMaximum MinimumIn. mm. In. mm. In. mm. In. mm. In. mm. In. mm. In. mm.In. mm. In. mm.1 .390 9.91 .390 9.91 .260 6.60 .790 20.07 .095 2.41 .032 0.81 .750 19.05 .230 5.84 .100 2.542 .669 16.99 .669 16.99 .310 7.87 .790 20.07 .140 3.56 .032 0.81 .790 20.07 .500 12.70 .170 4.323 .945 24.00 .945 24.00 .390 9.91 .980 24.89 .200 5.08 .040 1.02 .980 24.89 .800 20.32 .240 6.10Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com31E-Mail: sales@glenair.com11 - JULY - 2013

<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Shrink Boots809B060, 809SL060 and 809SU060Lipped 45° Angle Shrink Boots- DimensionsDABCGAS SUPPLIED(EXPANDED)AFTER SHRINKING(FULLY RECOVERED)EFBootSizeA Min. B Min. C Max. D Ref E Max. F Ref. G Ref. Cable RangeIn. mm. In. mm. In. mm. In. mm. In. mm. In. mm. In. mm. Max. In. Max. mm. Min. In. Min. mm.1 .390 9.9 .390 9.9 .260 6.60 .600 15.24 .080 2.03 .030 0.76 .560 14.22 .230 5.84 .100 2.542 .669 17.0 .669 17.0 .300 7.62 .640 16.26 .140 3.56 .035 0.89 .620 15.75 .500 12.70 .170 4.323 .945 24.0 .945 24.0 .390 9.91 .500 12.7 .160 4.06 .040 1.02 .750 19.05 .800 20.32 .240 6.10Lipped Straight Long Tail Shrink Boots- Dimensions<strong>HD</strong>FABCEBootSizeAS SUPPLIED(EXPANDED)AFTER SHRINKING(FULLY RECOVERED)A Min. B Min. C Max. D Ref E Max. F Ref. H Ref. Cable RangeIn. mm. In. mm. In. mm. In. mm. In. mm. In. mm. In. mm. Max. In. Max. mm. Min. In. Min. mm.1 .390 9.9 .390 9.9 .280 7.11 2.500 63.50 .080 2.03 .045 1.14 .750 19.05 .230 5.84 .100 2.542 .669 17.0 .669 17.0 .310 7.87 2.500 63.50 .140 3.56 .045 1.14 .750 19.05 .500 12.70 .170 4.323 .945 24.0 .945 24.0 .390 9.91 2.500 63.50 .200 5.08 .045 1.14 .750 19.05 .800 20.32 .240 6.10Lipped Straight USB Shrink Boots- DimensionsHFøAøBøCBootSizeAS SUPPLIED(EXPANDED)Dimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com32E-Mail: sales@glenair.com11 - JULY - 2013DAFTER SHRINKING(FULLY RECOVERED)A Min. B Min. C Max. D Ref E Max. F Ref. H Ref. Cable RangeIn. mm. In. mm. In. mm. In. mm. In. mm. In. mm. In. mm. Max. In. Max. mm. Min. In. Min. mm.1 .550 13.97 .360 9.14 .330 8.38 2.000 50.80 .090 2.29 .055 1.40 1.130 28.70 .250 6.35 .090 2.29øE

<strong>Series</strong> <strong>811</strong> <strong>Mighty</strong> <strong>Mouse</strong> <strong>High</strong> <strong>Density</strong> (<strong>HD</strong>)Contacts and ToolsBand-Master Advanced Termination SystemBands and instructions<strong>Mighty</strong> <strong>Mouse</strong><strong>High</strong> <strong>Density</strong><strong>Glenair</strong> Band-Master Advanced Termination System: How To Order1Fast, cost-effective shield termination. Attach cable shields to backshells with Band-Master ATS stainlesssteel straps. The Band-Master ATS system offers fast termination and the flexibility to handle a wide rangeof parts with just one band size. Approved for aerospace and defense, these straps have successfully passedrigorous shock, vibration and environmental testing.1Band installation Tool. Use with .240" (6.10 mm)wide bands. 6.75 inches (172 mm) length, 1.2pounds (0.6 Kg.)2Figure Description Part Number1 Band installation Tool 600-058Standard Band, .240" (6.10 mm) wide. Availablein two lengths, flat or pre-coiled. Stainless steel.2Length Part Number Accommodates DiameterFigure in. mm Flat Pre-Coiled in. mm2 14.250 362.1 600-052 600-052-1 1.8 45.72 18.000 457.2 600-090 600-090-1 2.5 63.5Contact <strong>Glenair</strong> or visit our website (glenair.com) to view our complete line of Band-Master ATS products,including pneumatic tools for high volume production and calibration kits.LENGTH ± .060 (1.5).240 (6.10)Band-Master ATS Shield Termination instructions1. Prepare Cable Braid for termination process(Figure 1).2. Push Braid forward over Adapter Retention Lipto the Adapter incline Point (or .4" [10.2mm]minimum braid length). Milk Braid as requiredto remove slack and insure a snug fit aroundthe shield termination area (Figure 2).3. Prepare the Band in the following manner:IMPORTANT: Due to Connector/Adapter circumference,it may be necessary to preparethe Band around the Cable or Retention Area.A. Roll Band through the Buckle Slot twice.(Bands must be double-coiled.)B. Pull on Band until Mark ( ) is within approximately.250 inch (6.4mm) of BuckleSlot (Figure 3). The Band may be tightenedfurther if desired.NOTE: Prepared Band should have ( ) Markvisible approximately where shown in Figure 3..350 (8.9)Shield TerminationClamping Process (Figures 4 thru 8)NOTE: To free Tool Handles, move Holding Clipsto center of Tool.4. Squeeze Gripper Release Lever and insertBand into the front end opening of theTool. (NOTE: Circular portion of loopedband must always face downward.)5. Aligning the Band and Tool with the ShieldTermination Area, squeeze Black Pull-UpHandle repeatedly using short strokes untilit locks against Tool Body. (This indicatesthe Band is compressed to the Tool PrecalibratedTension.)NOTE: If alignment of band and shield isunsatisfactory, tension on band can berelaxed by pushing on slotted releaselever on top of tool. Make adjustments asnecessary and again squeeze black pull-uphandle.6. Complete the Clamping Process by squeezingthe Gray Cut-Off Handle.7. Remove excess band from tool and dispose.8. inspect Shield Termination.1357AdapterRetention LipConductorsBraidAdapterincline 2BuckleTAIL LENGTHINDICA OR MARKTTail Lengthindicator Mark468.400 (1.2mm) Min.Length Braid OverTermination AreaDimensions in <strong>Inc</strong>hes (millimeters) are subject to change without notice.© 2011 <strong>Glenair</strong>, <strong>Inc</strong>. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com33E-Mail: sales@glenair.com11 - JULY - 2013

U n i t e d S t a t e s • U n i t e d K i n g d o m • G e r m a n y • F r a n c e • N o r d i c • I t a l y • S p a i n • J a p a n<strong>High</strong> Speed <strong>High</strong> Bandwidthminiature connectorsfrom <strong>Glenair</strong>The world's broadest selection of high-speed,high bandwidth interconnect products for milaeroand other harsh environment applications<strong>Glenair</strong> offers a full range of products to solve the most demanding high-speed interconnect challenges—fromthe size- and weight-saving <strong>Mighty</strong> <strong>Mouse</strong> line, to Fiber Optic solutions that address the most demanding highbandwidth and EMI immunity requirements. Many <strong>Glenair</strong> connector technologies that are suitable for generalpurpose signal applications also excel in 100 Ohm high-speed differential impedance applications as well asother installations that require low insertion loss, low VSWR and high data-rate performance. These productsand tested and capable of delivering benchmarked high-speed performance. Please view these catalogs on ourwebsite for additional information<strong>Series</strong> 80 “<strong>Mighty</strong> <strong>Mouse</strong>” <strong>High</strong> Speed <strong>Connectors</strong><strong>Glenair</strong>’s revolutionary connector series that reduces interconnect system sizeand weight by 50% compared to MIL-DTL-38999 connectors. Originallydeveloped as a smaller and lighter alternative to D38999 connectorsfor aerospace applications, the <strong>Mighty</strong> <strong>Mouse</strong> is used on hundredsof mission-critical defense, medical, industrial and geophysicalapplications. The <strong>Mighty</strong> <strong>Mouse</strong> product line includes a broadrange of insert arrangments all equipped with special PFAinsulators for 100 Ohm high speed, high bandwidth applications. <strong>High</strong>speedcordsets, terminated to a broad range of commercial USB andEthernet interconnects are also available as standard catalog offerings.100 Ohm <strong>High</strong> Speed, <strong>High</strong> Bandwidth, Ultra-Miniature <strong>Connectors</strong>, Cables and Accessories<strong>Series</strong> 80 <strong>High</strong>-Speed<strong>Mighty</strong> <strong>Mouse</strong> <strong>Connectors</strong>S n e a k P e e k D r a f t E d i t i o n • S e p t e m b e r 2 0 1 1FeaturingDuPont Teflon ®PFA InsulatorsMIL-DTL-83513 Micro-D <strong>Connectors</strong> and Cables<strong>Glenair</strong> offers both Military Standard 83513 Micro-D connectors as wellas COTS selections, all of which are ready for use in high speed,high bandwidth applications up to 5 GHz with size #26 AWGwire. Our TwistPin contact provides superior performance—especially in vibration and shock applications. Whereinterconnect failure is simply not an option, the <strong>Glenair</strong> highreliabilityMicro-D offers a wealth of performance benefits whichfar outweigh any potential cost savings realized by specifyinga lesser caliber connector. If downtime is a critical concern,other connectors cannot match the long-term durability andperformance advantages of the MIL-DTL-83513 Micro-D.