Making Mead - BJCP

Making Mead - BJCP

Making Mead - BJCP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Making</strong> mead is a centuries-old practice that can be enjoyed by the home brewer. As with thepreparation of most foods and beverages, the making of a good mead is a blend of science andart. This kit is designed to help you understand the basic principles of mead making and guideyou through the process. It is intended as a primer for the beginner and as a resource for themore experienced home brewer.The History of<strong>Mead</strong> Brewing<strong>Mead</strong> is one of the world’soldest fermentedbeverages. Ancient mythsand writings throughout theworld contain references toalcoholic beverages thatwere drunk by both peopleand gods alike.<strong>Mead</strong> was a part of therituals of the Celts, Anglo-Saxons and Vikings. It wasbelieved to have magical,healing powers evencapable of increasingfertility. The word honeymoonis derived from thepractice of the newlywedsdrinking mead for onemonth (a moon) after thewedding. If the mead was"proper," a son would beborn nine months later.As civilizations andagricultural resourcesgrew, beverages such aswine made from grapes orother fruits, and ale madefrom barely and wheatreplaced mead in manyareas of the world. InNorthern Europe, wheregrapes were difficult togrow, mead remainedpopular until grape winewas imported fromsouthern regions.The roots of the variationsof mead we have todaycan be found in thecultures and agriculture ofold. The practice of addingbitter herbs (gruit) to meadbegan in the Middle Ages.Mixing grape and other fruitwines with mead can betraced to Roman times.Eventually, agriculturalcrops such as grapes,grains and hops, becamethe preferred ingredientsfor alcoholic beveragessuch as wine, beer andales.Varietiesof <strong>Mead</strong><strong>Mead</strong> is an alcoholicbeverage made byfermenting a mixture ofhoney and water.Traditional mead is simplythat — honey and water.Variations have existedthrough the ages andrange from the traditionalto complex mixes of fruitjuices and spices. (SeeTable 1.)<strong>Mead</strong> can be either still orsparkling. Sparkling meadresults from a secondfermentation that retainsdissolved carbon dioxide inthe bottled product.Other alcoholic beveragesmade from honey includebraggot and mead brandy.Braggot, made with maltedgrain and honey, is partbeer. <strong>Mead</strong> brandy is meadthat has been distilled. Ahoney liqueur is made byadding extra honey tomead brandy.National Honey Board • (303) 776-2337 • www.nhb.org • P a g e 1/12

Table 1. Varieties of <strong>Mead</strong>Traditional <strong>Mead</strong>HydromelSack <strong>Mead</strong>MetheglinSack MetheglinA fermented honey beverage made from approximatelytwo and one-half pounds of honey diluted with one gallonof water only.Weak, or watered mead<strong>Mead</strong> that is made sweeter by the addition of twenty totwenty-five percent more honey; a sauterne-like beverage.Spiced mead; originally spiced with a combination ofherbs (gruit) but later hops became more popular.Sweet spiced mead; traditionally similar to vermouth.Melomel, or Mulsum <strong>Mead</strong> made with fruit juice.CyserPyment, or ClarreHyppocrasA melomel made with apple juice or cider; similar to asherry wine.A melomel made with grape juice; sometimes referred toas honey-sweetened grape wine.Spiced pyment.National Honey Board • (303) 776-2337 • www.nhb.org • P a g e 2/12

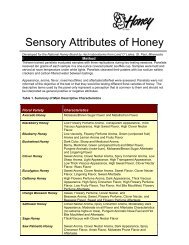

Basics for Brewing <strong>Mead</strong>Getting Started:IngredientsHONEYHoney is the first ingredientto consider when makingmead. The flavor and colorof the final product aredependent on the variety ofhoney used. In general, alight honey yields lightercolored and flavored meadand a dark honey, darkercolored and more robustflavored mead.The floral source of thehoney determines its flavorprofile and other sensoryattributes. Honey beesgather nectar and convert itto honey. There is somevariation in the amount ofsugar, minerals andvitamins in the nectars thatthe bees gather. Anenzyme (invertase)secreted by the beesconverts the sucrose in thenectar to fructose andglucose and anotherenzyme (glucose oxidase)changes the glucose togluconic acid and hydrogenperoxide. The watercontent in the nectar is alsoreduced in the process.The result is honey: afermentable sugar with pHof approximately 3.9, onaverage, and an 17.1percent water content.Choosing which honey touse is a matter of taste andthe type of mead desired.Stronger honeys go wellwith sweeter, heavy orspiced meads and milderhoneys with delicateflavors work well fortraditional or fruit meads.The National Honey Boardhas additional informationavailable on the floralsources of honey. A list ofhoney suppliers is availableon the National HoneyBoard’s Web site,www.nhb.org. A paper describingthe sensory attributesof U.S. honeyvarieties is available bothonline and as a hard copy.The United StatesDepartment of AgricultureTechnical Bulletin number1261 gives detailedinformation on thechemical composition,color and granulation ofvarious honey varieties.These resources will behelpful in selecting a honeyvariety.YEASTYeast is the next ingredientto consider and onceagain, there are severalchoices. Yeast is livingorganism that metabolizessugars in honey to carbondioxide and ethyl alcohol.Cultured wine yeast iscommonly used to makemead. In general, thosethat are used for whitewines, especially sauterneyeastwork well. The yeastused for wine and meadfermentation is Saccharomycescerviseae.Matching the appropriateyeast culture to the honeyvariety is key to developingthe desired taste andmouthfeel of mead.Formulation guideline forvarious types of yeasts andhoneys can be found inZymurgy: For the Homebrewerand Beer Lover,May-June 2000 issue.In addition to sugar, yeastneeds nitrogen,phosphorus and potassiumfor growth. Ingredientssuch as urea, peptone andpotassium phosphate areused to supply thesenutrients. It is alsopossible to buy packagednutrients speciallydesigned for mead.WATERThe third basic ingredientused to make mead iswater. The quality andchemical composition ofthe water used to makemead is critical.National Honey Board • (303) 776-2337 • www.nhb.org • P a g e 3/12

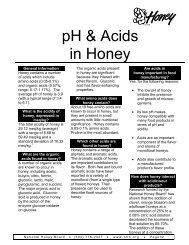

For example, water thathas a high chlorine contentmay produce off-flavors.Most mead makers recommendbottled or springwater but not distilled watersince it lacks sufficientminerals for the yeast.OTHER INGREDIENTSACIDS: Small amounts ofacids, such as malic,tartaric and citric acid, areadded to balance theflavor. Their tartnessoffsets the sweetness ofthe honey while combiningwith the alcohol to give adegree of stability againstspoilage.Some experts recommendan acid blend composed oftwenty-five percent citric,thirty percent malic andforty-five percent tartaricacids.SULFITES: Sodiumbisulfite or potassiummetabisulfite in tablet orpowder form are commonlyused for sanitation in winemaking.STABALIZERS: Whenmaking still mead,potassium sorbate, or winestabilizer, can be added atthe bottling stage toprevent a secondfermentation by killingremaining yeast cells.FRUIT: To create thefruit-containing mead, tento twenty percent fruit juiceor purees are added to thehoney-water mixture.Whole, pitted fruit can alsobe used. Twelve to fifteenpounds of fruit with twelveto fifteen pound of honey infive gallons arerecommended.SPICES AND HERBS:Almost any spice or herbcan be added to meadeither as an extract ordirectly at almost any timeduring the mead makingprocess. Blends of two ormore spices and herbs arecommonly used. If addeddirectly, they should notremain in the mix for longerthan twenty-four hoursbecause bitter componentsmay be extracted.A strong extract of mixedherbs (gruit), can be addedat bottling time. Or, astrong extract of eachspice can be prepared andadded at any time afterfermentation but before fining.To make an extract,boil the spices in a smallamount of water for 15minutes.HOPS: Adding hops tomead will add a distinctiveflavor, but moreimportantly, its resins, oils,tannins and pectin can helpto clarify the mead andpreserve its freshness.Tannin is sometimes usedby itself to add astringencyand aid in brewing andclarification.Getting Started:EquipmentHome brewers typicallymake five-gallon batches ofmead. The equipment theyneed is similar to what isused to make wine and isreadily available in homewine and brewing supplystores.Basic equipment needed toproduce five-gallon batchincludes:•= 1 (four-gallon)enameled or stainlesssteel pot•= 2 (five-gallon) glasscarboys*•= 1 fermentation lock withrubber cork to fit carboy•= 7 feet clear plastic siphoninghose, 5/16-inchdiameter•= 3 feet plastic blow-outhose, 5/16-inchdiameter•= Detergent and chlorinebleach•= Large funnel•= Corker or bottle capper•= Corks or bottle caps•= Bottles•= Wine hydrometer•= Thermometer•= Acid-testing kit*Note: A carboy is a glasscontainer with a narrow neck.National Honey Board • (303) 776-2337 • www.nhb.org • P a g e 4/12

ProcessingGuidelinesThere are seven basicsteps to making mead.(See Table 2.)SANITIZINGThe single most importantstep in making a goodmead is sanitation.Contamination with wildyeast, molds or bacteriawill result in mead that iscloudy and off-flavored.Wash all equipment andcontainers with detergentand water. Scrub well andrinse repeatedly. Afterrinsing, sanitize allequipment and bottles byimmersing them in ableach solution ofone-ounce chlorine bleachto 5 gallons water. Soak forat least 10 minutes; rinsewell with water.Equipment can also besanitized in a rinseless solutioncallediodophor sanitizer(available at brewingsupply stores).PREPARING THE MUSTMust is the unfermentedmix of honey, water andother ingredients. Thereare several methods forpreparing the must.Several factors should beconsidered in choosingwhich method to use.BOILING: Boiling thehoney and water for 10 to30 minutes will sterilize themust and cause a "coldbreak" which precipitatesthe protein and othercolloidal materials in thehoney. This will help clarifythe final mead.The disadvantage ofboiling is that it drives offthe delicate flavor componentsof the honey. Yeastnutrients and acid blendscan be added before orafter boiling.PASTEURIZATION: Heatingthe honey and water to190 °F for 10 to 20 minuteswill destroy any wild yeastin the honey but willpreserve more of the volatileflavor components.When preparing largebatches of mead (3 to 5gallons), it may beimpractical to heat the totalvolume of water. Instead,mix the honey with 1 or 2gallons of water. Heatsanitizethis mixture (boil orpasteurize) and when cool,transfer to the carboy. Addenough additional water tothe mixture in the carboy toequal the total volumeneeded.SULFITING: An alternativemethod of sanitizing themust is "sulfiting." Theadvantage of this methodis that there is no heating.Simply dissolve the honeyin water along with the acidblend and yeast nutrientsand add the sulfites. Themajor disadvantage is thatsome individuals areallergic to sulfites andwould not be able toconsume mead that ismade with sulfiting agents.Also care must be takennot add too much sulfite aslevels in the 60-70 ppmrange can inhibit yeastgrowth. Since properadjustment of levels requiresan accurate scaleand pH meter, sulfiting isnot recommended for theamateur mead maker.Sanitizing with sulfites isrecommended whenmaking Mulsum orMelomel. Since boiling fruitjuices will "set" the fruitpectin and prevent the finalmead from clarifying.ADDING THE YEASTIf the must has beensanitized by heating, theyeast can not be added or"pitched" until the must isat room temperature(approximately 70-75 °F).When using sulfites tosanitize, let the must standfor 24 hours before addingthe yeast. If using dryyeast, activate it by stirringthe packet of yeast into 4ounces of warm water(80 °F). Allow the yeast tohydrate for 10 minutesbefore stirring into themust.National Honey Board • (303) 776-2337 • www.nhb.org • P a g e 5/12

Table 2. Basic Steps For<strong>Making</strong> <strong>Mead</strong>1. Clean and sanitize allequipment andcontainers.2. Make the must (i.e.,honey-water mixture).3. Add the yeast or yeaststarter.4. Ferment until all visualsigns of air bubblesdisappear.5. Rack (fine first, ifdesired) two or moretimes.6. Age until clear andgood flavor develops.7. Bottle and cap with bottlecaps or corks.FERMENTATIONFermentation takes fromseveral weeks to severalmonths. During this step,the sugar in honey isconverted to alcohol andcarbon dioxide gas.Once the must has beensterilized (by boiling,pasteurization or sulfitetreatment), transfer it to thefermentation vessel(carboy) and add theactivated yeast.At the onset of fermentation,yeast need an amplesupple of dissolvedoxygen. Therefore, it ishelpful to cascade the coldmust into the carboy priorto adding the yeast. Air isexcluded during theremainder of thefermentation process byinstalling an air lock on theneck of the carboy.RACKINGRacking involves siphoningoff the clear mead into asecond sanitizedfermenter, leaving thesediment behind in thefirst. This step is repeatedas many times as isnecessary to achieve thedesired level of clarity,usually at three-monthintervals.Strict sanitation practicesmust be observed to preventcontamination. (Ifsulfiting agents are used asa disinfectant, they need tobe added at each rackingto ensure the desired levelof 50 ppm sulfur dioxide.)Care must also be taken tonot incorporate oxygenduring racking after theonset of fermentation.Excess exposure tooxygen once the processhas begun, can causespoilage. When filling thecarboy, headspace shouldbe limited to approximatelyone inch to minimize theavailable oxygen.FININGFining is an optional stepthat clarifies mead, usingagents such as bentonite,isinglass, egg white,gelatin, and casein. Acommercial product calledSparkolloid is alsoavailable. Fining agentscombine with chargedparticles in suspension,such as protein, andprecipitate them. The resultis clear mead that has asparkle. The drawbacks tofining are the amount ofmead left in the residueand the potential fordecolorizing the mead.Fining is usually donebefore racking or whenmead fails to clear. Afterracking, attach the air lock.Fermentation will begin inseveral hours or may takeseveral days. <strong>Mead</strong> is bestfermented at temperaturesbetween 70 °F and 80 °F.Fermenting at lowertemperatures will not harmthe mead flavor; it will justtake longer to complete.During fermentation, rackthe mead into a newcontainer as sedimentdevelops. If the mead sitson the sediment too long,the yeast will begin to feedon the sediment (autolysis)and result in an unpleasantflavor. Fermentation iscomplete when air bubblesare no longer visible.AGINGAging requires the mostpatience. During this step,the mead clears anddevelops its flavor. Usually,it moves from a harsh,acidic, unpleasant taste toa smooth, mellowbeverage with a nicebouquet and fragrance. Asthe dead yeast cellscontinue to settle, it isimportant to continueracking the mead. A steadytemperature below 70 °F(preferably around60 °F) is recommendedthrough the aging process.The length of aging cantake months or years,National Honey Board • (303) 776-2337 • www.nhb.org • P a g e 6/12

depending on a number offactors. In general, lightermeads will be ready soonerwhile darker, sweet meadsand those with higheralcohol content will needmore time to fully develop.Ultimately, the tastepreference of the meadmaker will determine whenit has aged enough.BOTTLINGThe last step is bottling andcapping. As with all thesteps, good sanitationpractices are essential andaeration during the transfershould be avoided.Standard caps or corks canbe used. Bottles with corksneed to be stored on theirsides or the corks need tobe dipped in melted paraffinto keep them fromdrying out. Headspaceshould be approximatelyone-half to three-quartersof an inch to limit exposureto oxygen.<strong>Making</strong> sparkling meadrequires a secondfermentation using a newyeast culture and primingsugar. The concentration ofsugar to mead should be60 grams or 2 ounces foreach gallon of must orthree-fourths to one cupper five gallons.The second fermentationoccurs in capped bottles,thus trapping the carbondioxide gas until the bottleis opened. Typically,sparkling mead has higheralcohol content. Additionalsediment settles in thebottom of the bottle. Thefinished sparkling meadshould be decanted off thesediment. Overall, carefulhandling of sparkling meadis required to preventpremature release of thecarbon dioxide gas andexploding bottles.Throughout themead-making process,it is important to testvarious parameters.Sugar levels of the honey,fruit juices, and mead aremeasured in brix or specificgravity, using a hydrometer.Acid levels aredetermined by measuringpH using acid test kits thatare readily available inbrewing supply stores. Agood thermometer isnecessary to monitor roomand brew temperaturesthroughout process.CommonProblemsOFF FLAVORSMost off flavors are theresult of poor sanitationpractices. All equipmentmust be sanitized toprevent contamination andthe resulting off flavors.The must needs to be freeof any wild yeast ofbacterial contaminationbefore fermentation starts(see "Preparing theMust") and good practicesmust continue throughoutthe brewing process. Also,any residue of sanitizer(bleach, sulfites, soaps)remaining on theequipment will affect theflavor of the final mead."STUCK"FERMENTATIONAfter adding the yeast tothe must, fermentationshould begin within severaldays. If fermentation doesnot start within 5 days, it isprobably because of a poornutrient balance or a weakstrain of yeast. The bestremedy is to rack the mustinto a sterilizedfermentation vessel andbegin again by adding newviable yeast.In other cases, yeastactivity may stop in themiddle of the fermentationperiod. All activity stopsand the specific gravityindicates that there isadequate sugars stillavailable for fermentation.The most common causeof this behavior is that thealcohol produced by theyeast has reached a levelin the mead that is too highto support yeast activity.When the level reachesapproximately 12 percent,yeast metabolism isinhibited.National Honey Board • (303) 776-2337 • www.nhb.org • P a g e 7/12

Basic Recipes/FormulasRecipes for mead abound—with each mead maker having his/her own slant on what and howmuch to use as well as how to put it altogether to create the right flavor and bouquet. Below area few basic recipes for mead and variations of mead to get you started. Use the guidelines inthe equipment and process sections to produce your mead.Basic <strong>Mead</strong> RecipesMorseTraditional <strong>Mead</strong> RecipeIngredientsHoney (preferablygoldenrod)WaterAmmonium phosphateUreaCream of tartar1:1 mixture of tartaricand citric acidYeastAnti-foam agentAmount3.5 lb1 gal4 g4 g4 g4 gOptionalMorse, R. A. 1980. "<strong>Making</strong> <strong>Mead</strong> (Honey Wine)."Wicwas Press, Cheshire, Conn."Wassail <strong>Mead</strong>"Yield: 5 gallons"St. Elizabeth’s Day" <strong>Mead</strong>Yield: 5 gallonsIngredientsHoneyWaterYeast nutrientStock sodium bisulfitesolution (add afterfermentation)Tartaric acidLiquid oak essence(optional)Prise de Mousse YeastOriginal brix: 25 °Total acid: 6-6.5%Amount18 lb5 gal2 oz5 tsp5 tbsp30 mL10 gBurch, B. 2000. <strong>Making</strong> Sense of <strong>Making</strong> <strong>Mead</strong>. Zymurgy:For the Homebrewer and Beer Lover. 23(3):39-40.IngredientsLight clover honeyAcid blendYeast nutrientWaterWine yeastOptional:Amount12.5 lb4 tsp5 tspto make 5 galsufficient for 5 gal1/3 tsp sodium orpotassiummetabisulfiteOriginal specific gravity: 1.110Source: Papazian, C. 1986. Brewing <strong>Mead</strong>. Wassail!Page 175 in "Mazers of <strong>Mead</strong>." Brewers Publications,Boulder, Colo.National Honey Board • (303) 776-2337 • www.nhb.org • P a g e 8/12

<strong>Mead</strong> VariationsMulsum or MelomelYield: 5 gallonsIngredientsAmountLight clover honey 9 lbCrushed Fruit (such as 10-15 lbraspberries, blackberries,marionberries, loganberries,mangoes, currants,peaches, plums orcherries)Yeast nutrient5 tspWaterto make 5 galWine yeast sufficient for 5galSodium metabisulfite 1/3 tspAcid blendto bring level to0.4 to 0.5%Approximate original specific gravity: 1.100to 1.120Special Instructions: Boiling grape or anyother fruit juice will "set" the fruit pectin andprevent the mead from clarifying. Therefore,sulfating agents should be used to disinfectthe must.Use an open fermenter (i.e., a clean fermentationpail covered with a snug aluminum foilor plastic sheet so gases can escape) forthe first to ten days. Then strain out thefruit, and siphon the ferment into a closedglass fermenter. Some fruit will unavoidablybe carried into the second fermenter. Aftertwo weeks, or when vigorous fermenting hassubsided, siphon ferment into another fermenterleaving virtually all the fruit and someof the yeast sediment behind.Papazian, C. 1986. Brewing <strong>Mead</strong>. Wassail! Pages183-184 in "Mazers of <strong>Mead</strong>." Brewers Publications,Boulder, Colo.Raspberry MelomelYield: 3 gallonsIngredientsAmountLight honey10 lbRaisins1/2 cupLemons juice from 3Crushed raspberries 1 to 2 ptChampagne yeast sufficient for 3 galWaterto make 3 galSodium metabisulfite 1/3 tspSpecial Instructions: Mix all ingredients exceptthe yeast and let sit overnight. Add thefruit directly to the must or suspend it in acheesecloth bag.Spence, P. 1997. "Mad About <strong>Mead</strong>! Nectar of theGods." Lluewellyn Publications, St. Paul Minn.Sack <strong>Mead</strong>Yield: 5 gallonsIngredientsAmountLight clover honey 15 lbAcid blend4 tspYeast nutrient 6 tspWaterto make 5 galWine yeastsufficient for 5 galSodium or1/3 tsppotassiummetabisulfite(optional)Approximate original specific gravity: 1.120to 1.130Note: To make "Sack Metheglin," add gruitas described in the "Metheglin" recipe.Source: Papazian, C. 1986. Brewing <strong>Mead</strong>. Wassail!Page 179 in "Mazers of <strong>Mead</strong>." Brewers Publications,Boulder, Colo.National Honey Board • (303) 776-2337 • www.nhb.org • P a g e 9/12

Pyment or ClarreYield: 5 gallonsIngredientsAmountLight clover honey 7 lbGrape juice2.5 galWaterto make 5 galYeast nutrient 5 tspWine yeastsufficient for 5 galSodium metabisulfite 1/3 tspAcid blendto bring level to 0.4 to0.5%Approximate original specific gravity: 1.100to 1.120Special Instructions: See "Mulsum" directions.Caution: Do not add grape skins to closedglass fermenter as they will plug the escapevent and could cause an explosion. Use anopen fermenter (i.e., a clean fermentationpail covered with a snug aluminum foil orplastic sheet so gases can escape) for thefirst to ten days, if adding crushed fruit.Papazian, C. 1986. Brewing <strong>Mead</strong>. Wassail! Page181 in "Mazers of <strong>Mead</strong>." Brewers Publications, Boulder,Colo.MetheglinYield: 5 gallonsIngredientsLight clover honeyAcid blendYeast nutrientWaterWine or champagneyeastSodium or potassiummetabisulfite (optional)Amount12 lb4 tsp5 tspto make 5 galsufficient for 5 gal1/3 tspGruit1 oz leaf hops or any of the following:•= 1 to 2 oz freshly grated ginger•= 2 to 4 oz lemongrass•= 1 to 2 oz crushed cinnamon bark•= Crushed fennel, anise, caraway seed orcloves•= Crushed hot chile pepper (with or withoutseeds)•= Combination of these and any other spice,herb, bark and seedsApproximate original specific gravity: 1.110Special Instructions: Make a strong extractof gruit ingredients by boiling spices in smallamount of water for 15 minutes. Add at bottlingtime or after vigorous fermentation hassubsided.Papazian, C. 1986. Brewing <strong>Mead</strong>. Wassail! Page180 in "Mazers of <strong>Mead</strong>." Brewers Publications, Boulder,Colo.IngredientsWildflower honeyLeaf hopsLemon and limeYeast energizerMontrachet YeastWaterHoney Hop MetheglinYield: 1 gallonAmount3 lb1 ozjuice and peel from halfof each1 tsp1 packetto make 1 galSpecial Instructions: Add half of hops in amesh bag to honey dissolved in 6 pints waterand heat to just below boiling. Hold forone hour. Then add citrus peel and juice,remaining hops and yeast energizer. Boil for1 hour, remove from heat and let cool overnight.Source: Spence, P. 1997. "Mad About <strong>Mead</strong>! Nectarof the Gods." Lluewellyn Publications, St. Paul, Minn.National Honey Board • (303) 776-2337 • www.nhb.org • Page 10/12

CyserYield: 5 gallonsIngredientsAmountLight clover honey 7 lbApple juice4.5 galWaterto make 5 galYeast nutrient 5 tspWine yeastSodium or potassium 1/3 tspmetabisulfiteAcid blend to bring level to 0.4to 0.5%Approximate original specific gravity: 1.100to 1.115Special Instructions: See "Mulsum" directions.Papazian, C.1986. Brewing <strong>Mead</strong>. Wassail! Page182 in "Mazers of <strong>Mead</strong>." Brewers Publications,Boulder, Colo."Rockport Still <strong>Mead</strong>"Yield: 3 gallonsIngredientsAmountOrange blossom 9 lbhoneyFermex yeast 3 tspnutrientYeast hulls1.5 tspYeast energizer 1/2 tspWyeast No. 3184 sufficient for 3 galmead yeastApproximate original specific gravity: 1.116Final specific gravity: 1.0212Boiling time: 5 min.Primary fermentation: 30 days at 68 ºF(20 ºC) in glassSecondary fermentation: 90 days at 68 ºF(20 ºC) in glassTertiary fermentation: 2 years at 68 ºF(20 ºC) in glassPrickly Pear/Mesquite MelomelSparklingYield: 5 gallonsIngredientsPrickly Pear PureeMesquite honeyYeast nutrientAcid blendDry mead yeastWyeast #3632Corn sugar for bottlingAmount7 lb12 lb1 tbsp4 tspsufficient for 5 gal1 cupBurch, B. 2000. Winner's Circle. Zymurgy: For theHomebrewer and Beer Lover. 23(3): 41.IngredientsFresh pressed sweetcider, tested and adjustedfor acidClover honeyAle or mead yeaststarterBit O’ Honey CyserYield: 5 gallonsAmount5 gal2 lb (or enough tobring the specificgravity to approximately1.065)sufficient for 5 galSpecial Instructions: Simmer honey with asmall amount of cider until honey warms andthins. Then add to 1 gallon of cider in glasscarboy. Add the yeast and then top withremaining cider. It takes at least six monthsfor cyser to clear and taste acceptable. Afterbottling, it should age at least fourmonths.Correnty, P. "The Art of Cidermaking." Brewers Publications,Boulder, Colo.Turczyn, A. 2000. Winner's Circle. Zymurgy: For theHomebrewer and Beer Lover. 23(3): 47.National Honey Board • (303) 776-2337 • www.nhb.org • Page 11/12

BOOKS•=•=Selected Resourcesand ReferencesCorrenty, P. "The Art of Cidermaking." BrewersPublications, Boulder, Colo.Furness, C. 1972. "Honey Wines and Beers."Northern Bee Books, West Yorkshire, UK.•=•=•=Kraus, B. 2000. When Mazers and MashersMeet: The Magic of Brewing with Honey. Zymurgy:For the Homebrewer and Beer Lover.23(3): 34-37, 58-59.Rollins, G. 2000. <strong>Making</strong> <strong>Mead</strong>. Bee Culture.128(12): 29-31.Schramm, K. and McConnel, D. 2000. Mastering<strong>Mead</strong> Formulation: The Art and Science of theSacred Honey Brew. Zymurgy: For the Homebrewerand Beer Lover. 23(3): 26-29, 54-57.•=•=•=Gayre, R. and Papazian, C. 1986. "Mazers of<strong>Mead</strong>." Brewers Publications, Boulder, Colo.Morse, R. 1980. "<strong>Making</strong> <strong>Mead</strong> (Honey Wine)."Wicwas Press, Cheshire, Conn.Spence, P. 1997. "Mad About <strong>Mead</strong>! Nectar ofthe Gods." Lluewellyn Publications, St. Paul,Minn.ARTICLES•=•=Berthold, R. 1998. <strong>Making</strong> a New Type of <strong>Mead</strong>.Bee Culture. 126(6): 32-34.Berthold, R. 1997. A New Concept in <strong>Mead</strong> <strong>Making</strong>.American Bee Journal. 137(10): 729-731.•=•=•=Steinkraus, K.H. and Morse, R.A. 1966. FactorsInfluencing the Fermentation of Honey in <strong>Mead</strong>Production. J. Apicultural Res. 5(1): 17-26.Weaver, M. and Weaver, B. 2000. ThoroughlyModern <strong>Mead</strong>. Bee Culture. 128(7): 40-41.White, J. W., Jr., Riethof, M.L., Subers, M.H. andKushnir, I. 1962. Composition of American Honeys.U.S. Dept. Agric. Tech. Bull. 1261: 1-124.INTERNET SITES•=<strong>Mead</strong>-Lover’s Digest, an online distribution of articlesfrom readers. Subscribe by e-mail sent tomead-request@talisman.com with the word“subscribe” in the subject line.•=Berthold, R. 1992. A New Concept in <strong>Mead</strong> <strong>Making</strong>.American Bee Journal. 132(2): 97-101•=www.talisman.com/mead, Web site for <strong>Mead</strong>Lover’s Digest and other material.•=Burch, B. 2000. <strong>Making</strong> Sense of <strong>Mead</strong>. Zymurgy:For the Homebrewer and Beer Lover.23(3): 38-41, 60-61.•=www.best.com/~davep/mme, The “<strong>Mead</strong> MadeEasy” book by Dave Polaschek in electronic format.•=Kime, R.M., Morse, R. A. and Steinkraus, K.H.1998. <strong>Mead</strong>: History, Current Technology andProspects. American Bee Journal. 138(2): 121-123.•= Kime, R.A., McLellan, M.R. and Lee, C.Y. 1991.An Improved Method of <strong>Mead</strong> Production. AmericanBee Journal. 131(5): 394-395•=•=•=•=www.brewery.org/brewery/Mhall.html, collectionof links to mead-related pages.www.brewery.org/brewery/library/beeslees.html, collection of mead recipes, formulas andtables.www.solorb.com/gfc/mead/mead.html, <strong>Mead</strong>Maker’s Page on mead basics and terminologywww.gotmead.com, Web site with mead-makingbasics and links.National Honey Board • (303) 776-2337 • www.nhb.org • Page 12/12