MT ST JOHN WASTEWATER TREATMENT PLANT

MT ST JOHN WASTEWATER TREATMENT PLANT

MT ST JOHN WASTEWATER TREATMENT PLANT

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

T O W N S V I L L E<strong>MT</strong> <strong>ST</strong> <strong>JOHN</strong> WA<strong>ST</strong>EWATER <strong>TREATMENT</strong> <strong>PLANT</strong>Sewage (wastewater) is water that hasbeen used in residential, commercialand industrial sites, which is no longerclean. After you have used water, thewastewater (or effluent) starts ajourney through a series of pipelines,and pump stations, which we call theSewerage System, where wastewateris pumped to the WastewaterTreatment Plant to receive treatment.Important resources are generatedfrom the wastewater treatment suchas gases, sludge and effluent andthese can be reused in many ways,for example for irrigation, generatingelectricity, mulching and top soil.Wastewater may contain pollutantsincluding human waste, paper, wood,grease, fats, plastic and chemicalsfrom industrial locations. It may alsocontain dissolved nutrients, nitrogen,phosphorus, and a range ofmicroscopic organisms such asbacteria and viruses, as well as lowlevels of oxygen. If this wastewater isreleased back into the environmentwith these harmful organismstogether with low levels of oxygen itcan kill species such as fish that livein the receiving waters, cause algaeblooms, along with otherenvironmental impacts. People mayalso be affected by being in contactwith that water or using thatenvironment.Mount Saint John WastewaterTreatment Plant receives wastewaterfrom many suburbs throughoutTownsville. Some of them includeCranbrook, Heatley, Vincent, Garbutt,Mt Louisa and Pallarenda. It alsoreceives sewage from suburbs inThuringowa including Kirwan and theUpper Ross.About 99% of sewage arriving at theMt St John Treatment Plant is water.On a dry weather day, this Plant maytreat between 11-13 million litres andduring wet weather this flowcan increase 3 fold. However, themajority of this will be rainwater andtherefore the wastewater will be of amuch lower strength than normalwastewater. Wastewater herereceives primary, secondary andUV disinfection treatments.Primary TreatmentThe primary treatment starts at theRotary Drum Screen which removessolids such as food particles, sand,rags, plastic, anything greater than3mm. This solid material is taken tothe dump by trucks 3 times a week.The wastewater now goes to theAerated Grit Tank where the bubblingof the water helps to separate theremaining sand and grit from theorganic material.The heavier sand and grit settles intohoppers at the bottom of the tankwhere it is pumped out and buried onsite.The remaining wastewater (oreffluent), still containing dissolvednutrients, organic matter, viruses andbacteria, goes to the Primary FlowDivider which splits the flow into twoPrimary Settling Tanks.Rotary Drum Screen

T O W N S V I L L EPrimary Settling TankIn the Primary Settling Tanks (alsocalled Primary Clarifier), largerparticles of organic matter (called rawsludge) settle to the bottom. Thesethen are removed from the tanks by aRotating Submerged Raking Systemto a central hopper and then it isdischarged to a Raw Sludge Well.From the well, the sludge is pumped totwo Anaerobic Digesters for furthertreatment.Any floating material (scum) is alsoremoved by a surface scraper on theRotating Bridge and are alsodischarged in to the Raw Sludge Well.Cleaner effluent flows overvee-notches (v-shaped openings) ofthe Primary Settling Tank and onto thenext stage where the flow is splitbetween the front two Biofilters. Hereis where the secondary treatmentstarts.Secondary TreatmentThe secondary treatment consists offour Biological Trickling Filters that willwork to kill viruses and bacteria, aswell as remove traces of sludge whichwere not heavy enough to settle in theprimary treatment.The Biological Trickling Filters arecircular concrete structures filled with atwo meter deep bed of rocks(approximately 70mm in size) coveredwith a slime layer containing helpfulmicro-organisms (called zooglealslime). The zoogloeal slime requiresdissolved oxygen to live andreproduce. This process is called the“aerobic process“. Their function is toremove dissolved and finelysuspended organic solids and todecompose these organic materialsbiologically, to form a cleaner product.This biological community consistsmainly of bacteria, fungi, protozoans,worms, insect larvae and snails. Theeffluent coming from the PrimarySettling Tanks is discharged over thetop of the filter stone media (Biofilter)by means of the Rotating Arms andtrickles down through the slimecovered stones. The purificationprocess proceeds continuouslyprovided that aerobic conditions(oxygen rich) are maintained within thebed of stones.Effluent leaves the system by a seriesof openings at the bottom of the outerwall which also serves to let air into thestone bed to maintain aerobicconditions and passes onto the backtwo Biological Filters. The wastewaterfrom the front two filters is transferredby pumps to the Secondary FlowDivider where it is split between theback two Biological Filters. This worksin the same manner as the front twofilters but because the effluent goesthrough two filters in series, there ismore breakdown of organic materialand therefore increased efficiency.Biological Trickle FilterThe trickling of the wastewater downthrough the stone bed results in someflushing effect and slime particles arecontinuously removed from the filtersand pass onto the Secondary SettlingTank as humus sludge particles. TheSecondary Settling Tanks removethese humus sludge particles from thefilter effluent by a Rotating HydraulicRaking System and is discharged tothe Sludge Well and from this ispumped back to the Plant inlet.Vee-notchesSecondary Flow DividerThe final cleaner effluent, flows overthe vee-notches of the SecondarySettling Tanks and is discharged bygravity to a drainage channel on thewestern boundary of the TownCommon which is connected to atributary of the Bohle river severalkilometres from the Plant.

T O W N S V I L L EUV DisinfectionApproximately 50% of the incomingsewage is treated using UVdisinfection. The UV disinfectionsystem comprises a series of specialfluorescent tubes that generateultra-violet lights. These UV rays killviruses and bacteria contained in thefinal effluent. UV disinfected effluentfrom Mt St John is reused to irrigatethe Rowes Bay Golf course, RAAFBase, the Pallarenda foreshore, as wellas the Treatment Plant grounds. Infact, treated effluent is anenvironmentally friendly and valuableresource that can, and should bereused for many purposes, includingirrigation of parks, public gardens,pastures and agriculture, for example.By reusing treated effluent we areconserving clean freshwater from ourcatchment, among other benefits.Citiwater is committed to evaluate andadopt sustainable alternatives, such asthe reuse of resources generated bythe wastewater treatment.Flow DiagramSite Layout

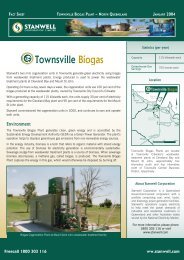

Wastewater Test LabEffluent QualityConstant monitoring, testing andsampling are important activities of thewastewater management system.Wastewater, at this Treatment Plant, istested every two weeks, in thelaboratory, by professional Citiwaterchemists. Samples are taken from theincoming raw (untreated) wastewater,after the primary, secondary treatmentsand UV disinfection. Mt St JohnTreatment Plant has a licence todischarge, issued by the EnvironmentProtection Agency. This licence sets thequality and quantity of the final product.SludgeAt Mt St John around 50,000 litres ofsludge is removed daily. The sludge andscum collected in the Raw Sludge Well ispumped at intervals to AnaerobicDigesters (no oxygen) where theobnoxious raw sludge is broken down byacid-forming and methane-formingbacteria. This breakdown of raw sludgesimplifies disposal problems because asubstantial overall reduction in theSludge Digester Tanksvolume of digested sludge to bedisposed of in the Drying Beds isachieved. The digested sludge is pouredonto sand beds where further water isremoved by evaporation and seepage.After several weeks the dried sludge ispicked up by a tractor and stockpiled.This is later taken to the dump as landfill.BiogasMethane gas is also produced in theSludge Digester and is used to power anelectricity generator. This in turn heatsthe digesting sludge to an optimumtemperature between 35 o C and 37 o C forgood bacteria to live and reproduce, andthus to break down the sludge.Townsville BiogasThe electricity generator uses 100% ofthe methane produced and is capableof powering 90% of the electricityneeded to run this Treatment Plant.Methane is a greenhouse gas whichcontributes to global warming. Byreusing this gas to produce electricity, weare cutting methane emissions into theatmosphere, thus keeping the air clean.Treatment of wastewater at Mount SaintJohn Wastewater Purification Plant is inaccordance with standards set by theDepartment of Environment. Citiwateroperates an International QualityManagement System that complies withthe requirements of ISO 9002. Byadopting a professional and best practiceapproach to manage Townsville’s waterand wastewater business, Citiwater isfulfilling its commitment towards thecommunity and the environment.Technical DataINFLUENT CHARACTERI<strong>ST</strong>ICSBOD 5 : 240 mg/LSuspended Solids: 300 mg/LAmmonia: 37 mg/LOrganic Nitrogen: 5.5 mg/LTotal Phosphorus: 6.9 mg/LEFFLUENT REQUIREMENTSBOD 5 : 30 mg/LSuspended Solids: 30 mg/L<strong>PLANT</strong> CAPACITYEquivalent Population: 40,000 EPDry Weather Flow rate: 11-13 ML/DayWet Weather Flow rate: 33-39 ML/DayCOMMISSION DATES:Module 1: December 1972Module 2: February 1980Unit Operations DetailsROTARY DRUM SCREENScreen Capacity 36 ML/dWedgewire Slot width: 3.0 mmAERATED GRIT REMOVAL TANKDepth: 3000 mmWidth: 3600 mmLength: 11500 mmDetention:Average Hour Flow: 10.5 minutes3 x Average DWF: 5.8 minutesPump Rate: 5.3 minutesPRIMARY CLARIFIER (EACH)Number: 2Diameter: 19800 mmDepth: 2740 mmDetention:Average Hour flow: 2.9 hoursMaximum 6 Hour Flow: 2.5 hours3 x Average Flow: 1.6 hoursPump Rate: 1.4 hoursSurface Settling Rate: 25 Kl/m 2 /dayOverflow Velocity: 124 Kl/m/dayBOD Removal (35%): 760 Kg/daySuspended Solids Removal 60%: 1630 Kg/dayBIOLOGICAL TRICKLING FILTER (EACH)Number: 4Diameter: 36000 mmDepth: 1680-1980 mmVolume Media: 1920 m 3Applied BOD 5 : 0.18 Kg/ m3 /dayHydraulic Loading: 3.72 Kl/m 2 /daySECONDARY CLARIFIER (EACH)Number: 2Diameter: 15850 mmDepth: 3200 mmDetention:Average Hour Flow: 2 hoursSurface Settling Rate: 40 Kl/m 2 /daySECONDARY <strong>TREATMENT</strong>(4 FILTERS PLUS 2 CLARIFIERS)BOD 5 Removal (87%): 1240 Kg/daySuspended Solids Removal (85%): 820 Kg/dayOUTFALL (EACH)Number: 2Diameter: 600 mmLength: 866 mmGravity Capacity: 764 Kl/hourSLUDGE DIGE<strong>ST</strong>ION TANK (EACH)Number: 2Diameter: 12200 mmVolume: 1132 m 3Operation: two stage heatedSLUDGE DRYING BEDSNumber of Units: 12Area: 186 m 2January 2002T O W N S V I L L EA Business Unit of the Townsville City Council ABN 81 143 904 097GARBUTT OPERATIONS CENTREHugh Street Townsville Queensland Australia PO<strong>ST</strong>AL ADDRESS: PO Box 1268 Townsville Qld 4810TELEPHONE: (07) 4727 8950 FACSIMILE: (07) 4727 8927 EMAIL: mxl@townsville.qld.gov.au INTERNET: http://www.townsville.qld.gov.au