a s rc E N E R G Y . c o m - ASRC Energy Services

a s rc E N E R G Y . c o m - ASRC Energy Services

a s rc E N E R G Y . c o m - ASRC Energy Services

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Notable Projects<br />

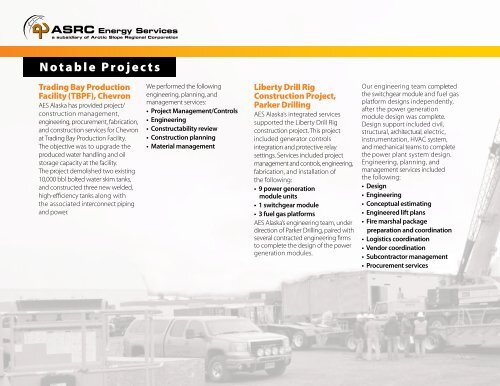

Trading Bay Production<br />

Facility (TBPF), Chevron<br />

AES Alaska has provided project/<br />

construction management,<br />

engineering, procurement, fabrication,<br />

and construction services for Chevron<br />

at Trading Bay Production Facility.<br />

The objective was to upgrade the<br />

produced water handling and oil<br />

storage capacity at the facility.<br />

The project demolished two existing<br />

10,000 bbl bolted water skim tanks,<br />

and constructed three new welded,<br />

high-efficiency tanks along with<br />

the associated inte<strong>rc</strong>onnect piping<br />

and power.<br />

We performed the following<br />

engineering, planning, and<br />

management services:<br />

• Project Management/Controls<br />

• Engineering<br />

• Constructability review<br />

• Construction planning<br />

• Material management<br />

Liberty Drill Rig<br />

Construction Project,<br />

Parker Drilling<br />

AES Alaska’s integrated services<br />

supported the Liberty Drill Rig<br />

construction project. This project<br />

included generator controls<br />

integration and protective relay<br />

settings. <strong>Services</strong> included project<br />

management and controls, engineering,<br />

fabrication, and installation of<br />

the following:<br />

• 9 power generation<br />

module units<br />

• 1 switchgear module<br />

• 3 fuel gas platforms<br />

AES Alaska’s engineering team, under<br />

direction of Parker Drilling, paired with<br />

several contracted engineering firms<br />

to complete the design of the power<br />

generation modules.<br />

Our engineering team completed<br />

the switchgear module and fuel gas<br />

platform designs independently,<br />

after the power generation<br />

module design was complete.<br />

Design support included civil,<br />

structural, a<strong>rc</strong>hitectural, electric,<br />

instrumentation, HVAC system,<br />

and mechanical teams to complete<br />

the power plant system design.<br />

Engineering, planning, and<br />

management services included<br />

the following:<br />

• Design<br />

• Engineering<br />

• Conceptual estimating<br />

• Engineered lift plans<br />

• Fire marshal package<br />

preparation and coordination<br />

• Logistics coordination<br />

• Vendor coordination<br />

• Subcontractor management<br />

• Procurement services<br />

a s r c E N E R G Y . c o m