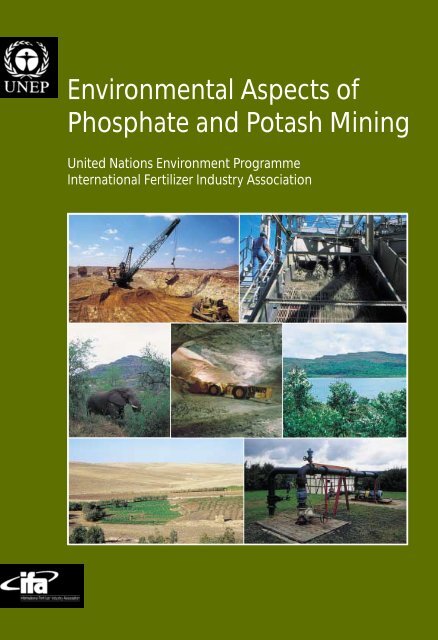

Environmental Aspects of Phosphate and Potash Mining

Environmental Aspects of Phosphate and Potash Mining

Environmental Aspects of Phosphate and Potash Mining

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong><strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>United Nations Environment ProgrammeInternational Fertilizer Industry Association

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong><strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>United Nations Environment ProgrammeInternational Fertilizer Industry AssociationUnited Nations Environment ProgrammeDivision <strong>of</strong> Technology, Industry <strong>and</strong> Economics39-43, Quai André Citroën75739 Paris Cedex 15 - FranceTel: +33 1 44 37 14 50Fax: +33 1 44 37 14 74E-mail: unep.tie@unep.frWeb: www.uneptie.orgInternational Fertilizer Industry Association28, rue Marbeuf75008 Paris - FranceTel: +33 1 53 93 05 00Fax: +33 1 53 93 05 45 / 47E-mail: ifa@fertilizer.orgWeb: www.fertilizer.org

AcknowledgementsA number <strong>of</strong> people provided comments <strong>and</strong> corrections. Particularly substantial inputs were made by:Mr Jon Higgins, researcher, is largely responsible for writing the present documentThe IFA member companies that voluntarily participated in the site visitsMr Keith Isherwood, former Head <strong>of</strong> IFA’s Information Service, for his sustained supportUNEP staff involved in the production <strong>of</strong> the publication were:Mrs Jacqueline Aloisi de Larderel, Assistant Director GeneralMs W<strong>and</strong>a M.A. Hoskin, Senior Programme Officer, <strong>Mining</strong>Ms Wei Zhao, Production <strong>and</strong> Consumption Programme OfficerCo-ordination: Mr Michel Prud’homme <strong>and</strong> Ms Kristen Sukalac, IFALayout: Ms Claudine Aholou-Pütz, IFAGraphics: Ms Hélène Ginet, IFA<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>.First edition. Printed by UNEP <strong>and</strong> IFA, Paris, December 2001.Copyright 2001 UNEP.This publication may be reproduced in whole or in part <strong>and</strong> in any form for educational or non-pr<strong>of</strong>it purposes withoutspecial permission from this copyright holder, provided acknowledgement <strong>of</strong> the source is made. UNEP would appreciatereceiving a copy <strong>of</strong> any publication that uses this publication as a source.No use <strong>of</strong> this publication may be made for resale or any other commercial purpose whatsover without prior permissionin writing from UNEP.The designation employed <strong>and</strong> the presentation <strong>of</strong> the material in this publication do not imply the expression whatsoeveron the part <strong>of</strong> the United Nations Environment Programme concerning the legal status <strong>of</strong> any country, territory, city orarea or its authorities, or concerning delimitation <strong>of</strong> its frontiers <strong>and</strong> boundaries. Moreover, the views expressed do notnecessarily represent the decision or the stated policy <strong>of</strong> the United Nations Environment Programme, nor does citing <strong>of</strong>trade names or commercial processes constitute endorsement.UNITED NATIONS PUBLICATIONISBN: 92-807-2052-XThe text <strong>of</strong> this publication can be downloaded from IFA ‘s web site.Copies can be obtained from:IFA28, rue Marbeuf75008 Paris, FranceTel: +33 1 53 93 05 00Fax: +33 1 53 93 05 45 / 47E-mail: publications@fertilizer.orgWeb: www.fertilizer.org

Contents1. Introduction 11.1 The <strong>Mining</strong> <strong>of</strong> <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>and</strong> the Environment 11.2 The Global Environment Agenda <strong>and</strong> the <strong>Mining</strong> Industry 21.3 The Life Cycle <strong>of</strong> the <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> Industry 42. Overview <strong>of</strong> <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> <strong>and</strong> Beneficiation 62.1 <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> 62.2 <strong>Phosphate</strong> Rock <strong>Mining</strong> <strong>and</strong> Beneficiation 62.3 <strong>Potash</strong> <strong>Mining</strong> <strong>and</strong> Beneficiation 103. The <strong>Environmental</strong> Approach <strong>of</strong> the <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> Industry 143.1 The <strong>Environmental</strong> Challenges 143.2 Mine Development: Exploration, Planning, Approval <strong>and</strong> Construction 153.3 Extraction 173.4 H<strong>and</strong>ling 223.5 Beneficiation <strong>and</strong> Concentration 243.6 Waste Management <strong>and</strong> Disposal 273.7 Mine Closure 363.8 Rehabilitation 363.9 <strong>Environmental</strong> Management 434. Emerging <strong>Environmental</strong> Issues <strong>and</strong> Trends 49Appendices 50Appendix A. Selected References <strong>and</strong> Reading Resources 50Appendix B. Illustrated Examples Contact Information 52Appendix C. Australian <strong>Mining</strong> Industry Code for <strong>Environmental</strong> Management 54Appendix D. Glossary <strong>of</strong> Fertilizer <strong>and</strong> <strong>Mining</strong> Technical Terms 56Appendix E. Acronyms 58Appendix F. Selected Organizations 59

PrefaceThis report on the environmental aspects <strong>of</strong> phosphate<strong>and</strong> potash mining is the fifth in a seriespublished jointly by the International FertilizerIndustry Association (IFA) <strong>and</strong> the United NationsEnvironment Programme (UNEP). Previous studiesincluded : The Fertilizer Industry, World Food Supplies <strong>and</strong>the Environment; Mineral Fertilizer Production <strong>and</strong> the Environment; Mineral Fertilizer Distribution <strong>and</strong> the Environment,<strong>and</strong> Mineral Fertilizer Use <strong>and</strong> the Environment.As such, this publication completes a series that looksat environmental aspects <strong>of</strong> the fertilizer industrythroughout the life-cycle <strong>of</strong> mineral fertilizer products.In this volume, the holistic way <strong>of</strong> looking at anissue is applied to the activities <strong>of</strong> the fertilizer rawmaterials sector, incorporating the concept <strong>of</strong> thewhole-<strong>of</strong>-mine-life thinking <strong>and</strong> planning.Chapter 1 is an introduction to environmental issuesassociated with mining phosphate <strong>and</strong> potash ores.Chapter 2 gives an overview <strong>of</strong> the processes involvedin extracting these minerals <strong>and</strong> preparing them forfertilizer production. Chapter 3, the focus <strong>of</strong> the document,looks at some <strong>of</strong> the industry's responses toassociated environmental challenges. Finally, Chapter4 considers how the mining sector might best contributeto the sustainability <strong>of</strong> the overall fertilizerindustry in years to come.The study reinforces the fact that the environmentalperformance <strong>of</strong> the fertilizer raw materials industryhas improved over recent decades, although challengesremain. This publication therefore, explores the variety<strong>of</strong> approaches <strong>and</strong> techniques which are beingused in different parts <strong>of</strong> the world to address environmentalconcerns.It is our sincere hope that, not only will this reportprove useful, but that companies will continue tostrive to achieve ever cleaner <strong>and</strong> safer production aspart <strong>of</strong> their ongoing efforts to contribute to sustainabledevelopment.Luc M. MaeneDirector GeneralInternational Fertilizer Industry Association (IFA)Jacqueline Aloisi de LarderelAssistant Executive DirectorUNEP Divisions <strong>of</strong> Technology, Industry <strong>and</strong>Economics

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>1. Introduction1.1 The <strong>Mining</strong> <strong>of</strong> <strong>Phosphate</strong> Rock<strong>and</strong> <strong>Potash</strong> <strong>and</strong> the EnvironmentFigure 1.1World mineral fertilizer productionFertilizers are a key factor in sustaining the world'sagricultural output. They supply nutrients that areneeded by all plants for normal growth, development<strong>and</strong> health. Maintaining an adequate supply <strong>of</strong> foodfor human consumption requires: A supplementary source <strong>of</strong> plant nutrients if thenatural supply is insufficient. Replacement <strong>of</strong> the many possible nutrient losses.Ammonia<strong>Phosphate</strong>rock<strong>Potash</strong>Million tonnes nutrients12010080604020These replacement <strong>and</strong>/or supplementary suppliescan be provided through organic manures <strong>and</strong>/ormineral fertilizers.1990 to 20000This publication concerns the provision <strong>of</strong> raw materialsfor two important mineral fertilizers, phosphate<strong>and</strong> potash.Three major nutrients are required in large quantitiesfor plant growth, nitrogen, phosphorous <strong>and</strong> potassium.Three secondary nutrients are required in smallerquantities on some soils; sulfur, calcium <strong>and</strong> magnesium.Seven micronutrients may be required in smallamounts where deficient. Each nutrient has a specificbiological function <strong>and</strong>, while there may be synergiesbetween the nutrients, none has a substitute.By far the most important for the present publication,in terms <strong>of</strong> the quantity mined <strong>and</strong> potential impacton the environment, are phosphate <strong>and</strong> potash.The production <strong>of</strong> phosphorous <strong>and</strong> potassium mineralfertilizers relies essentially on the mining <strong>of</strong>mineral concentrations, in the form <strong>of</strong> ore depositsfrom the earth's crust. Nitrogen mineral fertilizers, onthe other h<strong>and</strong>, are almost entirely based on ammoniamanufactured from the abundant source <strong>of</strong> atmosphericnitrogen, water <strong>and</strong> energy.The production <strong>of</strong> nitrogen fertilizers has been discussedextensively in the earlier publication byUNEP/UNIDO/IFA on ‘Mineral Fertilizer Production<strong>and</strong> the Environment: Part 1 - The Fertilizer Industry'sManufacturing Processes <strong>and</strong> <strong>Environmental</strong> Issues’<strong>and</strong> will not be covered further here.World production <strong>of</strong> phosphorous <strong>and</strong> potassiummineral fertilizers in 1998/99 was 34 Mt P 2 O 5 (1) <strong>and</strong>25.5 Mt K 2 O respectively. This required the extraction<strong>of</strong> 144 Mt <strong>of</strong> phosphate rock <strong>and</strong> more than 45 Mt <strong>of</strong>potash ore (2). Table 1.1 indicates the scale <strong>of</strong> the mineralfertilizer raw material mining industry incomparison to the mining <strong>of</strong> other bulk mineral <strong>and</strong>energy commodities.Table 1.1.Comparison <strong>of</strong> the World Production <strong>of</strong> SomeBulk Minerals in 1998/99ProductTonnageCoal 4,655,000,000Iron Ore 1,020,000,000Salt 186,000,000<strong>Phosphate</strong> Rock 144,000,000Bauxite 126,000,000Gypsum 107,000,000<strong>Potash</strong> Ore (2) 45,000,000(1) <strong>Phosphate</strong> <strong>and</strong> potash may be expressed as their elementalforms P <strong>and</strong> K, or as oxide forms P 2 O 5 <strong>and</strong> K 2 O. In thispublication the oxide form is used.Mt = million tonnes(3) In KCl equivalent (sylvinite). Actual tonnages are larger,including kieiserite, langbeinite <strong>and</strong> carnallite ore.

Introduction2During recent decades, attention <strong>and</strong> concern hasbeen focused increasingly on the environmentalimpacts <strong>of</strong> human activities, especially industrialactivities such as mining. The public perception <strong>of</strong> themining industry has been tainted by a legacy <strong>of</strong> environmentaldamage from past practices combined witha number <strong>of</strong> highly publicized failures <strong>of</strong> metal miningtailings dams. As the scale <strong>of</strong> operations <strong>and</strong> thearea disturbed by the mining industry continue togrow, so too has the public's concern over the industry'scapacity to manage <strong>and</strong> mitigate environmentalimpacts. In response, most governments haveimposed stricter legislative <strong>and</strong> regulatory requirementson the mining industry in order to protect theecosystem, to maintain a safe <strong>and</strong> secure environment<strong>and</strong> to protect people living in the vicinity <strong>of</strong> themine-site.Leading mining companies have taken up the challenge<strong>and</strong> are pushing beyond minimum legalrequirements through voluntary initiatives, to ensuretheir continued “license-to-operate” from the communityas well as increasing their competitiveadvantage through continuous, voluntary improvementsin environmental performance.As with all mining activities, the extraction <strong>and</strong> beneficiation<strong>of</strong> phosphate rock <strong>and</strong> potash to producemineral fertilizer raw material has the potential tocause environmental impacts. These impacts can takethe form <strong>of</strong> changes to the l<strong>and</strong>scape, water contamination,excessive water consumption <strong>and</strong> airpollution.The l<strong>and</strong>scape may be disturbed through the removal<strong>of</strong> topsoil <strong>and</strong> vegetation, excavation <strong>and</strong> deposition<strong>of</strong> overburden, disposal <strong>of</strong> processing wastes <strong>and</strong>underground mining induced surface subsidence.The quality <strong>of</strong> surface <strong>and</strong> groundwater may beadversely affected by the release <strong>of</strong> processing water<strong>and</strong> the erosion <strong>of</strong> sediments <strong>and</strong> leaching <strong>of</strong> toxicminerals from overburden <strong>and</strong> processing wastes.Water resources may be affected by dewatering operationsor beneficiation processes.The quality <strong>of</strong> the air can be affected by the release <strong>of</strong>emissions such as dust <strong>and</strong> exhaust gases.The fertilizer raw material mining industry, as a subsector<strong>of</strong> the larger global mining industry, is notexempt from the prevailing social <strong>and</strong> political climate.This publication demonstrates how thephosphate rock <strong>and</strong> potash mining industry hasresponded to the challenges presented by the changingenvironmental, political <strong>and</strong> cultural values <strong>of</strong> society,through an overview <strong>of</strong> the industry's environmentalperformance worldwide. Information on companyenvironmental practices has been gathered from anextensive series <strong>of</strong> site visits to fertilizer raw materialmining, beneficiation, <strong>and</strong> processing operations, inaddition to a review <strong>of</strong> available literature. The companies<strong>and</strong> organizations involved in the project arelisted in Appendix B. While this does not provide acomplete picture <strong>of</strong> the current state <strong>of</strong> the industry, itdoes demonstrate the direction <strong>of</strong> development, <strong>and</strong>the range <strong>of</strong> systems, practices <strong>and</strong> technologiesemployed.The publication focuses on the environmental aspectsassociated with the mining <strong>of</strong> raw materials for themanufacture <strong>of</strong> phosphorous <strong>and</strong> potassium mineralfertilizers. Earlier joint publications by UNEP, UNIDO<strong>and</strong> IFA have covered the environmental issues associatedwith the downstream processing, distribution<strong>and</strong> use <strong>of</strong> mineral fertilizers (3).1.2 The Global Environment Agenda<strong>and</strong> the <strong>Mining</strong> Industry<strong>Environmental</strong> impact is an increasingly importantissue against which human activities must be weighed.A key factor is the scale <strong>of</strong> natural resource consumption,such as that <strong>of</strong> minerals, agricultural l<strong>and</strong>, wood<strong>and</strong> fisheries.The issue <strong>of</strong> resource consumption requires that thecausal factors be addressed, such as: The continued world population growth; The material consumption patterns <strong>of</strong> the developedworld, which are increasingly being adoptedby the developing world; The imbalance in development, opportunities <strong>and</strong>resource allocation between the developed <strong>and</strong>developing world; The correct pricing <strong>of</strong> the resource to account forscarcity <strong>and</strong> the environmental <strong>and</strong> social costs <strong>of</strong>production; <strong>and</strong> The efficiency <strong>of</strong> resource use by industry throughthe implementation <strong>of</strong> best available techniques.(3) The earlier UNEP, UNIDO <strong>and</strong> IFA publications are listedin Appendix A. These can be obtained from either IFA orUNEP.

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>These are complex, interlinked issues. “Sustainabledevelopment” has been proposed as a holisticapproach for dealing with these complexities.Sustainable development integrates economic, environmental<strong>and</strong> social considerations in order toimprove the lives <strong>of</strong> the current generation <strong>and</strong> ensurethat future generations will have adequate resources<strong>and</strong> opportunities.Over recent decades, public awareness <strong>and</strong> concernhas grown, as has knowledge <strong>of</strong> the effects <strong>of</strong> ouractivities on the environment. The 1992 UnitedNations Conference on Environment <strong>and</strong>Development (UNCED) held in Rio de Janeiro, Brazilresulted in Agenda 21, an action plan for the implementation<strong>of</strong> sustainable development throughout alllevels <strong>of</strong> society. Agenda 21 identified the global economic,environmental, <strong>and</strong> social issues to beaddressed <strong>and</strong> provided a detailed framework formoving society towards sustainable development.In the case <strong>of</strong> phosphorus <strong>and</strong> potassium, althoughthe best quality <strong>and</strong> most easily accessible deposits aremined first, the total available resources are sufficientfor hundreds or thous<strong>and</strong>s <strong>of</strong> years. But no mineralresource is infinite <strong>and</strong> the efficient extraction <strong>and</strong> use<strong>of</strong> phosphate <strong>and</strong> potash are an important contributionto a certain degree <strong>of</strong> sustainability.The mining industry has an important role to play inthis respect: Rehabilitation allows the l<strong>and</strong> disturbed by theextraction <strong>of</strong> the mineral resource to be returnedto the pool <strong>of</strong> l<strong>and</strong> available for other uses; Optimization <strong>of</strong> the recovery <strong>of</strong> the resource maybe encouraged through the use <strong>of</strong> the most efficienttechniques <strong>and</strong> technologies available; Any unrecovered resources can be left in a conditionsuch that possible future improvements intechnological capability <strong>and</strong> economics will beable to access <strong>and</strong> recover the resource; <strong>and</strong> The development <strong>of</strong> more efficient mining <strong>and</strong>processing methods <strong>and</strong> techniques can extendcurrent resource life, <strong>and</strong> help to recover, recycle<strong>and</strong> reuse minerals.These principles have application across all sections <strong>of</strong>the mining industry, including that <strong>of</strong> the phosphaterock <strong>and</strong> potash mining industry. The mining industryhas responded to the sustainability issues that arechallenging it on a number <strong>of</strong> fronts. Several <strong>of</strong> themare discussed in this report.<strong>Mining</strong> Members <strong>of</strong> the World Business Council onSustainable Development (WBCSD) established theGlobal <strong>Mining</strong> Initiative (GMI) in 1998. The GMI,representing some <strong>of</strong> the worlds leading mineral <strong>and</strong>mining companies, was established to provide leadership<strong>and</strong> direction for the future development <strong>of</strong> themining industry in a sustainable manner. To this end,the GMI approached the International Institute <strong>of</strong>Environment <strong>and</strong> Development to commission the<strong>Mining</strong>, Minerals <strong>and</strong> Sustainable Development(MMSD) project, to determine how mining can mosteffectively contribute to sustainable development.Regional groups have been established, stakeholdersengaged <strong>and</strong> consulted, issues identified, <strong>and</strong> researchcommissioned to determine how the services <strong>of</strong> themining industry can be orientated to sustainabledevelopment <strong>and</strong> develop an action plan to guide theindustry in coming decades. This action plan is to beimplemented by the new International Council on<strong>Mining</strong> <strong>and</strong> Metals (formally The InternationalCouncil on Metals <strong>and</strong> the Environment).National mining associations have developed <strong>and</strong> disseminatingcharters or voluntary codes <strong>of</strong> practice toimprove the level <strong>of</strong> environmental management. Anexample <strong>of</strong> this is the Australian <strong>Mining</strong> IndustryCode for <strong>Environmental</strong> Management developed bythe Minerals Council <strong>of</strong> Australia (see Appendix C).This voluntary code has been widely adopted by miningcompanies within Australia. These are required topublish public environmental reports to demonstrateprogress on the implementation <strong>of</strong> the code's principles.The World Bank has been actively developing miningsector capacity in developing countries. Programshave focused on drafting mining legislation, buildingup environmental management capabilities <strong>and</strong> creatingincentives for private investment.NGO co-operation with the mining industry hasincreased at local <strong>and</strong> global levels in recent years. TheWorld Wide Fund for Nature (WWF) has been activein developing relationships with the mining industryto foster improved performance. The WWF has beenleading the development <strong>of</strong> an independent miningcertification system in partnership with Placer Dome(Australia). This system is based on the ForestStewardship Council (FSC) model that has beeneffective in fostering improvement <strong>of</strong> the environmentalperformance <strong>of</strong> the forestry industry.

Introduction4Figure1.2The mineral fertilizer life cycleThe flow <strong>of</strong> the macro-nutrients phosphorous <strong>and</strong> potassiumSource : Concept for the schematic is drawn from the Natural ResoucesCanada report "Sustainable Development <strong>and</strong> Minerals <strong>and</strong> Metals"Figure1.3The mining life cycleto concentrate oreplanningSource : Concept for the schematic is drawn from the Natural ResoucesCanada report "Sustainable Development <strong>and</strong> Minerals <strong>and</strong> Metals"1.3 The Life Cycle <strong>of</strong> the <strong>Phosphate</strong>Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> IndustryThe industry approach to environmental issues hasmoved from ‘end-<strong>of</strong>-pipe’ solutions, towards a pollutionprevention strategy. This strategy requires anintegrated, holistic view <strong>of</strong> activities. Tools have beendeveloped to assist management, including cleanerproduction, life cycle assessment <strong>and</strong> industrial ecology.Each <strong>of</strong> these looks at the life cycle <strong>of</strong> the productor service, to identify where the major environmentalissues or problems may arise <strong>and</strong> where the most costeffectivesolutions can be developed. Planning for thelife <strong>of</strong> the mine, including closure <strong>and</strong> site rehabilitation,permits a more efficient <strong>and</strong> environmentallyeffective outcome. It identifies <strong>and</strong> creates opportunitiesfor improving the economic <strong>and</strong> environmentalperformance <strong>of</strong> the operation. Previously unrecoveredresources may be retrieved <strong>and</strong> former wastes convertedinto useful products.A schematic view <strong>of</strong> the mining life cycle is depicted inFigure 1.3. This highlights the sequential nature <strong>of</strong> theactivities <strong>of</strong> the phosphate rock <strong>and</strong> potash miningindustry. Emphasis is placed on closing the circle, orlife cycle, with the rehabilitation <strong>of</strong> the site, <strong>and</strong> on theimportance <strong>of</strong> planning for this from the outset.Activities <strong>of</strong> the mining life cycle may include: Prospecting <strong>and</strong> exploration to identify potentialeconomic mineral deposits; Assessment <strong>of</strong> the mineral deposit to determinewhether it can be economically extracted <strong>and</strong>processed under current <strong>and</strong> predicted futuremarket conditions; Design, planning <strong>and</strong> construction <strong>of</strong> the mine,h<strong>and</strong>ling, processing plant <strong>and</strong> associated infrastructuresuch as roads, power generation <strong>and</strong>ports; Removal <strong>of</strong> the overburden or mining <strong>of</strong> theunderground declines, shafts <strong>and</strong> tunnels to accessthe ore; Extraction <strong>of</strong> the ore; H<strong>and</strong>ling <strong>of</strong> the ore from the mine to the beneficiationplant; Beneficiation <strong>and</strong> primary processing <strong>of</strong> the ore toproduce a concentrated product (phosphate rock<strong>and</strong> potash); Treatment <strong>and</strong> disposal <strong>of</strong> solid <strong>and</strong> liquid wastes; Closure <strong>of</strong> the mining operation after exhaustion<strong>of</strong> the economic ore reserve <strong>and</strong> completion <strong>of</strong>rehabilitation; <strong>and</strong>

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>Subsequent h<strong>and</strong>ing over <strong>of</strong> the site to the pool <strong>of</strong>available l<strong>and</strong>.Planning, environmental management <strong>and</strong> rehabilitationare conducted throughout the mining life cycle,encompassing all other activities.By examining each stage <strong>of</strong> the life cycle, the potentialenvironmental effects can be identified <strong>and</strong> actionstaken to mitigate or prevent them. Synergies can bedeveloped, <strong>and</strong> opportunities identified, avoidingadditional costs <strong>and</strong> potentially creating new streams<strong>of</strong> revenue, resulting in an improved <strong>of</strong> the performanceboth environmentally <strong>and</strong> economically.Companies are beginning to adopt life-cycle thinking.This is evidenced through the environmental reportingexample presented in Figure 1.4. The diagram issupported by figures on the input <strong>and</strong> output flows,including emissions, wastes <strong>and</strong> net l<strong>and</strong> disturbanceto provide a measure <strong>of</strong> environmental performance.Figure 1.4:WMC Community <strong>and</strong> Environment

Overview <strong>of</strong> <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> <strong>and</strong> Beneficiation2. Overview <strong>of</strong> <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> <strong>and</strong>Beneficiation2.1 <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong>Although phosphate rock <strong>and</strong> potash are used as rawmaterials for a wide range <strong>of</strong> applications, the mostimportant use by far is the manufacture <strong>of</strong> mineralfertilizers.The primary source <strong>of</strong> these minerals is geological oredeposits formed through past sedimentary or igneousactivities. In the case <strong>of</strong> potash, concentrated brinesare also a significant source.This chapter provides a brief overview <strong>of</strong> the majoractivities involved in the mining, h<strong>and</strong>ling <strong>and</strong> beneficiation<strong>of</strong> phosphate rock <strong>and</strong> potash ore.downstream concentrated fertilizer products. Theeconomies <strong>of</strong> scale <strong>of</strong> the complex in turn influencethe scale <strong>of</strong> the mining operation.The l<strong>and</strong> area affected by the surface operations mayvary widely, depend on the orebody geometry <strong>and</strong>thickness <strong>and</strong> the ore extraction rate. At similarextraction rates, mining <strong>of</strong> flat-lying thin orebodies asfound in Florida (USA) will affect a far wider area <strong>of</strong>l<strong>and</strong> than the mining <strong>of</strong> thicker, or steeply dippingorebodies as found in Brazil <strong>and</strong> Idaho (USA). Thedepth <strong>of</strong> excavations may range from a few metres tomore than 100 metres.2.2 <strong>Phosphate</strong> Rock <strong>Mining</strong> <strong>and</strong>Beneficiation6<strong>Phosphate</strong> Rock <strong>Mining</strong>At present, most phosphate rock is mined using largescalesurface methods. In the past, undergroundmining methods played a greater role, but their contributionto world production has declined. Majormining <strong>and</strong> beneficiation techniques <strong>and</strong> processesemployed by the industry are listed in Figure 2.1.Surface phosphate rock mining operations can varygreatly in size. Extraction may range from severalthous<strong>and</strong> to more than 10 million tonnes <strong>of</strong> ore peryear. In many cases, operations supply feed to a nearbyfertilizer processing complex for the production <strong>of</strong>Surface mining <strong>of</strong> phosphate rock with dragline, Florida -Cargill Fertilizers Inc., USACurrently, most phosphate rock production worldwideis extracted using opencast dragline or open-pitshovel/excavator mining methods. This method isemployed widely in parts <strong>of</strong> the United States <strong>of</strong>America, Morocco <strong>and</strong> Russia.Underground mining methods are currently used inTunisia, Morocco, Mexico <strong>and</strong> India. The area <strong>of</strong> thel<strong>and</strong> surface affected by these operations is generallysmall <strong>and</strong> limited to the area immediately adjacent tothe access decline or shaft.The following discussion will focus on surface methodsdue to their significance.Surface mining <strong>of</strong> phosphate rock, with bucketwheel - OfficeTogolais des <strong>Phosphate</strong>s (OTP), Togo

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>Figure 2.1Common phosphate rock mining processes<strong>and</strong> equipmentExtractionSurfaceUndergroundDraglineBucketwheel excavatorShovelFront-end-loader (FEL)ExcavatorContinuous mining machineLongwallShaft / Decline<strong>Phosphate</strong> Rock BeneficiationBeneficiation (or concentration) processes are generallyused to upgrade the phosphate content byremoving contaminants <strong>and</strong> barren material prior t<strong>of</strong>urther processing. A few ores are <strong>of</strong> sufficiently highquality to require no further concentration. The naturallyoccurring impurities contained in phosphaterock ore depend heavily on the type <strong>of</strong> deposit (sedimentaryor igneous), associated minerals, <strong>and</strong> theextent <strong>of</strong> weathering. Major impurities can includeorganic matter, clay <strong>and</strong> other fines, siliceous material,carbonates, <strong>and</strong> iron bearing minerals. These characteristicsinfluence the beneficiation processesemployed.H<strong>and</strong>lingSurfaceUndergroundSlurry pipelineRoad or haul trucksConveyorsStockpile <strong>and</strong> reclaimerConveyorsFeed binsShaft or decline haulageThe removal <strong>of</strong> fines such as clays <strong>and</strong> fine-grainedaluminium <strong>and</strong> iron phosphates is usually conductedthrough a combination <strong>of</strong> crushing/grinding, scrubbing,water washing, screening, <strong>and</strong>/or hydrocyclones.The fines are disposed <strong>of</strong> either to rivers, mined outareas, or specially engineered storage impoundments.Siliceous material, s<strong>and</strong>, may require an additionalfroth flotation stage for separation. This is typicallypumped to storage impoundments or mined-outareas for disposal.Beneficiation / concentrationSize reductionCrushingGrindingScreeningHydrocyclonesConcentrationWashingFlotationCarbonate reductionCalcinationFlotationMagnetic separationHeavy-media separationAcid washingDry screening - Copebras SA, BrazilIron mineral removalMagnetic separationDewateringDryingCentrifugesBelt filtersRotary ovensFluidised bed dryersStorageConveyorsShedsTanksCone crusher - Fosfertil, Brazil

Overview <strong>of</strong> <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> <strong>and</strong> BeneficiationFollowing beneficiation, the concentrated phosphaterock is stockpiled prior to transport to downstreamprocessing plants for the manufacture <strong>of</strong> phosphatemineral fertilizers. In some instances, phosphate rockwith suitable properties may be directly applied tocrops as a soil amendment by farmers.Wet screening - IMC <strong>Phosphate</strong>, Florida, USA<strong>Phosphate</strong> fertilizer plant, Conda, USA - Agrium Inc., Canada8Grinding mills - Fosfertil, BrazilGenerally, the major waste streams produced duringphosphate rock beneficiation are clay fines, s<strong>and</strong> tailings<strong>and</strong> significant quantities <strong>of</strong> process water.Magnetite tailings may also be associated with igneousorebodies. These are disposed <strong>of</strong> by a number <strong>of</strong>means including discharge to rivers or other waterbodies, <strong>and</strong> disposal to engineered storage dams, ormined-out areas. The process water may be recovered<strong>and</strong> reused.Flotation tanks - IMC <strong>Phosphate</strong>, FloridaThe presence <strong>of</strong> carbonates in the form <strong>of</strong> dolomite<strong>and</strong> calcite may cause downstream processing problems<strong>and</strong> may reduce the quality <strong>of</strong> the end product.They are primarily removed through the use <strong>of</strong> calcinationfollowed by slaking with water to remove theCaO <strong>and</strong> MgO produced.Iron minerals may be present in the form <strong>of</strong> magnetite,hematite <strong>and</strong> goethite. These are typicallyremoved through scrubbing <strong>and</strong> size classification, ormagnetic separation.Decantation <strong>of</strong> clarified water - Cargill Fertilizers Inc., USA

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>Clay settling pond - Cargill Fertilizers Inc., USADrying plant - Office Chérifien des <strong>Phosphate</strong>s (OCP),Khouribga, MoroccoSurface <strong>Mining</strong> <strong>and</strong> Beneficiation Operations inMorocco<strong>Phosphate</strong> rock mining <strong>and</strong> beneficiation are illustratedby the operations <strong>of</strong> Office Chérifien des<strong>Phosphate</strong>s (OCP) in Morocco.At the Khouribga <strong>and</strong> Benguerir opencast draglinemining operations in Morocco, the overburden is initiallydrilled <strong>and</strong> blasted. Bulldozers prepare thesurface for draglines to remove the broken overburden<strong>and</strong> expose the ore. The ore is excavated withoutblasting into trucks using smaller draglines, shovels orfront-end loaders. The trucks transport the ore to ascreening plant for the separation <strong>and</strong> disposal <strong>of</strong> theoversize low-grade material followed by stockpiling.The screened ore is reclaimed from the stockpile <strong>and</strong>transferred by conveyor to the beneficiation plant.Theore is washed <strong>and</strong> dried to remove clay fines <strong>and</strong> insome instances is subjected to calcination, to producea concentrated phosphate rock.The concentrated phosphate rock is transported byrail either to the industrial complexes located at JorfLasfar <strong>and</strong> Safi for further processing, or directly toport for export.Sizing <strong>and</strong> stockpile plant - Office Chérifien des <strong>Phosphate</strong>s(OCP), Khouribga, MoroccoConveyor <strong>and</strong> stacker - Office Chérifien des <strong>Phosphate</strong>s(OCP), Khouribga, MoroccoLoading phosphate rock - Office Chérifien des <strong>Phosphate</strong>s(OCP), Khouribga, Morocco

Overview <strong>of</strong> <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> <strong>and</strong> BeneficiationSurface brine deposits are exploited using solar evaporationponds to concentrate <strong>and</strong> precipitate thepotash. The evaporation ponds are extensive, withsome operations covering in excess <strong>of</strong> 90 square kilometers<strong>of</strong> l<strong>and</strong> area to produce around 8 milliontonnes <strong>of</strong> potash ore per year.Washing plant - Office Chérifien des <strong>Phosphate</strong>s (OCP),Khouribga, MoroccoConventional mechanized underground mining operationsare the most widely used method for theextraction <strong>of</strong> potash ore. A variety <strong>of</strong> mining techniques<strong>and</strong> equipment may be employed dependingon factors such as: the orebody depth, geometry,thickness <strong>and</strong> consistency, the geological <strong>and</strong> geotechnicalconditions <strong>of</strong> the ore <strong>and</strong> surrounding rock, <strong>and</strong>the presence <strong>of</strong> overlying aquifers. Methods in widespreaduse include variations <strong>of</strong> room <strong>and</strong> pillar,longwall, cut <strong>and</strong> fill, <strong>and</strong> open stope techniques.10Port, Jorf Lasfar - Office Chérifien des <strong>Phosphate</strong>s (OCP),Morocco2.3 <strong>Potash</strong> <strong>Mining</strong> <strong>and</strong> Beneficiation<strong>Potash</strong> is a generic term applied to all potassium saltsthat are used as fertilizers.<strong>Potash</strong> <strong>Mining</strong><strong>Potash</strong> ore is extracted from two major ore deposittypes, deeply buried marine evaporite deposits thattypically range from 400 metres to greater than 1,000metres below the surface, <strong>and</strong> surface brine depositsassociated with saline water bodies such as the DeadSea in the Middle East <strong>and</strong> the Great Salt Lake inNorth America.Most potash is sourced from buried deposits usingconventional mechanized underground mining methods,though solution mining methods also areemployed. Generally these underground operationsproduce between 1 to 10 million tonnes <strong>of</strong> potash oreper year. The l<strong>and</strong> area affected is typically confined tothe immediate area <strong>of</strong> the shaft, plant <strong>and</strong> waste disposalarea but may be up to several square kilometers.After the ore is extracted, it is generally transferred bybridge conveyor, shuttle cars or load-haul-dump unitsto a system <strong>of</strong> conveyors that carry it to undergroundstorage bins, prior to haulage to the surface through ashaft by automated skips. On rare occasions shallowmines may use a decline <strong>and</strong> conveyor arrangement.Solution mining is currently used at a number <strong>of</strong>operations in North America. The process relies onthe greater solubility at elevated temperatures in brine<strong>of</strong> sylvite in comparison to salt (NaCl). Commonly,brine is heated on the surface then injected into theorebody through wells. The heated brine absorbssylvite from the orebody <strong>and</strong> is then pumped back tothe surface to a series <strong>of</strong> ponds, where the potash precipitatesas the brine cools. The potash is recoveredfrom the ponds by dredges <strong>and</strong> pumped to the plantfor processing. The brine is heated again <strong>and</strong> theprocess repeated. An advantage <strong>of</strong> the method is thatit allows ore extraction at greater depths than withconventional underground mining methods.<strong>Potash</strong> mine head <strong>and</strong> plant - <strong>Potash</strong> Corporation <strong>of</strong>Saskatchewan (PCS), Canada

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>Continuous mining machine - <strong>Potash</strong> Corporation <strong>of</strong>Saskatchewan (PCS), CanadaLongwall mining - Mines de Potasses d'Alsace, FranceDrilling holes for blasting explosive - Kali und Salz GmbH,GermanyContinuous mining machine - <strong>Potash</strong> Corporation <strong>of</strong>Saskatchewan (PCS), CanadaLoader (LHD-Load, hold, dump unit) - Kali und SalzGmbH, Germany

Overview <strong>of</strong> <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> <strong>and</strong> Beneficiation12Figure 2.2Common potash mining processes <strong>and</strong> equipmentExtractionH<strong>and</strong>lingUndergroundSolutionSurfaceBeneficiation / concentrationSize reductionDeslimingConcentrationDewateringDryingCompactionGranulationStorageContinuous miningmachineLongwallLoad-haul-dump (LHD) unitsDrill <strong>and</strong> blastInjection wellsRecovery wellsEvaporation pondsShuttle carsConveyorsFeed binsShaft or decline haulageBrine pipelinesCooling pondsCrushingGrindingScreeningHydrocyclonesAttrition scrubbingHydrocyclonesFlotationThermal dissolution--crystallizationElectrostatic separationHeavy-media separationFiltersThickenersCentrifugesRotary ovensFluidised bed dryersRotary compactorGranulatorConveyorsShedsAlthough it is not strictly mining, the concentration <strong>of</strong>brine in solar evaporation ponds is another method <strong>of</strong>producing potash ore. The method relies on the evaporation<strong>of</strong> brine through a series <strong>of</strong> shallow ponds.The initial ponds are used to precipitate halite (NaCl)<strong>and</strong> concentrate the desired minerals, the brine is thenpumped into a second series <strong>of</strong> ponds in which thepotash ore, mostly carnallite, is precipitated. The carnalliteis harvested <strong>and</strong> pumped as a slurry tobeneficiation facilities for processing.<strong>Potash</strong> BeneficiationThe processing <strong>of</strong> potash generally involves a series <strong>of</strong>steps including: Size reduction; Desliming; Separation; Drying; Compaction <strong>and</strong> granulation; Disposal <strong>of</strong> the waste streams.The specific process employed will depend on factorssuch as the characteristics <strong>and</strong> constituents <strong>of</strong> thepotash ore <strong>and</strong> the market specifications.Generally, the ore is reduced in size using a system <strong>of</strong>crushing <strong>and</strong> grinding to liberate the different mineralsfrom each other. This is usually followed bydesliming by intense agitation followed by flotation orhydrocyclones to separate the fines consisting <strong>of</strong> clays,dolomite <strong>and</strong> s<strong>and</strong> from the potash ore.Four basic techniques are used to separate the wasteminerals or by-products such as salt <strong>and</strong> concentratethe potash; flotation, electrostatic separation, thermaldissolution-crystallization, <strong>and</strong> heavy media separation.Several <strong>of</strong> these may be used together to enhancerecovery.Flotation is the most widely used technique, relying onthe difference in surface properties between mineralsto selectively float the desired mineral. Electrostaticseparation is a dry process in which the minerals areseparated using their different electrical conductivities.Thermal dissolution-crystallization relies on thesame principle as solution mining, whereby a heatedbrine preferentially dissolves potassium chloride.Heavy media separation relies on the difference in specificgravity between sylvite <strong>and</strong> halite to selectivelyfloat <strong>and</strong> remove the lighter sylvite particles.

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>After concentration, the potash concentrate is generallydried in a rotary or fluidized bed dryer to reduce themoisture content. Depending on market requirements,this may be followed by compaction at highpressure between rollers <strong>and</strong> then granulation to producea uniform size potash product.Three major waste streams are produced during beneficiation;brines, fines, <strong>and</strong> salt tailings. A variety <strong>of</strong>disposal methods are currently used, including: Stacking <strong>of</strong> the salt tailings on the surface; Retention <strong>of</strong> the fines <strong>and</strong> brines in surface pondsfor solar evaporation; Deep well injection <strong>of</strong> brines into confined permeablegeological strata; Backfilling <strong>of</strong> mined underground openings withsalt tailings, fines <strong>and</strong> brines; Release <strong>of</strong> wastes to water bodies such as rivers orseas.Filtering potash before drying - Kali und Salz GmbH,GermanyThese are discussed in greater detail in Chapter three.Figure 2.3Typical potash beneficiation processKali <strong>and</strong> Salz GmbH, GermanyMinePrimary crushingFine grindingFlotationHot leaching<strong>Potash</strong> rotary drier - <strong>Potash</strong> Corporation <strong>of</strong> Saskatchewan(PCS), CanadaClassificationCrystallizationDryingWashing processGranulationDryingDustfreeGranularKCl 99Storage / shipmentStorage / shipment<strong>Potash</strong> compaction rollers - <strong>Potash</strong> Corporation <strong>of</strong>Saskatchewan (PCS), Canada

BeneficiationH<strong>and</strong>ling ExtractiondevelopmentThe <strong>Environmental</strong> Approach <strong>of</strong> the <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> Industry3. The <strong>Environmental</strong> Approach <strong>of</strong> the <strong>Phosphate</strong> Rock <strong>and</strong><strong>Potash</strong> <strong>Mining</strong> Industry143.1 The <strong>Environmental</strong> ChallengesThe activities <strong>of</strong> the phosphate rock <strong>and</strong> potash miningindustry potentially result in a wide variety <strong>of</strong>adverse environmental effects. Typically, these effectsare quite localized, <strong>and</strong> in most cases, confined to themine site. At a specific site, the type <strong>and</strong> extent <strong>of</strong> environmentaleffects may depend on factors such as: The characteristics <strong>of</strong> the ore <strong>and</strong> overburden; The surface l<strong>and</strong> pr<strong>of</strong>ile (wetl<strong>and</strong>s, plains, hills,<strong>and</strong> mountains); The local climate; The surrounding ecosystem.However, <strong>of</strong> greater importance may be: The mining methods <strong>and</strong> equipment; The beneficiation <strong>and</strong> concentration processes; The waste disposal methods; The scale <strong>of</strong> the operation; The sites location to existing population centers<strong>and</strong> infrastructure.<strong>Environmental</strong> aspects that can be affected by miningactivities were grouped under ‘air, ‘water’, ’l<strong>and</strong>’ <strong>and</strong>‘social values’.Air quality can be affected by emissions <strong>of</strong>: Dust; Exhaust particulates <strong>and</strong> exhaust gases such as carbondioxide (CO 2 ), carbon monoxide (CO),nitrogen oxides (NO x ), <strong>and</strong> sulfur oxides (SO x ); Volatile organic compounds (VOC's) from fueling<strong>and</strong> workshop activities; Methane released from some geological strata.Greenhouse gases such as CO 2 <strong>and</strong> methane arebelieved to contribute to global warming.Dust is a common problem throughout all miningactivities. Dust generated by vehicle traffic can bereduced through a variety <strong>of</strong> means. Where waterresources are not limited, regular watering withmobile water trucks or fixed sprinkler systems is effective.Otherwise the application <strong>of</strong> surface bindingagents, the selection <strong>of</strong> suitable construction materials<strong>and</strong> the sealing <strong>of</strong> heavily used access ways may bemore suitable. Dust emitted during beneficiation canbe controlled by means such as water sprays, baghouses<strong>and</strong> wet scrubbers. Captured dust can generally bereturned to the beneficiation process.Figure 3.1.1Major potential environmental effects that may occurduring phosphate rock <strong>and</strong> potash mining activitiesClosure Waste disposal Mine...<strong>Environmental</strong> management <strong>and</strong> rehabilitation...Exploration,assessment,planning <strong>and</strong>constructionOverburden removalor orebody accessOre extractionTransportStorage <strong>and</strong> reclamationSize reduction(crushing, grinding,screens, cyclones)Separation,concentration <strong>and</strong>contaminant removalDrying, compaction,granulation, etc...Wastes to surfacestorage impoundments<strong>and</strong> piles, undergroundbackfilling, deep wellinjection, or releaseto the environmentRemoval <strong>of</strong> equipment<strong>and</strong> plant, shaft sealing,stabilisation, monitoringReturn <strong>of</strong> site to pool<strong>of</strong> available l<strong>and</strong>L<strong>and</strong> surface disturbanceAir emissionsWater contaminationNoise <strong>and</strong> vibrationL<strong>and</strong> surface disturbanceWater contaminationWater table loweringAir emissionsTopsoil degradationVegetation <strong>and</strong> wildlifedisruptionNoise <strong>and</strong> vibrationAir emissionsWater contaminationNoiseWaste generationWater consumptionWater contaminationAir emissionsNoise <strong>and</strong> vibrationResource maximizationProduct transportedto further processing,distribution <strong>and</strong> useL<strong>and</strong> surface disturbanceWater contaminationAir emissionsStabilityAesthetic changesLong term stabilitySafetyFuture l<strong>and</strong> useAir emissionsHazardous waste disposal

Minedevelopment<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>Water quality can be affected by the release <strong>of</strong> slurrybrines <strong>and</strong> contaminants into process water. Surfacewaters may be contaminated by: The erosion <strong>of</strong> fines from disturbed ground suchas open-cut workings, overburden dumps <strong>and</strong>spoil piles <strong>and</strong> waste disposal facilities;The release or leakage <strong>of</strong> brines;The weathering <strong>of</strong> overburden contaminants,which may then be leached.Large volumes <strong>of</strong> water are typically required by mining<strong>and</strong> beneficiation activities. This waterconsumption may lead to a fall in the level <strong>of</strong> the watertable, affecting the surrounding ecosystem <strong>and</strong> potentiallyresulting in competition with other users.The l<strong>and</strong> surface <strong>and</strong> sub-surface is disturbed by activitiessuch as: The extraction <strong>of</strong> ore; The deposition <strong>of</strong> overburden; The disposal <strong>of</strong> beneficiation wastes; The subsidence <strong>of</strong> the surface.These activities could result in wide range <strong>of</strong> potentialimpacts on the l<strong>and</strong>, geological structure, topsoil,aquifers <strong>and</strong> surface drainage systems. Additionally,the removal <strong>of</strong> vegetation may affect the hydrologicalcycle, wildlife habitat <strong>and</strong> biodiversity <strong>of</strong> the area. Insome instances, sites <strong>of</strong> archaeological, cultural orother significance may be affected.Social goods <strong>and</strong> intangible values such as communitylifestyles, l<strong>and</strong> values <strong>and</strong> the quality <strong>of</strong> theecosystem in the vicinity <strong>of</strong> the mine site could beaffected by factors such as: Modification <strong>of</strong> the l<strong>and</strong>scape; Noise <strong>and</strong> vibration from activities such as blasting<strong>and</strong> the operation <strong>of</strong> equipment; Changes in wildlife habitat.The major potentially adverse environmental effectscould occur during the different activities <strong>of</strong> the mininglife cycle in Figure 3.1.1. Generally the activities <strong>of</strong>most significance are construction, extraction, beneficiation<strong>and</strong> waste disposal. Associated activities mayhave an impact but these tend to be relatively lessimportant. Rehabilitation <strong>and</strong> closure can have someimpact, but these activities are carried out with theobjective <strong>of</strong> repairing any adverse effects that mayhave occurred during mining, to leave a safe <strong>and</strong> stablesite. Rehabilitation is more effective whenconducted progressively throughout the life <strong>of</strong> theoperation. Adopting a holistic approach to planning<strong>and</strong> environmental management, that encompassesthe entire life cycle, helps to prevent or mitigate environmenteffects from the outset, while fosteringstewardship <strong>of</strong> the ore resource <strong>and</strong> the l<strong>and</strong> underwhich it lies.The present chapter has been organized according tothe major activities associated with the mining lifecycle.Within each activity, the major environmentalissues are raised, followed by a general discussion <strong>of</strong>the environmental practices employed by industry.The discussion is illustrated by examples <strong>of</strong> good <strong>and</strong>innovative environmental practices identified duringthe project site visits. These demonstrate specificindustry responses.3.2 Mine Development: Exploration,Planning, Approval <strong>and</strong> ConstructionMine development consists <strong>of</strong> a sequence <strong>of</strong> activities: Prospecting <strong>and</strong> exploration work to locate <strong>and</strong>delineate the ore resource; Economic, environmental <strong>and</strong> technical feasibilityassessment <strong>of</strong> the orebody; Planning <strong>and</strong> design <strong>of</strong> the mine layout, site infrastructure<strong>and</strong> the mining sequence; Obtaining relevant government permits <strong>and</strong>approvals; Construction <strong>and</strong> commissioning <strong>of</strong> the operation.Most environmental impacts during this stage <strong>of</strong> themining life cycle are typically associated with exploration<strong>and</strong> construction. Effective planning,commencing at this stage <strong>and</strong> continuing throughoutthe life <strong>of</strong> the mine, has a great influence on minimizingthe impact <strong>of</strong> the operation.Figure 3.2.1Potential environmental effects : mine developmentExploration,assessment,planning <strong>and</strong>constructionL<strong>and</strong> surface disturbanceAir emissionsWater contaminationNoise <strong>and</strong> vibrationPlanning is important to avoid or reduce adverse environmentalimpacts over the life <strong>of</strong> the mine <strong>and</strong> afterclosure. Planning is most effective when the entire life<strong>of</strong> mine is encompassed. Defining the final objectives<strong>of</strong> mine closure from the outset allows an optimumbalance between operational, rehabilitation <strong>and</strong> closuregoals to be selected, thus minimizing the cost <strong>of</strong>these activities.

The <strong>Environmental</strong> Approach <strong>of</strong> the <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> Industry16Planning takes account <strong>of</strong> factors such as air <strong>and</strong> waterquality, l<strong>and</strong> surface disturbance, noise <strong>and</strong> vibration,surrounding <strong>and</strong> post-mining l<strong>and</strong> uses, wildlife <strong>and</strong>biodiversity <strong>and</strong> cultural <strong>and</strong> historic site locations.Valuable information for planning purposes is gatheredduring the preparation <strong>of</strong> environmental impactassessments (EIA) <strong>and</strong> permit applications. Thisallows sensitive aspects to be identified <strong>and</strong> potentialrisks evaluated. The knowledge developed creates astrong foundation for the development <strong>of</strong> later operationalmanagement systems, procedures, <strong>and</strong>practices.Repeated evaluation <strong>of</strong> different options addresses theenvironmental impacts, the changing regulatoryrequirements, community expectations, <strong>and</strong> engineering<strong>and</strong> cost limitations, while also allowing newtechnology to be more easily incorporated.ExplorationExploration activities have some environmentalimpacts. These are largely related to l<strong>and</strong> disturbancesfrom the clearing <strong>of</strong> vegetation, construction <strong>of</strong>camps, access roads, drilling sites <strong>and</strong> sumps fordrilling fluids <strong>and</strong> fines. Noise <strong>and</strong> vibration fromThe ‘Team Permitting Process’IMC <strong>Phosphate</strong> in central western Florida, (USA) hasapplied a "team permitting process" to theConsolidated Development Application (CDA) for theproposed Ona <strong>and</strong> Pine Level mines.The CDA covers the majority <strong>of</strong> permits required forapproval to mine phosphate in Florida. Permits typicallyfocus on the areas <strong>of</strong>: Water quality; Water supply; Wetl<strong>and</strong>s; Wildlife.Typically, several permits will be required for eacharea, encompassing a wide range <strong>of</strong> issues. Onceachieved, the permits apply to the life <strong>of</strong> the mine.The team permitting process speeds up the development<strong>and</strong> approval <strong>of</strong> the CDA through two majorinnovations. First, at the outset all stakeholders arebrought together. This allows major concerns to beidentified before the CDA starts. The issues can thenbe addressed efficiently, reducing the need for multipleiterations <strong>of</strong> the CDA.Second, the CDA undergoes concurrent review byboth the community <strong>and</strong> regulatory agencies. Thereview provides an opportunity for questions to beraised about the CDA. The company must addressthese sufficiently before approval is granted.As a trade-<strong>of</strong>f for benefiting from the acceleratedteam permitting process, the company must provideenvironmental benefits beyond those required for thest<strong>and</strong>ard permitting process. This results in a win-winsolution for the company <strong>and</strong> community. The companyobtains its mine permit approval faster, thecommunity has a greater sense <strong>of</strong> ownership throughearly involvement <strong>and</strong> input, <strong>and</strong> enjoys more environmentbenefits.Mine site - Foskor Ltd, South AfricaDragline avoids bird's nest - Cargill Fertilizers Inc., USAseismic surveys <strong>and</strong> drilling operations may also be <strong>of</strong>concern.Effective planning <strong>of</strong> the exploration activities reducespotential impacts by using existing infrastructurewhere possible, taking appropriate care during theconstruction <strong>of</strong> access tracks <strong>and</strong> containing anydrilling fluids <strong>and</strong> fines in sumps. On completion <strong>of</strong>exploration, rehabilitation <strong>of</strong> disturbed areas isenhanced by the capping or grouting <strong>of</strong> drill holes, thefilling <strong>of</strong> sumps, the ripping <strong>of</strong> compacted areas, <strong>and</strong>the replacement <strong>of</strong> removed topsoil <strong>and</strong> revegetation.Modern remote sensing exploration techniquesreduce the area disturbed by exploration activities.The use <strong>of</strong> gravity <strong>and</strong> geomagnetic surveys allowswide areas to be covered with little or no impact,

Extraction<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>reducing the need for more intrusive exploration techniques.ConstructionConstruction activities have significant potential tohave adverse environmental impacts. During thisphase, <strong>of</strong>ten a large transient workforce is employed,workforce numbers tend to peak <strong>and</strong> material <strong>and</strong>equipment movements tend to be large. Impacts aretypically related to l<strong>and</strong> disturbance caused by earthworks,air emissions from dust, noise from equipment<strong>and</strong> construction activities <strong>and</strong> heavy volumes <strong>of</strong> trafficon access roads.In many cases, specialized third party companies <strong>and</strong>consultants conduct mine construction activities.‘Turn key’ construction contracts are commonlyawarded. The ability <strong>of</strong> the mine site's owner to controlenvironmental impacts can be maintained tosome extent by considering potential issues <strong>and</strong>explicitly addressing them in the drafting <strong>of</strong> the tender<strong>and</strong> contract.3.3 ExtractionSurface mining methods, by nature, tend to affect awide area <strong>of</strong> l<strong>and</strong> <strong>and</strong> could result in a variety <strong>of</strong>effects such as: l<strong>and</strong> surface disturbance, contaminationor depletion <strong>of</strong> ground <strong>and</strong> surface water, <strong>and</strong> areduction in air quality. Currently, most phosphaterock <strong>and</strong> a small quantity <strong>of</strong> potash ore are sourcedusing surface mining.Figure 3.3.1Potential environmental effects : ore extractionOverburden removalor orebody accessOre extractionL<strong>and</strong> surface disturbanceWater contaminationWater table loweringAir emissionsTopsoil degradationVegetation <strong>and</strong> wildlifedisruptionNoise <strong>and</strong> vibrationmay become contaminated or deplete overlyingaquifers. Underground mining methods are used tosource potash ore from deeply buried marine evaporitepotash deposits. A lesser quantity <strong>of</strong> phosphaterock is sourced using underground methods.L<strong>and</strong> Surface DisturbanceExtraction activities disturb the l<strong>and</strong> surface throughclearing <strong>of</strong> vegetation, removal <strong>of</strong> topsoil, excavation<strong>of</strong> ore <strong>and</strong> overburden <strong>and</strong> the construction <strong>of</strong> overburdendumps or solar evaporation ponds.Removal <strong>and</strong> stockpiling <strong>of</strong> topsoil for subsequentrehabilitation is carried out at many mining operations.In a number <strong>of</strong> cases, topsoil is removed <strong>and</strong>placed directly on l<strong>and</strong>scaped reclaimed areas. Thisavoids the cost <strong>of</strong> re-transporting topsoil from stockpiles<strong>and</strong> the possible reduction <strong>of</strong> biodiversity.Moreover, close coordination <strong>and</strong> planning is requiredbetween the mining <strong>and</strong> rehabilitation operations toensure that areas are prepared in a timely manner. There-planting <strong>of</strong> small trees from areas to be mined <strong>and</strong>the placement <strong>of</strong> dead trees on rehabilitated areas hasbeen used to accelerate the establishment <strong>of</strong> vegetation<strong>and</strong> provide a wildlife habitat.Generally, overburden (4) is either dumped directlyinto the adjacent mined-out areas or placed in speciallydesigned overburden dumps. On closure, thismaterial is l<strong>and</strong>scaped, covered with a layer <strong>of</strong> topsoil<strong>and</strong> revegetated. These activities are discussed furtherin Section 3.7 “Rehabilitation”.The costs associated with transporting <strong>and</strong> l<strong>and</strong>scapingoverburden are minimized in many cases bydesigning <strong>and</strong> managing overburden dumping operationsso as to ensure that they are placed as close aspossible to the final desired location <strong>and</strong> to the finalshape. Bucketwheel excavator operations are particularlyflexible, allowing selective placement <strong>of</strong> theoverburden in the order <strong>of</strong> extraction <strong>and</strong> the creation<strong>of</strong> a flat final l<strong>and</strong>scape. This has advantages for laterrehabilitation.Underground mining methods tend to create fewerenvironmental problems, the major issue being possiblesurface subsidence. This is induced by the removal<strong>of</strong> extensive flat-lying ore deposits, followed by thesubsequent collapse <strong>of</strong> overlying rock. Some minorenvironmental effects may be associated with the disposal<strong>of</strong> rock removed to access the orebody. Also,ground water inflow into the underground openings(4) The term overburden is usually applied to the barrenmaterial (clay, s<strong>and</strong>, or rock) removed to expose the ore insurface mines. Underground mines produce a far more limitedvolume <strong>of</strong> barren waste rock during excavation <strong>of</strong> theaccess ways such as shafts <strong>and</strong> tunnels. Finally, processingoperations generally produce a number <strong>of</strong> solid wastes such assalt tailings, s<strong>and</strong>s, <strong>and</strong> clays. The term overburden will beapplied to all barren material stripped from the surface toallow the ore to be extracted.

The <strong>Environmental</strong> Approach <strong>of</strong> the <strong>Phosphate</strong> Rock <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong> IndustryOpen Cut BackfillingThe Rasmussen Ridge mine, located in mountainous terrainin southeast Idaho, is owned <strong>and</strong> operated byAgrium, Inc. Open pit mining methods are used toextract two closely spaced, steeply dipping ore bodiesusing shovel, front-end-loaders <strong>and</strong> trucks. The pit isaround 100 metres deep, <strong>and</strong> will ultimately be minedaround 3,000 metres along the strike <strong>of</strong> the orebody.The mine <strong>and</strong> reclamation plan sequences the pit, whichis to be mined to its final depth progressively along thestrike. Once a sufficient length <strong>of</strong> pit has been mined,backfilling with overburden removed from the activemining area is carried out. External overburden dumpsare thus only required during the initial stage.The backfilled pit is l<strong>and</strong>scaped to blend in with the naturalmountainous topography, re-establishing surfacedrainage patterns while minimizing the potential forerosion.Topsoil, generally from clearing in front <strong>of</strong> the pitface, is applied, followed by seed <strong>and</strong> fertilizer applicationto re-establish vegetation.This approach significantly reduces the area <strong>of</strong> l<strong>and</strong> disturbedby external overburden dumps, <strong>and</strong> reduces thevolume <strong>of</strong> pit left empty on completion <strong>of</strong> mining operations.This in turn prevents the formation <strong>of</strong>post-mining pit lakes <strong>and</strong> the safety risk <strong>of</strong> exposedsteep pit walls.An additional benefit is the isolation <strong>of</strong> selenium-contaminatedoverburden. Selective placement at thebottom <strong>of</strong> the pit prevents selenium leaching into surfacewaters, potentially causing toxicity in livestock <strong>and</strong>fauna downstream. The development <strong>of</strong> best managementpractices for selenium control is discussed furtherin Section 3.9 “ <strong>Environmental</strong> Management”.L<strong>and</strong>scaped pits with snow, Conda, USA - Agrium Inc., USA18Open pit mining, Conda, USA - Agrium Inc., USAL<strong>and</strong>scaped overburden dump with transplanted trees indistance, Conda, USA - Agrium Inc., USAThe wide area <strong>of</strong> l<strong>and</strong> surface disturbed by surfacemining operations could require relocation <strong>and</strong> compensation<strong>of</strong> people living above the orebody.In some instances, surface subsidence induced byunderground mining may alter river <strong>and</strong> streamdrainage patterns, disrupt overlying aquifers, <strong>and</strong>damage buildings <strong>and</strong> infrastructure. The degree <strong>of</strong>subsidence depends on factors such as orebody thickness<strong>and</strong> geometry, the thickness <strong>of</strong> the overlying rock<strong>and</strong> the amount <strong>of</strong> ore recovered. The effects <strong>of</strong> subsidencehave been reduced to some extent, througheither:The design <strong>of</strong> the ore extraction layout so as toreduce the rate <strong>and</strong> extent <strong>of</strong> subsidence, orBy backfilling openings with processing wastessuch as salt tailings, to reduce or prevent subsidence.Where subsidence occurs, there is potential for damageto overlying buildings or infrastructure. To avoidsafety risks <strong>and</strong> property damage, close coordination<strong>and</strong> communication is required between the company<strong>and</strong> relevant government bodies, other companies <strong>and</strong>communities. This needs to be supported by a welldefinedsystem for reporting <strong>and</strong> repairing damage, or

<strong>Environmental</strong> <strong>Aspects</strong> <strong>of</strong> <strong>Phosphate</strong> <strong>and</strong> <strong>Potash</strong> <strong>Mining</strong>L<strong>and</strong> RentalThe phosphate rock orebody in Togo being extractedby the Office Togolais des <strong>Phosphate</strong>s (OTP) is locatednear the coast in an area <strong>of</strong> intensive small-scale farming.Surface mining methods are used to remove theoverburden <strong>and</strong> extract the phosphate rock ore. Thisrequires the progressive relocation <strong>of</strong> farmers <strong>and</strong> villagecommunities as mining occurs. In compensation,the company pays farmers a rental for the l<strong>and</strong> disturbedduring the mining process. New villages areconstructed in advance outside the mining area, to rehousedisplaced villagers. The l<strong>and</strong> rental continuesuntil rehabilitation is completed <strong>and</strong> the l<strong>and</strong> is onceagain suitable for farming.for providing compensation to avoid conflict.Solarevaporation ponds used to extract potash from surfacebrine deposits usually cover a wide area <strong>of</strong> l<strong>and</strong>,with operations in the region <strong>of</strong> 90 square kilometres.The precipitation <strong>and</strong> build up <strong>of</strong> salt in the pondsover time presents an issue.Water ConsumptionIn some locations, water consumption during extractionactivities may lead to a lowering <strong>of</strong> the surroundingwater table.Water inflow is a common problem where open pits<strong>and</strong> underground openings intersect aquifers.Generally, water is pumped from the excavations orfrom nearby wells to maintain a dry, safe <strong>and</strong> efficientoperating environment for the equipment. This maypotentially lead to the lowering <strong>of</strong> the surroundingwater table <strong>and</strong> the depletion <strong>of</strong> nearby surface waterbodies. In some locations, measures have been takento confine the area affected by water table depression<strong>and</strong> protect the surrounding ecosystem.Ecosystem Protection Through the Use <strong>of</strong>Perimeter DitchesThe elevated water table is a prominent feature <strong>of</strong> theFlorida ecosystem. Frequent surface appearance <strong>of</strong>the aquifer has produced a patchwork <strong>of</strong> wetl<strong>and</strong>s,streams, rivers <strong>and</strong> lakes.This presents an issue for theefficient extraction <strong>of</strong> the phosphate rock deposit bydraglines. If the opencast pit contains water, draglineoperators have difficulty identifying the boundarybetween the ore <strong>and</strong> overburden, potentially resultingin the loss <strong>of</strong> ore or dilution by barren rock. Tomaintain dry excavations <strong>and</strong> an efficient operatingenvironment, the water table may be depressed to alevel below the ore by pumping from wells or sumps.However, this may lead to negative effects on the surroundingwater-sensitive ecosystem. To overcomethis, companies such as IMC <strong>Phosphate</strong> <strong>and</strong> CargillFertilizers Inc have implemented protection systems,using a perimeter ditch to confine the impact on thewater table to the immediate mining area.Before pumping commences, a perimeter ditch isexcavated around the mining area to a depth belowthe water table. The ditch is filled with water that ismaintained at a level consistent with the originalwater table, using a series <strong>of</strong> weirs <strong>and</strong> pumps. Whenthe water table is depressed by mining activities,recharge occurs from water in the ditch.Performance <strong>of</strong> the system is monitored by both dailyvisual inspection <strong>of</strong> the ditches <strong>and</strong> by weekly measurements<strong>of</strong> the water table, through a series <strong>of</strong>piezometers located outside the perimeter ditch.The effectiveness <strong>of</strong> the method has been improvedby reshaping the overburden immediately adjacent tothe perimeter ditch as soon as possible on completion<strong>of</strong> mining. This allows the water table to partiallyreestablish itself inside the perimeter ditch.The application <strong>of</strong> this approach protects the surroundingwater-sensitive ecosystem by confining thedepression <strong>of</strong> the water table to the area delineatedby the ditch.Waste water produced during the extraction stage canbe used for downstream processing operations, reducingthe dem<strong>and</strong> on other sources. In some places,water <strong>of</strong> suitable quality has been used for the irrigation<strong>of</strong> local farming operations. This is <strong>of</strong> greaterimportance in arid climates where water resources arelimited.Water ContaminationExcavation activities may contaminate surface waterthrough the release <strong>of</strong> fines generated during clearing,blasting <strong>and</strong> excavation operations, the weathering <strong>of</strong>overburden contaminants susceptible to leaching <strong>and</strong>the release <strong>of</strong> salt from brines <strong>and</strong> potash ore.Perimeter ditch - IMC <strong>Phosphate</strong>, USA