enerka-becker conveyors - Bateman Engineered Technologies

enerka-becker conveyors - Bateman Engineered Technologies

enerka-becker conveyors - Bateman Engineered Technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ENERKA-BECKER<br />

CONVEYORS<br />

www.batemanengineering.com/bet<br />

Conveying<br />

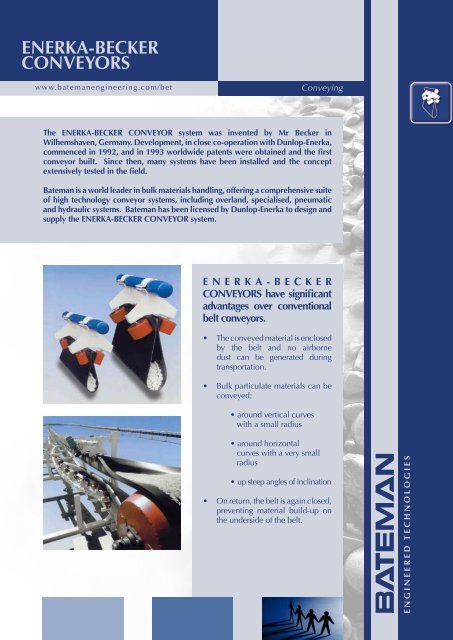

The ENERKA-BECKER CONVEYOR system was invented by Mr Becker in<br />

Wilhemshaven, Germany. Development, in close co-operation with Dunlop-Enerka,<br />

commenced in 1992, and in 1993 worldwide patents were obtained and the first<br />

conveyor built. Since then, many systems have been installed and the concept<br />

extensively tested in the field.<br />

<strong>Bateman</strong> is a world leader in bulk materials handling, offering a comprehensive suite<br />

of high technology conveyor systems, including overland, specialised, pneumatic<br />

and hydraulic systems. <strong>Bateman</strong> has been licensed by Dunlop-Enerka to design and<br />

supply the ENERKA-BECKER CONVEYOR system.<br />

E N E R K A - B E C K E R<br />

CONVEYORS have significant<br />

advantages over conventional<br />

belt <strong>conveyors</strong>.<br />

•<br />

•<br />

•<br />

The conveyed material is enclosed<br />

by the belt and no airborne<br />

dust can be generated during<br />

transportation.<br />

Bulk particulate materials can be<br />

conveyed:<br />

• around vertical curves<br />

with a small radius<br />

• around horizontal<br />

curves with a very small<br />

radius<br />

• up steep angles of inclination<br />

On return, the belt is again closed,<br />

preventing material build-up on<br />

the underside of the belt.

ENERKA-BECKER CONVEYORS<br />

Features:<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

The multipoint drive system<br />

permits the use of tension<br />

members with one rating for<br />

all possible conveyor layouts,<br />

irrespective of capacity or belt<br />

width.<br />

A uniform belt strength for each<br />

belt width and a standard belt<br />

supply facilitates stock-keeping.<br />

The simple conveyor layout and<br />

few moving parts result in low<br />

maintenance costs.<br />

Belt splicing is easy and can be<br />

performed by personnel qualified<br />

to splice normal textile belting.<br />

The low belt tension requires<br />

only simple support and minimal<br />

foundations – reducing capital<br />

cost.<br />

The belt width and speed combine<br />

to produce high conveying<br />

capacities.<br />

The conveyor belt with its edging<br />

of solid rubber triangles consists<br />

effectively of one homogenous<br />

piece of rubber – ensuring<br />

durability.<br />

Specifications<br />

Belt sizes:<br />

Type Width<br />

Enerka 3080 800<br />

Enerka 3140 1400<br />

Belt Cover Qualities<br />

Conveying<br />

Various cover qualities are available:<br />

• Abrasion-resistant.<br />

• Oil and grease-resistant.<br />

• Heat-resistant, up to 80°C