- Page 3 and 4: TABLE OF CONTENTS Preface..........

- Page 5 and 6: Appendix 3 - Airflow in the Real Wo

- Page 7 and 8: This report was prepared by Pacific

- Page 9: � Energy savings estimates for de

- Page 14 and 15: HVAC ELECTRICITY SAVINGS ARE ESTIMA

- Page 16 and 17: F IGURE 3: O VERVIEW OF G UIDELINE

- Page 18 and 19: X8X fans for typical large VAV appl

- Page 20 and 21: … PRODUCING A PRODUCT THAT WORKS

- Page 22 and 23: … SLIGHTLY MORE THAN 20% OF ALL C

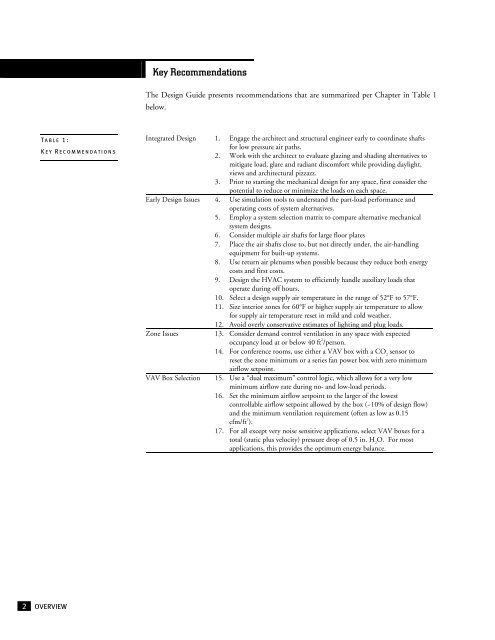

- Page 24 and 25: X14X INTRODUCTION EARLY DESIGN ISSU

- Page 26 and 27: T ABLE 3: HVAC AND A RCHITECTURAL C

- Page 28 and 29: X18X INTRODUCTION 1. Tool Expense:

- Page 30 and 31: F IGURE 5: T HE R OLE OF S IMULATIO

- Page 32 and 33: A SYSTEM SELECTION MATRIX CAN ACCOM

- Page 34 and 35: X24X INTRODUCTION of these two syst

- Page 36 and 37: Performance Attribute Floor Space R

- Page 38 and 39: X28X INTRODUCTION Location and Size

- Page 40 and 41: F IGURE 9: T YPICAL D UCT R ISER X3

- Page 42 and 43: X32X INTRODUCTION However, there ar

- Page 44 and 45: X34X INTRODUCTION coil cost and air

- Page 46 and 47: T ABLE 6: M INIMUM V ENTILATION R A

- Page 48 and 49: X38X INTRODUCTION significant time

- Page 50 and 51: F IGURE 10: M EASURED L IGHTING S C

- Page 52 and 53: X42X INTRODUCTION Monitored Lightin

- Page 54 and 55: T ABLE 8: E QUIPMENT P OWER D ENSIT

- Page 56 and 57: X46X INTRODUCTION Monitored Plug Lo

- Page 58 and 59: X48X INTRODUCTION Performance Targe

- Page 60 and 61: X50X ZONE ISSUES ZONE ISSUES This s

- Page 62 and 63:

X52X ZONE ISSUES Zoning and Thermos

- Page 64 and 65:

X54X ZONE ISSUES The 2005 Title 24

- Page 66 and 67:

X56X ZONE ISSUES � DCV Using Crit

- Page 68 and 69:

X58X ZONE ISSUES A good article on

- Page 70 and 71:

X60X VAV BOX SELECTION VAV BOX SELE

- Page 72 and 73:

F IGURE 21: VAV H OT W ATER R EHEAT

- Page 74 and 75:

X64X VAV BOX SELECTION � By reduc

- Page 76 and 77:

F IGURE 24: D UAL M AXIMUM WITH VAV

- Page 78 and 79:

X68X VAV BOX SELECTION 1. The minim

- Page 80 and 81:

X70X VAV BOX SELECTION Air Change E

- Page 82 and 83:

X72X VAV BOX SELECTION higher) A/D

- Page 84 and 85:

T ABLE 13: S AMPLE C ALCULATION OF

- Page 86 and 87:

X76X VAV BOX SELECTION Design Maxim

- Page 88 and 89:

T ABLE 14: VAV B OX M AXIMUM A IRFL

- Page 90 and 91:

F IGURE 28: S ITE 3 VAV B OX D EMAN

- Page 92 and 93:

F IGURE 30: D UAL D UCT - F ROM H E

- Page 94 and 95:

T ABLE 16: C OMPARISON OF D UAL- D

- Page 96 and 97:

X86X VAV BOX SELECTION sufficient f

- Page 98 and 99:

X88X VAV BOX SELECTION Other Issues

- Page 100 and 101:

X90X VAV BOX SELECTION 4. DDC zone

- Page 102 and 103:

X92X VAV BOX SELECTION to most owne

- Page 104 and 105:

X94X DUCT DESIGN 2. Use standard le

- Page 106 and 107:

F IGURE 34: P RESSURE D ROP T HROUG

- Page 108 and 109:

F IGURE 36: P RESSURE D ROP T HROUG

- Page 110 and 111:

X100X DUCT DESIGN indicator since n

- Page 112 and 113:

X102X DUCT DESIGN Design Friction R

- Page 114 and 115:

X104X DUCT DESIGN Return Air System

- Page 116 and 117:

F IGURE 38: P OOR D ISCHARGE C ONFI

- Page 118 and 119:

X108X DUCT DESIGN But for sound att

- Page 120 and 121:

X110X SUPPLY AIR TEMPERATURE CONTRO

- Page 122 and 123:

F IGURE 41: C OMPARISON OF M ILD D

- Page 124 and 125:

X114X SUPPLY AIR TEMPERATURE CONTRO

- Page 126 and 127:

X116X FAN TYPE, SIZE AND CONTROL Re

- Page 128 and 129:

T ABLE 20: C OMPARISON OF C OMMON V

- Page 130 and 131:

F IGURE 43: A T YPICAL M ANUFACTURE

- Page 132 and 133:

F IGURE 46: G AMMA C URVE F IGURE 4

- Page 134 and 135:

F IGURE 50: G AMMA C URVES FOR A LL

- Page 136 and 137:

F IGURE 54: F AN B ELT E FFICIENCY

- Page 138 and 139:

F IGURE 56: C ASE S TUDY A - S ELEC

- Page 140 and 141:

F IGURE 60: C ASE S TUDY A - 60 IN.

- Page 142 and 143:

F IGURE 63: C ASE S TUDY A - P ART

- Page 144 and 145:

F IGURE 67: C ASE S TUDY A - L OAD

- Page 146 and 147:

F IGURE 70: C ASE S TUDY A - C ARRI

- Page 148 and 149:

Discharge Sound Power Manuf. Unit C

- Page 150 and 151:

F IGURE 73: C ASE S TUDY B - S ELEC

- Page 152 and 153:

F IGURE 77: C ASE S TUDY B - H ISTO

- Page 154 and 155:

F IGURE 80: C ASE S TUDY B S IMULAT

- Page 156 and 157:

F IGURE 82: V ELOCITY P ROFILE O FF

- Page 158 and 159:

X148X FAN TYPE, SIZE AND CONTROL re

- Page 160 and 161:

X150X FAN TYPE, SIZE AND CONTROL pr

- Page 162 and 163:

X152X FAN TYPE, SIZE AND CONTROL ex

- Page 164 and 165:

F IGURE 87: G RAPHICS S CREEN S HOW

- Page 166 and 167:

F IGURE 89: S AMPLE S UPPLY A IR T

- Page 168 and 169:

F IGURE 91: O PTIMAL S TAGING (PERF

- Page 170 and 171:

F IGURE 95: "PARALLELING" - H IGH F

- Page 172 and 173:

X162X FAN TYPE, SIZE AND CONTROL Fa

- Page 174 and 175:

X164X COILS AND FILTERS Filter Area

- Page 176 and 177:

Site Coil Dimensions AIR SIDE Capac

- Page 178 and 179:

X168X OUTSIDE AIR/RETURN AIR/EXHAUS

- Page 180 and 181:

X170X OUTSIDE AIR/RETURN AIR/EXHAUS

- Page 182 and 183:

F IGURE 99: R ETURN F AN T RACKING

- Page 184 and 185:

F IGURE 101: I NJECTION F AN WITH D

- Page 186 and 187:

Isolation Zones X176X OUTSIDE AIR/R

- Page 188 and 189:

F IGURE 103: A IRSIDE E CONOMIZER C

- Page 190 and 191:

X180X OUTSIDE AIR/RETURN AIR/EXHAUS

- Page 192 and 193:

T ABLE 24: H IGH L IMIT S WITCH R E

- Page 194 and 195:

T ABLE 25: S UMMARY OF M ONITORING

- Page 196 and 197:

F IGURE 109: S ITE 1, M ONITORED HV

- Page 198 and 199:

X188X APPENDIX 1 - MONITORING SITES

- Page 200 and 201:

X190X APPENDIX 1 - MONITORING SITES

- Page 202 and 203:

T ABLE 26: O FFICE B UILDING E NERG

- Page 204 and 205:

F IGURE 116: P EAK D AY E LECTRIC D

- Page 206 and 207:

X196X APPENDIX 3 - AIRFLOW IN THE R

- Page 208 and 209:

F IGURE 121: S ITE 4, S AMPLE OF I

- Page 210 and 211:

F IGURE 124: S ITE 4, S AMPLE OF P

- Page 212 and 213:

F IGURE 127: T OTAL S YSTEM A IRFLO

- Page 214 and 215:

F IGURE 130: S ITE 2 (LIGHT BAR INC

- Page 216 and 217:

F IGURE 134: S AMPLE P ART L OAD P

- Page 218 and 219:

F IGURE 136: P ART L OAD P ERFORMAN

- Page 220 and 221:

X210X APPENDIX 5 - DOE-2 FAN CURVES

- Page 222 and 223:

X212X APPENDIX 6 - SIMULATION MODEL

- Page 224 and 225:

System Properties X214X APPENDIX 6

- Page 226 and 227:

F IGURE 140: F AN P ERFORMANCE C UR

- Page 228 and 229:

T ABLE 30: S UPPLY A IR T EMPERATUR

- Page 230 and 231:

APPENDIX 7 - VAV BOX MINIMUM AND MA

- Page 232 and 233:

F IGURE 145: E QUEST I NPUTS FOR M

- Page 234 and 235:

X224X APPENDIX 8 - HOW TO MODEL DIF

- Page 236 and 237:

F IGURE 149: D UAL M AXIMUM WITH VA

- Page 238 and 239:

F IGURE 151: E Q UEST I NPUT TO E N

- Page 240 and 241:

F IGURE 153: H ISTOGRAM OF D AMPER

- Page 242 and 243:

F IGURE 156: D UAL M AXIMUM WITH CV

- Page 244 and 245:

F IGURE 158: S IMULATED D UAL M AXI

- Page 246 and 247:

F IGURE 160: S AMPLE SV-A R EPORT F

- Page 248 and 249:

F IGURE 162: A NNUAL U TILITY C OST

- Page 250 and 251:

F IGURE 166: O CCUPANCY S CHEDULE a

- Page 252 and 253:

T ABLE 31: B ASECASE M ODELING A SS

- Page 254 and 255:

F IGURE 168: VAV F LOW R ATIO AND H

- Page 256 and 257:

F IGURE 171: F AN F LOW H ISTOGRAM

- Page 258 and 259:

T ABLE 33: P ARAMETRIC R UNS X248X

- Page 260 and 261:

F IGURE 173: Z ONE A IR F LOW C ONT

- Page 262 and 263:

X252X APPENDIX 10: HOW TO MODEL DCV

- Page 264 and 265:

F IGURE 178: A IR F LOW T AB FOR T

- Page 266 and 267:

F IGURE 181: E Q UEST S YSTEM L EVE

- Page 268 and 269:

F IGURE 183: Z ONE O UTSIDE A IR T

- Page 270 and 271:

F IGURE 185: Z ONE H OURLY R EPORT

- Page 272 and 273:

APPENDIX 11: ANALYSIS OF DCV IN DEN

- Page 274 and 275:

F IGURE 190: O CCUPANCY S CHEDULES

- Page 276 and 277:

F IGURE 195: C OMPARISON OF A IRFLO

- Page 278 and 279:

F IGURE 197: F AN S YSTEM C OMPONEN

- Page 280 and 281:

F IGURE 198: T UNING D ATA FOR 660

- Page 282 and 283:

F IGURE 199: T UNING D ATA FOR C HA

- Page 284 and 285:

F IGURE 201: F AN E FFICIENCY AS A

- Page 286 and 287:

F IGURE 203: C OOK 660 CPL-A P LENU

- Page 288 and 289:

F IGURE 205: E XTRAPOLATION OF F AN

- Page 290 and 291:

F IGURE 207: H OUSED A IRFOIL F ANS

- Page 292 and 293:

F IGURE 211: G AMMA AT P EAK VS. D

- Page 294 and 295:

F IGURE 213: E XAMPLE M OTOR E FFIC

- Page 296 and 297:

F IGURE 215: C OMBINED M OTOR AND D

- Page 298 and 299:

X288X APPENDIX 12: FAN SYSTEMS Fan

- Page 300 and 301:

X290X APPENDIX 12: FAN SYSTEMS Saft

- Page 302 and 303:

F IGURE 219: A DAPTER P HOTO COURTE

- Page 304 and 305:

T ABLE 38: S UPPLY A IR T EMPERATUR

- Page 306 and 307:

F IGURE 223: S UPPLY A IR T EMPERAT

- Page 308 and 309:

F IGURE 225: S UPPLY A IR T EMPERAT

- Page 310 and 311:

F IGURE 226: S UMMARY OF S TATIC P

- Page 312 and 313:

F IGURE 229: S TATIC P RESSURE R ES

- Page 314 and 315:

X304X APPENDIX 14 - ZONE DEMAND BAS

- Page 316 and 317:

F IGURE 232: P RESSURE AND T EMPERA

- Page 318 and 319:

T ABLE 41: D EMAND C ONTROLLED V EN

- Page 320 and 321:

X310X APPENDIX 15 - REFERENCES APPE

- Page 322 and 323:

X312X APPENDIX 15 - REFERENCES Yu-P

- Page 324 and 325:

X314X APPENDIX 15 - REFERENCES Filt

- Page 326:

X316X APPENDIX 15 - REFERENCES Sche