Magnus VLF Quantum Platesetter - Kodak

Magnus VLF Quantum Platesetter - Kodak

Magnus VLF Quantum Platesetter - Kodak

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Magnus</strong> <strong>VLF</strong><strong>Quantum</strong> <strong>Platesetter</strong>

Productivity, reliability, andstability in <strong>VLF</strong> thermal imagingFast imagingYou can get to press more quickly withthe <strong>Magnus</strong> <strong>VLF</strong> <strong>Quantum</strong> <strong>Platesetter</strong>,which is one of the fastest fully automated<strong>VLF</strong> platesetters on the market. TheX-speed configuration enables imaging ofup to 28.2 plates per hour (2,070 mm /81.5 in.), or 48 plates per hour (1,030 mm/ 40.5 in.) at 2400 dpi. You can achieveeven faster speeds with the AutomaticPallet Loader—52.6 plates per hour(1,030 mm).Multiple automation optionsfor productivity gainsIncreasing the amount of time yourplatesetter runs unattended can providebig gains in efficiency and productivityin prepress. Less time is wasted loadingplates, the platesetter is not idle awaitingattention, and operators can concentrateon other tasks. The ContinuousLoadoption for the <strong>Magnus</strong> <strong>VLF</strong> <strong>Platesetter</strong>allows two-plate queuing and automaticplate eject to an online processor. TheMulti-Cassette Unit (MCU) optionallows the <strong>Magnus</strong> <strong>VLF</strong> <strong>Platesetter</strong> tooperate with four cassettes of up to 75plates per cassette with automatic slipsheet removal. You are able to operatecontinuously for longer, and the chancefor errors due to manual plate loadingis reduced.The Automatic Pallet Loader (APL)option enables easy and efficient bulkloading. Simply load between one and sixpallets with up to 600 plates each, andthe APL does the rest. It automaticallyselects the correct size plate based onthe job, removes slip sheets, and loadsthe plates with no operator intervention.The result is faster plate loading, reducedmanual handling, and extremely longunattended operation.Further productivity gains can beachieved with the dual-plate option,allowing you to load two platesconcurrently, and the Side-EdgeRegistration option, which enables platesimaged in portrait orientation to beregistered to the long edge.Integrated punchenhances automationThe <strong>Magnus</strong> <strong>VLF</strong> <strong>Platesetter</strong> featuresa fully integrated punch option withaccurate three-point registration, helpingeliminate costly errors. The punch optionis available with ContinuousLoad, MCU,or APL automation options, and is fullyconfigurable to match a wide variety ofpress requirements.The inline punch automatically correctsfor temperature-related plate expansiondifference between platesetters forprecise registration of plates.Choose your preferred sizeand speedThe <strong>Magnus</strong> <strong>VLF</strong> <strong>Platesetter</strong> is availablein four sizes. The largest can image platesup to 1,600 x 2,083 mm (63 x 82 in.), andthe smallest can image plates up to 1,168x 1,804 mm (46 x 71 in.). Speed optionsallow you to choose the number of platesper hour your device will produce.Large drum, small footprintWith its large drum size, the <strong>Magnus</strong><strong>VLF</strong> <strong>Platesetter</strong> is capable of imaginglarger plates for new <strong>VLF</strong> presses. Thedevice uses floor space efficiently withits linear design, including an enclosurethat integrates head cooling and debriscollection within the machine.

squarespot ImagingTechnologyThe <strong>Magnus</strong> <strong>VLF</strong> <strong>Quantum</strong> <strong>Platesetter</strong>features advanced <strong>Kodak</strong> squarespotImaging Technology for exceptionalstability in imaging. squarespotTechnology improves press utilization bydelivering plates with excellent accuracyand repeatability, and notably better tonalconsistency throughout the developerlife cycle, reducing waste and improvingmakeready. You can keep your largeformatpress operating steadily, makingroom for shorter run lengths and greatercustomization. squarespot Technologyalso helps you maintain end-to-end dataintegrity, from the original file throughto the press, even as process conditionsfluctuate. The high-resolution laser helpsensure that the resulting dots on plate areconsistent and repeatable from plate toplate, platesetter to platesetter, and day today. Plates made on different platesettersusing squarespotTechnology will match infit, quality, and register.Temperature compensationsystem enhances accuracyTo improve fit and register on press,a unique temperature compensationsystem adjusts for changes in ambienttemperature and corrects for plateexpansion and contraction. This systemalso reduces the number of wasted plates.High-fidelity StaccatoScreening includedsquarespot Technology, combined with 10or 20-micron <strong>Kodak</strong> Staccato Screening,allows you to produce photorealisticprints to distinguish your business.Bundled with <strong>Magnus</strong> <strong>VLF</strong> <strong>Quantum</strong><strong>Platesetter</strong>s, Staccato Screeningproduces high-fidelity, artifact-freeimages that exhibit fine detail withouthalftone rosettes, screening moiré,gray level limitations, abrupt jumps intone, or impact on RIPing or renderingtime. Staccato Screening brings tonaland color stability to the pressroom byreducing variations in dot gain and colorcontamination from paper.Renowned worldwideservice and support from<strong>Kodak</strong><strong>Kodak</strong> Service and Support offers anetwork of global response centers,an easy-to-use Internet supportportal, and over 3,000 geographicallydispersed, factory trainedprofessionals.<strong>Kodak</strong> Service Wire remote supportallows our response center to directlyinteract with your <strong>Kodak</strong> <strong>Platesetter</strong>,saving you time and helping ensuremaximum uptime. With our flexibleservice programs, you can optimizeyour operations by taking advantageof our fast response times, preventivemaintenance services, extensive partsinventory, and comprehensive globalcoverage.Complete solutionfrom <strong>Kodak</strong><strong>Kodak</strong> is the one vendor that canoffer you a complete and truly unifiedsolution, including CTP device, plates,plateline equipment, and workflow.With over 15,000 thermal CTPinstallations, plate manufacturingplants located throughout the world,and a highly skilled and responsivesupport network, <strong>Kodak</strong> is an idealpartner for your <strong>VLF</strong> plate makingneeds.<strong>Magnus</strong> <strong>VLF</strong> <strong>Platesetter</strong>

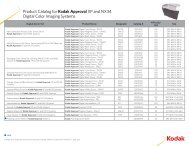

<strong>Magnus</strong> <strong>VLF</strong> <strong>Quantum</strong> <strong>Platesetter</strong>Automation options• Semi-automatic: Utilizing static load/unload tables, plates are electronically 3-point registered to the imaging engine.• ContinuousLoad: While one plate is being imaged, the second plate is placed in standby and loads automatically afterthe plate on the drum unloads to an online processor.• Multi-Cassette Unit: Holds up to 300 plates in four cassettes, each with up to 75 plates with slip sheets. The requiredcassette is automatically selected according to the job definition. Empty cassettes can be reloaded while theplatesetter is running.• Automatic Pallet Loader: Loads plates directly from shipping pallets into the <strong>Magnus</strong> <strong>VLF</strong> <strong>Platesetter</strong>. Capable ofholding between one and six pallets of up to 600 plates each for very high capacity and no operator handling of plates.Performance for <strong>Kodak</strong> Thermal Gold Digital Plates and <strong>Kodak</strong> DITP Gold Thermal PlatesModel number 4570/5570 5183/63831030 mm (40.5 in.) platesS-speedF-speedV-speedX-speed with CL/MCUX-speed with APL1524 mm (60 in.) platesS-speedF-speedV-speedX-speed2070 mm (81.5 in.) platesS-speedF-speedV-speedX-speedRepeatabilityAccuracyRegistrationImaging specificationsResolutionMedia Specificationspph = plates per hour12.5 pph20.5 pph25.8 pph39.9 pph39.9 pph9.1 pph15.6 pph20.4 pph33.2 pph7.0 pph12.4 pph16.6 pph28.2 pph13.7 pph (dual plate)23.8 pph (dual plate)31.3 pph (dual plate)48.0 pph (dual plate)52.6 pph (dual plate)15 microns (0.6 mil.) between two plates imaged by the same device (at largest plate size and over fulltemperature range)35 microns (1.4 mil.) between two plates imaged by the same device (at largest plate size and over fulltemperature range)25 microns (1.0 mil.) between image (near registration points) and registration points (for all plate sizes over the fullrange of temperature)<strong>Magnus</strong> <strong>VLF</strong> <strong>Quantum</strong> <strong>Platesetter</strong>: squarespot Imaging Technology, 17.7 lines/mm (450 lines/in.) maximumresolution and optional 20- or 10-micron <strong>Kodak</strong> Staccato ScreeningS-speed: 96 dpmm (2,400 dpi) or 100 dpmm (2,540 dpi)F-speed: 96 dpmm (2,400 dpi) or 100 dpmm (2,540 dpi)V-speed: 47.2 dpmm (1,200 dpi), 96 dpmm (2,400 dpi) or 100 dpmm (2,540 dpi)X-speed: 96 dpmm (2,400 dpi)Model number 4570 5183 5570 6383Media typePlate sizesminimum to maximum,around drum x along drum(Minimum plate size for APL is483 x 584 mm/19 x 23 in. in eitherportrait or landscape)Plate thickness830 nm thermal IR-sensitive aluminum plate483 x 394 mm(19 x 15.5 in) to1,168 x 1,804 mm(46 x 71 in.)483 x 394 mm(19 x 15.5 in) to1,296 x 2,083 mm(51 x 82 in.)483 x 394 mm(19 x 15.5 in) to1,422 x 1,804 mm(56 x 71 in.)Semi-automatic: 0.15 - 0.4 mm (0.006 - 0.016 in.)ContinuousLoad / Multi-Cassette Unit / Automatic Pallet Loader: 0.2 - 0.4 mm (0.008 - 0.016 in.)483 x 394 mm(19 x 15.5 in) to1,600 x 2,083 mm(63 x 82 in.)To learn more about solutions from <strong>Kodak</strong>:Visit graphics.kodak.comOr in North America, call +1-866-563-2533Produced using <strong>Kodak</strong> Technologies.Eastman <strong>Kodak</strong> Company343 State StreetRochester, NY 14650 USA©<strong>Kodak</strong>, 2012. <strong>Kodak</strong>, <strong>Magnus</strong>, <strong>Quantum</strong>, squarespot, Staccato, andThermal Gold, are trademarks of <strong>Kodak</strong>.Subject to technical change without notice.W.PS.107.0312.en.02 (K-231)*10-micron Staccato screening capability is media dependentThe platesetter is a Class 1 Laser Product and fully complies withEN60825-1 and US Federal Regulations 21 CFR 1040.10 - CDRH.