202767 ASSET SALES - Hilco Industrial

202767 ASSET SALES - Hilco Industrial

202767 ASSET SALES - Hilco Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HILCAST<br />

WEBCAST<br />

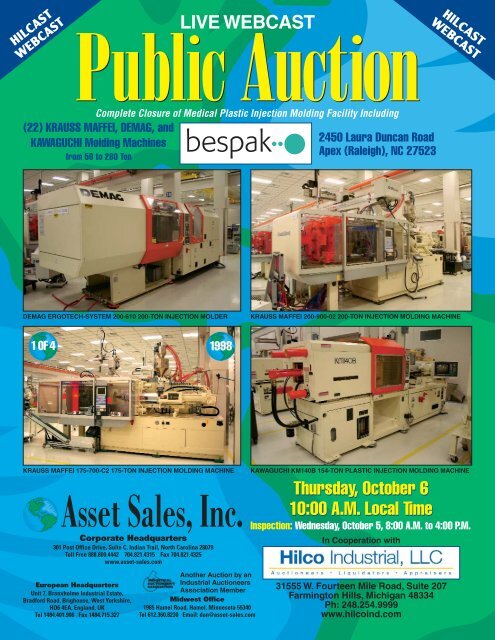

Public Auction<br />

(22) KRAUSS MAFFEI, DEMAG, and<br />

KAWAGUCHI Molding Machines<br />

from 50 to 280 Ton<br />

Asset Sales, Inc.<br />

Corporate Headquarters<br />

301 Post Office Drive, Suite C, Indian Trail, North Carolina 28079<br />

Toll Free 888.800.4442 704.821.4315 Fax 704.821.4325<br />

www.asset-sales.com<br />

European Headquarters<br />

Unit 7, Branxholme <strong>Industrial</strong> Estate,<br />

Bradford Road, Brighouse, West Yorkshire,<br />

HD6 4EA, England, UK<br />

Tel 1484.401.906 Fax 1484.715.327<br />

Another Auction by an<br />

<strong>Industrial</strong> Auctioneers<br />

Association Member<br />

Midwest Office<br />

1985 Hamel Road, Hamel, Minnesota 55340<br />

Tel 612.360.8230 Email: dan@asset-sales.com<br />

1998 COVER NEEDS TO<br />

BE FINISHED<br />

Thursday, October 6<br />

10:00 A.M. Local Time<br />

HILCAST<br />

WEBCAST<br />

DEMAG ERGOTECH-SYSTEM 200-610 200-TON INJECTION MOLDER KRAUSS MAFFEI 200-900-02 200-TON INJECTION MOLDING MACHINE<br />

1OF4<br />

KRAUSS MAFFEI 175-700-C2 175-TON INJECTION MOLDING MACHINE<br />

LIVE WEBCAST<br />

Complete Closure of Medical Plastic Injection Molding Facility Including<br />

2450 Laura Duncan Road<br />

Apex (Raleigh), NC 27523<br />

KAWAGUCHI KM140B 154-TON PLASTIC INJECTION MOLDING MACHINE<br />

Inspection: Wednesday, October 5, 8:00 A.M. to 4:00 P.M.<br />

In Cooperation with<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph: 248.254.9999<br />

www.hilcoind.com

Thursday, October 6 at 10:00 A.M. Local Time<br />

KRAUSS MAFFEI 200-900-02 200-TON INJECTION MOLDING MACHINE<br />

DEMAG ERGOTECH-SYSTEM 200-610 200-TON INJECTION MOLDING MACHINE<br />

2<br />

PLASTIC<br />

INJECTION<br />

MOLDING<br />

MACHINES<br />

KAWAGUCHI 280-Ton Horizontal<br />

Plastic Injection Molding<br />

Machine, serial number P1-<br />

RZ1007 (1991), Toggle Clamp,<br />

Platen Size 35"H x 35"V,<br />

Distance Between Tie Bars 24"H<br />

x 24"V, Screw Diameter 63mm,<br />

Max Shot Weight 680 Grams.<br />

KRAUSS Maffei Model 200-<br />

900-C2 200-Ton Horizontal<br />

Plastic Injection Molding<br />

Machine, serial number 174047<br />

(1996), Machine #27, Hydraulic<br />

Clamp, Platen Size 36"H x 36"V,<br />

Distance Between Tie Bars 22"H<br />

x 22"V, Screw Diameter 55mm,<br />

Max Shot Weight 476 Grams,<br />

Injection Unit 900, Shot Size 523<br />

cm 3 Max, Mold Height Range<br />

13.7" Minimum to 27-1/2" Max,<br />

Ejector Stroke 7.8", Core Pull,<br />

Hydraulic Accumulator, 42 Kw,<br />

Microprocessor Controls.<br />

MANNESMANN Demag<br />

Ergotech-System Model 200-<br />

610 200-Ton Horizontal Plastic<br />

Injection Molding Machine,<br />

serial number 877-0033 (1993),<br />

Machine #28, Toggle Clamp,<br />

International Size Code 2000-<br />

610, Platen Size 32.6"H x 32.6"V,<br />

Distance Between Tie Bars 22"H<br />

x 22"V, Screw Diameter 45mm,<br />

Injection Unit 610, Max Shot<br />

Weight 288 Grams, Max Daylight<br />

48", Ejector Stroke 7", Core Pull,<br />

Demag NC4 Microprocessor<br />

Controls.<br />

Email us your address to<br />

get early notification of<br />

upcoming auctions!<br />

sales@asset-sales.com

1OF4<br />

Inspection: Wednesday, October 5 • 8:00 A.M. to 4:00 P.M.<br />

KRAUSS MAFFEI 175-700-C2 175-TON INJECTION MOLDING MACHINE<br />

3<br />

1998<br />

PLASTIC INJECTION MOLDING<br />

MACHINES, continued<br />

(4) KRAUSS Maffei Model 175-700-C2 175-Ton<br />

Horizontal Plastic Injection Molding Machines,<br />

serial numbers 174252, 174306, 174307, 174308 (All<br />

1998), Machine #’s 26, 16, 15, 30, Hydraulic Clamp,<br />

Platen Size 36"H x 36"V, Distance Between Tie Bars<br />

22"H x 22"V, Screw Diameter 45mm, Max Shot<br />

Weight 278 Grams, Injection Unit 700, Shot Size 305<br />

cm3 Max, Mold Height Range 13.7" minimum to 27-1/2"<br />

Max, Ejector Stroke, Core Pull, Hydraulic Accumulator,<br />

42 Kw, Microprocessor Controls.<br />

KAWAGUCHI Model KM140B 154-Ton Horizontal<br />

Plastic Injection Molding Machine, serial number<br />

JF-NZO318 (1991), Machine #18, Toggle Clamp,<br />

Platen Size 26"H x 26"V, Distance Between Tie Bars<br />

18"H x 18"V, Screw Diameter 40 mm, Max Shot<br />

Weight 200 Grams, Shot Size 213.6 cm3 Screw<br />

Stroke 6.7", Clamp Stroke 14.5", Mold Height Range<br />

7.8" Minimum to 17.7" Max, Ejector Stroke 3.5", Core<br />

Pull, Kawaguchi Bright 301 Microprocessor Controls.<br />

(2) KRAUSS Maffei Model 150-700-C2 150-Ton<br />

Horizontal Plastic Injection Molding Machines,<br />

serial numbers 154209 (1997), Machine #10, 154105<br />

(1996), Machine #11, Hydraulic Clamp, Platen Size<br />

30.7"H x 31.1"V, Distance Between Tie Bars 19.7"H<br />

x 19.7"V, Screw Diameter 50mm, Max Shot Weight<br />

343 grams, Injection Unit 700, Shot Size 340 cm3 Max, Mold Height Range 11.8" minimum to 23.6"<br />

Max, Ejector Stroke 5.9", Core Pull, Hydraulic<br />

Accumulator, 27 Kw, Microprocessor Controls.<br />

<<br />

KAWAGUCHI KM140B 154-TON<br />

PLASTIC INJECTION<br />

MOLDING MACHINE<br />

1OF2 CAN’T ATTEND<br />

THE SALE?<br />

BID LIVE ON-LINE<br />

IN REAL TIME.<br />

SEE PAGE 11<br />

FOR DETAILS.<br />

<<br />

KRAUSS MAFFEI 150-700-C2<br />

150-TON INJECTION<br />

MOLDING MACHINE

1OF3<br />

Thursday, October 6 at 10:00 A.M. Local Time<br />

DEMAG D150-452 150-TON INJECTION MOLDING MACHINE<br />

Live Real Time Webcast<br />

Conversational Bidding,<br />

See Page 11 for Details.<br />

If you cannot attend the sale<br />

please call and place a proxy bid<br />

888-800-4442<br />

><br />

KRAUSS MAFFEI 80-160-C2 80-TON<br />

INJECTION MOLDING MACHINE<br />

4<br />

1OF3<br />

PLASTIC INJECTION MOLDING<br />

MACHINES, continued<br />

(4) MANNESMANN Demag Model D150-452 150-Ton<br />

Horizontal Plastic Injection Molding Machines,<br />

serial numbers 816-1047 (1993), Machine #31, 816-0721<br />

(1990), Machine #22, 816-0590 (1989), Machine #23,<br />

816-0813 (1990), Machine, Toggle Clamp, Platen Size<br />

27.5"H x 27.5"V, Distance Between Tie Bars 18"H x<br />

18"V, Screw Diameter 45mm, Injection Unit 452, Max<br />

Shot Weight 230 Grams, Daylight Range 7.8" Minimum<br />

to 16.9" Max, Ejector Stroke 6.3", Core Pull, Demag<br />

NCIII System Microprocessor Controls.<br />

(2) KRAUSS Maffei Model 80-160-C2 80-Ton<br />

Horizontal Plastic Injection Molding Machines,<br />

serial numbers 64849 (1998), Machine #9, 64454<br />

(1996), Machine #20, Hydraulic Clamp, Platen Size<br />

24"H x 24"V, Distance Between Tie Bars 15.9"H x<br />

15.9"V, Screw Diameter 30mm, Max Shot Weight 68<br />

Grams, Injection Unit 160, Mold Height Range 9.8"<br />

Minimum to 29.5" Max, Clamp Stroke 19.7", Ejector<br />

Stroke 5.9", Hydraulic Accumulator, Core Pull, 17 Kw,<br />

Microprocessor Controls.<br />

KAWAGUCHI Model KM80B 88-Ton Horizontal<br />

Plastic Injection Molding Machine, serial number<br />

FJ-QZO373 (1993), Machine #17, Toggle Clamp, Platen<br />

Size 21"H x 21"V, Distance Between Tie Bars 14"H x<br />

14"V, Screw Diameter 34mm, Max Shot Weight 100<br />

Grams, Shot Size 118 cm 3 Screw Stroke 5", Clamp<br />

Stroke 13.7", Mold Height Range 7" Minimum to 13.7"<br />

Max, Ejector Stroke 2.75", Core Pull, Kawaguchi Bright<br />

301 Microprocessor Controls.<br />

<<br />

DEMAG D150-452<br />

150-TON INJECTION<br />

MOLDING MACHINE<br />

1OF2 1998

Inspection: Wednesday, October 5 • 8:00 A.M. to 4:00 P.M.<br />

DEMAG D60-182 60-TON INJECTION MOLDING MACHINE<br />

Email us your address to get early<br />

notification of upcoming auctions!<br />

sales@asset-sales.com<br />

OFFICE SPACE FOR LEASE IN<br />

INDIAN TRAIL, NORTH CAROLINA<br />

Great Location in New Office Park<br />

1250 sq. ft., 1500 sq. ft. or 3000 sq. ft. available<br />

Convenient to Charlotte, I-485, I-77, & I-85<br />

For more information call Carla at 888-800-4442<br />

><br />

KRAUSS MAFFEI 50-135-C2<br />

50-TON INJECTION<br />

MOLDING MACHINE<br />

5<br />

KAWAGUCHI<br />

KM80B 88-TON<br />

INJECTION<br />

MOLDING<br />

MACHINE<br />

PLASTIC INJECTION<br />

MOLDING MACHINES,<br />

continued<br />

KAWAGUCHI Model KM80B 88-Ton<br />

Horizontal Plastic Injection Molding<br />

Machine, serial number FF-NZO153<br />

(1991), Machine #29, Toggle Clamp, Platen<br />

Size 21"H x 21"V, Distance Between Tie<br />

Bars 14"H x 14"V, Screw Diameter 34mm,<br />

Max Shot Weight 100 Grams, Shot Size<br />

118 cm 3 Screw Stroke 5", Clamp Stroke<br />

13.7", Mold Height Range 7" Minimum to<br />

13.7" Max, Ejector Stroke 2.75", Core Pull,<br />

Kawaguchi Bright 301 Microprocessor<br />

Controls.<br />

(3) MANNESMANN Demag Model D60-<br />

182 60-Ton Horizontal Plastic Injection<br />

Molding Machines, serial numbers 812-1081<br />

(1990), Machine #13, 812-0975 (1989),<br />

Machine #24, 812-1077 (1989), Machine<br />

#12, Toggle Clamp, Platen Size 18.9"H x<br />

18.9"V, Distance Between Tie Bars 12.6"H<br />

x 12.6"V, Screw Diameter 32mm, Injection<br />

Unit 182, Max Shot Weight 87 Grams,<br />

Daylight Range 3.9" Minimum to 12.2"<br />

Max, Ejector Stroke 3.9", Core Pull, Demag<br />

NCIII System Microprocessor Controls.<br />

KRAUSS Maffei Model 50-135-C2<br />

50-Ton Horizontal Plastic Injection<br />

Molding Machine, serial number 44392<br />

(1996), Machine #19, Hydraulic Clamp,<br />

Platen Size 21"H x 21"V, Distance<br />

Between Tie Bars 12.5"H x 12.5"V, Screw<br />

Diameter 30mm, Max Shot Weight 68<br />

Grams, Injection Unit 160, Shot Size 74 cm 3,<br />

Mold Height Range 7.8" Minimum to 21.6"<br />

Max, Clamp Stroke 13.7", Ejector Stroke<br />

3.94", Hydraulic Accumulator, Core Pull,<br />

17 Kw, Microprocessor Controls.

SAILOR SERVO ROBO RZ-200H-B 3-AXIS CNC<br />

PARTS HANDLING ROBOT<br />

STAR AUTOMATION TS-800<br />

FAIIH ROBOT<br />

(8) MOTAN MATERIAL SURGE BINS,<br />

W/VACUUM LOADERS<br />

Thursday, October 6 at 10:00 A.M. Local Time<br />

STAR XQ-800F 3-AXIS CNC<br />

PARTS HANDLING ROBOT<br />

Note: Photos below are all part of the<br />

bulk material system which may be<br />

offered as a whole.<br />

PARTS HANDLING ROBOTS<br />

SAILOR Servo Robo Model RZ-200H-B 3-Axis CNC Parts Handling Robot, serial number<br />

2378 (1997), With Console Control (Machine #9).<br />

STAR AUTOMATION Model TS-800FAII H 3-Axis CNC Parts Handling Robot, Dual Arm,<br />

Star Seiki STEC-300 Console Control, Machine #23.<br />

STAR AUTOMATION Model TW-650-FM-3 3-Axis CNC Parts Handling Robot, serial number<br />

80FXM12-0032, With STEC-400M Programmable Console Controller, (Machine #17).<br />

(6) STAR AUTOMATION Model XQ-800F 3-Axis CNC Parts Handling Robots, With Hand<br />

Pendant Control, Machine #’s 10, 11, 26, 15, 20, 12.<br />

(2) STAR AUTOMATION Model XQ-600F 3-Axis CNC Parts Handling Robots, With Hand<br />

Pendant Controls, Machine #29, #19.<br />

(2) STAR Model XQ-800F Robots, serial number 9601-31371.<br />

1 OF 6 1 OF 2<br />

MOTAN BLOWER & FILTER CARTS<br />

STAR XQ-600F 3-AXIS CNC<br />

PARTS HANDLING ROBOT<br />

Can’t Attend the Sale?<br />

Bid Live On-line in Real Time.<br />

Go to Page 11 for Details.<br />

6<br />

MOTAN CONTROL<br />

PANEL<br />

MOTAN BULK MATERIAL<br />

FEED SYSTEM<br />

(NOTE: THIS MAY BE OFFERED UP<br />

AS ONE COMPLETE<br />

DELIVERY/HANDLING SYSTEM)<br />

New 1998, Including (8) Model 29-950<br />

Pneumatic Operated Bulk Material<br />

Container Tippers, serial numbers<br />

981086-4-8, 981086-4-7, 981086-4-6,<br />

981086-4-5, 981086-4-4, 981086-4-3,<br />

981086-4-2, 981086-4-1.<br />

(8) Bulk Material Surge Bins, Bin Size<br />

48" x 48" x 48", Cone Bottom, Steel Leg<br />

Mounted, Closed Top, Motan Vacuum<br />

Loader, Electronic Level Sensor.<br />

(4) MOTAN Material Blower and Filter<br />

Assemblies, 2-1/2" Line Size, Model<br />

FM-25 Filter Unit, Self Cleaning Filters.<br />

MOTAN Material Proofing Control<br />

Panel, With Programmable Operator<br />

Interface Terminal.<br />

(8) MOTAN Vacuum Loaders (Product<br />

Return Lines), With Electronic Level<br />

Sensors.<br />

Approx. (13) MOTAN ECO Additive<br />

Feeders With Programmable Controllers.<br />

Approx. (15) Vacuum Receivers.<br />

Large Quantity of 2-1/2" Aluminized<br />

Delivery Piping.<br />

(8) MOTAN VACUUM LOADERS MOTAN SURGE BINS & LOADERS MATSUI JET LOADER & DRYER

Inspection: Wednesday, October 5 • 8:00 A.M. to 4:00 P.M.<br />

PLASTIC MOLDING<br />

SUPPORT EQUIPMENT<br />

ELECTRO-MECHANICAL SPECIALTIES 12 Station Rotary Indexing<br />

Special Assembly Machine, With (2) Moorefeed Infeed Stations, 24"<br />

Stainless Steel Vibratory Bowl Feeder, With Vibratory Feed and Hopper<br />

and Inline Conveyor, Variable Controls, Sound Enclosure, 36" Stainless<br />

Steel Vibratory Bowl Feeder, With Vibratory Feed and Hopper and Inline<br />

Conveyor, Variable Controls, Sound Enclosure, Quality Gaging Systems<br />

Microflow T-1 Single Channel Electronic Flowmeter, Allen Bradley Panel<br />

View 600 PLC Control, Auto Pick-N-Place Arms, Exit Conveyor, Enclosures.<br />

MATSUI Model DM2-80 Dehumidifying Dryer, serial number 02865<br />

(1996), With Matsui Jet Loader, Vacuum Receiver and Hopper, (Connected<br />

into Motan Bulk Delivery System).<br />

MATSUI Model JL4-V11 Jet Loader Vacuum Loader, serial number<br />

A338 (1996), With Matsui Model DMZ – 80 Dehumidifying Dryer, serial<br />

number 03509, With Dual Canister Filter Unit, Microprocessor Controls.<br />

(37) THERMAL CARE Aquatherm RD Series Model RD092004<br />

Temperature Controllers, serial numbers 21500109902, 07650019806,<br />

75680050105, 75680110105, 75680010105, 92040019711,<br />

21490039902, 21500169902, 21500179902, 21500039902,<br />

21490059902, 21490019902, 21500029902, 21500139902,<br />

21500069902, 07650029806, 21500059902, 9101001971,<br />

21500159902, 21500119902, 75680090105, 75680100105,<br />

07650039806, 75680040105, 92040029711, 21490049902,<br />

21500149902, 75680060105, 75680020105, 21500209902,<br />

21500099902, 21500129902, 21500199902, 21500119902,<br />

92040049711, 2 HP Process Pump, 9 Kw Heater, Max Operating<br />

Temperature 250 Degrees F., Heat Transfer Fluid: Water.<br />

(4) CRIZAF 6" Flighted Belt Portable Adjustable Conveyors, serial<br />

numbers 612240, 612239, 612217 (1997).<br />

(5) MOLDING AUTOMATION CONCEPTS 6" x 8" Portable Flighted<br />

Belt Parts Conveyors, with Adjustable Stands, serial numbers 897004-<br />

097-019-008-03, 897004-097-019-008-01.<br />

AMERICAN MSI CORPORATION Model V24-DDT-20 Hot Runner<br />

Station, with Delta Programmable Controls, serial number 200118.<br />

AMERICAN MSI CORPORATION Model V12 15 KVA Hot Runner<br />

Station, with Delta Programmable Controls, serial number 200636.<br />

AEC WHITLOCK Auto Loader Portable Vacuum Loader.<br />

CACTUS MACHINERY Model 25 Super Dryer, With Vacuum Receiver.<br />

(5) MOLDING AUTOMATION CONCEPTS 6 Station Programmable<br />

Rotary Parts Collection Carousels, serial numbers 897CO43097-<br />

019-009-03, 897CO43097-019-009-06, 897CO43097-019-009-02,<br />

799CO42299-006-002-02, Allen Bradley Micro View PLC Controls.<br />

(3) CRIZAF Model CS-0610 6-Station Programmable Rotary Parts<br />

Collection Carousels, serial numbers 612241, 612230 (Both 1997),<br />

Crizaf A004-C Programmable Controls.<br />

Approx. (15) Custom Multi Station Water Manifold Units, 8, 12, and<br />

16 Station.<br />

VIEW OF NISSUI PLASTICS GRINDERS<br />

7<br />

(2 OF 37) THERMAL CARE AQUA THERM RD SERIES<br />

TEMPERATURE CONTROLLERS<br />

MAC-CRIZAF 6-STATION PROGRAMMABLE ROTARY PARTS<br />

COLLECTION CAROUSELS<br />

PLASTICS GRINDERS<br />

(2) NISSUI Model SA-24 Plastics Grinders, serial numbers SA240160 (1997), SA240147<br />

(1996), 2 HP Gear Reduced Drive, Open Top Feed, 22" x 22" Opening.<br />

(3) NISSUI Model FNSK-15 Plastics Grinders, serial numbers F151002 (1997), F15986<br />

(1996), F15924 (1996), 2 HP Gear Reduced Drive, Open Top Feed, 22" x 22" Opening.<br />

NISSUI Model SA23 Plastics Grinder, serial number SA230166 (1996), .75 Kw Gear<br />

Reduced Drive, Open Top Feed.<br />

(2) NISSUI Plastics Grinders, Approx. 2 HP Gear Reduced Drive, Open Top Feed.

1998<br />

AGIE ELOX MONDO 2 CNC EDM<br />

EXCELLENT<br />

MICROCUT VERTICAL MILLING MACHINE<br />

Thursday, October 6 at 10:00 A.M. Local Time<br />

ELECTRICAL<br />

DISCHARGE<br />

MACHINE<br />

AGIE Elox Mondo 2 3-Axis Ram Type Die<br />

Sinker EDM, serial number M2-AF3-002023<br />

(1998), Work Table Size 15.7" x 11.8", Work Tank<br />

Size 25" x 17" x 10.6", Nominal Work Piece<br />

Dimensions 25" x 15" x 6", Travels: 11.8" X Axis,<br />

9.8" Y Axis, 9.8" Z Axis, Throat Clearance 14.3",<br />

Platen to Table Clearance 10.6" Minimum to 20.4"<br />

Max, Agie Futura III Power Supply, Reach Pendant,<br />

Self Contained Dielectric Fluid System.<br />

CLAUSING-METOSA C1440 LATHE<br />

MICROCUT & SUPERMAX MILLING MACHINES HARIG 618 AUTOMATIC<br />

SURFACE GRINDER<br />

8<br />

1992<br />

1993<br />

LIKE<br />

NEW<br />

STARTRITE 18 T-10 18"<br />

VERTICAL BANDSAW<br />

MILLING MACHINES<br />

MICROCUT Model 1050 3 HP Variable Speed Vertical Milling Machine, serial number<br />

90154 (1990), Table Size 9" x 48", Spindle Speeds 60 to 4200 RPM, Servo Type 150 Power<br />

Table and Saddle Feeds, Acu Rite III 2 Axis Readout.<br />

SUPERMAX Titan Series Model YC-1-VS-T 3 HP Variable Speed Vertical Milling Machine,<br />

serial number T8104123 (1992), Table Size 9" x 48", Spindle Speed Range 60 to 4200 RPM,<br />

Servo Type 150 Power Table and Saddle Feeds, Acu-Rite Millmate 2 Axis Readout.<br />

LATHES<br />

CLAUSING – METOSA Model C1440 14/19" x 40" Gap Bed Engine Lathe, serial number<br />

22863 (1993), 18 Spindle Speeds 30 to 2000 RPM, Quick Change Threading, 1-5/8" Hole<br />

Thru Spindle, Coolant, Splash Guard.<br />

JET Model DBD-1340 13/19x40" Belt Drive Bench Lathe, serial number 01112N1095B,<br />

12 Spindle Speeds from 60 to 1240 RPM, Quick Change Threading, Removable Gap, Cabinet<br />

Base, 5C Collet Chuck, Face Plate, Follow Rest.<br />

SURFACE GRINDER<br />

HARIG 618 Automatic 6" x 18" Hydraulic Surface Grinder, serial number 8327-H (1992),<br />

Magna-Lock Electromagnetic Chuck, With Variable Control.<br />

SAWS<br />

STARTRITE Model 18-T-10 18" Vertical Band Saw, serial number 95117, (10) Blade<br />

Speeds 56 to 3200 FPM.

Inspection: Wednesday, October 5 • 8:00 A.M. to 4:00 P.M.<br />

INSPECTION<br />

BATY Shadowmaster Model R550 20" Optical Comparator,<br />

serial number 3376, 10x, 20x, 50x Magnification Lenses, Table<br />

Size 7-1/2" x 23-1/2", Mitutoyo Geo-Chek 2 Axis Readout.<br />

OPTICAL GAGING PRODUCTS Opticom Qualifier 14B 14"<br />

Optical Comparator, serial number OOB14102, Side<br />

Projection, OGP Di Metric Plus 2 Axis Vision Computer Readout.<br />

NIKON MM-11B Stereo Microscope, X, Y Positions Tables,<br />

PC Interface, Fostec Illumination Unit, serial number 220222.<br />

NIKON Model 10 Stereo Microscope, X, Y Positions Tables,<br />

PC Interface, Fostec Illumination Unit, serial number 66681.<br />

ROCK OF AGES 24" x 36" Granite Surface Plate.<br />

STARRETT 24" x 36" 2 Ledge Granite Surface Plate, serial<br />

number 924880.<br />

ACCUPRO Rockwell Hardness Tester, serial number 0066.<br />

MITUTOYO 176-902-1A Toolmakers Microscope, serial<br />

number 110114.<br />

1 OF 2<br />

PIEDMONT CRANE & HOIST 2-TON X 45' SINGLE GIRDER BRIDGE CRANE<br />

NEW<br />

2004<br />

SULLAIR SR-1000W DRYER<br />

SULLAIR LS-20 100 HP.<br />

AIR COMPRESSOR<br />

SULLAIR TS-20 200 HP. AIR COMPRESSOR<br />

SULLAIR SRD-500 & 300 AIR DRYERS<br />

NEW<br />

2004<br />

Email us your address to get early<br />

notification of upcoming auctions!<br />

sales@asset-sales.com<br />

9<br />

NIKON 11B COMPUTER INTERFACED<br />

STEREO MICROSCOPE<br />

<<br />

BATY SHADOWMASTER 20"<br />

OPTICAL COMPARATOR<br />

CRANES<br />

(2) PIEDMONT Crane and Hoist 2-Ton x 45'<br />

Span Top Riding Single Girder Bridge<br />

Cranes, (1998), Yale 2 Ton Cable Hoist, 6 Way<br />

Variable Frequency Drives, Radio Controller,<br />

Each With Approx. 195' Free Standing Support<br />

Runway.<br />

PIEDMONT Hoist and Crane 2-Ton x 30'<br />

Span Top Riding Single Girder Bridge<br />

Cranes, Yale Cable Hoist, 6 Way Variable<br />

Frequency Drives, 6 Way Pendant, Approx. 50'<br />

Free Standing Support Runway.<br />

PIEDMONT CRANE & HOIST 2-TON X 30' SINGLE GIRDER<br />

BRIDGE CRANE<br />

AIR COMPRESSORS & DRYERS<br />

SULLAIR Model TS-20-200H/W 200 HP Rotary Screw Air<br />

Compressor, serial number 003-135093 (2004), Water Cooled,<br />

(2) Sullair Liquid Heat Exchangers, Open Skid Base, Sullair<br />

Supervisor Programmable Control, 135 PSIG.<br />

SULLAIR Model LS-20-100HAC 100 HP Rotary Screw Air<br />

Compressor, serial number 003-112801, 125 PSIG, Sound<br />

Enclosure Panels.<br />

SULLAIR Model SR-1000W Refrigerated Compressed Air<br />

Dryer, serial number 2714630001 (2004), 1000 SCFM, Max Air<br />

Pressure 174 PSIG, Water Cooled, Ambient Temperature Range<br />

41 Degrees to 122 Degrees F.<br />

SULLAIR Model SRD-500-AC Refrigerated Compressed Air<br />

Dryer, serial number 003-D14431.<br />

SULLAIR Model SRD-300-AC Refrigerated Compressed Air<br />

Dryer, serial number 003-D8624.<br />

Vertical Air Receiver Tank, (1999), MAWP 137 PSI at 450<br />

Degrees F.<br />

(6) SULLAIR OH-2858-5 In-Line Automatic Drain Valves.<br />

Quantity of 4" Copper Air Line Piping.

Thursday, October 6 at 10:00 A.M. Local Time<br />

OVERVIEW PACKAGING LINE BEST PAK CASE SEALERS<br />

VIEW VIDMAR CABINETS<br />

VIEW OF PALLET RACKING<br />

WAREHOUSE<br />

& PACKAGING<br />

(48) Sections of 102"W x 42"D x 144"<br />

Adjustable Pallet Racking, Drop Slat Style<br />

With Spring Clips, Water Sprinkler Pipes.<br />

BEST PACK Model 6SAM 4 Head Side Taper<br />

Case Sealer, serial number 926008 (1992), 90<br />

Degrees Infeed With Pusher.<br />

BEST PACK Model MT12-3 Case Sealer,<br />

serial number 003035, Top and Bottom Tape<br />

Heads, Power Thru Feed Conveyor.<br />

PNEU TOUCH Programmable Robotic Label<br />

Applicator.<br />

ROACH 24" x 8' Power Roller Conveyor.<br />

24" Gravity Roller Conveyor.<br />

INFRA PAK Model HSP-Hawk Pallet Shrink<br />

Wrap Machine, serial number 894930, 50" x<br />

50" Table, 72" Vertical.<br />

YALE FORKLIFT<br />

VIEW OF PORTABLE PARTS RACKS<br />

(BAKERY RACKS)<br />

WEIGH-TRONIX 48" x 48" x 5000-Lb.<br />

Capacity Electronic Platform Scale, With WI-125<br />

Programmable Readout.<br />

(2) INTERMEC Easy Coder 3400E Label Printer.<br />

SCISSORLIFTS<br />

SKYJACK Model SJ III-3226 Self Propelled<br />

Electric Scissorlift Platform, serial number<br />

28229 (2001), 26' Max Platform Height, 500-Lb.<br />

Capacity, 30" x 86" Platform, 36" Platform<br />

Extension, Non-Mar Tires.<br />

FORKLIFTS<br />

10<br />

2000<br />

YALE Model ESCO25ABN24TE-083SPL<br />

Docker 2300-Lb. Capacity Stand Up Rider<br />

Electric Forklift, serial number A824N07436X<br />

(2000), 190" Lift, Side Shift, Non-Mar Tires,<br />

24 Volt.<br />

INFRA PAK HAWK PALLET<br />

SHRINK WRAP MACHINE<br />

SKYJACK SJ III-3226 SCISSORLIFT<br />

ADJUSTABLE DIE STORAGE RACK<br />

2001<br />

YALE Model ESCO30ABN24SE083 Docker<br />

3000-Lb. Capacity Stand Up Rider Electric<br />

Forklift, serial number 455287, 190" Lift, 24<br />

Volt, Side Shift.<br />

ATLAS Model XTFXXSN/100TFV360<br />

2200-Lb. Capacity Sit Down Rider Narrow<br />

Aisle Electric Forklift, serial number<br />

XTF11780 (2000), 171" Lift, Reach Forks.

Inspection: Wednesday, October 5 • 8:00 A.M. to 4:00 P.M.<br />

SHOP & FACTORY EQUIPMENT<br />

Adjustable Die Storage Racking System, Pallet Rack Type Frame<br />

Construction, (16) 36" x 36" Roll-Out Storage Shelves, 2000-Lb. Shelf<br />

Capacity.<br />

(8) STANLEY Vidmar 59" 11 and 13 Drawer Cabinets; (3)<br />

BOTT/KENNEDY/LYON 32" Multi Drawer Tool Cabinets, With Hardwood<br />

Bench Tops; (5) LYON 60" 9 Drawer and 15 Drawer Tool Cabinets; (3)<br />

LISTA 60" 11, 15 and 8 Drawer Tool Cabinets; (3) LYON and GLOBAL<br />

60" 2-Door Supply Cabinets; WESCO 32" x 48" Hydraulic Die Lift Table;<br />

(2) 24" x 36" Hydraulic Die Lift Tables; (4) 4' x 8' Heavy Duty Steel Work<br />

Tables; (2) NUMATIC TTB 455/100S 20" Battery Powered Walk Behind<br />

Floor Scrubbers; Approx. 75 72" x 24" x 80" High 4 Tier Material Stock<br />

Carts (Bakery Carts) Adjustable Shelves; MSC 6" Belt/9" Disc Combination<br />

Grinder; BALDOR No. 7307 1/2 HP 7" Double End Grinder; MINUTEMAN<br />

and SHOP VAC Shop Vacuums; DAYTON Model 32918 16-1/2" Drill<br />

Press; MSC Model 09011602 1 HP 6" Double End Carbide Tool<br />

Grinder; BALDOR Model 333B 3/4 HP Double End Buffer; BALDOR<br />

Model 8100M 3/4 HP 8" Double End Grinder; PURE WASH SYSTEMS<br />

Parts Washer and Degreasers; (2) Oxygen Acetylene Torch Outfits;<br />

PARKER Model 10MF-40SA-10C 1X853006 Portable Oil Filtration Unit;<br />

RAYTECH Model RB-4 12" Portable Abrasive Blast Cabinet, serial number<br />

919; TRION Big Mac Dual Cartridge Type Dust Collector; Portable;<br />

MILLER Millermatic 250X Wire Feed Welder, serial number LA179048<br />

(2000); FISHER Isotemp Model 282A Vacuum Oven, serial number<br />

00SN0041, Dimensions 12" High x 12" Wide x 18" Deep, Temperature<br />

Range Ambient to 280 Degrees C.<br />

11<br />

VIDEO CONFERENCE ROOM CONFERENCE ROOM<br />

Workstation Stands; Workstations; Benches;<br />

Carts; Supply Cabinets; Tote Boxes and Pans;<br />

Cubicle Stations; Counting Scales; Bench Scales;<br />

PCs; Pallet Jacks; Hand Trucks; Shop Office<br />

Workstations; Toolroom and Maintenance<br />

Equipment and Supplies; Cleaning Supplies; Etc.<br />

OFFICE<br />

Office Furniture – Approx 15,000 Sq. Ft. Offices With<br />

Steelcase Modular Office Furnishings as new as<br />

2002 Including: Cubicle Workstations; Upholstered<br />

Divider Panels; Work Desks; File Cabinets; Chairs;<br />

Tables; Conference Suites; Etc.<br />

Computer Equipment and Office Machines Including:<br />

PCs; Monitors; Printers; Plotters; Faxes; Copiers;<br />

Audio/Visual Equipment; TVs; Projectors; Etc.<br />

FRONT DISPLAY<br />

CASE<br />

BID FROM THE COMFORT OF YOUR OFFICE!!<br />

If you can’t personally attend the auction sale, you don’t have to miss out on the bidding. You can bid on the equipment in the<br />

following ways:<br />

• LIVE PHONE BID: Call us by October 5 to set up the details.*<br />

• PROXY BID: Call us and we’ll fax you a proxy bid form. Fill it out, fax it back and we’ll bid on your machine<br />

for you.*<br />

• Bid live on the Internet, see www.asset-sales.com or www.hilcoind.com.<br />

*We must receive a 25% deposit of all proxy and phone bids before auction to secure your bid. No credit cards.<br />

Webcast Auction Information<br />

Hilcast Webcast Technology<br />

Hilcast Conversational Webcast Technology allows bidders to speak directly with the<br />

auctioneer and eliminates the mouse from the auction process.<br />

Our new technology speeds up the process while providing real time ability to confirm bids<br />

directly with the auctioneer – as if you were standing on the auction floor.<br />

Buyer’s choice, option & privilege? No Problem! Just tell the auctioneer what you want.<br />

Visit www.asset-sales.com or www.hilcoind.com to register as a new member at any time,<br />

even on auction day.<br />

Preview the assets with detailed digital photographs, lot catalogs with indepth<br />

descriptions, and even view or download a virtual brochure prior to the auction online at<br />

www.asset-sales.com or www.hilcoind.com. At the time of the auction, listen to the<br />

Auctioneer live on the web and/or telephone while the current asset up for bid is displayed<br />

on your computer screen. It’s convenient, simple, free, and IT WORKS!<br />

Unable to use the Conversational Webcast technology or attend the auction in person?<br />

Submit a proxy bid and we will bid for you. Please contact us at 888-800-4442 for more<br />

information.<br />

How to Bid on a Hilcast Webcast Auction<br />

Auctions conducted using Hilcast Webcast Bidding Technology offer bidders two methods<br />

of placing bids. A traditional On Site auction is conducted and “broadcast” via the web,<br />

allowing Internet users to see the progression of the sale through a special online<br />

presentation. The auctioneer on site can communicate with both the bidders in the room with<br />

him, and the bidders on the web. Because all computers are not of equal capability, and<br />

because different Internet connection speeds may affect the transmission of a bid, Hilcast<br />

bids are not placed by clicking a button, but rather by joining a live conference call hosted<br />

by <strong>Hilco</strong>. In this way, Hilcast bidders are able to hear in real time as bids are being placed<br />

both on the auction floor and by Internet bidders. This method gives bidders the “best of both<br />

worlds,” allowing them to bid from the comfort of their own home or office, without<br />

sacrificing the visibility and timeliness of being on the auction floor.<br />

For complete information and details go to www.asset-sales.com or www.hilcoind.com.<br />

These terms are subject to amendments and modifications announced by the Auctioneer at the time<br />

of the auction. Any person participating in the auction shall be bound by the following terms<br />

and conditions. This brochure is meant only as a guide. The auctioneer does not warrant the accuracy,<br />

genuineness, authenticity, description, weight, count or measure of any listings specified herein.<br />

All bidders must register immediately upon entering the site. All announcements made on the<br />

auction day shall take precedence over previously distributed information.<br />

Everything will be sold to the highest bidder or bidders for cash in accordance with the<br />

Auctioneer’s Terms and Conditions, copies of which are available at the auction site. All bidding<br />

and invoicing will be in U.S. Dollars ($), we will accept all currency according to the terms.<br />

All purchases must be paid IN FULL on the day of the auction sale. We will accept cash, a<br />

cashier’s check, wire transfer and/or a company check accompanied by a bank letter of guarantee.<br />

We accept no credit cards. Your bank letter should be similar to the following: “Mr. (Customer<br />

Name) is a customer of this bank. This bank will guarantee unqualified payment to Asset Sales,<br />

Inc. on the account listed herein up to the amount of $_____. This letter is valid until (date).”<br />

All checks must be made payable to Asset Sales, Inc. All invoices must be checked on the day<br />

of the sale as no adjustments will be made thereafter. Purchases that are not removed within<br />

the designated time will be considered abandoned. All sales are final, on an “as is - where is,”<br />

“in place,” “with all faults” basis with no conditions or warranties whether expressed, implied,<br />

statutory or otherwise, including without limitation, warranties or conditions as to title,<br />

description, fitness for purpose, quantity, quality, merchantability, state, condition, location or<br />

otherwise. By submitting a bid, the buyer/bidder affirms it has inspected all items before bidding.<br />

Purchasers shall be deemed to have relied entirely upon inspections and investigations. Delivery<br />

will be made of purchased property only after completion of the sale and payment of invoice.<br />

No reselling will be allowed from the premises.<br />

All bidders are responsible for all applicable taxes.<br />

No article shall be removed unless paid in full and all articles purchased shall be removed in the<br />

time allocated by the auctioneer. No item, no matter how small or how far the purchaser has to<br />

travel, may be removed until the close of the auction sale. Rigging/Removal of sold equipment<br />

is the sole responsibility of the buyer and must be completed by the posted date. All small<br />

items must be removed within 24 hours of the completion of the sale.<br />

Rigging/Removal may not begin until payment has been made in full and the auction sale is<br />

complete. All heavy rigging requiring the use of forklifts, cranes, etc. whether performed by the<br />

customer or a rigging company, must present a certificate of insurance for $1,000,000.00<br />

naming Asset Sales, Inc. as the insured.<br />

Asset Sales, Inc. reserves the right to correct any mistakes or typographical errors made by it<br />

or on its behalf in any of its announcements or documents, without the ability of deriving right<br />

from the corrected announcements.<br />

If you are unable to attend, please contact us to place a proxy bid, or visit our website at<br />

www.asset-sales.com.<br />

A 12% Buyer’s Premium (15% for Internet bidders) will apply to all purchases.

Public<br />

Auction<br />

BESPAK<br />

Apex (Raleigh), North Carolina<br />

IP-5<strong>202767</strong><br />

Asset Sales, Inc.<br />

Corporate Headquarters<br />

301 Post Office Drive, Suite C,<br />

Indian Trail, North Carolina 28079<br />

Toll Free 888.800.4442 • 704.821.4315<br />

Fax 704.821.4325 • www.asset-sales.com<br />

Lance Mannion NC Lic. #6003, Asset Sales NC Lic. #6625<br />

<strong>Hilco</strong> <strong>Industrial</strong> LLC, #NCFL7506, Lee Martin Danhauer, Auctioneer, Lic. #NCAL8030<br />

Want to join our Email List?<br />

Want to update your address?<br />

Want a brochure for an upcoming auction?<br />

(circle the auction below)<br />

Want to be removed from our mailing list?<br />

Just write the info on this back cover and fax it to 704.821.4325<br />

UPCOMING AUCTIONS<br />

September 22 – Profile Metal<br />

Tullahoma, Tennessee — Amada Shop<br />

September 29 – Griffco Plastics, Inc.<br />

Quitman, Mississippi – Plastic Pipe Extrusion<br />

October 5 – Spectrum Manufacturing<br />

Salt Lake City Area, Utah – Late Model CNC Machining & Fabricating<br />

October 11–12 – Alstom Manufacturing<br />

England – Railroad Wheel Manufacturer & Rebuilder<br />

Complete Wheel Line Available!<br />

October 13 – Daws<br />

England – CNC & Machine Shop<br />

November 1 & 2 – National Tool<br />

Kennilworth, New Jersey – CNC Grinding & Machine Shop<br />

Check Our Website Daily for More Upcoming Sales<br />

www.asset-sales.com<br />

Thursday<br />

October 6<br />

10:00 A.M. Local Time<br />

Inspection<br />

Wednesday, October 5<br />

8:00 A.M. to 4:00 P.M.<br />

In Cooperation with<br />

1OF2<br />

KRAUSS MAFFEI 150-700-C2<br />

150-TON INJECTION<br />

MOLDING MACHINE<br />

Can’t Attend the Sale?<br />

Bid Live On-line<br />

in Real Time.<br />

Go to Page 11 for Details.<br />

Live On-Line Bidding at www.Asset-Sales.com<br />

1OF3<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Eugene, Oregon<br />

Permit No. 305<br />

DIRECTIONS<br />

From Raleigh-Durham International Airport:<br />

Exit Raleigh-Durham airport to I-40 East.<br />

Follow I-40 East toward downtown Raleigh<br />

for 7 miles to Exit 293A, US 64 West/<br />

US1 South. Follow US64 West/US1 South<br />

3.5 miles to Exit 98B, US64/US1 Split.<br />

Continue on US 64 West 2.5 miles to Laura<br />

Duncan Road. Turn right on Laura Duncan<br />

Road and proceed 3/4 of a mile to the sale<br />

site on the right. Watch for auction and<br />

parking signs.<br />

HOTEL<br />

Holiday Inn Express<br />

1006 Marco Drive, Apex, North Carolina......<br />

............................................(919) 387-3636<br />

DEMAG D150-452 150-TON INJECTION MOLDING MACHINE